Professional Documents

Culture Documents

Maintenance of Valve Chamber

Uploaded by

Devang PatelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance of Valve Chamber

Uploaded by

Devang PatelCopyright:

Available Formats

Scope of Work for Maintenance of Steel Pipeline Valve Chamber

SCOPE OF WORK

FOR

MAINTENANCE

OF

STEEL PIPELINE VALVE CHAMBERS

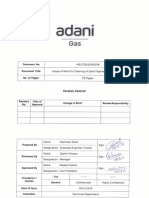

Doc. No. AGL/TSD/2019/078 Rev. No. 01

Scope of Work for Maintenance of Steel Pipeline Valve

Doc. Title Rev. Date 13.02.20

Chambers

Scope of Work for Maintenance of Steel Pipeline Valve Chamber

1.0 INTRODUCTION

ADANI GAS LTD (herein after called “AGL”), Adani Group Company is engaged in supply of Piped

Natural Gas (PNG) to Households, Commercial & Industrial consumers and Compressed Natural

Gas (CNG) to Automotive sector. AGL is in the process of expanding its City Gas Distribution

network in various Geographical Areas authorized by the PNGRB.

AGL is now inviting competitive bids for carrying out Maintenance of Steel Pipeline Valve

chambers installed along existing steel pipeline network in its various geographical areas.

Frequency of maintenance will be yearly as defined in this document.

2.0 GENERAL

In steel pipeline network, Sectionalizing Valves are installed at regular intervals for easy and safe

isolation, in case of any Emergency / planned shutdown of pipeline network. These valves are

installed inside valve chambers which will require periodic cleaning and maintenance.

AGL require services for regular cleaning of the valve chambers.

3.0 SCOPE OF WORK

The intent of this scope of work is to cover the following minimum activities but not limited to:

3.1 Obtain Work Permit with JSA (Job Safety Assessment) from AGL EIC and carry out toolbox talk

with Maintenance crew before start of work.

3.2 Maintenance crew shall work with appropriate PPE as per AGL approved HSE procedure as

mentioned in the scope and JSA, site situation.

3.3 Proper Barricading shall be done before doing any such activities for valve chamber cleaning.

3.4 Remove obstruction / debris around valve chambers and from valve chamber covers.

3.5 Carefully remove valve chamber covers - RCC / Chequered plates.

3.6 Before start of any activity, carry out gas leak detection using GMI make gas detectors.

3.7 Carry out de-watering of valve chamber, if water is present inside the chambers.

3.8 Clean mainline valves, vent valves and steel pipelines inside valve chamber.

3.9 Paint valves with Blue Color and steel pipeline with Yellow color with Berger make paint.

3.10 Check for damaged or broken valve chambers and carry out necessary civil repair works like PCC,

RCC etc as required.

Doc. No. AGL/TSD/2019/078 Rev. No. 01

Scope of Work for Maintenance of Steel Pipeline Valve

Doc. Title Rev. Date 13.02.20

Chambers

Scope of Work for Maintenance of Steel Pipeline Valve Chamber

3.11 Paint valve chamber internal walls with white lime color.

3.12 Paint valve chamber metal covers and support frames with black color. Paint make shall be Berger.

3.13 Replace broken RCC valve chamber covers as per direction of AGL EIC.

3.14 As per the instructions / clearance of AGL EIC, close Valve chamber.

3.15 Dispose removed water / debris at respective Municipal Corporation designated location.

3.16 Submit report to AGL EIC in AGL approved format.

3.17 All consumables including paint, thinner, cotton waste, cloth etc shall be in the scope of the

Contractor.

3.18 All Tools & Tackles including Dewatering pump etc shall be in the scope of the Contractor.

3.19 The preventive maintenance work shall normally be done during working hours, in case it is not

possible during working hours due to expansion works of road by municipal corporation then

activity shall be done at night hours only.

3.20 The Contractor shall arrange for his own vehicle for carrying out the Maintenance activities.

3.21 The Contractor shall depute a Supervisor during Maintenance activities.

4.0 HSE REQUIREMENT

4.1 The Contractor shall conform to the safety requirements and life savers of AGL as per AGL HSE

Annexure–A.

4.2 The Contractor shall send their personnel for safety training (which will be given by AGL HSE

department) prior to engaging in the work. AGL will issue a Safety Technical & Operational

Competency (STOC) Certificate to individual after successful training. No one shall undertake work

without a valid STOC certificate. AGL will arrange such trainings as per the request from the

Contractor.

4.3 Work Permit: Contractor shall be issued the necessary work permits or extension of work permit

while working at site. Contractor shall ensure adherence to HSE norms as directed by AGL from

time to time.

4.4 Personnel Protective Equipment: Contractor shall ensure usage of all suitable Personal Protective

Equipment for all the personnel during performing the entire job.

4.5 Contractor shall ensure Annual health check-up of all his employees is done mandatorily as

required by AGL IMS based on ISO 45001:2018.

Doc. No. AGL/TSD/2019/078 Rev. No. 01

Scope of Work for Maintenance of Steel Pipeline Valve

Doc. Title Rev. Date 13.02.20

Chambers

Scope of Work for Maintenance of Steel Pipeline Valve Chamber

4.6 Environment: Contractor shall ensure all prevailing norms for preserving the environmental

aspects including safe disposal of oil rags, grease, paints, edge sharp material & other chemicals.

Safe and periodic disposal of waste generated during maintenance activities as required by AGL

IMS based on ISO 14001:2018 and submission of documented proof in format as statutorily

mandated or desired by AGL shall be in the scope of the Contractor.

4.7 Security: Contractor shall ensure that the existing installations are not damaged during the job,

including security aspects at site for assets, material, personnel, information, etc.

4.8 Contractor shall follow all the HSE policies and guidelines of AGL throughout the contract period.

Refer Annexure-VIII for AGL Standard Safety Requirement.

4.9 Contractor shall ensure that all the workmen / staff deployed by him are medically, physically and

mentally fit as well as technically competent.

4.10 Contractor shall ensure that all the near misses, accidents occurred during execution of contract

are reported to AGL HSE/EIC/CNG O&M In-Charge.

4.11 Contractor shall not carry out any work at any premises which are under construction. Permissions

and instructions must be sought from AGL EIC/CNG O&M in-Charge in case of exceptional

circumstances.

4.12 Contractor shall ensure an injury free workplace and protect people from harm caused by work

activity.

4.13 During the execution of work, Contractor shall ensure that it shall not obstruct any of the routine

activities performed by other agencies.

4.14 Contractor shall strictly abide by the work permit system and safe control of operation procedures

wherever applicable and explained by AGL HSE/ EIC/ CNG O&M In-Charge.

4.15 Contractor’s personnel shall not smoke or resort to misuse of drugs, medicines or alcohol while

on duty.

Doc. No. AGL/TSD/2019/078 Rev. No. 01

Scope of Work for Maintenance of Steel Pipeline Valve

Doc. Title Rev. Date 13.02.20

Chambers

Scope of Work for Maintenance of Steel Pipeline Valve Chamber

Schedule of Rates

Sr.

Description UOM Qty. Rate Amount

No.

Maintenance and Cleaning of valve chambers

installed along existing steel pipeline network as

1

per the scope of work defined in the tender

document:

1.1 2” Valve Chamber Nos.

1.2 4” Valve Chamber Nos.

1.3 6” Valve Chamber Nos.

1.4 8” Valve Chamber Nos.

1.5 12” Valve Chamber Nos.

Doc. No. AGL/TSD/2019/078 Rev. No. 01

Scope of Work for Maintenance of Steel Pipeline Valve

Doc. Title Rev. Date 13.02.20

Chambers

You might also like

- Pipe Fabrication - ErectionDocument18 pagesPipe Fabrication - ErectionShrichand G. Bathv50% (2)

- Coils For Fired Heaters and Boilers: ScopeDocument12 pagesCoils For Fired Heaters and Boilers: ScopeAna Bella RosarioNo ratings yet

- MRS MaintenanceDocument15 pagesMRS MaintenanceDevang PatelNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument52 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesAsif ChougleNo ratings yet

- Detail Engineering Services For Engen Tank X368 RebuildDocument9 pagesDetail Engineering Services For Engen Tank X368 RebuildpavanNo ratings yet

- Saep 317Document22 pagesSaep 317brecht1980100% (1)

- Scope of SupplyDocument23 pagesScope of SupplymoodydoodyNo ratings yet

- 2004A Rev 7Document78 pages2004A Rev 7Sri Dhar0% (1)

- Method Statement Damaged Spool ReplacentDocument12 pagesMethod Statement Damaged Spool ReplacentMohsen KeramatiNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Document9 pagesSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaNo ratings yet

- 038-Pro Welding Consumable Control Procedure PDFDocument20 pages038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- CW9 Part 1Document9 pagesCW9 Part 1Steve CowanNo ratings yet

- 10-Division 2-Section 02230 DI Pipelines-Version 2.0Document10 pages10-Division 2-Section 02230 DI Pipelines-Version 2.0Avaan IvaanNo ratings yet

- Comp MechDocument235 pagesComp Mechgopvij1No ratings yet

- Artistic Milliners W.H.R.boiler Simplex (JGS-320)Document13 pagesArtistic Milliners W.H.R.boiler Simplex (JGS-320)EngrSaimaAskariNo ratings yet

- Water-Tube Boilers - Part 8: Installation and Operation: National Standard of The People'S Republic of ChinaDocument32 pagesWater-Tube Boilers - Part 8: Installation and Operation: National Standard of The People'S Republic of ChinaNATTHAPONG BUNSOMPOPNo ratings yet

- Ongc 2004a Rev 7Document78 pagesOngc 2004a Rev 7dzardoniNo ratings yet

- D-01 NocDocument29 pagesD-01 NocRochdi Sahli100% (1)

- 200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationDocument15 pages200-1013-06-003 RFQ Full Package and High Pressure Coil Design CalculationBilel MahjoubNo ratings yet

- 1 SS Ci 004Document26 pages1 SS Ci 004chells.sakthiNo ratings yet

- JERES - Non Metalic PipingDocument12 pagesJERES - Non Metalic PipingDidit RizkyNo ratings yet

- Essar Steel PlantDocument62 pagesEssar Steel PlantKrishnadev C.SNo ratings yet

- Flanged Joints, Gaskets, and Bolting: ScopeDocument20 pagesFlanged Joints, Gaskets, and Bolting: Scopebenedicto soto mestanzaNo ratings yet

- Installation and Servicing InstructionsDocument40 pagesInstallation and Servicing InstructionsOwain JonesNo ratings yet

- 3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsDocument14 pages3.2 Big Block Assembly 3.2.1 Work Shop Assembly Pre-RequisitionsEur-Ing Nicola GalluzziNo ratings yet

- X PGNDP0464 03 ECI SPC 020 Control Valve Specification RevADocument7 pagesX PGNDP0464 03 ECI SPC 020 Control Valve Specification RevAgrantNo ratings yet

- Cooling TowersDocument4 pagesCooling TowersHerlys PereiraNo ratings yet

- Vacuum Breaker Valve Data SheetDocument4 pagesVacuum Breaker Valve Data SheetMathivanan AnbazhaganNo ratings yet

- 43 00 00 - LPG InstallationDocument13 pages43 00 00 - LPG InstallationNiong David100% (1)

- Guide To The Inspection of Single Flue Industrial Steel ChimneysDocument17 pagesGuide To The Inspection of Single Flue Industrial Steel Chimneyssomnath karmakarNo ratings yet

- Structural Fabrication SpecificationDocument18 pagesStructural Fabrication Specificationravirawat15No ratings yet

- LPG Blending Facilities - List of Documents For TenderDocument235 pagesLPG Blending Facilities - List of Documents For TenderManish MehtaNo ratings yet

- Q11439 RFQ Fabrication SOWDocument15 pagesQ11439 RFQ Fabrication SOWVijil Renix LindaNo ratings yet

- Final TSDocument123 pagesFinal TSdebabratadas1234No ratings yet

- C5000 16 G28 B V04 B02 PDFDocument321 pagesC5000 16 G28 B V04 B02 PDFAhmed OmarNo ratings yet

- GP-03!12!01 Valve SelectionDocument11 pagesGP-03!12!01 Valve Selectionabenitech100% (1)

- Welding Consumable Control ProcedureDocument15 pagesWelding Consumable Control ProcedureJoni Carino Suni89% (9)

- 44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONDocument51 pages44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONAvinash ShuklaNo ratings yet

- Tdt10ballvalves PDFDocument18 pagesTdt10ballvalves PDFsswahyudiNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument15 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- HIA Mid-Field Fuel Farm Expansion - Welding of Steel StructuresDocument18 pagesHIA Mid-Field Fuel Farm Expansion - Welding of Steel Structuressrp. mohammedNo ratings yet

- BS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFDocument28 pagesBS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFambition1340cn100% (2)

- So R2020 BATLrev 01Document246 pagesSo R2020 BATLrev 01Cíntya LiraNo ratings yet

- f1273 Flame ArresterDocument5 pagesf1273 Flame ArresterIndil Veha100% (1)

- Flame StraighteningDocument3 pagesFlame StraighteningAvishek Gupta100% (1)

- Attachment I - WS-1 Rev 2Document82 pagesAttachment I - WS-1 Rev 2sendelkrNo ratings yet

- 44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTDocument6 pages44AC9100-000-V.02-0106-A4 - Rev B - GENERAL SPECIFICATION FOR EXPANDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Shop Welding InspectionDocument4 pagesShop Welding InspectionIndra Nath MishraNo ratings yet

- Bolted Flange and Gasket Joints Assembly ProcedureDocument9 pagesBolted Flange and Gasket Joints Assembly ProceduremohdNo ratings yet

- DRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDocument11 pagesDRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDaniel Martinez100% (1)

- Pip Pnsmv004Document12 pagesPip Pnsmv004Ricardo Zárate GodinezNo ratings yet

- Method For Spool PipingDocument13 pagesMethod For Spool PipingrealstrojmanNo ratings yet

- Contoh Prosedur Untuk Burried PipeDocument31 pagesContoh Prosedur Untuk Burried PipeLord MobileNo ratings yet

- 1 SS PP 007Document44 pages1 SS PP 007SURAJ PRSADNo ratings yet

- Water-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaDocument21 pagesWater-Tube Boilers - Part 1: General Requirement: National Standard of The People'S Republic of ChinaNATTHAPONG BUNSOMPOPNo ratings yet

- 1 Engg DBD PP 010Document19 pages1 Engg DBD PP 010sanketNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisFrom EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisRating: 5 out of 5 stars5/5 (1)

- Government Eprocurement System: National Informatics CentreDocument5 pagesGovernment Eprocurement System: National Informatics CentreDevang PatelNo ratings yet

- How To Apply Under SATAT Through IOCL E-Tendering Portal Website Address: Https://iocletenders - Nic.in/nicgep/appDocument37 pagesHow To Apply Under SATAT Through IOCL E-Tendering Portal Website Address: Https://iocletenders - Nic.in/nicgep/appDevang PatelNo ratings yet

- Government Eprocurement System: National Informatics CentreDocument5 pagesGovernment Eprocurement System: National Informatics CentreDevang PatelNo ratings yet

- Government Eprocurement System: National Informatics CentreDocument5 pagesGovernment Eprocurement System: National Informatics CentreDevang PatelNo ratings yet

- CGD PaintingDocument11 pagesCGD PaintingDevang PatelNo ratings yet

- Scope of Work FOR Supply, Installation & Maintenance OF Pipeline Route MarkersDocument13 pagesScope of Work FOR Supply, Installation & Maintenance OF Pipeline Route MarkersDevang PatelNo ratings yet

- Scope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDocument9 pagesScope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDevang PatelNo ratings yet

- UntitledDocument6 pagesUntitledDevang PatelNo ratings yet

- MRS DRS MaintenanceDocument18 pagesMRS DRS MaintenanceDevang PatelNo ratings yet

- SOW - Buffing WorkDocument3 pagesSOW - Buffing WorkDevang PatelNo ratings yet

- THIXATROL GST Coatings Specialities I LTDDocument2 pagesTHIXATROL GST Coatings Specialities I LTDManoel Caetano DamascenoNo ratings yet

- Method Statement For Internal Painting Rev 2Document20 pagesMethod Statement For Internal Painting Rev 2Ngô Trung NghĩaNo ratings yet

- Unipoxy LiningDocument3 pagesUnipoxy LiningDien Thoai Nguyen HuuNo ratings yet

- Muki Z 2001: Technical Data SheetDocument5 pagesMuki Z 2001: Technical Data SheetIan PerdanaNo ratings yet

- ChemflakeDocument5 pagesChemflakeManohar SeetharamNo ratings yet

- Mr. Color Paint ListDocument6 pagesMr. Color Paint Listhscottarmstrong3302No ratings yet

- Unnati - Chemical, Fertilizer, Agriculture and Sugar - 2018Document77 pagesUnnati - Chemical, Fertilizer, Agriculture and Sugar - 2018Wuzmal HanduNo ratings yet

- Ship PaintsDocument30 pagesShip PaintsMahami M ProsperNo ratings yet

- Report On Business Strategies of Berger Paints Bangladesh LimitedDocument19 pagesReport On Business Strategies of Berger Paints Bangladesh LimitedNahin AminNo ratings yet

- TN144-Paint Systems. MRTS QueenslandDocument71 pagesTN144-Paint Systems. MRTS QueenslandbradrimmNo ratings yet

- Resene Uracryl 402: Urethane Acrylic Semi-Gloss FinishDocument2 pagesResene Uracryl 402: Urethane Acrylic Semi-Gloss FinishPeter ThomsonNo ratings yet

- Structural Steel FramingDocument21 pagesStructural Steel FramingAlejandro MorelNo ratings yet

- BCM-V U1 Part-C 28.06.2021Document36 pagesBCM-V U1 Part-C 28.06.2021hyperloop707 designNo ratings yet

- Ethanol - Brief Profile - ECHADocument35 pagesEthanol - Brief Profile - ECHARaluca DragoiuNo ratings yet

- Uniprime 200 HS: (Product Code) (ERP 1335) (ERP 3900) (ERP 7101) (ERP 9106) (ERX 1755) Not Color Code (See Note 4)Document2 pagesUniprime 200 HS: (Product Code) (ERP 1335) (ERP 3900) (ERP 7101) (ERP 9106) (ERX 1755) Not Color Code (See Note 4)Svetoslav Stoimenov0% (1)

- Sikagard 403W PDSDocument3 pagesSikagard 403W PDSPRERAKNo ratings yet

- Nuancier Montana 94Document2 pagesNuancier Montana 94cyrilNo ratings yet

- BS 3416 1991Document12 pagesBS 3416 1991viraj100% (2)

- Sample BQDocument10 pagesSample BQmohdshahrircheabdul100% (1)

- Company List Sales AnalysisDocument36 pagesCompany List Sales AnalysisMit MotaNo ratings yet

- Emissivity Table enDocument1 pageEmissivity Table enSinan YıldızNo ratings yet

- Carta Colores AutenticoDocument11 pagesCarta Colores AutenticoPilar CapulinoNo ratings yet

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDocument5 pagesSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakimNo ratings yet

- Acronal Ds 6262 TdsDocument1 pageAcronal Ds 6262 TdsLong An DoNo ratings yet

- Painting BonereapersDocument6 pagesPainting BonereapersAnonymous jnydRw8100% (2)

- Mil PRF 85285eDocument24 pagesMil PRF 85285emurphygtNo ratings yet

- SEM Sample PreparationDocument4 pagesSEM Sample PreparationSanjay PatelNo ratings yet

- Encor: Pure Acrylic Latex For Interior and Exterior PaintsDocument2 pagesEncor: Pure Acrylic Latex For Interior and Exterior PaintsAPEX SONNo ratings yet

- Caracteristicas General de Polimeros PDFDocument4 pagesCaracteristicas General de Polimeros PDFmarylorena01No ratings yet

- Fictional Reality 1Document70 pagesFictional Reality 1alaling1No ratings yet