Professional Documents

Culture Documents

Materials Engineering Problem

Uploaded by

Nieves Guardian0 ratings0% found this document useful (0 votes)

5 views1 pageThe document discusses the effects of cooling rate on the properties of metals produced from molten states. Uneven or non-constant cooling can result in uneven hardness, stress distribution, distortion, cracking, or soft spots. Cracks and rust can be remedied through sealing, filling, or removal. Various elements like carbon, silicon, sulfur, manganese, and phosphorus impart different properties when added to iron, such as hardness, strength, machinability, and brittleness. Controlled amounts of impurities like silicon, sulfur, phosphorus, oxygen, and nitrogen within specified percentages are required to obtain the desired properties for specific iron and steel products.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the effects of cooling rate on the properties of metals produced from molten states. Uneven or non-constant cooling can result in uneven hardness, stress distribution, distortion, cracking, or soft spots. Cracks and rust can be remedied through sealing, filling, or removal. Various elements like carbon, silicon, sulfur, manganese, and phosphorus impart different properties when added to iron, such as hardness, strength, machinability, and brittleness. Controlled amounts of impurities like silicon, sulfur, phosphorus, oxygen, and nitrogen within specified percentages are required to obtain the desired properties for specific iron and steel products.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageMaterials Engineering Problem

Uploaded by

Nieves GuardianThe document discusses the effects of cooling rate on the properties of metals produced from molten states. Uneven or non-constant cooling can result in uneven hardness, stress distribution, distortion, cracking, or soft spots. Cracks and rust can be remedied through sealing, filling, or removal. Various elements like carbon, silicon, sulfur, manganese, and phosphorus impart different properties when added to iron, such as hardness, strength, machinability, and brittleness. Controlled amounts of impurities like silicon, sulfur, phosphorus, oxygen, and nitrogen within specified percentages are required to obtain the desired properties for specific iron and steel products.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

ENGR. JHO ANA MAE D.

MORALES

1. What happens to the solid produced from the molten state if the rate of

cooling will not be constant?

Rate of cooling is considered to be the controlling factor in developing either a soft or a

hard metal. Rapid cooling results to hard structure while slow cooling results to soft

structure. If the rate of cooling will not be constant, it will result to uneven hardness and

unfavorable distribution of stress. This may cause distortion cracking or soft spots.

When water is used in cooling, the steel parts may rust.

2. What remedies can be made to correct the defects?

Cracks can be remedied by sealing/filling the cracks with suitable sealant or filler.

Rust can be remedied using rust converter or rust remover.

3. Enumerate the different properties imparted in adding these elements in iron.

Elements:

• Carbon – Increasing carbon content increases hardness and strength and

improves hardenability but carbon also increases brittleness and reduces

weldability because of its tendency to form martensite.

• Silicon – It is an important element in making grey cast iron because it is known

as a graphite stabilizing element in cast iron. Thus, it promotes the development

of graphite in place of iron carbides. It also helps to purify the iron ore during

the smelting process by deoxidizing it and removing other impurities from it. It is

also used for hardening purposes.

• Sulfur – Improve machinability. Weldability of steel decreases with the increase

in sulfur content. Increasing sulfur contents in gray cast iron alters the

morphology of manganese sulfide inclusions and increases inclusion sizes. The

greatest effect of sulfur is hot brittleness at elevated temperatures.

• Manganese – It removes oxygen and sulfur when iron ore (an iron and oxygen

compound) is converted into iron. It also is an essential alloy that helps convert

iron into steel. As an alloy, it decreases the brittleness of steel and imparts

strength. Added to steel to increase the working properties and tensile strength

and machinability. Increase the toughness and hardenability.

• Phosphorus – Excessive phosphorus content raises the brittleness of gray iron

because of the brittle and intergranular steadite and reduces tensile strength. It

has limited solubility in austenite, which decreases by increasing the carbon

content. Therefore, during the solidification of cast iron, phosphorus segregates

into the melt. It is always used with sulfur to improve machinability. Increases

strength.

4. How does the amount of impurities be imparted to obtain the required

amount for a specific iron and steel products?

Impurities like silicon – 0.1% to 0.3%, sulfur – 0.015% to 0.6%, phosphorus – 0.04%

(structural steel) 0.035% (tool steel), oxygen – above 0.025%, nitrogen – 0.005% to

0.3% (in welds) should be limited only to these percentage to attain quality iron and

steel products.

You might also like

- Effects of Alloying ElementsDocument3 pagesEffects of Alloying Elementsdraj1875977No ratings yet

- Lecture-1, Description of Different AlloysDocument30 pagesLecture-1, Description of Different Alloyssatish chinthamNo ratings yet

- Effects of Alloying Elements in SteelDocument12 pagesEffects of Alloying Elements in SteelyatheendravarmaNo ratings yet

- Modern Steel - Lecture 1Document54 pagesModern Steel - Lecture 1Jojo Hany100% (1)

- Effect of Alloying Elements On Steel PropertiesDocument5 pagesEffect of Alloying Elements On Steel PropertiesgovimanoNo ratings yet

- Engineering Materials NotesDocument25 pagesEngineering Materials NotesRoobanesh ManoharanNo ratings yet

- Effects of Elements On SteelDocument4 pagesEffects of Elements On SteelmichaelNo ratings yet

- Effect of Elements in SteelDocument3 pagesEffect of Elements in SteelJayakrishnan Radhakrishnan100% (1)

- Conmatest 7Document46 pagesConmatest 7Ian BondocNo ratings yet

- L-1 Steel StructureDocument22 pagesL-1 Steel StructureRukhsar JoueNo ratings yet

- Metals 2Document13 pagesMetals 2arooj anjumNo ratings yet

- Metals 2023 2024Document36 pagesMetals 2023 2024Joshua TupasNo ratings yet

- Tratamientos Térmicos: Carlos Bohórquez 2010Document61 pagesTratamientos Térmicos: Carlos Bohórquez 2010procesosun2010No ratings yet

- Structure and PropertiedDocument43 pagesStructure and PropertiedJalaj GaurNo ratings yet

- 150 Sample-Chapter PDFDocument25 pages150 Sample-Chapter PDFMochammad Waris SNo ratings yet

- Iron and It's TypesDocument12 pagesIron and It's TypesSakshi SharmaNo ratings yet

- Cast Iron - WikipediaDocument48 pagesCast Iron - WikipediaLAliNo ratings yet

- Steel and Its AlloyDocument23 pagesSteel and Its AlloyHemang ChopraNo ratings yet

- Section 4 PDFDocument3 pagesSection 4 PDFSatyamKumarNo ratings yet

- Steel ManufacturingDocument29 pagesSteel ManufacturingNDTInstructor100% (3)

- SteelDocument34 pagesSteelSumit GhartimagarNo ratings yet

- Topic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONDocument11 pagesTopic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONsandeep kumarNo ratings yet

- Effects of Alloying Elements in SteelDocument3 pagesEffects of Alloying Elements in SteelEslam NagyNo ratings yet

- ReportDocument3 pagesReportShamRock CasasNo ratings yet

- Control of PropertiesDocument65 pagesControl of PropertiesJezzrel Xandy BalmesNo ratings yet

- Module 3-MetalsDocument13 pagesModule 3-MetalsLiz Gaviola PescoNo ratings yet

- Types of Cast IronDocument5 pagesTypes of Cast Ironmanas310jntuhNo ratings yet

- Metals: Uploaded By: Engr - Ahmad SameerDocument48 pagesMetals: Uploaded By: Engr - Ahmad Sameercuong304No ratings yet

- Cast Iron - WikipediaDocument11 pagesCast Iron - WikipediaBhumikNo ratings yet

- Cast Iron: Cast Iron Is A Group of Iron-Carbon Alloys With A Carbon Content Greater ThanDocument8 pagesCast Iron: Cast Iron Is A Group of Iron-Carbon Alloys With A Carbon Content Greater ThanspibluNo ratings yet

- Effects of Alloying ElementDocument4 pagesEffects of Alloying Elementamber2211No ratings yet

- Unit 6-Metals & Non-MetalsDocument8 pagesUnit 6-Metals & Non-MetalsRahul KumarNo ratings yet

- Aceros y Hierros InglesDocument19 pagesAceros y Hierros InglesivanbfNo ratings yet

- Cast Iron BMEDocument2 pagesCast Iron BMEsahitya karaheNo ratings yet

- Metals: Maj Dr. JawedDocument41 pagesMetals: Maj Dr. JawedBlac_Thunder2209No ratings yet

- Assignment 1Document20 pagesAssignment 1Md Ashraful RahmanNo ratings yet

- Types of Cast IronDocument7 pagesTypes of Cast IronEddy VëraNo ratings yet

- 7steel and Heat TreatmentDocument19 pages7steel and Heat TreatmentManoj BallaNo ratings yet

- METALSDocument48 pagesMETALSMian Afzaal 72No ratings yet

- Material Science 1Document3 pagesMaterial Science 1Mehul BansalNo ratings yet

- Note CHP 4 Material Science 281 Uitm Em110Document52 pagesNote CHP 4 Material Science 281 Uitm Em110bino_ryeNo ratings yet

- aLLOY STEEL 15 For Name 205Document40 pagesaLLOY STEEL 15 For Name 205Sakib RafeeNo ratings yet

- Iron Man of SteelDocument32 pagesIron Man of SteelDeepak jose vargheseNo ratings yet

- Steel Lecture Notes 1 PDFDocument6 pagesSteel Lecture Notes 1 PDFMary Grace BorinagaNo ratings yet

- MetalsDocument27 pagesMetalsArun PrasadNo ratings yet

- Aircraft Maintenance Ferrous MetalsDocument8 pagesAircraft Maintenance Ferrous MetalsRocker HuzzNo ratings yet

- Composition and Grades of Cast IronDocument5 pagesComposition and Grades of Cast IronahmedNo ratings yet

- Assignment CompioDocument4 pagesAssignment CompioDominic CompioNo ratings yet

- Alloying ElementsDocument4 pagesAlloying ElementsLakshmi NarayananNo ratings yet

- STEELDocument13 pagesSTEELAjinkya GholveNo ratings yet

- Cast Iron - WikipediaDocument17 pagesCast Iron - Wikipedia257 Satyam YadavNo ratings yet

- Iron and Steel Production-Class LetureDocument30 pagesIron and Steel Production-Class LetureAustin Okoth Omondi100% (1)

- Effects of Alloying Elements in SteelDocument3 pagesEffects of Alloying Elements in SteelfaizalzolNo ratings yet

- CH 5 - Ferrous Metals and AlloysDocument45 pagesCH 5 - Ferrous Metals and AlloysYhan SombilonNo ratings yet

- Alloying Elements of Steels and PropertiesDocument3 pagesAlloying Elements of Steels and PropertiesdaimaheshNo ratings yet

- Cast Iron PropertiesDocument8 pagesCast Iron PropertiesGerardo JM Palacios100% (1)

- Metal and AlloysDocument20 pagesMetal and AlloysShifat RashidNo ratings yet

- Heat Treatment of Cast IronsDocument4 pagesHeat Treatment of Cast IronshamidrezachamaniNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

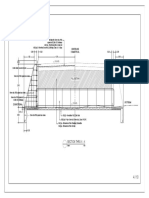

- Window and DoorsDocument1 pageWindow and DoorsNieves GuardianNo ratings yet

- Detailed ColumnDocument1 pageDetailed ColumnNieves GuardianNo ratings yet

- Inspection Report Template For PIDocument1 pageInspection Report Template For PINieves GuardianNo ratings yet

- Detailed BeamDocument1 pageDetailed BeamNieves GuardianNo ratings yet

- Request For InformationDocument2 pagesRequest For InformationNieves GuardianNo ratings yet

- SlabDocument1 pageSlabNieves GuardianNo ratings yet

- Placing of Concrete ChecklistDocument2 pagesPlacing of Concrete ChecklistNieves GuardianNo ratings yet

- Inspection Request FormDocument1 pageInspection Request FormNieves GuardianNo ratings yet

- Non Conformity ReportDocument2 pagesNon Conformity ReportNieves GuardianNo ratings yet

- Construction LogbookDocument1 pageConstruction LogbookNieves GuardianNo ratings yet

- Dah BD ReportDocument49 pagesDah BD ReportNieves GuardianNo ratings yet

- Detailed Plan Spillway 2Document1 pageDetailed Plan Spillway 2Nieves GuardianNo ratings yet

- Lot PlanDocument1 pageLot PlanNieves GuardianNo ratings yet

- ScheduleDocument12 pagesScheduleNieves GuardianNo ratings yet

- Multipurpose HallDocument15 pagesMultipurpose HallNieves Guardian100% (1)

- Floor PlanDocument1 pageFloor PlanNieves GuardianNo ratings yet

- MHR - Unit 3 Atoms, Elements, and CompoundsDocument12 pagesMHR - Unit 3 Atoms, Elements, and Compoundsfriscokid13No ratings yet

- Chemistry Handout 9 REF #: 009: The Mole and Chemical ReactionsDocument3 pagesChemistry Handout 9 REF #: 009: The Mole and Chemical ReactionsNaomi JohnsonNo ratings yet

- Rhenium Review - Millensifer2010 PDFDocument22 pagesRhenium Review - Millensifer2010 PDFGeorgeGoodNo ratings yet

- Paic MCQDocument12 pagesPaic MCQManish MahadevwalaNo ratings yet

- 19 - Carboxylic Acids and Derivatives PDFDocument16 pages19 - Carboxylic Acids and Derivatives PDFAzhar GoolfeeNo ratings yet

- Chemistry Form 4 Definition ListDocument3 pagesChemistry Form 4 Definition ListSyazana Mohd RosliNo ratings yet

- Technical Data Sheet Spectek 787 Bright Nickel Process: Salient FeaturesDocument8 pagesTechnical Data Sheet Spectek 787 Bright Nickel Process: Salient Featuresshanmukha MechanicalNo ratings yet

- Exemplar Science Lesson Plan For Senior High School General Chemistry 1Document4 pagesExemplar Science Lesson Plan For Senior High School General Chemistry 1Arnel MetilloNo ratings yet

- Chapter 12 Study GuideDocument8 pagesChapter 12 Study GuideAegislash 777No ratings yet

- Chemistry 11th Edition by Chang ISBN 007766695X Test BankDocument20 pagesChemistry 11th Edition by Chang ISBN 007766695X Test Bankandrea100% (23)

- CH 4 Problems 5th Edition PDFDocument6 pagesCH 4 Problems 5th Edition PDFnisannn100% (1)

- Tech Data: RO PerfectDocument11 pagesTech Data: RO PerfectFadhilah SurotoNo ratings yet

- Redox ReactionsDocument29 pagesRedox ReactionsSoniaAlexNo ratings yet

- Stoichiometry Exam Style QuestionDocument2 pagesStoichiometry Exam Style QuestionKelvin RequenaNo ratings yet

- Mole Concept Fedeliano J. Bernardo, Jr.Document42 pagesMole Concept Fedeliano J. Bernardo, Jr.Joreen Divine GammadNo ratings yet

- Comparison of Octahedral and Tetrahedral FieldsDocument30 pagesComparison of Octahedral and Tetrahedral FieldsShubham Kumar100% (1)

- LAB ACT 6 aCIDS, bASE AND sALTSDocument8 pagesLAB ACT 6 aCIDS, bASE AND sALTSJerome MosadaNo ratings yet

- Notes For Better Brew v60 and Detailed KnowledgeDocument5 pagesNotes For Better Brew v60 and Detailed KnowledgeАлишер НурушевNo ratings yet

- Form PurchaseDocument25 pagesForm PurchaseAnton WahyudiNo ratings yet

- Test Description/ Characteris Tics Reagents Procedure Product Responsible For Color Positive Result Biuret TestDocument4 pagesTest Description/ Characteris Tics Reagents Procedure Product Responsible For Color Positive Result Biuret TestYroen Faith D. TalonNo ratings yet

- Effects of Alloying Elements in SteelDocument4 pagesEffects of Alloying Elements in SteelRahulNo ratings yet

- Atomic Structure WKSTDocument2 pagesAtomic Structure WKSTAmanda ClayNo ratings yet

- Metallic Bonding: What Is A Metallic Bond?Document3 pagesMetallic Bonding: What Is A Metallic Bond?Najam Us SamadNo ratings yet

- All DataDocument121 pagesAll DataShashank SaxenaNo ratings yet

- 5387ff99e4b03f3448bd8c9b Ash90 1401893299295 UnimportantDocument6 pages5387ff99e4b03f3448bd8c9b Ash90 1401893299295 UnimportantKeaton EisenmengerNo ratings yet

- 2016 Specimen Paper 4 Mark SchemeDocument6 pages2016 Specimen Paper 4 Mark SchemelolismNo ratings yet

- Aiats Jee Main2014 Paper 1 Test1Document10 pagesAiats Jee Main2014 Paper 1 Test1Chanderpal BarupalNo ratings yet

- Chemistry 2015 Paper1Document17 pagesChemistry 2015 Paper1evango21No ratings yet

- Answers To End-Of-Chapter Questions For Chapter 3, Atomic StructureDocument2 pagesAnswers To End-Of-Chapter Questions For Chapter 3, Atomic StructureAliNo ratings yet

- Drotaverine HCL MOADocument15 pagesDrotaverine HCL MOASachin KumarNo ratings yet