Professional Documents

Culture Documents

3 Inch NB Nozzle Calulation For Tank

Uploaded by

SACHIN PATELOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Inch NB Nozzle Calulation For Tank

Uploaded by

SACHIN PATELCopyright:

Available Formats

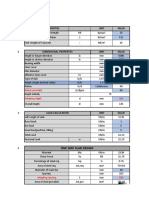

DESIGN CALCULATION FOR SET IN, SET ON NOZZLE

Page No

WITH AND WITHOUT PAD AND SELF REINFORCED

Doc. No. Revision

SHELL INPUTS

Internal pressure P kgf/cm2 0.23209 CONSIDER LIQUID HEAD

Internal diameter of the shell D mm 2300

WITHOUT CORROSION

Reqd. thickness of shell (corresponding to internal pressure) tr,int mm 4.2 ALLOWANCE

WITHOUT CORROSION

Reqd. thickness of shell (corresponding to external pressure) tr,ext mm 0 ALLOWANCE

Allowable stress in shell at given temp Sv kgf/cm2 1203.27

Corrosion allowance of shell c.a.,shell mm 3.2

Shell thickness provided t' mm 6

NOZZLE INPUTS

SELECT FROM DROP

set in nozzle with pad DOWN LIST

type of nozzle

Nozzle O.D. d' mm 88.9

Nozzle wall thickness provided tn' mm 7.52

nozzle projection outside the vessel wall Lpr1 mm 100

allowable stress in nozzle Sn kgf/cm2 1203.27

Offset distance Off mm 0

reqd. nozzle thickness(corresponding to external pressure) tr n,ext mm 0

REINFORCING PAD INPUTS

outside diameter of reinforcing pad Dp mm 190

thickness of reinforcing pad te mm 6

SELECT FROM DROP

is it split type padding NO DOWN LIST

INTEGRAL NOZZLE INPUTS

hub height of integral nozzle h mm 0

height of beveled transition L' mm 0

hub thickness of integral nozzle X mm 0 FALSE

WELD LEGS INPUTS

weld leg between pad and shell leg1 mm 6

weld leg between nozzle and pad/shell leg2 mm 6

CERTAIN DERIVED PARAMETERS

corrosion allowance of nozzle (internal only) c.a.,nozzle mm 3.2

allowable stress in reinforcing pad at given temp Sp kgf/cm2 1203.27

Shell thickness after corrosion t mm 2.8

Nozzle wall thickness after corrosion tn mm 4.32

inside diameter of nozzle d mm 80.26

width of reinforcing pad W mm 50.55

layout angle θ radian 0

reqd. nozzle thk tr n mm 0.00857

Reqd. thickness of shell (governing the case) tr mm 4.2

USE ASME CODE SECTION-8 DIVISION I (UG-37)

USE ASME CODE SECTION-8 DIVISION I (UG-37)

You might also like

- Nozzle 1Document2 pagesNozzle 1francisco zepedaNo ratings yet

- 6 Inch NB Nozzle Calulation For TankDocument12 pages6 Inch NB Nozzle Calulation For TankSACHIN PATELNo ratings yet

- Nozzle 1Document25 pagesNozzle 1Sasikumar JothiNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Nozzle 1Document25 pagesNozzle 1panjiajinugroho23No ratings yet

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument25 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNo ratings yet

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument24 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleAboMuhmadSr.No ratings yet

- Reinforcement of NozzleDocument24 pagesReinforcement of NozzleJimmy RojasNo ratings yet

- New Reinforcement of Nozzle 1xls - CompressDocument24 pagesNew Reinforcement of Nozzle 1xls - CompressBharat BhoirNo ratings yet

- New - Reinforcement of NozzleDocument24 pagesNew - Reinforcement of NozzleVaniya GoelNo ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Document7 pagesSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNo ratings yet

- 93 Qc20 J 414 Inlet NozzleDocument6 pages93 Qc20 J 414 Inlet NozzleHgagselim SelimNo ratings yet

- Design Calculations For Pressure VesselsDocument43 pagesDesign Calculations For Pressure VesselsMoises Alvarez LeandroNo ratings yet

- WRC For NozzleDocument43 pagesWRC For NozzleSachin55860% (1)

- Part-Uhx (U-Tube) .Document5 pagesPart-Uhx (U-Tube) .AKSHAY BHATKARNo ratings yet

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDocument10 pagesTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Input ValuesDocument5 pagesInput ValuesmasoodNo ratings yet

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- Design Data Sheet For Air ReceiverDocument3 pagesDesign Data Sheet For Air ReceivergksakthiNo ratings yet

- Branch RF CalcDocument6 pagesBranch RF CalcHarish Harish0% (1)

- Final ExaminationDocument7 pagesFinal ExaminationAwanNo ratings yet

- CK Tourqe CalculationDocument7 pagesCK Tourqe Calculationamit amity100% (1)

- InputDocument5 pagesInputTrần Văn NhânNo ratings yet

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDocument12 pagesR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- Builtup SectionDocument4 pagesBuiltup SectionSuhas MangaloreNo ratings yet

- Mark: Detail - A: InputDocument2 pagesMark: Detail - A: InputRajib MaharjanNo ratings yet

- Deep Groove Ball Bearing: Main Dimensions & Performance DataDocument1 pageDeep Groove Ball Bearing: Main Dimensions & Performance DataCutberto MartinezNo ratings yet

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- SL045016-D-PP: Cylindrical Roller BearingDocument2 pagesSL045016-D-PP: Cylindrical Roller BearingOlawale John AdeotiNo ratings yet

- Blind Flange DesignDocument1 pageBlind Flange DesignSachin5586No ratings yet

- Tapered Roller Bearing: Schaeffler IDDocument2 pagesTapered Roller Bearing: Schaeffler IDFlorian GhioculescuNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellRamuAlagappan100% (1)

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellRamuAlagappan100% (4)

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellSateesh MokasiNo ratings yet

- Tanque A PresionDocument16 pagesTanque A PresionJuan MendozaNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellRamalingameSattiamoortyNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellClaudia BonocoreNo ratings yet

- Tebalvesel PerhitunganDocument16 pagesTebalvesel Perhitungancharleshutabara951No ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellClaudia BonocoreNo ratings yet

- 3 Inch NB Design Calulation For Varible ThicknessDocument5 pages3 Inch NB Design Calulation For Varible ThicknessSACHIN PATELNo ratings yet

- INPUT VALUES, Nozzle Description: N3 DRAIN From: 10Document1 pageINPUT VALUES, Nozzle Description: N3 DRAIN From: 10Nerubian AssasinNo ratings yet

- Beam Column ConnectionDocument2 pagesBeam Column ConnectionHAZIRACFS SURATNo ratings yet

- Za Prikljucke Na DancuDocument13 pagesZa Prikljucke Na Dancunikolamil1993No ratings yet

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Document2 pagesE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Rajesh KumarNo ratings yet

- Welding Calculation ModulDocument5 pagesWelding Calculation ModulricardoNo ratings yet

- Beam DesignDocument2 pagesBeam DesignBilal A BarbhuiyaNo ratings yet

- Api 650 RF Pad CalculationDocument1 pageApi 650 RF Pad Calculationfauzy2504No ratings yet

- Page 1 of 6Document6 pagesPage 1 of 6Devesh SinghNo ratings yet

- WRC CalculationsDocument20 pagesWRC Calculationsanu radha50% (2)

- Design Excel SheetDocument17 pagesDesign Excel SheetbuntyNo ratings yet

- 30 8-2RSDocument1 page30 8-2RSdharmendraNo ratings yet

- Frame ConnectionsDocument14 pagesFrame ConnectionsShawkat Ali KhanNo ratings yet

- Pressure Vessel Calculations-ASME SectioDocument11 pagesPressure Vessel Calculations-ASME SectioShojib khanNo ratings yet

- Pressure Vessel Calculations ASME SectioDocument11 pagesPressure Vessel Calculations ASME Sectioivan chirinosNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Standards of ServicesDocument72 pagesStandards of ServicesSACHIN PATELNo ratings yet

- Disc o Flex - RATHI PDFDocument28 pagesDisc o Flex - RATHI PDFSACHIN PATELNo ratings yet

- Maca For FeaDocument15 pagesMaca For FeaSACHIN PATELNo ratings yet

- MR FlangesDocument21 pagesMR FlangesSACHIN PATELNo ratings yet

- Cryogenic Tank ManualDocument49 pagesCryogenic Tank ManualSACHIN PATELNo ratings yet

- CRN PresentationDocument15 pagesCRN PresentationSACHIN PATELNo ratings yet

- Ne CFD 2020 Combine Case Study PDFDocument17 pagesNe CFD 2020 Combine Case Study PDFSACHIN PATELNo ratings yet

- ChevronDocument81 pagesChevronSantosh100% (1)

- Flange Material TCDocument1 pageFlange Material TCSACHIN PATELNo ratings yet

- Lifting LugDocument2 pagesLifting LugSACHIN PATELNo ratings yet

- Ga BomDocument1 pageGa BomSACHIN PATELNo ratings yet

- Fdocuments - in Separator Sizing SpreadsheetDocument31 pagesFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaNo ratings yet

- Nozzle Load & Saddle CalculationDocument26 pagesNozzle Load & Saddle CalculationSACHIN PATEL100% (1)

- Certificate of Conformance: HONEYWELL Field ProductsDocument1 pageCertificate of Conformance: HONEYWELL Field ProductsSACHIN PATELNo ratings yet

- Honeywell Smart Line Calibration Report & Certificate of ConformanceDocument1 pageHoneywell Smart Line Calibration Report & Certificate of ConformanceSACHIN PATELNo ratings yet

- 3 Inch NB Nozzle Calculation UG-37Document3 pages3 Inch NB Nozzle Calculation UG-37SACHIN PATELNo ratings yet

- Honeywell: Smartline Stt700 Hart Temperature Transmitter Sil 2/3 CertificatesDocument3 pagesHoneywell: Smartline Stt700 Hart Temperature Transmitter Sil 2/3 CertificatesSACHIN PATELNo ratings yet

- 3 Inch NB Nozzle Calculation Appendex 1-10Document6 pages3 Inch NB Nozzle Calculation Appendex 1-10SACHIN PATELNo ratings yet

- Certificate of Conformance: HONEYWELL Field ProductsDocument1 pageCertificate of Conformance: HONEYWELL Field ProductsSACHIN PATELNo ratings yet

- Honeywell Smart Line Calibration Report & Certificate of ConformanceDocument1 pageHoneywell Smart Line Calibration Report & Certificate of ConformanceSACHIN PATELNo ratings yet

- 6 Inch NB Nozzle Calculation Appendex 1-7Document11 pages6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNo ratings yet

- 6 Inch NB Nozzle Calculation Appendex 1-7Document11 pages6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNo ratings yet

- 3 Inch NB Design Calulation For Varible ThicknessDocument5 pages3 Inch NB Design Calulation For Varible ThicknessSACHIN PATELNo ratings yet

- 6 Inch NB Nozzle Calculation Appendex 1-7Document11 pages6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNo ratings yet

- 3 Inch NB Nozzle Calculation Appendex 1-10Document6 pages3 Inch NB Nozzle Calculation Appendex 1-10SACHIN PATELNo ratings yet

- 3 Inch NB Nozzle Calculation Appendex 1-10Document6 pages3 Inch NB Nozzle Calculation Appendex 1-10SACHIN PATELNo ratings yet

- 3 Inch NB Design Calulation For Varible ThicknessDocument5 pages3 Inch NB Design Calulation For Varible ThicknessSACHIN PATELNo ratings yet

- 3 Inch NB Nozzle Calculation UG-37Document3 pages3 Inch NB Nozzle Calculation UG-37SACHIN PATELNo ratings yet

- 53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions and Answers PDF - MCQs Preparation For Engineering Competitive ExamsDocument7 pages53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions and Answers PDF - MCQs Preparation For Engineering Competitive Examseid ibrahimNo ratings yet

- Couplings PDFDocument41 pagesCouplings PDFAshishAgarwal89% (18)

- C4 Inlet Bellmouth Casing (Top & Bottom Half) Coating ThicknessDocument19 pagesC4 Inlet Bellmouth Casing (Top & Bottom Half) Coating ThicknessDave CheungNo ratings yet

- Kuliah 12 Aliran KompresibelDocument67 pagesKuliah 12 Aliran KompresibelherawanadifNo ratings yet

- Olivetti Copia 9910 SMDocument159 pagesOlivetti Copia 9910 SMvenci_kamenovNo ratings yet

- Design and Fabrication of Mini Ball MillDocument33 pagesDesign and Fabrication of Mini Ball MillJagjot SinghNo ratings yet

- Dynamic Rotary Inverted PendulumDocument18 pagesDynamic Rotary Inverted PendulumNguyễn SangNo ratings yet

- NCERT Class 12 Physics Book (Part I)Document236 pagesNCERT Class 12 Physics Book (Part I)Deepesh TiwariNo ratings yet

- HDPEDocument14 pagesHDPESandy YansikuNo ratings yet

- Work Power Energy QuestionsDocument17 pagesWork Power Energy QuestionsAnupam MNo ratings yet

- Comparative Study of Moisture Removal Techniques For Mineral-Based Insulation OilDocument6 pagesComparative Study of Moisture Removal Techniques For Mineral-Based Insulation OilDante FilhoNo ratings yet

- Methods of Artificial Lift: Presented To: Prof DR: El Ayouty - ElsaidDocument11 pagesMethods of Artificial Lift: Presented To: Prof DR: El Ayouty - Elsaidcmrig74No ratings yet

- Q200680 - Ledeen Technical DescriptionDocument7 pagesQ200680 - Ledeen Technical Descriptioncoyana9652No ratings yet

- Model Calculation of Heat Balance of Wood PyrolysiDocument10 pagesModel Calculation of Heat Balance of Wood PyrolysiqwerNo ratings yet

- Defaults Wave SolderingDocument8 pagesDefaults Wave SolderingTANNo ratings yet

- WWW - Manaresults.Co - In: Engineering MechanicsDocument2 pagesWWW - Manaresults.Co - In: Engineering MechanicsNoor IslamNo ratings yet

- Fuel CellsDocument16 pagesFuel Cellspramod gaikwadNo ratings yet

- T78u PDFDocument1 pageT78u PDFRenny DevassyNo ratings yet

- BS en 10228 4 2016 Non Destructive Testi PDFDocument30 pagesBS en 10228 4 2016 Non Destructive Testi PDFDaryna KupriianovaNo ratings yet

- Sem 3 - Lab Thermal Expansion of Solid and LiquidDocument8 pagesSem 3 - Lab Thermal Expansion of Solid and LiquidLuqman Hakim100% (1)

- Static IndeterminacyDocument36 pagesStatic IndeterminacyKarthik KrishNo ratings yet

- #Derivation of Mechanical Properties For SandDocument8 pages#Derivation of Mechanical Properties For SandkingmajorNo ratings yet

- A Review of Methods of Molecular Weight Determination of PolymersDocument4 pagesA Review of Methods of Molecular Weight Determination of PolymerspejvakNo ratings yet

- Ps2 GeoDocument9 pagesPs2 GeoRio Fae BautistaNo ratings yet

- GRP Pipes Fittings CatalogDocument8 pagesGRP Pipes Fittings CatalogFaseen ibnu Ameer Ahasen0% (1)

- Me8391 Engineering ThermodynamicsDocument1 pageMe8391 Engineering ThermodynamicsAiam PandianNo ratings yet

- Novw 266861 - DBDocument47 pagesNovw 266861 - DBathalia athisaNo ratings yet

- Non-returns-DampersDocument1 pageNon-returns-DampersProject enghvacNo ratings yet

- MP4004 Advanced Manufacturing and Nanotechnology: ContentDocument26 pagesMP4004 Advanced Manufacturing and Nanotechnology: ContentVincent KohNo ratings yet

- Asp QBDocument38 pagesAsp QBMansi KadelNo ratings yet