Professional Documents

Culture Documents

V6.0.1 motor test report

Uploaded by

amine zighaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V6.0.1 motor test report

Uploaded by

amine zighaCopyright:

Available Formats

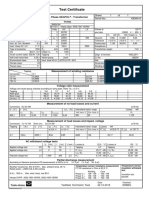

V6.0.1 - 1.0.7605.

26547

Date of Issue: 30.11.2020

Type Test Report

Tests have been carried out for motor no. 3G1F1951645571,

which is identical in electrical design with motor type(s) Type: M3AA 80A 4

stated in this report. Product Code: 3GAA082311-_SE

Rating:

V Hz kW r/min A cos φ Duty

3~Motor 400 Y 50 0,55 1406 1,29 0,78 S1

Ins. Class F 230 D 50 0,55 1406 2,24 0,78 S1

460 Y 60 0,55 1721 1,15 0,74 S1

Eff class IE2 50Hz: IE2 - 77.1(100%) - 78.6(75%) - 76.8(50%)

60Hz: IE2 - 75.5(100%)

Winding resistance Measured at Calculated at

22 °C 20 °C

U1 - V1 24,161 Ω 23,973 Ω Insulation resistance after heat run at 44 °C

U1 - W 1 24,148 Ω 23,960 Ω 190500 MΩ , tested at 1000 V

V1 - W 1 24,173 Ω 23,985 Ω

Withstand voltage test for winding 2206 V 1s

Test Torque Line Input Output

[Nm] U[V] f[Hz] I[A] P1 [kW] P2 [kW] n[r/min] cos φ h [%] s [%]

No-load test 399,9 Y 50 0,80 0,06 0,11

Short circuit test 83,9 Y 50 1,29 0,14 0,72

Temp. rise test S1 3,7 400,2 Y 50 1,29 0,70 0,55 1407 0,78 78,1 6,23

Partial load points:

~75% load 2,8 400,3 Y 50 1,10 0,53 0,42 1433 0,70 79,5 4,43

~50% load 1,9 400,2 Y 50 0,94 0,37 0,29 1457 0,56 78,2 2,88

~25% load 0,9 400,1 Y 50 0,84 0,21 0,15 1478 0,36 69,7 1,46

Temperature rise at rated load. [°C] [K] Method Measurement method

Stator winding : 31 1 1 Resistance

Frame : 21 2 2 Thermocouples

Bearing D-end : 18 2 3 Thermometer

Rotor : 32 3

Ambient Temperature : 21 2

Starting current (IS / IN) : 5,45

Locked rotor torque (TL / T N) : 2,81

Current unbalance at full load: 0,91 %

Manufactured and tested acc. to IEC/EN 60034-1:2017 and IEC/EN 60034-2-1:2014 Method 2-1-1B.

On behalf of customer

On behalf of manufacturer Date of test: 18.2.2020

Tested by ABB Oy, Motors and Generators, Vaasa, Finland

Test laboratory has been certified acc. to ISO/IEC 17025:2017 Tommi Pantti, Test Floor Manager

ABB, Motors and Generators Telephone +358 10 2211

www abb.com/motors&generators Telefax +358 10 22 47372

You might also like

- Caterpillar D11R CD Carrydozer Implement Systems ManualDocument68 pagesCaterpillar D11R CD Carrydozer Implement Systems ManualMaquinarias Pesadas100% (4)

- 3A90L 4 1.5kW400V PDFDocument6 pages3A90L 4 1.5kW400V PDFMuthukumar SivaramanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Hi-Vac (400 Series) Operations ManualDocument80 pagesHi-Vac (400 Series) Operations ManualMatias Contreras Köbrich100% (1)

- Large Capacity Supercritical SetsDocument55 pagesLarge Capacity Supercritical Setsbidyut100100% (5)

- M3AA 180MLB 4 Type Test ReportDocument1 pageM3AA 180MLB 4 Type Test ReportdiablolcNo ratings yet

- Type Test Report: Measurement Method 1 Resistance 2 Thermometer 3 ThermocouplesDocument1 pageType Test Report: Measurement Method 1 Resistance 2 Thermometer 3 ThermocouplesdiablolcNo ratings yet

- M3AA 180MLA 8 G 400V 50Hz 11kWDocument1 pageM3AA 180MLA 8 G 400V 50Hz 11kWdiablolcNo ratings yet

- M3AA 180MLA 6 G 400V 50Hz 15kWDocument1 pageM3AA 180MLA 6 G 400V 50Hz 15kWdiablolcNo ratings yet

- M3JM 280SMC 2 - 3GJM281230 - DG - 110kW - 400VD - 50Hz - IE2Document1 pageM3JM 280SMC 2 - 3GJM281230 - DG - 110kW - 400VD - 50Hz - IE2Saber AbdelaalNo ratings yet

- M3JP 315MLB 6L 400V 50Hz 132kWDocument1 pageM3JP 315MLB 6L 400V 50Hz 132kWCamillo VaccaNo ratings yet

- 6.2. Type Test Sheet 61195708-00Document1 page6.2. Type Test Sheet 61195708-00Martin FoxxxNo ratings yet

- 3G1F2043709296B JM JP KP 90LD4 400VY 50Hz 1,5kW 3GZF021009-138Document1 page3G1F2043709296B JM JP KP 90LD4 400VY 50Hz 1,5kW 3GZF021009-138Kidzoy ShopNo ratings yet

- Test Report: Measurement Method 1 Resistance Ambient 2 Thermometer Frame 3 Thermocouples BearingDocument1 pageTest Report: Measurement Method 1 Resistance Ambient 2 Thermometer Frame 3 Thermocouples BearingHARDWARE ONENo ratings yet

- M2BAX 200MLA 2,3GBA201410-DF, 30kW, 400VD, 50HzDocument1 pageM2BAX 200MLA 2,3GBA201410-DF, 30kW, 400VD, 50HzPein AkatsukiNo ratings yet

- Motor Electrico ABB 4 KWDocument1 pageMotor Electrico ABB 4 KWAlvaro Reimar Ferrufino MartinezNo ratings yet

- (NP3A-220) Motor DataDocument6 pages(NP3A-220) Motor DataEn FaizulNo ratings yet

- L.E.M.T.: TEST REPORT n°51251689EADocument9 pagesL.E.M.T.: TEST REPORT n°51251689EANguyen ngoc thongNo ratings yet

- Test Certificate: 3 - Phase GEAFOL - TransformerDocument1 pageTest Certificate: 3 - Phase GEAFOL - Transformergusfabi1No ratings yet

- DatasheetDocument2 pagesDatasheetEdgarNo ratings yet

- Power Transformer Test 001ADocument7 pagesPower Transformer Test 001ADinesh KumarNo ratings yet

- Test Report 2.2 - Type Test (EN 10204) : 1 Rated Motor DataDocument9 pagesTest Report 2.2 - Type Test (EN 10204) : 1 Rated Motor DatazsmithNo ratings yet

- 65695-200 kVA (AUX01)Document1 page65695-200 kVA (AUX01)Marudavanan SomasundaramNo ratings yet

- Experiment-6 - Filled by The Student 2Document11 pagesExperiment-6 - Filled by The Student 2Rishika SharmaNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument10 pagesData Sheet: Three Phase Induction Motor - Squirrel CageSergeiNo ratings yet

- General Test Information:: Excitation Curve DataDocument2 pagesGeneral Test Information:: Excitation Curve DataJeans GonzalezNo ratings yet

- Test Result MotorDocument1 pageTest Result MotoragungNo ratings yet

- General Test Information:: Siemens - 1700927 - 4 - s1-s2 Page 1 of 4Document4 pagesGeneral Test Information:: Siemens - 1700927 - 4 - s1-s2 Page 1 of 4ChomsaniNo ratings yet

- Pump ATEX, IEC, Test ReportsDocument49 pagesPump ATEX, IEC, Test ReportsPhúc Phạm ThànhNo ratings yet

- General Test Information:: Excitation Curve DataDocument2 pagesGeneral Test Information:: Excitation Curve DataJeans GonzalezNo ratings yet

- Spare Feeder P10Document80 pagesSpare Feeder P10Yogesh JethwaNo ratings yet

- N.V. Bergerat Monnoyeur S.A.: InformationDocument2 pagesN.V. Bergerat Monnoyeur S.A.: InformationMohammad FathiNo ratings yet

- General Test Information:: Excitation Curve DataDocument2 pagesGeneral Test Information:: Excitation Curve DataJeans GonzalezNo ratings yet

- Test ReportDocument40 pagesTest ReportMourad BenderradjiNo ratings yet

- +K01 FinalDocument94 pages+K01 FinalMERLYNNo ratings yet

- 3 Phase Induction Motor - LRVPDocument3 pages3 Phase Induction Motor - LRVPLance AyoubNo ratings yet

- Spare Feeder - P10 - 2Document79 pagesSpare Feeder - P10 - 2Yogesh JethwaNo ratings yet

- Transformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Document4 pagesTransformer Testing For New 10mva Power Transfomer: Batangas Ii Electric Cooperative (Batelec Ii)Edmar BataqueNo ratings yet

- Mot-Ec - enDocument8 pagesMot-Ec - enYERKO ANDRÉS GONZÁLEZNo ratings yet

- Load Test On Single Phase Transformer: Shubham Sharma: RA2111003010611: 28.10.21Document11 pagesLoad Test On Single Phase Transformer: Shubham Sharma: RA2111003010611: 28.10.21shubhamNo ratings yet

- PDF NT73-2 NHGDocument2 pagesPDF NT73-2 NHGMarco SolorzanoNo ratings yet

- Ficha Técnica Batería Solar 200AH GEL SunbattDocument2 pagesFicha Técnica Batería Solar 200AH GEL SunbattJhon AltamarNo ratings yet

- ABB Motors Technical Data SheetDocument1 pageABB Motors Technical Data SheetAgung AfrizalNo ratings yet

- Data-Sheet Curves - 500KW - Brahmani DamDocument7 pagesData-Sheet Curves - 500KW - Brahmani DammanishabariyaNo ratings yet

- WEG synchronous machine test report for Francis turbineDocument8 pagesWEG synchronous machine test report for Francis turbineDarwin SilvaNo ratings yet

- GH 1C 12LDocument2 pagesGH 1C 12LRoberto MendesNo ratings yet

- Motor WEG Data SheetDocument10 pagesMotor WEG Data SheetMohamed ElsayedNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Three Phase Induction Motor - Squirrel CageKamil KościelakNo ratings yet

- Özgüney: Test TransformerDocument1 pageÖzgüney: Test TransformermominzadahNo ratings yet

- Safety Interlock Switches GuideDocument7 pagesSafety Interlock Switches GuideAdel ChiedNo ratings yet

- NVFMCZ20DC12VDocument2 pagesNVFMCZ20DC12VPatrik GasparikNo ratings yet

- Product Information Packet: 5KFS291ZWL2047 WI215Document5 pagesProduct Information Packet: 5KFS291ZWL2047 WI215Edison Paul Tierra TierraNo ratings yet

- Test Report OM3 - 180L - 4: 22,00 KW: ISO14000 ISO9001Document13 pagesTest Report OM3 - 180L - 4: 22,00 KW: ISO14000 ISO9001Desmon GultomNo ratings yet

- Motor - WEG 00236ET3E145T-W22 11456827Document2 pagesMotor - WEG 00236ET3E145T-W22 11456827Luis GuerreroNo ratings yet

- GFMJ 300Document2 pagesGFMJ 300Hilina MedferNo ratings yet

- General Test Information:: Excitation Curve DataDocument2 pagesGeneral Test Information:: Excitation Curve Dataanon_42298864No ratings yet

- General Test Information:: Excitation Curve DataDocument2 pagesGeneral Test Information:: Excitation Curve DataRicky Bernard SinagaNo ratings yet

- Test Object - Device Settings: Substation/BayDocument2 pagesTest Object - Device Settings: Substation/BayWaruna RasanjayaNo ratings yet

- Datasheet 42SH38Document1 pageDatasheet 42SH38Edgar AmundarayNo ratings yet

- GL50AADocument2 pagesGL50AAأبو زينب المهندسNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument7 pagesData Sheet: Three Phase Induction Motor - Squirrel Cagegego2No ratings yet

- Power Transformer Test ReportDocument41 pagesPower Transformer Test ReportMonir100% (1)

- ADAMS Elevator OtisDocument84 pagesADAMS Elevator Otisamine zighaNo ratings yet

- US4520904Document10 pagesUS4520904amine zighaNo ratings yet

- Otis Safety Equipment CatalogDocument98 pagesOtis Safety Equipment Catalogamine zighaNo ratings yet

- 2 Unbalancedmotors Vib 2 56Document20 pages2 Unbalancedmotors Vib 2 56amine zighaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1073D Simotics GP - 71 M - Im B5 - 8PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1AV1073D Simotics GP - 71 M - Im B5 - 8PdianerlNo ratings yet

- 1LE1503-2AB53-4FB4 Datasheet enDocument1 page1LE1503-2AB53-4FB4 Datasheet enamine zighaNo ratings yet

- Hyundai Fork Loaders Diesel 7 Series 20/25/30 / 33D-7 Hydraulic System Page 3080 Hydraulic Oil TankDocument2 pagesHyundai Fork Loaders Diesel 7 Series 20/25/30 / 33D-7 Hydraulic System Page 3080 Hydraulic Oil TankhamedNo ratings yet

- Mp533e PDFDocument4 pagesMp533e PDFEdgar CanelasNo ratings yet

- XCPC CilindrosDocument3 pagesXCPC CilindrosAngel ArteagaNo ratings yet

- Dnce en PDFDocument40 pagesDnce en PDFshuny51No ratings yet

- AIAGPlating System Assessment, 2nd EditionDocument152 pagesAIAGPlating System Assessment, 2nd EditionGiacomo ZammattioNo ratings yet

- RT-flex60C R DemmerleDocument69 pagesRT-flex60C R DemmerlerafaelNo ratings yet

- Hi Kal Catalogue New OptDocument16 pagesHi Kal Catalogue New Optask101No ratings yet

- Electric Drive Selection for Motion Control SystemsDocument88 pagesElectric Drive Selection for Motion Control Systemsgabriel santhosh kumar gNo ratings yet

- 1 1 2 1-17Document7 pages1 1 2 1-17api-275559543No ratings yet

- Agitator Design FactorsDocument6 pagesAgitator Design Factorsserleb44No ratings yet

- Catalogues .EBERSPÄCHERDocument19 pagesCatalogues .EBERSPÄCHERyenNo ratings yet

- Parts Manual: Onan Generator Set For RVDocument64 pagesParts Manual: Onan Generator Set For RVThePathToHomeNo ratings yet

- 787 No-Bleed Systems:: Saving Fuel and Enhancing Operational EfficienciesDocument6 pages787 No-Bleed Systems:: Saving Fuel and Enhancing Operational EfficienciesRuben RamonNo ratings yet

- Spare Parts TPK1000 Special VP 12Document2 pagesSpare Parts TPK1000 Special VP 12Jose VelasquezNo ratings yet

- Drilling OperationDocument16 pagesDrilling OperationKishore DKNo ratings yet

- Ariel Process WebDocument9 pagesAriel Process WebDarmawan PutrantoNo ratings yet

- Brochure. 416 Series. Variable Axial Piston Pump. Options - FeaturesDocument4 pagesBrochure. 416 Series. Variable Axial Piston Pump. Options - FeaturesObaid Shaikh100% (1)

- Craftsman 3 Bin Craftsman Bagger 917.249890Document16 pagesCraftsman 3 Bin Craftsman Bagger 917.249890Kevins Small Engine and Tractor Service100% (1)

- JBR 2014 and Up SKYACTIV MAZDA 3-6 and CX5 Oil Catch Can Installation InstructionsDocument20 pagesJBR 2014 and Up SKYACTIV MAZDA 3-6 and CX5 Oil Catch Can Installation InstructionsDavid ThomasNo ratings yet

- bl250d Lathe ManualDocument33 pagesbl250d Lathe ManualfquenNo ratings yet

- 11 Corolla / Auris (Cont. Next Page) : Engine Control (1ND-TV)Document3 pages11 Corolla / Auris (Cont. Next Page) : Engine Control (1ND-TV)varenziaNo ratings yet

- John Deere Tractor Service Manual JD S Tm4336Document14 pagesJohn Deere Tractor Service Manual JD S Tm4336oscarNo ratings yet

- 310-1512715 Bilge System H01Document11 pages310-1512715 Bilge System H01buturca sorinNo ratings yet

- Legend Sheet P&ID For As-Built - Drafting On 20210722-1Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-1Ludi D. LunarNo ratings yet

- Worksheets T3 (Second Unit)Document5 pagesWorksheets T3 (Second Unit)MarvinNo ratings yet

- Kaeser Marine CompressorsDocument24 pagesKaeser Marine CompressorsMazhar SafdarNo ratings yet

- Parts Guide Manual: Bizhub C10 4556261Document86 pagesParts Guide Manual: Bizhub C10 4556261Paul AlbuNo ratings yet