Professional Documents

Culture Documents

PSV Preliminary Documents - Oxidizer Burner

Uploaded by

EsneyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSV Preliminary Documents - Oxidizer Burner

Uploaded by

EsneyCopyright:

Available Formats

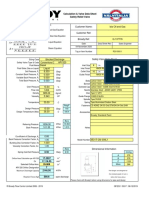

AGCSL Pressure Relief Valve Sizing & Selection Report

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 Valve ID 41 SIZING DATA

I

2 Tag No. PSV-81013A & PSV-82013A 42 Design Code ASME Section I Sizing Std.

3 Service Superheated Steam 43 Sizing Basis Blocked Discharge

4 PID No. 44 Fluid State at Inlet Steam

5 Line No. Safety Valve-I onSuperheater Outlet Quantity 45 Relieving Case Pressure Relief

6 2 46 Fluid Properties

C

7 GENERAL 47 Fluid Name Steam

8 Valve Type Conventional, Direct Spring-Op 48 Molecular Weight, M 18.020

9 Safety / Relief Safety Balanced No 49 Compressibility, Z 1.000

10 Nozzle Full Bonnet Open 50 Ratio of Sp. Heats, k (Cp / Cv) 1.310

11 CONNECTIONS 51 Saturation Temperature 266.122 °C

12 Inlet 3" Flngd. 1500# RF Standard 52

N

13 Outlet 6" Flngd. 150# RF ASME B16.5 53

14 MATERIALS OF CONSTRUCTION 54

15 Body / Base AS SA217-WC6 55

16 Bonnet / Cylinder AS SA217-WC6 56

17 Nozzle Stainless Steel 57

18 Disc Inconel® 58

19 Seat Metal 59 Sizing Coefficients Unit -

E

20 Spindle Stainless Steel 60 K, Steam Kd, Steam 0.878 0.975

21 Guide Nickel Alloy 61 Kb Kc 1.0 1

22 Spring High Temp Alloy Steel 62 Kn Ksh 1 0.761

23 Gaskets N/A 63 Ksc

24 Bellows N/A 64 Required Capacity Unit kg/hr

25 Cap Type Plain Lift Lever 65 Total 39522

R

26 NACE MR0175/ISO 15156:2015 N/A 66

Accessories

27 Test Gag 67 Pressures Unit kg/cm² g

28 Weather Hood 68 MAWP Operating 51 47.2

29 69 Set CDTP 50.25 50.25

30 70 Over Pressure 1.508 3%

31 SIZING / SELECTION SUMMARY 71 Built-Up 0

E

32 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL 72 Back Constant Superimposed 0

33 Brand Crosby® 73 Pressure Variable Superimposed 0

34 Area Calculated Selected 3.373 3.976 74 Total 0

35 (in²) Data Set Orifice ASME M2 75 Inlet Loss 0 0%

36 Unit Required kg/hr 39522 76 Atmospheric (Barometric) 1.033 kg/cm² a

37 Flow Saturated Superheated 46591.363 77 Temperatures Unit °C

Normal System

F

38 78

39 Reaction Force, Open Discharge 14510.2 N 79 Operating Relieving 532 532

40 Noise Level (db), Open Discharge 157.5 at 1-m 80 Design Min Design Max 560

1. Painting shall be as per manufacturers standard PS-114. A

2. ASME V Stamp shall be provided. 8.75

3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable. B

Valve Dimensions

in

4. MPT for Body/Bonnet.

E

7.5

5. LPT for Nozzle/Disc

Tag Notes

C

6. IGC for Nozzle.

7. PMI for Trim as applicable. 39.12

8. Restricted capacity @90% is 41933 Kg/Hr. Weight

9. There wont be any effect on performance of the valve with 10% back pressure.

kg

10. Blowdown shall be 2-4%.

193.23

11. Spring MOC shall be Tungsten Alloy Steel.

R

Printed On: 16-Jul-2021 PRV²SIZE Software Version pr7_20200901.1 Page : 1

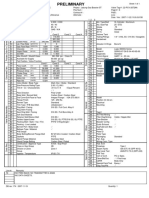

AGCSL Pressure Relief Valve Calculation Report

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 VALVE ID 11 CALCULATION NOTES

I

2 Tag No. PSV-81013A & PSV-82013A 12 1. Painting shall be as per manufacturers standard PS-114.

3 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL Qty. 2 13 2. ASME V Stamp shall be provided.

4 SIZING DATA 14 3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable.

4. MPT for Body/Bonnet.

5 Design Code ASME Section I Sizing Std. 15

5. LPT for Nozzle/Disc

6 Fluid State at Inlet Steam 16 6. IGC for Nozzle.

C

7 CALCULATION SUMMARY

8 Required 39522 kg/hr 18 Required 3.373 in²

Flow Area

9 Rated 46591.363 kg/hr 19 Selected 3.976 in²

10 Reaction Force, Open Discharge 14510.2 N 20 Noise Level (db), Open Discharge 157.5 at 1 m

Variable Type Variable Name Symbol Input Value Equation Value

Fluid Properties Molecular Weight M 18.020 18.020

N

Ratio of Specific Heats k 1.310 1.310

Inlet Stagnation Enthalpy ho 3507.1 KJ/kg 1507.8 BTU/lb

Process Cond. Required Mass Flow Wreq 39522 kg/hr 87131.095 lb/hr

Set Pressure Pset 50.25 kg/cm² g 714.723 psig

Over Pressure Pover 1.508 kg/cm² g 21.442 psig

Inlet Line Loss Ploss 0 kg/cm² g 0 psig

Back Pressure Pback 0 kg/cm² g 0 psig

E

Atmospheric Pressure Patm 1.033 kg/cm² a 14.696 psia

Relieving Temperature T 532 °C 1449.270 °R

Distance from Valve (noise) r 1m 3.2808 ft

Rupture Disc CCF Kc 1 1

Superheat Correction Factor Ksh 0.761 0.761

Supercritical Correction Factor Ksc 1.0 1.0

R

Valve Data Discharge Coefficient (actual) Kd 0.975 0.975

Discharge Coefficient (derated) K 0.878 0.878

Orifice Area A 3.976 in² 3.976 in²

Back Press. Correction Factor Kb 1.0 1.0

Outlet Diameter Do 6.06 in 6.06 in

Calculate Inlet Relieving Pressure, Outlet Pressure, Absolute Pressure Ratio

E

P1 = Pset + Pover - Ploss + Patm P1 750.861 psia

P2 = Pback + Patm P2 14.696 psia

PR = P2 / P1 PR 0.02

Calculate Napier Correction Factor Kn 1

If (1500 psia ≤ P1 ≤ 3200 psia) and (Kn > 1), then Kn = (0.1906* P1 - 1000) / (0.2292 * P1 - 1061), else Kn = 1.0

F

Calculate Capacity of Selected Valve W 46591.363 kg/hr 102716.374 lb/hr

W = 51.5 * A * P1 * K * Kb * Kc * Kn * Ksh * Ksc

Calculate Required Orifice Area Areq 3.373 in² 3.373 in²

Areq = A * Wreq / W

E

Printed On: 16-Jul-2021 PRV²SIZE Software Version pr7_20200901.1 Page : 2

R

AGCSL Pressure Relief Valve Calculation Report

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 VALVE ID 11 CALCULATION NOTES

I

2 Tag No. PSV-81013A & PSV-82013A 12 1. Painting shall be as per manufacturers standard PS-114.

3 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL Qty. 2 13 2. ASME V Stamp shall be provided.

4 SIZING DATA 14 3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable.

4. MPT for Body/Bonnet.

5 Design Code ASME Section I Sizing Std. 15

5. LPT for Nozzle/Disc

6 Fluid State at Inlet Steam 16 6. IGC for Nozzle.

C

7 CALCULATION SUMMARY

8 Required 39522 kg/hr 18 Required 3.373 in²

Flow Area

9 Rated 46591.363 kg/hr 19 Selected 3.976 in²

10 Reaction Force, Open Discharge 14510.2 N 20 Noise Level (db), Open Discharge 157.5 at 1 m

Calculate Mass Flow (for Noise Calc) W 114129.304 lb/hr

W = 51.5 * A * P1 * Kd * Kb * Kc * Kn * Ksh * Ksc

N

Calculate Noise Level at 100-ft (30-m) L100 127.9 db

L100 = [6.5 * log( 1/PR ) + 51.28] + [10 * log(0.29354 * W * k * T / M)]

Calculate Noise Level at Distance, r Lp 157.5 db

Lp = L100 - 20 * log(r / 100)

E

Calculate Outlet Static Pressure Po 40.778 psig

Ao = (π * Do^2) / 4

Po = [0.02764 * A * P1 * Kd * Kn * Ksh * Ksc * Kc * ((ho - 823)^0.5) / Ao] - Patm

Calculate Reaction Force for Open Discharge Fr 14510.2 N 3262 lbf

Fr = 0.03593 * A * P1 * Kd * Kn * Ksh * Ksc * Kc * ((ho - 823)^0.5) + (Ao * Po)

R

Printed On: 16-Jul-2021 PRV²SIZE Software Version pr7_20200901.1 Page : 3

E

F

E

R

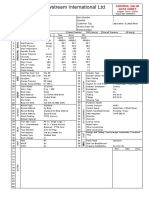

AGCSL Pressure Relief Valve Dimensional Drawing

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 Valve ID 7 SELECTION SUMMARY

I

2 Tag No. PSV-81013A & PSV-82013A 8 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL

3 Service Superheated Steam 9 Brand Crosby®

4 PID No. 10 CONNECTIONS

5 Line No. Safety Valve-I onSuperheater Outlet Quantity 11 Inlet 3" Flngd. 1500# RF Standard

6 2 12 Outlet 6" Flngd. 150# RF ASME B16.5

C

Wt.= 426 lb = 193.23 kg

N

A= 8.75 in = 222.25 mm

E B= 7.5 in = 190.50 mm

C= 39.12 in = 993.78 mm

R

E= 3 in = 76.20 mm

E

F

1. Painting shall be as per manufacturers standard PS-114.

2. ASME V Stamp shall be provided. • Accessories not shown.

3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable. • Actual valve may vary from.

Dimension Notes

4. MPT for Body/Bonnet.

image.

E

Tag Notes

5. LPT for Nozzle/Disc

6. IGC for Nozzle.

7. PMI for Trim as applicable.

8. Restricted capacity @90% is 41933 Kg/Hr.

9. There wont be any effect on performance of the valve with 10% back pressure.

10. Blowdown shall be 2-4%.

11. Spring MOC shall be Tungsten Alloy Steel.

R

AGCSL Pressure Relief Valve Sizing & Selection Report

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 Valve ID 41 SIZING DATA

I

2 Tag No. PSV-81013B & PSV-82013B 42 Design Code ASME Section I Sizing Std.

3 Service Superheated Steam 43 Sizing Basis Blocked Discharge

4 PID No. 44 Fluid State at Inlet Steam

5 Line No. Safety Valve-II onSuperheater OutletQuantity 45 Relieving Case Pressure Relief

6 2 46 Fluid Properties

C

7 GENERAL 47 Fluid Name Steam

8 Valve Type Conventional, Direct Spring-Op 48 Molecular Weight, M 18.020

9 Safety / Relief Safety Balanced No 49 Compressibility, Z 1.000

10 Nozzle Full Bonnet Open 50 Ratio of Sp. Heats, k (Cp / Cv) 1.310

11 CONNECTIONS 51 Saturation Temperature 266.737 °C

12 Inlet 3" Flngd. 1500# RF Standard 52

N

13 Outlet 6" Flngd. 150# RF ASME B16.5 53

14 MATERIALS OF CONSTRUCTION 54

15 Body / Base AS SA217-WC6 55

16 Bonnet / Cylinder AS SA217-WC6 56

17 Nozzle Stainless Steel 57

18 Disc Inconel® 58

19 Seat Metal 59 Sizing Coefficients Unit -

E

20 Spindle Stainless Steel 60 K, Steam Kd, Steam 0.878 0.975

21 Guide Nickel Alloy 61 Kb Kc 1.0 1

22 Spring High Temp Alloy Steel 62 Kn Ksh 1 0.761

23 Gaskets N/A 63 Ksc

24 Bellows N/A 64 Required Capacity Unit kg/hr

25 Cap Type Plain Lift Lever 65 Total 39522

R

26 NACE MR0175/ISO 15156:2015 N/A 66

Accessories

27 Test Gag 67 Pressures Unit kg/cm² g

28 Weather Hood 68 MAWP Operating 51 47.2

29 69 Set CDTP 50.75 50.75

30 70 Over Pressure 1.522 3%

31 SIZING / SELECTION SUMMARY 71 Built-Up 0

E

32 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL 72 Back Constant Superimposed 0

33 Brand Crosby® 73 Pressure Variable Superimposed 0

34 Area Calculated Selected 3.340 3.976 74 Total 0

35 (in²) Data Set Orifice ASME M2 75 Inlet Loss 0 0%

36 Unit Required kg/hr 39522 76 Atmospheric (Barometric) 1.033 kg/cm² a

37 Flow Saturated Superheated 47053.055 77 Temperatures Unit °C

Normal System

F

38 78

39 Reaction Force, Open Discharge 14670.1 N 79 Operating Relieving 532 532

40 Noise Level (db), Open Discharge 157.6 at 1-m 80 Design Min Design Max 560

1. Painting shall be as per manufacturers standard PS-114. A

2. ASME V Stamp shall be provided. 8.75

3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable. B

Valve Dimensions

in

4. MPT for Body/Bonnet.

E

7.5

5. LPT for Nozzle/Disc

Tag Notes

C

6. IGC for Nozzle.

7. PMI for Trim as applicable. 39.12

8. Restricted capacity @90% is 42348 Kg/Hr. Weight

9. There wont be any effect on performance of the valve with 10% back pressure.

kg

10. Blowdown shall be 2-4%.

193.23

11. Spring MOC shall be Tungsten Alloy Steel.

R

Printed On: 16-Jul-2021 PRV²SIZE Software Version pr7_20200901.1 Page : 1

AGCSL Pressure Relief Valve Calculation Report

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 VALVE ID 11 CALCULATION NOTES

I

2 Tag No. PSV-81013B & PSV-82013B 12 1. Painting shall be as per manufacturers standard PS-114.

3 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL Qty. 2 13 2. ASME V Stamp shall be provided.

4 SIZING DATA 14 3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable.

4. MPT for Body/Bonnet.

5 Design Code ASME Section I Sizing Std. 15

5. LPT for Nozzle/Disc

6 Fluid State at Inlet Steam 16 6. IGC for Nozzle.

C

7 CALCULATION SUMMARY

8 Required 39522 kg/hr 18 Required 3.340 in²

Flow Area

9 Rated 47053.055 kg/hr 19 Selected 3.976 in²

10 Reaction Force, Open Discharge 14670.1 N 20 Noise Level (db), Open Discharge 157.6 at 1 m

Variable Type Variable Name Symbol Input Value Equation Value

Fluid Properties Molecular Weight M 18.020 18.020

N

Ratio of Specific Heats k 1.310 1.310

Inlet Stagnation Enthalpy ho 3506.6 KJ/kg 1507.6 BTU/lb

Process Cond. Required Mass Flow Wreq 39522 kg/hr 87131.095 lb/hr

Set Pressure Pset 50.75 kg/cm² g 721.835 psig

Over Pressure Pover 1.522 kg/cm² g 21.655 psig

Inlet Line Loss Ploss 0 kg/cm² g 0 psig

Back Pressure Pback 0 kg/cm² g 0 psig

E

Atmospheric Pressure Patm 1.033 kg/cm² a 14.696 psia

Relieving Temperature T 532 °C 1449.270 °R

Distance from Valve (noise) r 1m 3.2808 ft

Rupture Disc CCF Kc 1 1

Superheat Correction Factor Ksh 0.761 0.761

Supercritical Correction Factor Ksc 1.0 1.0

R

Valve Data Discharge Coefficient (actual) Kd 0.975 0.975

Discharge Coefficient (derated) K 0.878 0.878

Orifice Area A 3.976 in² 3.976 in²

Back Press. Correction Factor Kb 1.0 1.0

Outlet Diameter Do 6.06 in 6.06 in

Calculate Inlet Relieving Pressure, Outlet Pressure, Absolute Pressure Ratio

E

P1 = Pset + Pover - Ploss + Patm P1 758.186 psia

P2 = Pback + Patm P2 14.696 psia

PR = P2 / P1 PR 0.019

Calculate Napier Correction Factor Kn 1

If (1500 psia ≤ P1 ≤ 3200 psia) and (Kn > 1), then Kn = (0.1906* P1 - 1000) / (0.2292 * P1 - 1061), else Kn = 1.0

F

Calculate Capacity of Selected Valve W 47053.055 kg/hr 103734.230 lb/hr

W = 51.5 * A * P1 * K * Kb * Kc * Kn * Ksh * Ksc

Calculate Required Orifice Area Areq 3.340 in² 3.340 in²

Areq = A * Wreq / W

E

Printed On: 16-Jul-2021 PRV²SIZE Software Version pr7_20200901.1 Page : 2

R

AGCSL Pressure Relief Valve Calculation Report

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 VALVE ID 11 CALCULATION NOTES

I

2 Tag No. PSV-81013B & PSV-82013B 12 1. Painting shall be as per manufacturers standard PS-114.

3 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL Qty. 2 13 2. ASME V Stamp shall be provided.

4 SIZING DATA 14 3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable.

4. MPT for Body/Bonnet.

5 Design Code ASME Section I Sizing Std. 15

5. LPT for Nozzle/Disc

6 Fluid State at Inlet Steam 16 6. IGC for Nozzle.

C

7 CALCULATION SUMMARY

8 Required 39522 kg/hr 18 Required 3.340 in²

Flow Area

9 Rated 47053.055 kg/hr 19 Selected 3.976 in²

10 Reaction Force, Open Discharge 14670.1 N 20 Noise Level (db), Open Discharge 157.6 at 1 m

Calculate Mass Flow (for Noise Calc) W 115260.256 lb/hr

W = 51.5 * A * P1 * Kd * Kb * Kc * Kn * Ksh * Ksc

N

Calculate Noise Level at 100-ft (30-m) L100 127.9 db

L100 = [6.5 * log( 1/PR ) + 51.28] + [10 * log(0.29354 * W * k * T / M)]

Calculate Noise Level at Distance, r Lp 157.6 db

Lp = L100 - 20 * log(r / 100)

E

Calculate Outlet Static Pressure Po 41.319 psig

Ao = (π * Do^2) / 4

Po = [0.02764 * A * P1 * Kd * Kn * Ksh * Ksc * Kc * ((ho - 823)^0.5) / Ao] - Patm

Calculate Reaction Force for Open Discharge Fr 14670.1 N 3298 lbf

Fr = 0.03593 * A * P1 * Kd * Kn * Ksh * Ksc * Kc * ((ho - 823)^0.5) + (Ao * Po)

R

Printed On: 16-Jul-2021 PRV²SIZE Software Version pr7_20200901.1 Page : 3

E

F

E

R

AGCSL Pressure Relief Valve Dimensional Drawing

'Formerly Pentair Sanmar Limited' YSS1 15-Jul-2021

India

A

ksm1@sanmargroup.com

Quote Number: No Prpd. Chk. Appr. Date Revision

Client: Thermax Babcock and Wilcox Energy Solutions

Location: End-User Ref. No.:

Project: PL2022-24-PEMEX Project Ref. No.:

1 Valve ID 7 SELECTION SUMMARY

I

2 Tag No. PSV-81013B & PSV-82013B 8 Valve Model No. 3 M2 6 HCI-R-68-FN-SPL

3 Service Superheated Steam 9 Brand Crosby®

4 PID No. 10 CONNECTIONS

5 Line No. Safety Valve-II onSuperheater OutletQuantity 11 Inlet 3" Flngd. 1500# RF Standard

6 2 12 Outlet 6" Flngd. 150# RF ASME B16.5

C

Wt.= 426 lb = 193.23 kg

N

A= 8.75 in = 222.25 mm

E B= 7.5 in = 190.50 mm

C= 39.12 in = 993.78 mm

R

E= 3 in = 76.20 mm

E

F

1. Painting shall be as per manufacturers standard PS-114.

2. ASME V Stamp shall be provided. • Accessories not shown.

3. RT/UT as applicable for Body/Bonnet/Nozzle/Disc as applicable. • Actual valve may vary from.

Dimension Notes

4. MPT for Body/Bonnet.

image.

E

Tag Notes

5. LPT for Nozzle/Disc

6. IGC for Nozzle.

7. PMI for Trim as applicable.

8. Restricted capacity @90% is 42348 Kg/Hr.

9. There wont be any effect on performance of the valve with 10% back pressure.

10. Blowdown shall be 2-4%.

11. Spring MOC shall be Tungsten Alloy Steel.

R

You might also like

- PRESSURE SAFETY VALVE DATA SHEETDocument1 pagePRESSURE SAFETY VALVE DATA SHEETBABILIN VNo ratings yet

- General: ASTM A351 Gr. CF3MDocument1 pageGeneral: ASTM A351 Gr. CF3MPipeline EngineerNo ratings yet

- Israel Flores Valvula 2Document2 pagesIsrael Flores Valvula 2Israel Flores MamaniNo ratings yet

- Practica # 2 PRV2SIZE PDFDocument4 pagesPractica # 2 PRV2SIZE PDFCarmen Zurita VeizagaNo ratings yet

- ECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportDocument6 pagesECP Jo Colombia 3102124385 Quote Number:: Pressure Relief Valve Sizing & Selection ReportJorge LemusNo ratings yet

- Valvula de Seguridad Patin Auxiliar TerniumDocument1 pageValvula de Seguridad Patin Auxiliar TerniumSearch45No ratings yet

- Valbrac quote provides sizing details for safety relief valveDocument1 pageValbrac quote provides sizing details for safety relief valveRODRIGO CARDOSONo ratings yet

- PSV SizingDocument8 pagesPSV SizingMinh DoNo ratings yet

- Valvula-Emerson 1Document6 pagesValvula-Emerson 1Jesus Ibarra SotoNo ratings yet

- Anderson Greenwood Crosby Sanmar Limited 147, Karapakkam Village, Chennai - 600097, Tamil Nadu, INDocument2 pagesAnderson Greenwood Crosby Sanmar Limited 147, Karapakkam Village, Chennai - 600097, Tamil Nadu, INVenkatesan ManikandanNo ratings yet

- 1 Pieza PSV-3X4Document4 pages1 Pieza PSV-3X4jose ocanaNo ratings yet

- EMI Marco Antonio Serrano Bazán Bolivia 6945986 Quote NumberDocument1 pageEMI Marco Antonio Serrano Bazán Bolivia 6945986 Quote NumberMarcoAntonioSerranoBazanNo ratings yet

- ValvulaDocument1 pageValvulaSergio Jhordan Garcia ClarosNo ratings yet

- Alejandra PDFDocument1 pageAlejandra PDFCristian Melendres OrellanaNo ratings yet

- Zeus Energy SAC Peru +51949827888 Quote Number:: Pressure Relief Valve Sizing & Selection ReportDocument5 pagesZeus Energy SAC Peru +51949827888 Quote Number:: Pressure Relief Valve Sizing & Selection ReportJorge Rodriguez HerreraNo ratings yet

- PSV 2302Document1 pagePSV 2302Tomás MercadoNo ratings yet

- Quote Number:: Pressure Relief Valve Sizing & Selection ReportDocument1 pageQuote Number:: Pressure Relief Valve Sizing & Selection ReportJavier DelgadoNo ratings yet

- PSV-2 Inch 600# To 3 Inch 600#Document1 pagePSV-2 Inch 600# To 3 Inch 600#leontius dwi mesantonoNo ratings yet

- Relief 5Document5 pagesRelief 5Mo ZeroNo ratings yet

- PSV Bombas AcpilodosDocument1 pagePSV Bombas AcpilodosJulian Camilo Segura BermudezNo ratings yet

- PRV SizingDocument28 pagesPRV Sizingjithin.rjn4055No ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- PSV GLP 31-0CT-23Document1 pagePSV GLP 31-0CT-23victor.arcia.etmNo ratings yet

- HMV CALLE 70 # 7-30 Colombia 5716439500 Quote Number:: Pressure Relief Valve Sizing & Selection ReportDocument1 pageHMV CALLE 70 # 7-30 Colombia 5716439500 Quote Number:: Pressure Relief Valve Sizing & Selection ReportJulian Camilo Segura BermudezNo ratings yet

- PVVDocument10 pagesPVVJorge Arturo Rodríguez HerreraNo ratings yet

- Emerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote NumberDocument1 pageEmerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote NumberYamil Castro FernandezNo ratings yet

- PSV 2404Document1 pagePSV 2404Tomás MercadoNo ratings yet

- PSV-2404Document1 pagePSV-2404Tomás MercadoNo ratings yet

- Gate valve technical specificationDocument1 pageGate valve technical specificationkoraina2015No ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Document1 pagePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNo ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- CONTROL VALVE DATA SHEETDocument2 pagesCONTROL VALVE DATA SHEETMateus EliasNo ratings yet

- A11627SE-08 - CVDS Rev B Technical Specification 840GDocument2 pagesA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNo ratings yet

- PSV 1403Document1 pagePSV 1403Tomás MercadoNo ratings yet

- Data Sheets-T220425-499Document9 pagesData Sheets-T220425-499pedro torresNo ratings yet

- PVSV 1340 1341Document1 pagePVSV 1340 1341Nelson NavaNo ratings yet

- Swing Check Valve Data Sheet: Comision Federal de ElectricidadDocument1 pageSwing Check Valve Data Sheet: Comision Federal de Electricidadjos ToricesNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- Free Vent For Tank Sizing PDFDocument5 pagesFree Vent For Tank Sizing PDFoppila100No ratings yet

- PSV-1404Document1 pagePSV-1404Tomás MercadoNo ratings yet

- Abb-02-Ics-Das-Enf-000-00001-00 Z-03Document2 pagesAbb-02-Ics-Das-Enf-000-00001-00 Z-03mvdeole7056No ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- VALVE SPECSDocument3 pagesVALVE SPECSazitaggNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- r2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage DischargeDocument17 pagesr2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage Dischargedavid perezNo ratings yet

- PCR SvformDocument5 pagesPCR SvformHendrias A.SNo ratings yet

- Ball Valve SpecificationDocument2 pagesBall Valve SpecificationEsteban ArguelloNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument6 pagesPressure Safety Valve-Preliminary Sizing: Input DataPIDNo ratings yet

- Back Pressure Valve (BPV) DatasheetDocument2 pagesBack Pressure Valve (BPV) DatasheetSyed Waqas HaiderNo ratings yet

- Ed0581b-1639e 01 Ap1Document5 pagesEd0581b-1639e 01 Ap1Erol DAĞNo ratings yet

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- SBD 0631 ValveDocument3 pagesSBD 0631 ValvewodrNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data SheetsisesetNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- Ball Valve Specification and Sizing SheetsDocument2 pagesBall Valve Specification and Sizing SheetsEsteban ArguelloNo ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- Deep Learning For Sentiment Analysis of Tunisian DDocument21 pagesDeep Learning For Sentiment Analysis of Tunisian DJamila HamdiNo ratings yet

- Yoke Calibration Test Bar Parker Research Corporation Mpi Magnetic Particle Inspection Probe ElectromagnetDocument2 pagesYoke Calibration Test Bar Parker Research Corporation Mpi Magnetic Particle Inspection Probe Electromagnetnewton5805No ratings yet

- Schematic Learning Definition of Term Technique: Basic Terms General DefinitionsDocument8 pagesSchematic Learning Definition of Term Technique: Basic Terms General DefinitionsKifaru Micro-electronics100% (1)

- Database Administration AssessmentDocument10 pagesDatabase Administration AssessmentEsubalewNo ratings yet

- Mineral-Insulated Thermocouples According To DIN 43710 and DIN EN 60584Document11 pagesMineral-Insulated Thermocouples According To DIN 43710 and DIN EN 60584Veryco BudiantoNo ratings yet

- Motion Assignment Class 9Document73 pagesMotion Assignment Class 9Monica SreeNo ratings yet

- Spract 4Document24 pagesSpract 4Jennifer SmithNo ratings yet

- Heredity and Genetics ExplainedDocument43 pagesHeredity and Genetics ExplainedNewsonNo ratings yet

- B.tech Cse VTR Uge2021 de SyllabusDocument4 pagesB.tech Cse VTR Uge2021 de SyllabusBOLLIGARLA MOHAN SAI AKASH,CSE2021 Vel Tech, ChennaiNo ratings yet

- Freyssinet Webinar Introduction To Passive Control System For Seismic Damage Mitigation - Tri SuryadiDocument62 pagesFreyssinet Webinar Introduction To Passive Control System For Seismic Damage Mitigation - Tri SuryadiAnto Destianto100% (1)

- The ancient Mayan mathematics systemDocument5 pagesThe ancient Mayan mathematics systemDebby Wura AbiodunNo ratings yet

- Practice 2.8 A: Sketch The Graph of Each Linear InequalityDocument4 pagesPractice 2.8 A: Sketch The Graph of Each Linear InequalityKadi SantanaNo ratings yet

- R ManualDocument124 pagesR ManualLeonard Horobet-stoianNo ratings yet

- 3064 A CG Assignment-2Document57 pages3064 A CG Assignment-2nokexo6067No ratings yet

- Tyre Curing GuideDocument6 pagesTyre Curing GuideMALAY GUPTANo ratings yet

- Blastrite Product ID Sheet Rev7Document1 pageBlastrite Product ID Sheet Rev7Mohd YusriNo ratings yet

- Mentum Ellipse BrochureDocument4 pagesMentum Ellipse BrochureUbaid YounusNo ratings yet

- MSTE Module 6Document2 pagesMSTE Module 6jovar jumao-asNo ratings yet

- Sailor Rt2048Document94 pagesSailor Rt2048Belha Lozano SanchezNo ratings yet

- Manual Testing - Common Interview QuestionsDocument31 pagesManual Testing - Common Interview QuestionsSravanthi AylaNo ratings yet

- Analysis On Spatial Variation of Rainfall and Groundwater Fluctuation in Hebballa Watershed, Mysore District, Karnataka, IndiaDocument7 pagesAnalysis On Spatial Variation of Rainfall and Groundwater Fluctuation in Hebballa Watershed, Mysore District, Karnataka, IndiaEditor IJTSRDNo ratings yet

- Analysis and Modification of Bogie Suspension SystemDocument76 pagesAnalysis and Modification of Bogie Suspension SystemKrishnaSingh0% (2)

- Transparent Proxy With Linux and Squid mini-HOWTODocument10 pagesTransparent Proxy With Linux and Squid mini-HOWTONursalim S komNo ratings yet

- Comparative analysis of pressure vessel cylindrical shell calculation and resultsDocument5 pagesComparative analysis of pressure vessel cylindrical shell calculation and resultszajednosexNo ratings yet

- ps08 sp12 PDFDocument8 pagesps08 sp12 PDFQ_TNo ratings yet

- Segmentsjointin Precast Tunnel Lining DesignDocument9 pagesSegmentsjointin Precast Tunnel Lining Designsravan_rubyNo ratings yet

- Trigonometric Functions MCQDocument2 pagesTrigonometric Functions MCQHinaud DdbNo ratings yet

- Sinopec Ammonia Retrofit Paper PDFDocument4 pagesSinopec Ammonia Retrofit Paper PDFChakravarthy BharathNo ratings yet

- Learning From DataDocument402 pagesLearning From DataAnuvrat TikuNo ratings yet

- Chapter 4Document100 pagesChapter 4khgvouy hvogyflNo ratings yet