Professional Documents

Culture Documents

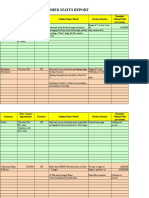

(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )

Uploaded by

Elias EliasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )

Uploaded by

Elias EliasCopyright:

Available Formats

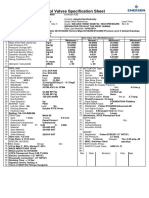

PRELIMINARY Sheet 1 of 1

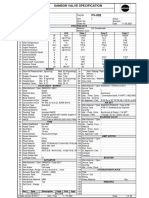

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2072AA

Control Valve Specification PO # : Proj Num : Page # : 6

Prepared By : Serial # : .006 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

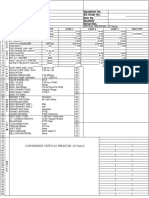

PRELIMINARY Sheet 1 of 1

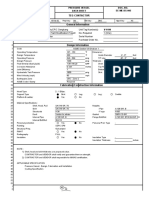

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2072AB

Control Valve Specification PO # : Proj Num : Page # : 7

Prepared By : Serial # : .007 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

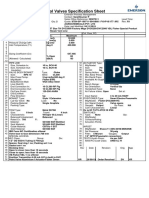

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2072BA

Control Valve Specification PO # : Proj Num : Page # : 8

Prepared By : Serial # : .008 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

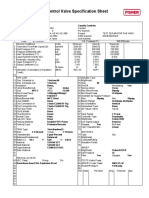

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2072BB

Control Valve Specification PO # : Proj Num : Page # : 9

Prepared By : Serial # : .009 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2082AA

Control Valve Specification PO # : Proj Num : Page # : 10

Prepared By : Serial # : .010 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2082AB

Control Valve Specification PO # : Proj Num : Page # : 11

Prepared By : Serial # : .011 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2082BA

Control Valve Specification PO # : Proj Num : Page # : 12

Prepared By : Serial # : .012 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2082BB

Control Valve Specification PO # : Proj Num : Page # : 13

Prepared By : Serial # : .013 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 125.100 116.800 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 340.000 340.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 1.600 1.540 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 1.693 1.884 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 38.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 606.800 481.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) 77.000 77.000 73 Model

24 Valve Vel (mach#) 0.026 0.025 74

25 Pipe Vel (mach#) 0.024 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .81 Cv:17.4 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2094AA

Control Valve Specification PO # : Proj Num : Page # : 14

Prepared By : Serial # : .014 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 22.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 71.000 73 Model

24 Valve Vel (mach#) 0.005 0.010 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .38 Cv:3.0 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2094AB

Control Valve Specification PO # : Proj Num : Page # : 15

Prepared By : Serial # : .015 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 22.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 71.000 73 Model

24 Valve Vel (mach#) 0.005 0.010 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .38 Cv:3.0 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2094BA

Control Valve Specification PO # : Proj Num : Page # : 16

Prepared By : Serial # : .016 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 22.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 71.000 73 Model

24 Valve Vel (mach#) 0.005 0.010 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .38 Cv:3.0 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2094BB

Control Valve Specification PO # : Proj Num : Page # : 17

Prepared By : Serial # : .017 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 22.000 41.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 71.000 73 Model

24 Valve Vel (mach#) 0.005 0.010 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 2.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .38 Cv:3.0 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2091A

Control Valve Specification PO # : Proj Num : Page # : 18

Prepared By : Serial # : .018 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 37.000 52.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 72.000 73 Model

24 Valve Vel (mach#) 0.019 0.039 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 1.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .31 Cv:2.8 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

CLASS SHALL BE CL600 INSTEAD OF CL300 SINCE PRESS&TEMP PROCESS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2091B

Control Valve Specification PO # : Proj Num : Page # : 19

Prepared By : Serial # : .019 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 37.000 52.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 72.000 73 Model

24 Valve Vel (mach#) 0.019 0.039 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 1.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .31 Cv:2.8 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

CLASS SHALL BE CL600 INSTEAD OF CL300 SINCE PRESS&TEMP PROCESS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2092A

Control Valve Specification PO # : Proj Num : Page # : 20

Prepared By : Serial # : .020 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 37.000 52.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 72.000 73 Model

24 Valve Vel (mach#) 0.019 0.039 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 1.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .31 Cv:2.8 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

CLASS SHALL BE CL600 INSTEAD OF CL300 SINCE PRESS&TEMP PROCESS.

DB rev: 174 : 2007-11-19 Quantity: 1

PRELIMINARY Sheet 1 of 1

Customer : MMC Project : Jabung Gas Booster ST Valve Tag # : 22-PCV-2092B

Control Valve Specification PO # : Proj Num : Page # : 21

Prepared By : Serial # : .021 Contract # : P&ID :

Flowserve Corporation Rev/By : 0.0/Ang Stevanus Alternate : Line :

Springville Utah Application : Date / Ver : 2007-11-22 /10.0.0.6130

1 2 3 1 2 3

1 Pipe Size, Up/Down 2.000 / 2.000 51 Act. Type/Matl VL Cylinder / Aluminum

2 Pipe Sch, Up/Down 40 / 40 52 Act. Size/Fab 25 / STD

3 Allow Noise/Add Attn/Type 85 / 0 / 53 Stroke .75

Process Data For Control Valve Selection

4 Process Fluid/Crit. Press. GAS / N/A 54 Spring Standard

Actuator

5 Design Press./Temp. / 55 Air To Close

6 Cond 1 Cond 2 Cond 3 Cond 4 56 Volume Tank

7 Temperature (°F) 118.700 111.600 57 Tubing/Fittings 1/4" / 316L SS / 316 SS / Swagelok

8 Inlet Press (psi (g)) 946.800 821.200 58 Handwheel

9 Outlet Press (psi (g)) 246.000 246.000 59

10 Liq Flow Rate (galUS/min) 0 0 60 Actuator O-Rings Buna-N

11 Gas Flow Rate (MMSCFD) 0.224 0.448 61

12 Viscosity (cP) 0.000 0.000 62 Model Logix 3000IQ Series

13 Vapor Press (psi (a)) 0.000 0.000 63 Model # 3200IQ-07-D6-E-04-40-0G-00

14 SG-MW 17.830 17.830 64 Diagnostic Standard

15 Max Shutoff / Shutoff Class 961.500 psi / Class IV 65 Comm/Signal HART / 4 - 20 mA

Positioner

16 Available Air Supply 60.000 psi (g) 66 Housing/Conn Aluminum, White / 1/2" NPT

17 Fail Position / Valve Function Open / Throttling 67 Temperature -40°F - 185°F (-40°C to 85°C)

18 Cond 1 Cond 2 Cond 3 Cond 4 68 Shaft Linear-D Shaft

19 Flow Coeff. (Cv) 0.233 0.535 69 Action 4-Way

Calculated Data

20 Est Stroke (Percent) 37.000 52.000 70 Feedback None

21 Pressure Drop (psi ) 700.800 575.200 71 Gauges 2 SS-Brass PSI/BAR/KPA

22 Choke Drop (psi ) 721.125 626.925 72 Positioner Tag

23 Noise [IEC] (dBA) <70 72.000 73 Model

24 Valve Vel (mach#) 0.019 0.039 74

25 Pipe Vel (mach#) 0.009 75

Pos Ind Sw

26 Valve Model / Body Type Mark One / Globe / Standard 76

27 Size/Pressure Rating/Type 1.00 / CL 600 / 77

28 Trim # - Cv / Characteristic .31 Cv:2.8 / Equal Percent 78

29 / / 79

30 Flow Direction Flow Under 80

31 Body Matl / Bonnet Matl Carbon Steel / Carbon Steel 81

32 End Conn/Sch/Face to Face Integral Flange / / ISA S75.08.01 82 Model

33 Flange Finish 125 - 250 Ra 83 Position On De-en

Solenoid

34 Bonnet Type Standard 84 Electrical

35 Trim Type / P/B Seal Matl. Unbalanced / 85 Mounting

Valve Body Assembly

36 Plug Matl / Facing 316 SS / Full Cont. Alloy 6 86

37 Plug Stem Facing 87

38 Seat Ring Matl / Facing 316 SS / Full Bore Alloy 6 88 Tag #

39 Soft Seat Material 89 Air Filter/Mnting /

40 Retainer Matl/Sleeve Matl 316 SS / 90 Filter-Reg/Mnting Valtek / Nipple Mtd

41 Guides Upper/Lower 316 SS, GL PTFE/316 SS, GL PTFE 91 Flow Booster /

42 Packing Matl / Style / Vac / Fire PTFE V-Ring/Single// 92 Booster Config

43 Packing - Live-Loaded 93 Quick Exhaust /

Others

44 Bonnet Port / Body Drain / 94 SupTube/Jctn Box /

45 Bellows Type / Material / 95 Lockup

46 P/B Design 96 Plate ID

47 Body Bolting/Bonnet Flange Matl B7-2H Zinc Coated / Carbon Steel 97 Plate Type

48 Gaskets PTFE 98 Packaging Standard

49 Gland Flange Material Stainless Steel 99 Pwr. Sup.

50 Gland Flange Bolting Carbon Steel, Plated 00 Wiring Conn. Type

01 Certification / Approval Type ATEX / Expl Proof 01 Rad. Exm

Certs Req

02 Class or Gas Group IIB 02 Drawings Type I

03 Division or Zone Zone 1 03 Assem Hydro ISA-S75.19 (SPP 4012)

Special Req

04 Group 04 Seat Leak Test ANSI/FCI 70-2 (SPP-433)

05 Ingress / Temperature IP 65 / T4 05 PMI Test

06 Cert of Conf. PO or Spec.

07 Clean/Bld/Doc / / Final Insp

08 CMTR Body Only

09 Special Paint/Test Epoxy /

10 Diag Test/FM /

Line #: Remarks

70 NO FEED BACK/ NO TRANSMITTER 4-20MA

NO DATA SHEETS.

CLASS SHALL BE CL600 INSTEAD OF CL300 SINCE PRESS&TEMP PROCESS.

DB rev: 174 : 2007-11-19 Quantity: 1

You might also like

- Court Documents - Purdue Pharma CaseDocument236 pagesCourt Documents - Purdue Pharma CaseHung LeNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Basics: Architectural Design Designing Architecture Language of Space and Form Diagramming The Big Idea and ArchitectureDocument7 pagesBasics: Architectural Design Designing Architecture Language of Space and Form Diagramming The Big Idea and ArchitectureNaveen KishoreNo ratings yet

- Preliminary Control Valve Specification SheetDocument5 pagesPreliminary Control Valve Specification SheetElias EliasNo ratings yet

- Sizing Sheet Dengan Cv. 133 PDFDocument3 pagesSizing Sheet Dengan Cv. 133 PDFJoko WisnugrohoNo ratings yet

- Data Sheets-T220425-499Document9 pagesData Sheets-T220425-499pedro torresNo ratings yet

- Specification Sheet Rev 1Document12 pagesSpecification Sheet Rev 1nishanth NTNo ratings yet

- Weir Control & Choke Valves Technical Specification Sheet for Produced Water ServiceDocument1 pageWeir Control & Choke Valves Technical Specification Sheet for Produced Water ServiceKo Aung KoNo ratings yet

- PDF Actuator Datasheet - CompressDocument1 pagePDF Actuator Datasheet - Compresshellraizer1978No ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data SheetsisesetNo ratings yet

- Sliding Stem Control Valve SpecificationDocument2 pagesSliding Stem Control Valve SpecificationJackNo ratings yet

- KSB MIL Steam Vent Valve Spec SheetDocument36 pagesKSB MIL Steam Vent Valve Spec SheetNutan PowerNo ratings yet

- Ball Valve SpecificationDocument2 pagesBall Valve SpecificationEsteban ArguelloNo ratings yet

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- Ball Valve Specification and Sizing SheetsDocument2 pagesBall Valve Specification and Sizing SheetsEsteban ArguelloNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- SEVERN GLOCON CONTROL VALVE SPECIFICATION SHEETDocument6 pagesSEVERN GLOCON CONTROL VALVE SPECIFICATION SHEETAmit Surti0% (1)

- JVCVReport1215 PDFDocument1 pageJVCVReport1215 PDFUlises BadilloNo ratings yet

- Hojas de Datos Valvulas de ControlDocument4 pagesHojas de Datos Valvulas de ControlMauricio Cuevas HinojosaNo ratings yet

- VALVE SPECSDocument3 pagesVALVE SPECSazitaggNo ratings yet

- 1-Fisher Specification and Sizing Sheets - RevCDocument3 pages1-Fisher Specification and Sizing Sheets - RevCheikelNo ratings yet

- ANTAM Datasheet 10LAD21AA121 00Document1 pageANTAM Datasheet 10LAD21AA121 00heviNo ratings yet

- Control Valve Technical Specification Sheet Globe Service: GasDocument1 pageControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessNo ratings yet

- Control Valve DatasheetDocument1 pageControl Valve DatasheetretrogradesNo ratings yet

- Severn Glocon 3Document10 pagesSevern Glocon 3Amit SurtiNo ratings yet

- AnnexureDocument391 pagesAnnexureTommy ArjanggiNo ratings yet

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Document1 pagePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNo ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- Bray Sizing - OVS 5682Document16 pagesBray Sizing - OVS 5682crvitor1No ratings yet

- SizingDocument4 pagesSizingAlberto ReyesNo ratings yet

- Enerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSDocument4 pagesEnerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSHamza ShujaNo ratings yet

- 05 PCV 07 296a, BDocument2 pages05 PCV 07 296a, BSTG INSTRUMENTNo ratings yet

- Data - Sheet Hora CV Act DetailsDocument2 pagesData - Sheet Hora CV Act DetailsAnand K. MouryaNo ratings yet

- (cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationDocument2 pages(cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationmoceNo ratings yet

- MN-89242-22-7 SpecDocument6 pagesMN-89242-22-7 Specrenhat parulian sitorusNo ratings yet

- Main air compressor specificationsDocument37 pagesMain air compressor specificationsRK Panchal100% (2)

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessNo ratings yet

- A11627SE-08 - CVDS Rev B Technical Specification 840GDocument2 pagesA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNo ratings yet

- Control Valves Specification Sheet: PT. PI EnergiDocument1 pageControl Valves Specification Sheet: PT. PI EnergiAnoNo ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- 1523916823Document25 pages1523916823Thaís Dias ParteliNo ratings yet

- A-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils BrochureDocument2 pagesA-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils Brochurekeith dietrichNo ratings yet

- Fv101x - Specsht2Document1 pageFv101x - Specsht2Claudio Rivadeneira CarrascoNo ratings yet

- Valbrac quote provides sizing details for safety relief valveDocument1 pageValbrac quote provides sizing details for safety relief valveRODRIGO CARDOSONo ratings yet

- 1-2 Major Component Specifications (B) Outdoor UnitDocument1 page1-2 Major Component Specifications (B) Outdoor UnitmudhaffarNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetQichiix KiciNo ratings yet

- 1019 DPP Ele Dts 003 SDV Data SheetDocument2 pages1019 DPP Ele Dts 003 SDV Data SheetJoseNo ratings yet

- 05 PCV 07 252a, BDocument2 pages05 PCV 07 252a, BSTG INSTRUMENTNo ratings yet

- Control Valve Specification Sheet - LCV 2inch 600# R 1Document1 pageControl Valve Specification Sheet - LCV 2inch 600# R 1FIRMANSYAHNo ratings yet

- T070420 Spec (PCV2)Document12 pagesT070420 Spec (PCV2)Elias EliasNo ratings yet

- 265-PV-092 095 098Document3 pages265-PV-092 095 098Juan Pablo Palma PizarroNo ratings yet

- 2x GSD80485VA - Q1205,3 R410A t0 50 TC 105Document7 pages2x GSD80485VA - Q1205,3 R410A t0 50 TC 105viniciusschwabNo ratings yet

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- p10 3283pdfDocument4 pagesp10 3283pdfsrinuvoodiNo ratings yet

- Hyd. Calc of 43p17 Ab - As Per P&idDocument7 pagesHyd. Calc of 43p17 Ab - As Per P&idAnindyaNo ratings yet

- Project Survey: Selected CompressorsDocument7 pagesProject Survey: Selected CompressorsviniciusschwabNo ratings yet

- (cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationDocument2 pages(cm3) (MM) (MM) (KG) (°C) : Compressor ApplicationJean-Michel CadetNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- Technical Data SheetDocument6 pagesTechnical Data SheetCamilo CarreñoNo ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Corrosion coupon data sheet for amine contactorDocument1 pageCorrosion coupon data sheet for amine contactorElias Elias100% (1)

- Pressure Vessel Data Sheet for TEG ContactorDocument2 pagesPressure Vessel Data Sheet for TEG ContactorElias EliasNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Pressure Vessel Data Sheet for Residue Gas ScrubberDocument2 pagesPressure Vessel Data Sheet for Residue Gas ScrubberElias EliasNo ratings yet

- Cover Residue Gas Scrubber (V-1110)Document1 pageCover Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Cover TEG-Gas Exchanger (E-5050)Document1 pageCover TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Cover Coalescing Filter (F-909)Document1 pageCover Coalescing Filter (F-909)Elias EliasNo ratings yet

- Cover Sweet Gas Scrubber (V-1050)Document1 pageCover Sweet Gas Scrubber (V-1050)Elias EliasNo ratings yet

- Cover Amine Contactor (V-1040)Document1 pageCover Amine Contactor (V-1040)Elias EliasNo ratings yet

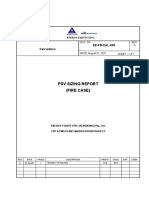

- Attachment For FireDocument8 pagesAttachment For FireElias EliasNo ratings yet

- CPP PSV sizing reportDocument5 pagesCPP PSV sizing reportElias EliasNo ratings yet

- Cover Coalescing Filter (F-9000)Document1 pageCover Coalescing Filter (F-9000)Elias EliasNo ratings yet

- CPP PSV sizing reportDocument5 pagesCPP PSV sizing reportElias EliasNo ratings yet

- CPP PSV sizing reportDocument5 pagesCPP PSV sizing reportElias EliasNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias EliasNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias EliasNo ratings yet

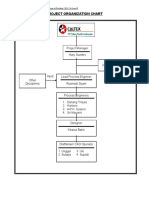

- PT Caltex CGS Upgrade Process ReviewDocument5 pagesPT Caltex CGS Upgrade Process ReviewElias EliasNo ratings yet

- Project Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateDocument3 pagesProject Client: Pt. Caltex Pacific Indonesia Discipline: Process Engineering Subject: Deliverable List & Manhour EstimateElias EliasNo ratings yet

- Task Name Kick of MeetingDocument3 pagesTask Name Kick of MeetingElias EliasNo ratings yet

- RFQ TEG Dehydration Package Cover-Mech SpecDocument1 pageRFQ TEG Dehydration Package Cover-Mech SpecElias EliasNo ratings yet