Professional Documents

Culture Documents

Bocle - Sop Format

Bocle - Sop Format

Uploaded by

Saurabh Mishra0 ratings0% found this document useful (0 votes)

23 views2 pagesThis document provides the standard operating procedures for a Tribology Department's BOCLE test equipment. It outlines the startup, monitoring, normal shutdown, and emergency shutdown procedures. The startup procedure includes checking electrical connections and air supply, switching equipment on in a specific sequence. Monitoring involves maintaining air pressure at 100 bar, relative humidity at 10%, and temperature at 25°C. The normal shutdown stops the air supply and switches equipment off sequentially. The emergency procedure immediately stops the air supply and cuts main power.

Original Description:

Original Title

Bocle - Sop Format (2)

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides the standard operating procedures for a Tribology Department's BOCLE test equipment. It outlines the startup, monitoring, normal shutdown, and emergency shutdown procedures. The startup procedure includes checking electrical connections and air supply, switching equipment on in a specific sequence. Monitoring involves maintaining air pressure at 100 bar, relative humidity at 10%, and temperature at 25°C. The normal shutdown stops the air supply and switches equipment off sequentially. The emergency procedure immediately stops the air supply and cuts main power.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views2 pagesBocle - Sop Format

Bocle - Sop Format

Uploaded by

Saurabh MishraThis document provides the standard operating procedures for a Tribology Department's BOCLE test equipment. It outlines the startup, monitoring, normal shutdown, and emergency shutdown procedures. The startup procedure includes checking electrical connections and air supply, switching equipment on in a specific sequence. Monitoring involves maintaining air pressure at 100 bar, relative humidity at 10%, and temperature at 25°C. The normal shutdown stops the air supply and switches equipment off sequentially. The emergency procedure immediately stops the air supply and cuts main power.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

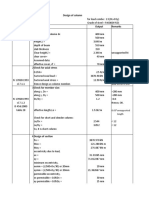

Tribology Department

Standard Operating Procedure

Test Equipment : BOCLE Asset No. : 70003688

FPR Name & Contact No. Rameshwar Chaudhary 9540989555

Saurabh Mishra 9713602246

SPR Name & Contact No.

Safety Coordinators & Contact No. Inder Singh 9810546058

Saurabh Mishra 9713602246

1 Start up procedure 1. Check that all the electrical connections of

both BOCLE test machines are in place. 3

Phase electrical supply is required for each

BOCLE machine.

2. Check that chiller is in working condition by

noting that DM water quantity is around 2

inches below full mark.

3. Switch ON the electrical main switch.

4. Check that pure air cylinder (99.99% purity)

is properly chained and there is no possibility

of leakage in pipeline circuitry.

5. Connect the regulator to the air cylinder, push

the BOCLE machine power switch button to

ON position, and open air supply,

sequentially.

6. Pressure indicated in gauge is 100 bar.

7. Specimen cleaning, assembling and

conducting of test as per ASTM D 5001

standard (attached).

2 Monitoring during 1. Air pressure should be maintained at 100 bar

its operations 2. Relative humidity should be maintained at

(Define critical around 10 %

parameters for 3. Temperature should be around 25 °C

checking and its safe

limits)

3 Normal Shut-off 1. Stop the air supply from cylinder.

procedure 2. Switch OFF the chiller power.

3. Switch OFF the BOCLE machine power.

4. Switch OFF the power from electricity mains.

4 Emergency Shut-off 1. Stop the air supply from cylinder by rotating

procedure key in clockwise direction to maximum limit.

2. Switch OFF the power from electricity mains.

5 Specific Hazards, if Air leakage from cylinder and pipeline circuit may

any be dangerous. Follow emergency shut off procedure.

Prepared by Approved and Issued by

Name Name

You might also like

- Sauer Compressor: Typ: WP 400Document206 pagesSauer Compressor: Typ: WP 400john smithNo ratings yet

- ConocoPhillips HF Alkylation Process Design Specifications - 2007Document147 pagesConocoPhillips HF Alkylation Process Design Specifications - 2007Farzad100% (1)

- EP500 English Technical Manual From Serial No 266 With E100 InterfaceDocument29 pagesEP500 English Technical Manual From Serial No 266 With E100 InterfaceYenireé Medina100% (1)

- Turbine Operating ProcedureDocument33 pagesTurbine Operating ProcedureYudi Permana100% (2)

- Chigo Service-manual-CS25-35 PDFDocument32 pagesChigo Service-manual-CS25-35 PDFabloemenveldNo ratings yet

- UN3C (Instruction Manual) PDFDocument28 pagesUN3C (Instruction Manual) PDFLucntNo ratings yet

- Chiller Testing Procedure Rev 3 PDFDocument11 pagesChiller Testing Procedure Rev 3 PDFOanh NguyenNo ratings yet

- The Purpose of This Manual: VP 500 DescriptionDocument11 pagesThe Purpose of This Manual: VP 500 DescriptionCarlos JuniorNo ratings yet

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssNo ratings yet

- CritiCool Quick Reference Guide - NewDocument12 pagesCritiCool Quick Reference Guide - NewMrunali PatilNo ratings yet

- Wap 50Document13 pagesWap 50prisilliawongNo ratings yet

- TSP-1 RevC 04-15Document8 pagesTSP-1 RevC 04-15boulacharNo ratings yet

- Insta Vac II AspiradorDocument6 pagesInsta Vac II AspiradorDavid EguezNo ratings yet

- Lab 8 (Group 2)Document12 pagesLab 8 (Group 2)shamma0721No ratings yet

- Refuge ChamberDocument23 pagesRefuge ChamberValerioNo ratings yet

- Medical Suction Unit YNK-SU100 Operating Manual: Master@yuilcorp - Co.kr WWW - Yuilcorp.co - KRDocument16 pagesMedical Suction Unit YNK-SU100 Operating Manual: Master@yuilcorp - Co.kr WWW - Yuilcorp.co - KRAntifly Control100% (1)

- DH3-31CW-T-SCT-0005 Commissioning Procedure of Modulating Control System REV.0Document7 pagesDH3-31CW-T-SCT-0005 Commissioning Procedure of Modulating Control System REV.0hungNo ratings yet

- TPCK Series Immersible Pump: Instruction ManualDocument8 pagesTPCK Series Immersible Pump: Instruction ManualThiago Teixeira PiresNo ratings yet

- Installation and Use of The Gas Vacuum Regulator M 40 C and M 50 CDocument15 pagesInstallation and Use of The Gas Vacuum Regulator M 40 C and M 50 Cankitt2007No ratings yet

- 31-Station Acwp - SopDocument3 pages31-Station Acwp - SopSiddhant Satpathy100% (1)

- Zeal International: Cement AutoclaveDocument4 pagesZeal International: Cement AutoclaveShreya Test HouseNo ratings yet

- Manual Book KHV-F15Document24 pagesManual Book KHV-F15Ari100% (1)

- Horno RftoDocument31 pagesHorno Rftojulio RCNo ratings yet

- D00064969 - Cryo Console Preventive Maintenance - RevBDocument16 pagesD00064969 - Cryo Console Preventive Maintenance - RevBrobertNo ratings yet

- SMP - O2 AnalyserDocument5 pagesSMP - O2 AnalyserPragneshNo ratings yet

- Drain ValveDocument1 pageDrain ValveJose MontielNo ratings yet

- Disconnector Type TestingDocument6 pagesDisconnector Type TestingalageshvijayNo ratings yet

- 5L Glass Fermenter 5GJ-Manual使用说明书Document61 pages5L Glass Fermenter 5GJ-Manual使用说明书mustaf mohamedNo ratings yet

- Centrifugal Chiller TC Procedure PDFDocument25 pagesCentrifugal Chiller TC Procedure PDFChia Woon LimNo ratings yet

- Calo-3 OprDocument39 pagesCalo-3 OprjmatallanaNo ratings yet

- MS - Fire ProtectionDocument7 pagesMS - Fire ProtectionBan DodoyNo ratings yet

- Watermicronworld AWG-C 5,000liter Prer Day - Operation ManualDocument16 pagesWatermicronworld AWG-C 5,000liter Prer Day - Operation ManualRobert RainmanNo ratings yet

- Auxiliary Blower Instruction ManualDocument35 pagesAuxiliary Blower Instruction ManualdigardbrandNo ratings yet

- Pajero Full 2008 15Document81 pagesPajero Full 2008 15Antonio Gaspar100% (1)

- SYD-0165A Vacuum Distillation TesterDocument10 pagesSYD-0165A Vacuum Distillation TesterMizanul HoqueNo ratings yet

- Industrial Chiller User ManualDocument15 pagesIndustrial Chiller User ManualJose Morillo CheoNo ratings yet

- Circuit Breakers, Air, Low-Voltage PowerDocument3 pagesCircuit Breakers, Air, Low-Voltage PowerHoneylyn IgnacioNo ratings yet

- Alderly FZE Metering Skid INSTALLATION AND COMMISSIONING INSTRUCTIONSDocument22 pagesAlderly FZE Metering Skid INSTALLATION AND COMMISSIONING INSTRUCTIONSenge.aqeelNo ratings yet

- Non-Contact Voltage Tester: Operating InstructionsDocument6 pagesNon-Contact Voltage Tester: Operating Instructionslutfi_05No ratings yet

- User S ManualDocument16 pagesUser S ManualYacine YaninaNo ratings yet

- Sea Land Surface Pump User ManualDocument8 pagesSea Land Surface Pump User Manualahmed alayanNo ratings yet

- Environment-Laboratory Ambient Conditions: Data Acceptance ProgramDocument5 pagesEnvironment-Laboratory Ambient Conditions: Data Acceptance ProgramAhmed AwwadNo ratings yet

- 123 Manual CO2 Inergen R1Document13 pages123 Manual CO2 Inergen R1MomoMaroufNo ratings yet

- GravesDocument15 pagesGravessrikanthNo ratings yet

- Experiment ESPDocument8 pagesExperiment ESPanasNo ratings yet

- Lalith Test EquipmentsDocument8 pagesLalith Test EquipmentssureshNo ratings yet

- Actual Model 81D Operating Manual 2015Document23 pagesActual Model 81D Operating Manual 2015Guillermo melendezNo ratings yet

- Circuit Switchers: 1. Visual and Mechanical InspectionDocument3 pagesCircuit Switchers: 1. Visual and Mechanical InspectionHoneylyn IgnacioNo ratings yet

- Microclor Control Philosophy 3Document2 pagesMicroclor Control Philosophy 3ExcelNo ratings yet

- Model N18-4.9 (470 ) 18Mw Condensing Steam TurbineDocument20 pagesModel N18-4.9 (470 ) 18Mw Condensing Steam TurbineFajarnurjamanNo ratings yet

- 0.5A 125V AC Qualified TypeDocument4 pages0.5A 125V AC Qualified TypeshyhuNo ratings yet

- IEEE STD C37.41 Ciclo TermicoDocument9 pagesIEEE STD C37.41 Ciclo Termicofelipe sanchezNo ratings yet

- Proceso de Mantenimiento Maquina AnestesiaDocument20 pagesProceso de Mantenimiento Maquina AnestesiaSHIRLEY GIRALDONo ratings yet

- A Honeywell Company: Certified QualitysystemDocument6 pagesA Honeywell Company: Certified QualitysystemLisaNo ratings yet

- Testing & Commissioning of Split Air Conditioning AC UnitsDocument3 pagesTesting & Commissioning of Split Air Conditioning AC Unitsvin ssNo ratings yet

- Operation Manual: Blower Heated Regeneration Adsorption Air DryerDocument16 pagesOperation Manual: Blower Heated Regeneration Adsorption Air DryerDavid AlencarNo ratings yet

- LO 15PTB英文说明书Document26 pagesLO 15PTB英文说明书Fernando Cesar MarachNo ratings yet

- BCWDocument13 pagesBCWRohit100% (2)

- Lab4 RK Dehydrator User Manual: Doc. N. C5574.012-E.MUB Data 18/01/10 Rev. BDocument10 pagesLab4 RK Dehydrator User Manual: Doc. N. C5574.012-E.MUB Data 18/01/10 Rev. BBilge AdamNo ratings yet

- HV1 - Student Kit - Sep 2023 (Final)Document29 pagesHV1 - Student Kit - Sep 2023 (Final)Meor NajmiNo ratings yet

- OM EIAWashDocument25 pagesOM EIAWashJose PersiaNo ratings yet

- 2019Document46 pages2019Saurabh MishraNo ratings yet

- Gdpi 2019Document43 pagesGdpi 2019Saurabh MishraNo ratings yet

- Anova #2Document94 pagesAnova #2Saurabh MishraNo ratings yet

- SEM Ppt2finalDocument115 pagesSEM Ppt2finalSaurabh MishraNo ratings yet

- Cover Letter: Encotec Energy (India) Pvt. LTDDocument5 pagesCover Letter: Encotec Energy (India) Pvt. LTDmalhi16001No ratings yet

- Основные моменты затяжки двигателя CAT 3054Document1 pageОсновные моменты затяжки двигателя CAT 3054Гайдар ДжахаевNo ratings yet

- Shuttle Tanker Propulsion 19993762Document9 pagesShuttle Tanker Propulsion 19993762hpss77No ratings yet

- Design of Column: Axial Stress 0.1fckDocument22 pagesDesign of Column: Axial Stress 0.1fckSudip ShresthaNo ratings yet

- Sky Tec Starter Installation InstructionDocument1 pageSky Tec Starter Installation InstructionYarisa VangeNo ratings yet

- Ueji 2004 Sci. Technol. Adv. Mater. 5 153Document11 pagesUeji 2004 Sci. Technol. Adv. Mater. 5 153le hoangNo ratings yet

- Series Camflex II Rotary Valve Spec Data Gea19376bDocument20 pagesSeries Camflex II Rotary Valve Spec Data Gea19376bPauloNo ratings yet

- Project Standards and Specifications Piping Design Criteria Rev1.0Document15 pagesProject Standards and Specifications Piping Design Criteria Rev1.0Alejandro AguanteNo ratings yet

- ME 461 Control Engineering: Semester: July 2017Document32 pagesME 461 Control Engineering: Semester: July 2017Sudipta PaulNo ratings yet

- Sanet - Ws - Steam Generation From Biomass. Construction and Design of Large BoilersDocument310 pagesSanet - Ws - Steam Generation From Biomass. Construction and Design of Large BoilersNgo Nhu Ngoan B1803415No ratings yet

- Oxygen Cylinder GuidanceDocument1 pageOxygen Cylinder GuidanceDarapu PrasanthiNo ratings yet

- CAESAR Load CaseDocument15 pagesCAESAR Load Casevijayanmks100% (1)

- Manual RC Uni Airc03Document11 pagesManual RC Uni Airc03kolinatorNo ratings yet

- PD80-01 SpecSheetDocument4 pagesPD80-01 SpecSheetJeremy DruffelNo ratings yet

- Perhitungan Evaporator TestDocument75 pagesPerhitungan Evaporator Testamalia rachelNo ratings yet

- Behaviour of Laterally Loaded PilesDocument42 pagesBehaviour of Laterally Loaded PilesunbezonkingNo ratings yet

- JLG Boom Annual ReportDocument1 pageJLG Boom Annual ReportucantcallmeeNo ratings yet

- Data Temp 2 3 4 5 R410ADocument60 pagesData Temp 2 3 4 5 R410Aangelo camposNo ratings yet

- University of Santo Tomas College of Architecture Building Technology 3Document26 pagesUniversity of Santo Tomas College of Architecture Building Technology 3Nelleane PastranaNo ratings yet

- Hvac Assignment: Overall Heat Transfer Coefficient, Compressor, Effects of Bend On DuctDocument29 pagesHvac Assignment: Overall Heat Transfer Coefficient, Compressor, Effects of Bend On DuctNeerajaNo ratings yet

- Davey Xp350p8cDocument2 pagesDavey Xp350p8cNum470% (1)

- 4-PassDocument1 page4-PasstauasiNo ratings yet

- Apparent Weight. Example PDFDocument5 pagesApparent Weight. Example PDFShamoon WahedNo ratings yet

- FM Approval Report PVC C900 DCRDocument6 pagesFM Approval Report PVC C900 DCRJuan David Chaguala FierroNo ratings yet

- MACAWI Respiratory Blower SpecificationsDocument4 pagesMACAWI Respiratory Blower SpecificationsChandru ChristurajNo ratings yet

- Zarya TurbineDocument66 pagesZarya TurbineEbrahim ZolfagharyNo ratings yet

- Study of Pneumatic Braking System With Pneumatic Bumper ProtectionDocument8 pagesStudy of Pneumatic Braking System With Pneumatic Bumper Protectionankush belkarNo ratings yet