Professional Documents

Culture Documents

m81738fp e

Uploaded by

Jackson Dias RochaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

m81738fp e

Uploaded by

Jackson Dias RochaCopyright:

Available Formats

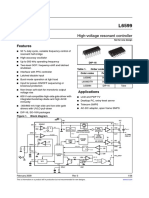

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

DESCRIPTION

M81738FP is high voltage Power MOSFET and IGBT gate PIN CONFIGURATION (TOP VIEW)

driver for half bridge applications.

NC NC

24

1

FEATURES

●Floating supply voltage up to 1200V NC HIN

●Low quiescent power supply current VB LIN

●Separate sink and source current output up to ±1A (typ) HPOUT

●Active Miller effect clamp NMOS with sink current up to 1A (typ)

FO_RST

●Input noise filters (HIN,LIN,FO_RST,FO) HNOUT1 CIN

●Over-current detection and output shutdown HNOUT2 GND

●High side under voltage lockout

●FO pin which can input and output Fault signals to communicate VS FO

with controllers and synchronize the shut down with other phases NC VCC

●Active clamp (power supply surge clamp) NC LPOUT

●24-Lead SSOP PACKAGE

NC LNOUT1

APPLICATIONS NC LNOUT2

Power MOSFET and IGBT gate driver for Medium and Micro

NC 12 VNO

inverter or general purpose.

13

Outline:SSOP24

NC:NO CONNECTION

BLOCK DIAGRAM

VB

Active Active

Clamp Clamp HV

Levelshift UV+POR

HPOUT

Logic HNOUT1

VregVCC Filter

GND Levelshift HNOUT2

VS

HIN VCC

VCC Vreg

Oneshot

Delay Pulse

Interlock Noise Filter

Vreg

Vreg1

LIN LPOUT

Delay

POR

VregVCC LNOUT1

Levelshift

LNOUT2

CIN Filter

Protection

Logic

Vreg1

VNO

VregVCC

Levelshift

Filter FO

FO_RST Filter

Publication Date : Jul. 2022

1

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings indicate limitation beyond which destruction of device may occur. All voltage parameters are absolute voltage

reference to GND unless otherwise specified.

Symbol Parameter Test conditions Ratings Unit

VB High side floating supply absolute voltage -0.5~1224 V

VS High side floating supply offset voltage VB -24~VB +0.5 V

VBS High side floating supply voltage VBS=VB-VS -0.5~24 V

VHO High side output voltage VS -0.5~VB +0.5 V

VCC Low side fixed supply voltage -0.5~24 V

VNO Power ground VCC -24~VCC +0.5 V

VLO Low side output voltage VNO -0.5~VCC +0.5 V

VIN Logic input voltage HIN, LIN, FO_RST -0.5~VCC +0.5 V

VFO FO input/output voltage -0.5~VCC +0.5 V

VCIN CIN input voltage -0.5~VCC +0.5 V

dVS/dt Allowable offset voltage slew rate VS -GND ±50 V/ns

Pd Package power dissipation Ta= 25°C ,On our standard PCB ~1.11 W

Kq Linear derating factor Ta≧25°C ,On our standard PCB ~11.1 mW/°C

Rth(j-a) Junction-ambient air thermal resistance On our standard PCB ~90 °C/W

Tj Junction temperature -40~125 ℃

Topr Operation temperature -40~100 ℃

Tstg Storage temperature On PCB -40~150 ℃

TL Solder reflow condition Pb-free 255:10s, max260 ℃

RECOMMENDED OPERATING CONDITIONS

For proper operation the device should be used within the recommended conditions. All voltage parameters are absolute voltages

referenced to GND unless otherwise specified.

Limits

Symbol Parameter Test conditions Unit

Min. Typ. Max.

VB High side floating supply absolute voltage VS+13.5 VS+15 VS+20 V

VS High side floating supply offset voltage VBS> 13.5V -5 - 900 V

VBS High side floating supply voltage VBS=VB-VS 13.5 15 20 V

VHO High side output voltage VS - VS+20 V

VCC Low side fixed supply voltage 13.5 15 20 V

VNO Power ground -0.5 - 5 V

VLO Low side output voltage VNO - VCC V

VIN Logic input voltage HIN, LIN, FO_RST 0 - VCC V

VFO FO input/output voltage 0 - VCC V

VCIN CIN input voltage 0 - 5 V

THERMAL DERATING FACTOR CHARACTERISTIC (MAXIMUM RATING)

1.2

Package Power Dissipation Pd (W)

0.8

0.6

0.4

0.2

0

0 25 50 75 100 125 150

Ambience Temperature (℃)

Publication Date : Jul. 2022

2

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

TYPICAL CONNECTION

Note: If HVIC is working in high noise environment, it is recommended to connect a 1nF ceramic capacitor (CFO) to FO pin.

Publication Date : Jul. 2022

3

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

ELECTRICAL CHARACTERISTICS (Ta=25℃, VCC=VBS (=VB–VS)=15V, unless otherwise specified)

Limits

Symbol Parameter Test conditions Unit

Min. Typ. Max.

IFS High side leakage current VB = VS = 1200V - - 10 uA

IBS VBS quiescent supply current HIN = LIN = 0V - 0.5 0.8 mA

ICC VCC quiescent supply current HIN = LIN = 0V - 1.0 1.5 mA

VOH High level output voltage IO = 0A, HPOUT, LPOUT 14.5 - - V

VOL Low level output voltage IO = 0A, HNOUT1, LNOUT1 - - 0.5 V

VIH High level input threshold voltage HIN, LIN, FO_RST 2.2 3.0 4.0 V

VIL Low level input threshold voltage HIN, LIN, FO_RST 0.6 1.5 2.1 V

IIH High level input bias current VIN = 5V 0.6 1.0 1.4 mA

IIL Low level input bias current VIN = 0V 0.00 0.00 0.01 mA

HIN on-pulse 80 200 500 ns

HIN off-pulse 80 200 500 ns

LIN on-pulse 80 200 500 ns

tFilter Input signals filter time

LIN off-pulse 80 200 500 ns

FO_RST on-pulse 80 200 500 ns

FO off-pulse 80 200 500 ns

High side active Miller clamp NMOS input

VHNO2 VIN = 0V 2.0 3.4 5.0 V

threshold voltage

Low side active Miller clamp NMOS input

VLNO2 VIN = 0V 6.0 7.6 9.0 V

threshold voltage

tVNO2 Active Miller clamp NMOS filter time VIN = 0V - 400 - ns

VOLFO Low level FO output voltage IFO = 1mA - - 0.95 V

VIHFO High level FO input threshold voltage 2.2 3.0 4.0 V

VILFO Low level FO input threshold voltage 0.6 1.5 2.1 V

VBSuvr VBS supply UV reset voltage 10.5 11.3 12.1 V

VBSuvt VBS supply UV trip voltage 10.0 10.8 11.6 V

VBSuvh VBS supply UV hysteresis voltage VBSuvh = VBSuvr-VBSuvt 0.2 0.5 0.8 V

tVBSuv VBS supply UV filter time 4 8 16 us

VCIN CIN trip voltage 0.40 0.50 0.60 V

VPOR POR trip voltage 4.0 5.5 7.5 V

Output high level short circuit pulsed HPOUT(LPOUT) = 0V, VIN = 5V, PW ≦

IOH - 1 - A

current 10us

HNOUT1(LNOUT1) = 15V, VIN = 0V, PW

IOL1 Output low level short circuit pulsed current - -1 - A

≦ 10us

Active Miller clamp NMOS output low level HNOUT2(LNOUT2) = 15V, VIN = 0V, PW

IOL2 - -1 - A

short circuit pulsed current ≦ 10us

ROH Output high level on resistance IO = 1A, ROH = (VOH-VO)/IO - 15 - Ω

ROL1 Output low level on resistance IO = -1A, ROL1 = VO/IO - 15 - Ω

Active Miller clamp NMOS output low level

ROL2 IO = -1A, ROL2 = VO/IO - 15 - Ω

on resistance

HPOUT short to HNOUT1 and HNOUT2,

tdLH(HO) High side turn-on propagation delay 1.00 1.27 1.62 us

CL = 1nF

HPOUT short to HNOUT1 and HNOUT2,

tdHL(HO) High side turn-off propagation delay 0.90 1.21 1.47 us

CL = 1nF

LPOUT short to LNOUT1 and LNOUT2,

tdLH(LO) Low side turn-on propagation delay 1.00 1.39 1.90 us

CL = 1nF

LPOUT short to LNOUT1 and LNOUT2,

tdHL(LO) Low side turn-off propagation delay 0.90 1.19 1.70 us

CL = 1nF

tr Output turn-on rise time CL = 1nF 10 40 80 ns

tf Output turn-off fall time CL = 1nF 10 40 80 ns

Delay matching, high side turn-on and low

DtdLH tdLH(HO)-tdHL(LO) -100 80 300 ns

side turn-off

Delay matching, high side turn-off and low

DtdHL tdLH(LO)-tdHL(HO) -20 180 400 ns

side turn-on

Vclamp Active clamp voltage Vcc – GND, VB - VS 24 - - V

Note: Typ is not specified

Publication Date : Jul. 2022

4

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

FUNCTION TABLE (Q: Keep previous status)

FO VBS/ VCC/ FO

HIN LIN FO_RST CIN HOUT LOUT Behavioral status

(Input) UV・POR POR (Output)

L L L L - H H L L H

L H L L - H H L H H

H L L L - H H H L H

H H L L - H H Q Q H Interlock active

X H X H - X H L L L CIN tripping when LIN = H

X L X H - X H Q Q H CIN not tripping when LIN = L

X X X X L X H L L - Output shuts down when FO = L

X X X X - X L L L H VCC power reset

X L L L - L H L L H VBS power reset

X H L L - L H L H H VBS power reset is tripping when LIN = H

Note1 : “L” status of VBS/UV indicates a high side UV condition; “L” status of VCC/POR indicates a VCC power reset condition.

Note2 : In the case of both input signals (HIN and LIN) are “H”, output signals (HOUT and LOUT) keep previous status.

Note3 : X (HIN) : L→H or H→L. Other : H or L.

Note4 : Output signal (HOUT) is triggered by the edge of input signal.

HIN

HOUT

FUNCTIONAL DESCRIPTION

1. INPUT/OUTPUT TIMING DIAGRAM

Publication Date : Jul. 2022

5

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

2. INPUT/OUTPUT TIMING DIAGRAM

When the input signals (HIN/LIN) are high level at the same time, the outputs (HOUT/LOUT) keep their previous status.

But if signals (HIN/LIN) are going to high level simultaneously, HIN signals will get active and cause HOUT to enter “H” status.

Note1 : The minimum input pulse width at HIN/LIN should be to more than 500ns (because of HIN/LIN input noise filter circuit).

Note2 : If a high-high status of input signals (HIN/LIN) is ended with only one input signal entering low level and another still being in high level,

the output will enter high-low status after the delay match time (not shown in the figure above).

Note3 : Delay times between input and output signals are not shown in the figure above.

3. SHORT CIRCUIT PROTECTION TIMING DIAGRAM

When an over-current is detected by exceeding the threshold at the CIN and LIN is at high level at the same time, the short circuit

protection will get active and shutdown the outputs while FO will issue a low level (indicating a fault signal).

The fault output latch is reset by a high level signal at FO_RST pin and then FO will return to high level while the output of the driver

will respond to the following active input signal.

Note1 : Delay times between input and output signals are not shown in the figure above.

Note2 : The minimum FO_RST pulse width should be more than 500ns (because of FO_RST input filter circuit).

Publication Date : Jul. 2022

6

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

4. FO INPUT TIMING DIAGRAM

When FO is pulled down to low level in case the FO of other phases becomes low level (fault happened) or the MCU/DSP sets FO

to low level, the outputs (HOUT, LOUT) of the driver will be shut down. As soon as FO goes high again, the output will respond to

the following active input signal.

Note1 : Delay times between input and output signals are not shown in the figure above.

Note2 : The minimum FO pulse width should be more than 500ns (because of FO input filter circuit).

5. LOW SIDE VCC SUPPLY POWER RESET SEQUENCE

When the VCC supply voltage is lower than power reset trip voltage, the power reset gets active and the outputs (HOUT/LOUT)

become “L”. As soon as the VCC supply voltage goes higher than the power reset trip voltage, the outputs will respond to the

following active input signals.

Note1 : Delay times between input and output signals are not shown in the figure above

Publication Date : Jul. 2022

7

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

6. HIGH SIDE VBS SUPPLY UNDER VOLTAGE LOCKOUT SEQUENCE

When VBS supply voltage drops below the VBS supply UV trip voltage and the duration in this status exceeds the VBS supply UV

filter time, the output of the high side is locked. As soon as the VBS supply voltage rises above the VBS supply UV reset voltage,

the output will respond to the following active HIN signal.

Note1 : Delay times between input and output signals are not shown in the figure above.

7. POWER START-UP SEQUENCE

At power supply start-up the following sequence is recommended when bootstrap supply topology is used.

① Apply VCC.

② Make sure that FO is at high level.

③ Set LIN to high level and HIN to low level so that

bootstrap capacitor could be charged.

④ Set LIN to low level.

Note : If two power supply are used for supplying VCC and VBS individually,

it is recommended to set VCC first and then set VBS.

Publication Date : Jul. 2022

8

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

8. ACTIVE MILLER EFFECT CLAMP NMOS OUTPUT TIMING DIAGRAM

The structure of the output driver stage is shown in following figure. This circuit structure employs a solution for the problem of

the Miller current through Cres in IGBT switching applications. Instead of driving the IGBT gate to a negative voltage to increase

the safety margin, this circuit structure uses a NMOS to establish a low impedance path to prevent the self-turn-on due to the

parasitic Miller capacitor in power switches.

Active Miller effect

clamp NMOS

When HIN/LIN is at low level and the voltage of the VOUT (IGBT gate voltage) is below active Miller effect clamp NMOS input

threshold voltage, the active Miller effect clamp NMOS is being turned on and opens a low resistive path for the Miller current

through Cres.

Active Miller effect clamp

NMOS input threshold

Active Miller effect clamp NMOS keeps

turn-on if TW does not exceed active Miller

clamp NMOS filter time

Publication Date : Jul. 2022

9

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

INTERNAL DIODE CLAMP CIRCUITS FOR INPUT AND OUTPUT

ENVIRONMENTAL CONSCIOUSNESS

M81738FP is compliant with the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment

(RoHS) directive 2011/65/EU+(EU)2015/863.

PACKAGE OUTLINE

Note) DIMENSIONS IN MILLIMETERS

SYMBOLS

1.*1,*2:Not include mold flash MIN NOM MAX

2.*3:Not include tie bar burrs e1 ー 7.62 ー

l2 1.27 ー ー

e ー 0.8 ー

b2 ー 0.5 ー

The above is one example.

Please design the mount pad with your evaluation.

Detail F

Publication Date : Jul. 2022

10

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

Main Revision for this Edition

Revision

Rev. Date Pages Points

A 10 Jan. 2012 - New making

B 3 Dec. 2014 - “PRELIMINARY” is deleted.

2 “TL” is added.

10 “ENVIRONMENTAL CONSCIOUSNESS” is added.

C 19 Jun. 2019 4 Change VBSuvr for VBSuvt

D 28 Apr. 2021 - Update format

E 26 Jul. 2022 4 Change “W” to “Ω” about the unit of ROH, ROL1 and ROL2

Publication Date : Jul. 2022

11

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

Important Notice

The information contained in this datasheet shall in no event be regarded as a guarantee of conditions or

characteristics. This product has to be used within its specified maximum ratings, and is subject to customer’s

compliance with any applicable legal requirement, norms and standards.

Except as otherwise explicitly approved by Mitsubishi Electric Corporation in a written document signed by

authorized representatives of Mitsubishi Electric Corporation, our products may not be used in any applications

where a failure of the product or any consequences of the use thereof can reasonably be expected to result in

personal injury.

In usage of power semiconductor, there is always the possibility that trouble may occur with them by the reliability

lifetime such as Thermal Cycle or others, or when having assembling stress (e.g. high temperature of reflow

process, or rinse after the reflow), or when used under special operating conditions (e.g. rise/fall time of the power

supply voltage, or excessive voltage/current injection), or when used under special circumstances (e.g.

condensation, high humidity, dusty, salty, highlands, environment with lots of organic matter / corrosive gas /

explosive gas, or situations which terminals of semiconductor products receive strong mechanical stress).

Therefore, please pay sufficient attention to such circumstances. Further, depending on the technical requirements,

our semiconductor products may contain environmental regulation substances, etc. If there is necessity of detailed

confirmation, please contact our nearest sales branch or distributor.

The contents or data contained in this datasheet are exclusively intended for technically trained staff. Customer's

technical departments should take responsibility to evaluate the suitability of Mitsubishi Electric Corporation

product for the intended application and the completeness of the product data with respect to such application. In

the customer's research and development, please evaluate it not only with a single semiconductor product but also

in the entire system, and judge whether it's applicable. As required, pay close attention to the safety design by

installing appropriate fuse or circuit breaker between a high voltage/large current power supply and power

semiconductor products(e.g. IGBT, MOSFET) to prevent secondary damage. Please also pay attention to the

application note and the related technical information.

Publication Date : Jul. 2022

12

<HVIC>

M81738FP

1200V HIGH VOLTAGE HALF BRIDGE DRIVER

Keep safety first in your circuit designs!

Mitsubishi Electric Corporation puts the maximum effort into making semiconductor products better and more

reliable, but there is always the possibility that trouble may occur with them. Trouble with semiconductors may

lead to personal injury, fire or property damage. Remember to give due consideration to safety when making your

circuit designs, with appropriate measures such as (i) placement of substitutive, auxiliary circuits, (ii) use of non-

flammable material or (iii) prevention against any malfunction or mishap.

Notes regarding these materials

•These materials are intended as a reference to assist our customers in the selection of the Mitsubishi

semiconductor product best suited to the customer’s application; they do not convey any license under

any intellectual property rights, or any other rights, belonging to Mitsubishi Electric Corporation or a third

party.

•Mitsubishi Electric Corporation assumes no responsibility for any damage, or infringement of any third-

party’s rights, originating in the use of any product data, diagrams, charts, programs, algorithms, or

circuit application examples contained in these materials.

•All information contained in these materials, including product data, diagrams, charts, programs and

algorithms represents information on products at the time of publication of these materials, and are

subject to change by Mitsubishi Electric Corporation without notice due to product improvements or

other reasons. It is therefore recommended that customers contact Mitsubishi Electric Corporation or an

authorized Mitsubishi Semiconductor product distributor for the latest product information before

purchasing a product listed herein.

The information described here may contain technical inaccuracies or typographical errors. Mitsubishi

Electric Corporation assumes no responsibility for any damage, liability, or other loss rising from these

inaccuracies or errors.

Please also pay attention to information published by Mitsubishi Electric Corporation by various means,

including the Mitsubishi Semiconductor home page (http://www.MitsubishiElectric.com/).

•When using any or all of the information contained in these materials, including product data, diagrams,

charts, programs, and algorithms, please be sure to evaluate all information as a total system before

making a final decision on the applicability of the information and products. Mitsubishi Electric

Corporation assumes no responsibility for any damage, liability or other loss resulting from the

information contained herein.

•Mitsubishi Electric Corporation semiconductors are not designed or manufactured for use in a device or

system that is used under circumstances in which human life is potentially at stake. Please contact

Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor when

considering the use of a product contained herein for any specific purposes, such as apparatus or

systems for transportation, vehicular, medical, aerospace, nuclear, or undersea repeater use.

•The prior written approval of Mitsubishi Electric Corporation is necessary to reprint or reproduce in

whole or in part these materials.

•If these products or technologies are subject to the Japanese export control restrictions, they must be

exported under a license from the Japanese government and cannot be imported into a country other

than the approved destination.

Any diversion or re-export contrary to the export control laws and regulations of Japan and/or the

country of destination is prohibited.

•Please contact Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product

distributor for further details on these materials or the products contained therein.

© Mitsubishi Electric Corporation

Publication Date : Jul. 2022

13

You might also like

- Programmable Power Management IC for Large LCD DisplaysDocument7 pagesProgrammable Power Management IC for Large LCD DisplaysJulião Marques100% (4)

- Road Kill Cafe MenuDocument1 pageRoad Kill Cafe MenuwjannuschNo ratings yet

- Design Calculations For Snap Fit Joints in Plastic Parts Ticona PDFDocument30 pagesDesign Calculations For Snap Fit Joints in Plastic Parts Ticona PDFSuteu Ionel100% (1)

- Scienctific Basis and Application of Information Fields in Medicine PDFDocument11 pagesScienctific Basis and Application of Information Fields in Medicine PDFMatsya das100% (1)

- Dual High Side DriverDocument7 pagesDual High Side DriverСаша ДыдаNo ratings yet

- Maxms14755 1Document11 pagesMaxms14755 1Sergei OssifNo ratings yet

- R1290K Series: 3ch DC/DC For TFT LCDDocument42 pagesR1290K Series: 3ch DC/DC For TFT LCDSergei OssifNo ratings yet

- VFM Step-Up DC/DC Converter: General Description FeaturesDocument9 pagesVFM Step-Up DC/DC Converter: General Description FeaturesPraful marakanaNo ratings yet

- Design high frequency push-pull DC/DC converterDocument5 pagesDesign high frequency push-pull DC/DC converterEdoardoNo ratings yet

- DC Converter With Low PassDocument38 pagesDC Converter With Low PassMuhammad Fikri Hidayat FikriNo ratings yet

- (Codientu - Org) - BD 9397Document30 pages(Codientu - Org) - BD 9397VươngNo ratings yet

- Bd9397efv eDocument30 pagesBd9397efv eGiovanni Carrillo VillegasNo ratings yet

- Oscilador Booster Led Sony BD9397EFVDocument30 pagesOscilador Booster Led Sony BD9397EFVAntonio Chavez100% (1)

- Xiner XNS24S72F6Document4 pagesXiner XNS24S72F6home madeNo ratings yet

- Up1605 uPISemiconductorDocument23 pagesUp1605 uPISemiconductorRBN HMNo ratings yet

- LT3469 Piezo Actuator Driver PDFDocument8 pagesLT3469 Piezo Actuator Driver PDFjacerosiete2952No ratings yet

- m81700fp eDocument5 pagesm81700fp eHai HeoNo ratings yet

- 300Ma Cmos Ldo Regulator With 15: Μμμμμa Quiescent CurrentDocument14 pages300Ma Cmos Ldo Regulator With 15: Μμμμμa Quiescent CurrentGABRIEL ALFONSONo ratings yet

- Richtek RT6150B 33GQW DatasheetDocument13 pagesRichtek RT6150B 33GQW Datasheetagsan.algabh2718No ratings yet

- Regulate MM 166f eDocument8 pagesRegulate MM 166f eDrazen MakarovNo ratings yet

- LTC 3124Document28 pagesLTC 3124m3rishorNo ratings yet

- ECN3297TF HitachiDocument17 pagesECN3297TF HitachiachillesNo ratings yet

- L6565 DatasheetDocument17 pagesL6565 DatasheetJose BenavidesNo ratings yet

- Features Descriptio: LTC1624 High Efficiency SO-8 N-Channel Switching Regulator ControllerDocument28 pagesFeatures Descriptio: LTC1624 High Efficiency SO-8 N-Channel Switching Regulator ControllervetchboyNo ratings yet

- NCP1560 Full Featured Voltage Mode PWM Controller: SO 16 D Suffix CASE 751BDocument20 pagesNCP1560 Full Featured Voltage Mode PWM Controller: SO 16 D Suffix CASE 751BraveendraNo ratings yet

- NCP45790 D-2317241Document13 pagesNCP45790 D-2317241SuBaRu GTNo ratings yet

- 500mA Peak, Thermal Folded Back CMOS LDO RegulatorDocument12 pages500mA Peak, Thermal Folded Back CMOS LDO RegulatorpeternewsNo ratings yet

- hc5fw300-s sp1Document7 pageshc5fw300-s sp1harigopalk12No ratings yet

- 20 Terminal Function of Ics: 20.1. Ic2800 (Rfkwmvkx60Ga) : Ic Micro-ProcessorDocument1 page20 Terminal Function of Ics: 20.1. Ic2800 (Rfkwmvkx60Ga) : Ic Micro-ProcessorncirNo ratings yet

- 300ma, Low Dropout, Low Noise Ultra-Fast Without Bypass Capacitor CMOS LDO RegulatorDocument11 pages300ma, Low Dropout, Low Noise Ultra-Fast Without Bypass Capacitor CMOS LDO RegulatordinhdtdNo ratings yet

- ROHM Semicon BD68610EFV E2 - C239853Document22 pagesROHM Semicon BD68610EFV E2 - C239853Fikri HidayatNo ratings yet

- Features Description: Lt1999-10/Lt1999-20/ Lt1999-50 High Voltage, Bidirectional Current Sense AmplifierDocument24 pagesFeatures Description: Lt1999-10/Lt1999-20/ Lt1999-50 High Voltage, Bidirectional Current Sense AmplifierkkkkNo ratings yet

- Data SheetDocument19 pagesData SheetRobertoBarbosaNo ratings yet

- R2J20657CNP: DatasheetDocument16 pagesR2J20657CNP: DatasheetLingam BharathiNo ratings yet

- AN-H61 MD7120 Class-D Audio Amplifier Design: Application NoteDocument5 pagesAN-H61 MD7120 Class-D Audio Amplifier Design: Application Notecvsstudio digitalNo ratings yet

- Bd9141muv eDocument25 pagesBd9141muv eKris OscarNo ratings yet

- NCP81152 ONSemiconductorDocument8 pagesNCP81152 ONSemiconductorwej10358No ratings yet

- NCP5212A, NCP5212T Single Synchronous Step-Down Controller: QFN16 Case 485apDocument19 pagesNCP5212A, NCP5212T Single Synchronous Step-Down Controller: QFN16 Case 485apokeinfoNo ratings yet

- High Voltage 8-CH LED Driver: Features General DescriptionDocument13 pagesHigh Voltage 8-CH LED Driver: Features General DescriptionSetiawan Abdul RochimNo ratings yet

- LM358 DatasheetDocument34 pagesLM358 DatasheetMai EsamNo ratings yet

- TB6575FNG: PreliminaryDocument13 pagesTB6575FNG: PreliminaryjicoelhoNo ratings yet

- LTC3612Document30 pagesLTC3612Alexandr IvanovNo ratings yet

- Data Sheet: Smartpower Enabled Combo Controller For High PF Led LightingDocument11 pagesData Sheet: Smartpower Enabled Combo Controller For High PF Led LightingIbrain MoranNo ratings yet

- ncp81152 DDocument9 pagesncp81152 DNikhil khadeNo ratings yet

- LT8390ADocument30 pagesLT8390A隋玉峰No ratings yet

- 3A, 1Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 1Mhz, Synchronous Step-Down Converter: General Description FeatureskiryanoffNo ratings yet

- Description Features: LT1952/LT1952-1 Single Switch Synchronous Forward ControllerDocument28 pagesDescription Features: LT1952/LT1952-1 Single Switch Synchronous Forward ControllerDuta HastaNo ratings yet

- Dual Operational Amplifiers: Features DescriptionDocument34 pagesDual Operational Amplifiers: Features DescriptionMario Sernaque RumicheNo ratings yet

- LTC 15389 FDocument32 pagesLTC 15389 FEdson HenriqueNo ratings yet

- PN43D490a1dxz Troubleshooting GuideDocument5 pagesPN43D490a1dxz Troubleshooting GuidemaapilarNo ratings yet

- LT 3741 - Controlador Corriente - VoltajeDocument24 pagesLT 3741 - Controlador Corriente - VoltajeMarta_d_eNo ratings yet

- R5323N Series: SOT23-6 150ma 2ch LDO REGULATORSDocument19 pagesR5323N Series: SOT23-6 150ma 2ch LDO REGULATORSIsmael GuzmanNo ratings yet

- Linear Technology LT2410 24bit - DatasheetDocument48 pagesLinear Technology LT2410 24bit - DatasheetdonatoNo ratings yet

- DS8816ADocument21 pagesDS8816AAgustin AyalaNo ratings yet

- Rt8816a-06 Gtx1070 Gigabyte MemoriasDocument21 pagesRt8816a-06 Gtx1070 Gigabyte Memoriastechgamebr85No ratings yet

- Dual-Phase PWM Controller With PWM-VID Reference: General Description FeaturesDocument21 pagesDual-Phase PWM Controller With PWM-VID Reference: General Description FeaturesДмитрий НичипоровичNo ratings yet

- Oscilador de ForwardDocument4 pagesOscilador de ForwardCarlos Reyes RiveraNo ratings yet

- TB67H400AHG: PWM Chopper-TypeDocument23 pagesTB67H400AHG: PWM Chopper-Typegeneric111No ratings yet

- MP1580Document4 pagesMP1580Francisco José Lencina SalarNo ratings yet

- Mc34060a D 104921Document17 pagesMc34060a D 104921Tic TicandoNo ratings yet

- Descriptio Features: Lt1370 500Khz High Efficiency 6A Switching RegulatorDocument16 pagesDescriptio Features: Lt1370 500Khz High Efficiency 6A Switching RegulatorvvvNo ratings yet

- MN cdd562L 564Document254 pagesMN cdd562L 564Jackson Dias RochaNo ratings yet

- DM00091013Document45 pagesDM00091013Jackson Dias RochaNo ratings yet

- Pata Nandrive™ Socket Board User Guide: April 2011Document13 pagesPata Nandrive™ Socket Board User Guide: April 2011Mohammad Ali Zare ZadeNo ratings yet

- 09 Chapter 16-56 10-23Document10 pages09 Chapter 16-56 10-23Jackson Dias RochaNo ratings yet

- CSM46 Modular Converter System: Installation & Operation ManualDocument40 pagesCSM46 Modular Converter System: Installation & Operation ManualJackson Dias RochaNo ratings yet

- MN CDMQXDocument260 pagesMN CDMQXJackson Dias RochaNo ratings yet

- pss05s72ft eDocument12 pagespss05s72ft eJackson Dias RochaNo ratings yet

- 7mbr35xpa120 50Document12 pages7mbr35xpa120 50Jackson Dias RochaNo ratings yet

- An101 Spi and Jtag In-System Programming (Isp) Guidelines For The Atmel Atmega Avr Flash Microcontroller FamilyDocument27 pagesAn101 Spi and Jtag In-System Programming (Isp) Guidelines For The Atmel Atmega Avr Flash Microcontroller FamilyJackson Dias RochaNo ratings yet

- MN Odm840Document364 pagesMN Odm840Jackson Dias RochaNo ratings yet

- CLI User Manual 3G/4G RouterDocument104 pagesCLI User Manual 3G/4G RouterJackson Dias RochaNo ratings yet

- MN Ctog 250 - 3 - 10 5 18 PDFDocument322 pagesMN Ctog 250 - 3 - 10 5 18 PDFHadyanto LanujayaNo ratings yet

- Manual Tecnico Micromotor Marathon Escort 2Document5 pagesManual Tecnico Micromotor Marathon Escort 2Jackson Dias RochaNo ratings yet

- Catalogo Primavera 2014Document76 pagesCatalogo Primavera 2014Jackson Dias RochaNo ratings yet

- Tungsten Halogen & Incandescent LampsDocument2 pagesTungsten Halogen & Incandescent LampsJackson Dias RochaNo ratings yet

- Shimoji 2020 Oi 200766 1604512873.81482Document11 pagesShimoji 2020 Oi 200766 1604512873.81482Jackson Dias RochaNo ratings yet

- Antibodies, Immunity, and COVID-19: Widespread AvailabilityDocument2 pagesAntibodies, Immunity, and COVID-19: Widespread AvailabilityJackson Dias RochaNo ratings yet

- Manual Honeywell Solaris ms7820 PDFDocument65 pagesManual Honeywell Solaris ms7820 PDFSérgio SenaNo ratings yet

- Efficacy and Safety of Hydroxychloroquine Vs Placebo For Pre-Exposure Sars-Cov-2 Prophylaxis Among Health Care Workers A Randomized Clinical TrialDocument8 pagesEfficacy and Safety of Hydroxychloroquine Vs Placebo For Pre-Exposure Sars-Cov-2 Prophylaxis Among Health Care Workers A Randomized Clinical TrialJackson Dias RochaNo ratings yet

- Jamainternal Wu 2020 Oi 200072 1601661089.65631Document7 pagesJamainternal Wu 2020 Oi 200072 1601661089.65631Jackson Dias RochaNo ratings yet

- Zhang 2020 Oi 200793 1601426865.2035Document13 pagesZhang 2020 Oi 200793 1601426865.2035Jackson Dias RochaNo ratings yet

- Flow Packs: Botões Max BottonDocument2 pagesFlow Packs: Botões Max BottonJackson Dias RochaNo ratings yet

- Letters: Assessment of Sars-Cov-2 Rna Test Results Among Patients Who Recovered From Covid-19 With Prior Negative ResultsDocument2 pagesLetters: Assessment of Sars-Cov-2 Rna Test Results Among Patients Who Recovered From Covid-19 With Prior Negative ResultsJackson Dias RochaNo ratings yet

- Seroprevalence of Antibodies To Sars-Cov-2 in 10 Sites in The United States, March 23-May 12, 2020Document11 pagesSeroprevalence of Antibodies To Sars-Cov-2 in 10 Sites in The United States, March 23-May 12, 2020Mario Josue ValladaresGarridoNo ratings yet

- Using The Serial Peripheral Interface (SPI) Module On 68HC (9) 08 MicrocontrollersDocument8 pagesUsing The Serial Peripheral Interface (SPI) Module On 68HC (9) 08 MicrocontrollersJackson Dias RochaNo ratings yet

- At Mega DatasheetDocument26 pagesAt Mega DatasheetTony StarkNo ratings yet

- Estimated Sars-Cov-2 Seroprevalence in The Us As of September 2020Document11 pagesEstimated Sars-Cov-2 Seroprevalence in The Us As of September 2020Jackson Dias RochaNo ratings yet

- Multi Contact SpecsDocument16 pagesMulti Contact SpecsJackson Dias RochaNo ratings yet

- VFD-VL M en 20111018Document275 pagesVFD-VL M en 20111018Percy Flores AquiseNo ratings yet

- 7e Lesson PlanDocument6 pages7e Lesson PlanDave Matthew LibiranNo ratings yet

- Jurnal Ilmiah Simantek ISSN. 2550-0414 Vol. 5 No. 1 Februari 2021Document5 pagesJurnal Ilmiah Simantek ISSN. 2550-0414 Vol. 5 No. 1 Februari 2021Muhamad IhsanNo ratings yet

- Mole Calculation Worksheet: Practice & SolutionsDocument3 pagesMole Calculation Worksheet: Practice & SolutionsQurrat Ul AinNo ratings yet

- Analysis of A Healthcare Risk Management PlanDocument6 pagesAnalysis of A Healthcare Risk Management PlanGeralds B GeraldNo ratings yet

- TheEconomist 2020 12 10Document296 pagesTheEconomist 2020 12 10merlindebergNo ratings yet

- Root-Knot and Root-Lesion Nematode SuppressionDocument6 pagesRoot-Knot and Root-Lesion Nematode SuppressionRAMIRO H.S.No ratings yet

- Kasco Safety Manual CurrentDocument171 pagesKasco Safety Manual CurrentLea Santos CidNo ratings yet

- Bảng Tính Cột Áp QuạtDocument4 pagesBảng Tính Cột Áp QuạtNguyen PhamNo ratings yet

- Rundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967Document15 pagesRundingan Perdagangan Antara Malaysia Dan Indonesia Di Wisma Putra, Kuala Lumpur 1967nixyingboNo ratings yet

- Solar SystemDocument27 pagesSolar SystemSheena Jane Tioc100% (1)

- Mag-Gage The Superior Magnetic Level Gauge: Process Level Technology, Ltd. 281.332.6241Document12 pagesMag-Gage The Superior Magnetic Level Gauge: Process Level Technology, Ltd. 281.332.6241BYRON ENRIQUE AGUILERA CHIMARRONo ratings yet

- Thuja's Effectiveness Against SmallpoxDocument361 pagesThuja's Effectiveness Against SmallpoxFrank NavaNo ratings yet

- Presented by M. Hassan ShafiqDocument25 pagesPresented by M. Hassan ShafiqMadiha Amna AndrabiNo ratings yet

- IJST - Vol (7) - No (4) December 2012Document153 pagesIJST - Vol (7) - No (4) December 2012Taghreed hashim AlnoorNo ratings yet

- CSFDocument5 pagesCSFjalan_zNo ratings yet

- Caldwell Schizophrenizing LacanDocument10 pagesCaldwell Schizophrenizing LacanaxisofelvisNo ratings yet

- Gang Violence in Jamaica: Causes, Effects and SolutionsDocument20 pagesGang Violence in Jamaica: Causes, Effects and SolutionsRicardoMoody50% (2)

- Drilling Fluid Processing System BrochureDocument20 pagesDrilling Fluid Processing System BrochureazkNo ratings yet

- Student Admission FormDocument2 pagesStudent Admission FormOmmsai co2011No ratings yet

- Trix Price List OCT 2018 PDFDocument2 pagesTrix Price List OCT 2018 PDFApNo ratings yet

- Hygro-Thermometer Pen: User's GuideDocument4 pagesHygro-Thermometer Pen: User's GuideTedosNo ratings yet

- DesignGyan17150517Seating System Components-Seating Terminology - FOR - TRAININGDocument42 pagesDesignGyan17150517Seating System Components-Seating Terminology - FOR - TRAININGK S RANJITH ランジットNo ratings yet

- Introduction To AluminumDocument33 pagesIntroduction To Aluminumilham fdhlman11No ratings yet

- Long-Term Memory - ProcessDocument30 pagesLong-Term Memory - ProcessALEXANDRA SAN PEDRONo ratings yet

- Reshaping Herbal Medicine - Knowledge, Education and Professional Culture (2005) PDFDocument200 pagesReshaping Herbal Medicine - Knowledge, Education and Professional Culture (2005) PDFLuiz FelipeNo ratings yet

- Parte 2 Segundo ParcialDocument23 pagesParte 2 Segundo ParcialJose Luis Rasilla GonzalezNo ratings yet

- Can Capitalism Bring Inclusive Growth?: - Suneel SheoranDocument4 pagesCan Capitalism Bring Inclusive Growth?: - Suneel SheoranSandeepkumar SgNo ratings yet