Professional Documents

Culture Documents

Experiment 4 - Geolab

Uploaded by

Lorenz BerroyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment 4 - Geolab

Uploaded by

Lorenz BerroyaCopyright:

Available Formats

Laboratory Experiment No.

4

DIRECT SHEAR TEST

LABORATORY EXPERIMENT NO. 4

DIRECT SHEAR TEST

CE152L – GEOTECHNICAL ENGINEERING 2 (LAB)

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

1

Laboratory Experiment No. 4

DIRECT SHEAR TEST

INTRODUCTION

One of the oldest and first type of determining the shear strength of soil is the Direct

Shear Test. Mohr discovered that the unparalleled combination of the normal and shearing stress

causes a failure on the plane of the soil. It is critical to know the right amount of horizontal and

vertical force to avoid failure, knowing only the maximum and minimum stress cannot stand

alone. Since the horizontal and vertical planes are interrelated, a certain angle (φ) can be drawn

from the two forces of normal and shear. This angle is called the angle of internal friction. This

angle is the result of the strength gained from internal friction resistance. Since there are various

types of sand, silt and gravel, there is a range of values for each. (See Table 12.1)

Mohr based his research from Coulomb’s book quote, “Essai sur une application des

règles des maximis et minimis à quelques problèmes de statique relatifs à l'architecture (

Test on an application of the rules of maximis and minimis to some problems of statics relating

to the architecture)” to determine the relationship of all the independent variables. He

substantiated the Mohr’s Circle Diagram we know today for calculating the shear stress, normal

stress, major principal stress, minor principal stress, deviator stress of a soil depending on the

parameters given. (See Figure 12.3)

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

2

Laboratory Experiment No. 4

DIRECT SHEAR TEST

The Shear Strength of Soil is one of the most important thing to consider in analyzing the

stability of soil. The internal resistance per unit area is the capacity of a soil to resist failure. It

can be attributed to three properties: a) the sliding resistance of soil with a solid particle, b)

Cohesion (same soil type) and Adhesion (with different soil type or surface) of two particles c)

Deformation of the soil.

One must be knowledgeable with the shear strength of soil because this is used to analyze

the stability of a soil. It can be applied in slope stability, bearing capacity of soil, foundations of

a structure (footing) and earth retaining structures.

OBJECTIVES

1. To perform the direct shear test using strain direct shear apparatus.

2. To determine the shear strength properties of soil cohesion and angle of internal friction.

STANDARD REFERENCE

ASTM D 3080 – Standard Test Method for Direct Shear Test of Soils Under Consolidated

Drained Conditions.

SIGNIFICANCE AND USE

The direct shear test is one of the oldest strength tests for soils. In this laboratory, a direct

shear device will be used to determine the shear strength of a cohesionless soil (i.e. angle of

internal friction (f)). From the plot of the shear stress versus the horizontal displacement, the

maximum shear stress is obtained for a specific vertical confining stress. After the experiment is

run several times for various vertical-confining stresses, a plot of the maximum shear stresses

versus the vertical (normal) confining stresses for each of the tests is produced. From the plot, a

straight-line approximation of the Mohr-Coulomb failure envelope curve can be drawn, f may be

determined, and, for cohesionless soils (c = 0), the shear strength can be computed from the

following equation: s = s tanf

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

3

Laboratory Experiment No. 4

DIRECT SHEAR TEST

APPARATUS AND MATERIALS (See figure)

Direct Shear Device

Shear Box

Weighing Scale

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

4

Laboratory Experiment No. 4

DIRECT SHEAR TEST

TEST SPECIMEN

Granular Soil (Sand)

TEST PROCEDURE (METHODOLOGY)

1. Before proceeding to the experiment, the following scopes are to be considered to assure

accurate and best results.

Figure 1: ASTM D 3080 – Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained

Conditions.1

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

5

Laboratory Experiment No. 4

DIRECT SHEAR TEST

2. A fine well graded granular sand is carefully selected to be

used as a test specimen. The initial mass of the empty

cylindrical vessel can is then measured. The sand is placed

in the can and the mass is measured together with the vessel.

The mass of sand can be calculated as (Mass of Can + Sand)

- (Mass of Can) = Mass of Sand.

3. The shear box is carefully disassembled from the direct

shear apparatus. The dimension of the shear box is

measured. Using a caliper, the inner diameter of the shear

box is measured. The height of the shear box from the inside

can be measured using a ruler. A 15% of the diameter in

millimeters is needed to allow a displacement for the

computation.

4. The sand is placed in the shear box. A filter paper is placed

on top of the sand. A porous stone is also placed on top of

the filter paper.

5. The shear box is prudently placed and assembled on the

direct shear device. This is done carefully to avoid the sand

from spilling from the vessel.

6. The screws from the alignment for the shear box is taken

away. The gap of the shear box is more or less 0.025in. The

gap is unbolted with the gap screws, the gap screws are then

returned.

7. The mass of the soil is recorded again

using the same formula, (Mass of Can

+ Sand) - (Mass of Can) = Mass of

Sand.

8. The apparatus is then bring together

completely, three gages are then set to

zero in the dial gage, these are

horizontal and vertical gage; and shear

load gage.

9. A prearranged value is set for the

vertical load. A mass is placed on the hook under the apparatus. The bleeder valve is then

closed.

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

6

Laboratory Experiment No. 4

DIRECT SHEAR TEST

10. Using the electronic dialing machine, the motor of

the apparatus is started with a constant speed. The

screen is then monitored by taking a video so that

the values can be plotted correctly and accurately

without missing a data. The readings of the 3 gages

are then tabulated and plotted.

11. Three tests are made using 3 different prearranged

masses of vertical loads until the horizontal

displacement reaches 15% or the horizontal shear

capacity reaches its maximum or minimum.

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

7

Laboratory Experiment No. 4

DIRECT SHEAR TEST

DATA, RESULTS, AND COMPUTATIONS:

Shear Box inside Diameter: 6 cm

Area (A): 9π cm 2 = 4.382530517 ¿2

Shear Box Height: 3.6 cm

Soil Volume: 101.787602 cm3\

Mass of soil and pan: 172g

Mass of soil: 156g

g

Density of soil: 1.532603155 3

cm

Normal Stress: 0.6493055556 psi

TIME HORIZONTAL HORIZONTAL SHEAR STRESS

(s) DISPLACEMENT (mm) SHEAR FORCE (N) (psi)

0 0 0 0

5 0.20 2 0.104

10 0.39 2 0.104

15 0.59 2 0.104

20 0.80 2 0.104

25 0.98 2 0.104

30 1.22 2 0.104

35 1.39 4 0.208

40 1.56 4 0.208

45 1.78 4 0.208

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

8

Laboratory Experiment No. 4

DIRECT SHEAR TEST

Normal Stress: 1.280082358 psi

TIME HORIZONTAL HORIZONTAL SHEAR STRESS

(s) DISPLACEMENT (mm) SHEAR FORCE (N) (psi)

0 0 0 0

5 0.20 2 0.104

10 0.45 3 0.156

15 0.62 5 0.260

20 0.97 8 0.416

25 1.15 10 0.520

30 1.33 10 0.520

35 1.49 10 0.520

40 1.64 11 0.572

45 1.83 12 0.624

Normal Stress: 1.920123538 psi

TIME HORIZONTAL HORIZONTAL SHEAR STRESS

(s) DISPLACEMENT (mm) SHEAR FORCE (N) (psi)

0 0 0 0

5 0.11 1 0.052

10 0.32 1 0.052

15 0.53 4 0.208

20 0.75 5 0.260

25 0.92 5 0.260

30 1.12 9 0.468

35 1.33 10 0.520

40 1.57 11 0.570

45 1.78 13 0.676

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

9

Laboratory Experiment No. 4

DIRECT SHEAR TEST

COMPUTATIONS:

Trial 1:

Nv

Sv =

A

1.275 x 2.2 lbs

Sv = 2

4.382530517 ¿

Sv =0.6493055556 psi

Fh

τ=

A

2 x 0.2248 lbs

τ=

4.382530517 ¿2

τ =0.1025891316 psi

Trial 2:

Nv

Sv =

A

2.55 x 2.2 lbs

Sv = 2

4.382530517 ¿

Sv =1.280082358 psi

Fh

τ=

A

2 x 0.2248 lbs

τ=

4.382530517 ¿2

τ =0.1025891316 psi

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

10

Laboratory Experiment No. 4

DIRECT SHEAR TEST

Trial 3:

Nv

Sv =

A

3.825 x 2.2 lbs

Sv = 2

4.382530517 ¿

Sv =1.920123538 psi

Fh

τ=

A

1 x 0.2248

τ=

4.382530517 ¿2

τ =0.05129456581 psi

Sample Plot of Horizontal Shear Stress vs. Horizontal Displacement

Trial 1: Shear Stress vs. Horizontal Displacement

0.25

0.208 0.208 0.208

0.2

horizontal shear stress (PSI)

0.15

0.104 0.104 0.104 0.104 0.104 0.104

0.1

0.05

0

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Horizontal displacement (in)

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

11

Laboratory Experiment No. 4

DIRECT SHEAR TEST

Trial 2: Shear Stress vs. Horizontal Displacement

0.7

0.624

0.6 0.572

0.52 0.52 0.52

horizontal shear stress (PSI)

0.5

0.416

0.4

0.3 0.26

0.2 0.156

0.104

0.1

0

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Horizontal displacement (in)

Trial 3: Shear Stress vs. Horizontal Displacement

0.8

0.676

0.7

0.6 0.57

horizontal shear stress (PSI)

0.52

0.5 0.468

0.4

0.3 0.26 0.26

0.208

0.2

0.1 0.052 0.052

0

0

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Horizontal displacement (in)

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

12

Laboratory Experiment No. 4

DIRECT SHEAR TEST

Peak Shear Stress:

Trial 1: 0.208 psi

Trial 2: 0.624 psi

Trial 3: 0.676 psi

Normal Stress:

Trial 1: 0.6493055556 psi

Trial 2: 1.280082358 psi

Trial 3: 1.920123538 psi

Sample Plot of Shear Stress vs. Normal Stress

0.8

0.676

0.7

0.624

0.6

0.5

shear stress (PSI)

0.4

0.3

0.208

0.2

0.1

0

0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

Normal Stress (PSI)

Using regression: y=mx+c

y= (0.3675641993) x+0.0310191351

(Since c≈0, rewrite equation to y=0.3675641993x) → c=0, cohesionless

tan φ = m

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

13

Laboratory Experiment No. 4

DIRECT SHEAR TEST

φ = tan-1(0.3675641993)

φ =20.18162068 °

DISCUSSION OF RESULT AND CONCLUSION

Results showed that the vertical force is correlated directly with the horizontal force.

Having balance for the horizontal and vertical forces is required for the soil not to shear or fail.

Initially, a sand was chosen carefully, it was run in a sieve #4 pan to remove the excess large

particles and impurities. The mass of the soil was then weighed. The shear box height and

diameter were measured to determine the volume of the sand. The density of the soil was

m g

calculated using the formula ρ = . The density of the soil is 1.532603155 3 . The soil was

v cm

then placed inside the shear box together with the filter paper and a porous stone. The shear box

was assembled together with the direct shear apparatus. Consequently, the apparatus’ dial gage

were set to 0 for the horizontal, vertical and shear load gage. The machine was then run in a

normal constant speed. The displacement showing on the screen of the apparatus was then

monitored until such the diameter of the shear box has already displaced 15%. Three trials were

made with different weights which are 1.275kg, 2.55kg, and 3.825kg, this is to better show how

increasing the vertical load can directly affect the horizontal force.

The results of the horizontal displacement (mm), horizontal shear force (N), and shear

stress (psi) were tabulated. The displacement and shear stress were then plotted in an x vs. y

N

plane. The normal stress was calculated with the formula: sv = v , where sv is the vertical

A

N

stress, v is the vertical load and A is the area of the shear box. The shearing stress was

F

calculated with the formula: τ = h , where τ is the horizontal stress, F h is the horizontal load,

A

and A is the area of the shear box. The peak shear force was selected from the 3 tables. The shear

stress and normal stress was plotted in an X vs. Y plot and the best fit line was drawn from the

graph. Using the regression formula, the equation of the line is y = 0.3675641993x +

0.0310191351, the intercept can be assumed zero. Getting the tangent of the slope gives the

relationship of the horizontal and vertical stress. This is called the angle of internal friction. The

angle calculated is φ =20.18162068 °. The test sample selected is a sand which has a less

property in cohesion, the particles of sand does not bind with each other. A semi-circle was

drawn from the top of the peak shear stress, this represents as the Mohr’s circle of the selected

granular sand. Basing from table 12.1, the angle of internal friction calculated is an outlier, this is

just a basis of some common sands. The minimal error may be caused by the erroneous setup of

the machine and some human error.

It can be concluded safely that a drained sand is cohesionless and there is a direct

relationship between the normal and horizontal stress. It should be in right balance to avoid

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

14

Laboratory Experiment No. 4

DIRECT SHEAR TEST

failure of the soil from shearing. The test is done for the applications of analyzing the soil to

avoid any soil and foundation failures in the field.

REFERENCES:

ASTM D3080 / D3080M-11, Standard Test Method for Direct Shear Test of Soils Under

Consolidated Drained Conditions, ASTM International, West Conshohocken, PA, 2011.

Retrieved from: www.astm.org

Das, B., & Sobhan, K. (2014). Principles of Geotechnical Engineering (8th ed.). Chapter 12:

Shear Strength of Soil (pp. 429-437). Stamford, CT: Cengage Learning.

Guwahati, Iit. (2009, December 31). Methods of Shear Strength Determination. Retrieved from:

http://nptel.ac.in/courses/105103097/45

Hadjuk, Edward L. (2013). Shear Strength of Soil. Retrieved from:

shttp://faculty.uml.edu/ehajduk/Teaching/14.330/documents/14.3302013ShearStrength.pdf

Reddy, Krishna R. (2002). Engineering Properties of Soils Based on Laboratory Testing.

Retrieved from: http://cemmlab.webhost.uic.edu/Experiment%2012-Direct%20Shear.pdf

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

15

Laboratory Experiment No. 4

DIRECT SHEAR TEST

GROUP # 7:

Group Members:

Berroya, Lorenz Cedric - Data and Results

Federizo, Rodrigo - Introduction

Fulton John Michael - Conclusion

Jucutan, Roy Michael - Discussion of Results and Reference

Quiobo, Amond Eve - Methodology

Rosario, Ryan - Computation and Tabulation

Valdez, Adrienne - Pictures, Computations and Methodology

CE152L – GEOTECHNICAL ENGINEERING 2 (LABORATORY)

16

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Department of Civil EngineeringDocument20 pagesDepartment of Civil EngineeringMohammad ParvejNo ratings yet

- CV 311 - Lab 4 - Direct Shear TestDocument5 pagesCV 311 - Lab 4 - Direct Shear TestavnishnandNo ratings yet

- VL2021220102506 Ast09Document6 pagesVL2021220102506 Ast09ty juNo ratings yet

- Unconfined Compressive Strength TestDocument5 pagesUnconfined Compressive Strength TestManish Arya0% (1)

- Lab Manual Submitted To: DR Jahanzeb Israr Submitted By: Ubaid Ullah Registration Number: 2018 Civ 15 Section: ADocument94 pagesLab Manual Submitted To: DR Jahanzeb Israr Submitted By: Ubaid Ullah Registration Number: 2018 Civ 15 Section: AOmar ShahidNo ratings yet

- Direct Shear TestDocument24 pagesDirect Shear TestObaid Khalid100% (14)

- Direct Shear Test On Sand ASTM D 3080Document6 pagesDirect Shear Test On Sand ASTM D 3080Muhammad ImranNo ratings yet

- Direct ShearDocument4 pagesDirect ShearQUEIZNo ratings yet

- CONSOLIDATION TEST Lab Manual PDFDocument6 pagesCONSOLIDATION TEST Lab Manual PDFmmNo ratings yet

- Report - Borehole Shear TestDocument11 pagesReport - Borehole Shear TestsatheekNo ratings yet

- Unconfined Compression TestDocument9 pagesUnconfined Compression TestAyman SobhyNo ratings yet

- Lab Report #01 The Direct Shear Test (ASTM D-3080)Document18 pagesLab Report #01 The Direct Shear Test (ASTM D-3080)AHMED SOHELNo ratings yet

- Kuliah PSB 02 NewDocument10 pagesKuliah PSB 02 NewadhityamspNo ratings yet

- Undrained Triaxial Test: DescriptionDocument12 pagesUndrained Triaxial Test: Descriptionkirti pawarNo ratings yet

- Geo Lab ReportDocument12 pagesGeo Lab ReportArivalagan Revichandran100% (1)

- FE - 6th Sem - Lab Manual - H R TrivediDocument52 pagesFE - 6th Sem - Lab Manual - H R TrivediShreyas PatelNo ratings yet

- Direct Shear TestDocument19 pagesDirect Shear TestBusiNess100% (7)

- Direct Shear TestDocument11 pagesDirect Shear Testshahrolhazrien91% (34)

- Geotechnical Laboratory Semester 2: Open-Ended LabDocument8 pagesGeotechnical Laboratory Semester 2: Open-Ended LabNor AziraNo ratings yet

- Vane Shear TestDocument10 pagesVane Shear TestManikyaMayankNo ratings yet

- Direct Shear Test Soil ReportDocument12 pagesDirect Shear Test Soil ReportNAJA MOHAMEDNo ratings yet

- Direct Shear TestDocument13 pagesDirect Shear Testskyxiaochen0% (2)

- Preface: The Fieldwork Was Commenced On 22 January 2008 Completed On 29 January 2008Document23 pagesPreface: The Fieldwork Was Commenced On 22 January 2008 Completed On 29 January 2008SUMANT KUAMR ROYNo ratings yet

- Report-Direct Shear Test 1Document20 pagesReport-Direct Shear Test 1Ash BlackForest50% (2)

- Natural Soil Deposits and Subsoil Exploration: Dr. ToufighDocument79 pagesNatural Soil Deposits and Subsoil Exploration: Dr. ToufighAmirali SahebzamaniNo ratings yet

- Consolidation TestDocument6 pagesConsolidation TestManish AryaNo ratings yet

- Direct Shear TestDocument32 pagesDirect Shear TestVarun Shastry0% (1)

- 2018 Civ 35Document61 pages2018 Civ 35Omar ShahidNo ratings yet

- Literature Review: Application of in Situ Direct Shear Device To Shear Strength Measurement of Rockfill MaterialsDocument12 pagesLiterature Review: Application of in Situ Direct Shear Device To Shear Strength Measurement of Rockfill Materials8108295484No ratings yet

- Lab 0 - Rock Mechanics Lab SubmissionDocument44 pagesLab 0 - Rock Mechanics Lab SubmissionankeshNo ratings yet

- 2023 Laboratory Manual 1 - ConsolidationDocument9 pages2023 Laboratory Manual 1 - ConsolidationMa. Kate BallesterosNo ratings yet

- Experiment No. 10 Direct Shear TestDocument4 pagesExperiment No. 10 Direct Shear Testmuhammad irfanNo ratings yet

- CIVL6077 Ground Investigation and Soil Testing Lecture 4 In-Situ TestsDocument126 pagesCIVL6077 Ground Investigation and Soil Testing Lecture 4 In-Situ TestsHamza NadeemNo ratings yet

- Consolidation Practicum Report - Soil MechanicsDocument26 pagesConsolidation Practicum Report - Soil MechanicsShiela Ariesta EfendiNo ratings yet

- Geotechnical Engineering-II Lab CE-313L CH (0+1) : Instructor: Engr. Zia UllahDocument26 pagesGeotechnical Engineering-II Lab CE-313L CH (0+1) : Instructor: Engr. Zia UllahJawad AliNo ratings yet

- Lab UCTDocument9 pagesLab UCTnursyafiqa100% (1)

- Kujaban Agartala1Document29 pagesKujaban Agartala1SUMANT KUAMR ROYNo ratings yet

- InsituDocument48 pagesInsituLouis BrightonNo ratings yet

- Table of Content: Annexes: Bore Hole Logs Laboratory Test Result Figures and PhotographsDocument19 pagesTable of Content: Annexes: Bore Hole Logs Laboratory Test Result Figures and PhotographsOm ConsultantNo ratings yet

- Civil Engineering Department Lab ManualDocument47 pagesCivil Engineering Department Lab Manualubaid quaziNo ratings yet

- Geotechnical Engineering LAB: Subhadip PalDocument8 pagesGeotechnical Engineering LAB: Subhadip PalGolu kumarNo ratings yet

- 2 Ss Unconfined Compression TestDocument10 pages2 Ss Unconfined Compression TestIqi IqahNo ratings yet

- Geomechanics - Lab Session No 8 - Direct Shear Test SheetDocument2 pagesGeomechanics - Lab Session No 8 - Direct Shear Test SheetharinderNo ratings yet

- Unconfined Compression Tests PDFDocument6 pagesUnconfined Compression Tests PDFHansen A JamesNo ratings yet

- Shear Box TestDocument13 pagesShear Box TestNoor100% (1)

- 1111PCX - ReportDocument6 pages1111PCX - ReportKamran JUTTNo ratings yet

- Test On Soils Direct, TriaxialDocument26 pagesTest On Soils Direct, TriaxialSpiderman THE SaviourNo ratings yet

- Cep GeotechnicalDocument14 pagesCep GeotechnicalAzmat NaseemNo ratings yet

- Ce121l Fluid Mechanics Laboratory ManualDocument51 pagesCe121l Fluid Mechanics Laboratory ManualJeremy PagdagdaganNo ratings yet

- Geotechnical Engineering Lab Report 2Document7 pagesGeotechnical Engineering Lab Report 2IanNo ratings yet

- Experiment 11 ConsolidationDocument26 pagesExperiment 11 ConsolidationRajeev Kusugal100% (1)

- Unconsolidated Undrained TriaxialDocument14 pagesUnconsolidated Undrained TriaxialSulaksha WimalasenaNo ratings yet

- Test 08Document6 pagesTest 08Ateafac Anastasia NjuafacNo ratings yet

- DS - Safyra Fix PDFDocument10 pagesDS - Safyra Fix PDFSafyra NurshafiyanaNo ratings yet

- Calc Copy PasteDocument3 pagesCalc Copy PasteLorenz BerroyaNo ratings yet

- '17-'18-3T Anal Geom 5 PtsDocument9 pages'17-'18-3T Anal Geom 5 PtsLorenz BerroyaNo ratings yet

- '17-'18-3T Solid Mens 5 PtsDocument3 pages'17-'18-3T Solid Mens 5 PtsLorenz BerroyaNo ratings yet

- '17-'18-3T Trigonometry 5 PtsDocument10 pages'17-'18-3T Trigonometry 5 PtsLorenz BerroyaNo ratings yet

- '17-'18-3T Algebra 5 PtsDocument10 pages'17-'18-3T Algebra 5 PtsLorenz BerroyaNo ratings yet

- '17-'18-3T Calculus 5 PtsDocument1 page'17-'18-3T Calculus 5 PtsLorenz BerroyaNo ratings yet

- BEC198 Solutions PhysicsDocument20 pagesBEC198 Solutions PhysicsEli Lilly Cemanes MarasiganNo ratings yet

- BEC198 - 1 Course SyllabusDocument4 pagesBEC198 - 1 Course SyllabusLorenz BerroyaNo ratings yet

- Solns of 5 PointsDocument2 pagesSolns of 5 PointsLorenz BerroyaNo ratings yet

- FDocument16 pagesFLorenz BerroyaNo ratings yet

- bBEC sOLUTIONSDocument3 pagesbBEC sOLUTIONSLorenz BerroyaNo ratings yet

- BEC198 (Finals)Document180 pagesBEC198 (Finals)Lorenz BerroyaNo ratings yet

- BEC Finals - 2Document2 pagesBEC Finals - 2Lorenz BerroyaNo ratings yet

- '16-'17-1T-CHEM 5 PtsDocument21 pages'16-'17-1T-CHEM 5 PtsLorenz BerroyaNo ratings yet

- Multiple Choice 2Document37 pagesMultiple Choice 2Dave SalvadorNo ratings yet

- Computation of Tension MembersDocument15 pagesComputation of Tension MembersLorenz BerroyaNo ratings yet

- Group 7 Plumbing EstimateDocument1 pageGroup 7 Plumbing EstimateLorenz BerroyaNo ratings yet

- EstimatesDocument2 pagesEstimatesLorenz BerroyaNo ratings yet

- Rak For Shitte BecDocument11 pagesRak For Shitte BecIsofNo ratings yet

- Group 7 Electrical EstimateDocument1 pageGroup 7 Electrical EstimateLorenz BerroyaNo ratings yet

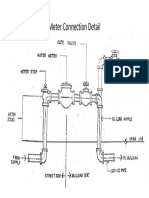

- Meter Connection DetailDocument1 pageMeter Connection DetailLorenz BerroyaNo ratings yet

- MP IndexDocument14 pagesMP IndexLorenz BerroyaNo ratings yet

- Geomitric DistributionDocument18 pagesGeomitric DistributionTaanzNo ratings yet

- 3 - Motion (Worksheet)Document13 pages3 - Motion (Worksheet)VARSHITHNo ratings yet

- Array RotationDocument3 pagesArray RotationAnshulNo ratings yet

- Chibesa Physics PDFDocument156 pagesChibesa Physics PDFMusanta Simmon SimzNo ratings yet

- Rhumb Line Calculations, BennetDocument8 pagesRhumb Line Calculations, Bennetandresmejia68No ratings yet

- Vedic MathsDocument8 pagesVedic Mathsnithin s gowda100% (1)

- Sec 1 Test 1 Factors and MultiplesDocument3 pagesSec 1 Test 1 Factors and MultiplesRanNo ratings yet

- BankSoalan Cikgujep Com Johor Add Maths P1 2017Document41 pagesBankSoalan Cikgujep Com Johor Add Maths P1 2017Loh Chee WeiNo ratings yet

- Mean-Variance Analysis and Efficient FrontierDocument69 pagesMean-Variance Analysis and Efficient FrontierNIKHIL DARYAVSING BHAMARENo ratings yet

- CodeVisionAVR Revision History 20051208Document20 pagesCodeVisionAVR Revision History 20051208letanbaospkt06No ratings yet

- Math Standards Grade 6Document8 pagesMath Standards Grade 6truadminNo ratings yet

- Chapter 2 Problem Analysis and DesignDocument35 pagesChapter 2 Problem Analysis and DesignWAN FAZLINI IDAYU BINTI WAN FAKARI - PKTNo ratings yet

- Simplex Algorithm - WikipediaDocument20 pagesSimplex Algorithm - WikipediaGalata BaneNo ratings yet

- Aggregate Demand I: Building The IS-LM Model: Questions For ReviewDocument10 pagesAggregate Demand I: Building The IS-LM Model: Questions For ReviewErjon SkordhaNo ratings yet

- CIVN3001-FINAL REPORT ... MDocument20 pagesCIVN3001-FINAL REPORT ... MThabiso MotalingoaneNo ratings yet

- Linear Differential Equations. ProblemsDocument14 pagesLinear Differential Equations. ProblemsPop RobertNo ratings yet

- Wellbore Heat Losses and Casing Temperatures During Steam Injection - API-66-025Document8 pagesWellbore Heat Losses and Casing Temperatures During Steam Injection - API-66-025nicessg@gmail.comNo ratings yet

- Asservissement PDFDocument5 pagesAsservissement PDFMouad TalhaNo ratings yet

- Linear Systems With Generalized Linear Phase Systems With Linear Phase Generalized Linear PhaseDocument12 pagesLinear Systems With Generalized Linear Phase Systems With Linear Phase Generalized Linear PhaseAbdullah BilalNo ratings yet

- ĐW /P Is An Exact Differential 1/P Is An Integrating FactorDocument18 pagesĐW /P Is An Exact Differential 1/P Is An Integrating FactorIrma Kurnia SariNo ratings yet

- Assignment-I - 1st SemDocument2 pagesAssignment-I - 1st SemA1 TRIANGLENo ratings yet

- Rudita Cahya Nadila - CH 4Document8 pagesRudita Cahya Nadila - CH 4Giovanni HebertNo ratings yet

- Iitk Cse ResumeDocument3 pagesIitk Cse ResumeAnimesh GhoshNo ratings yet

- Skills in Mathematics Integral Calculus For JEE Main and Advanced 2022Document319 pagesSkills in Mathematics Integral Calculus For JEE Main and Advanced 2022Harshil Nagwani100% (3)

- Final Exam - Basic MathDocument1 pageFinal Exam - Basic MathSheila Marie AmigoNo ratings yet

- Product Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667Document12 pagesProduct Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667jhon vargasNo ratings yet

- Hungarian Algorithm For Excel - VBADocument9 pagesHungarian Algorithm For Excel - VBAYinghui LiuNo ratings yet

- Immediate InferenceDocument56 pagesImmediate InferenceEdgardoNo ratings yet

- Polarization WavesDocument37 pagesPolarization WavesNil TaiiayNo ratings yet

- Short - Notes Complex Numbers - pdf-59Document10 pagesShort - Notes Complex Numbers - pdf-59aditya devNo ratings yet