Professional Documents

Culture Documents

WSPS 05 (1638A-English)

Uploaded by

Michael Dela CruzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSPS 05 (1638A-English)

Uploaded by

Michael Dela CruzCopyright:

Available Formats

Water Saturation Point Sensor Sheet No.

Series WSPS 05 1638 A

1. Water Saturation Point Sensor

1.1. Type index: (ordering example)

WSPS 05. VA. G. 4

1 2 3 4

1 series:

WSPS 05 = water saturation point sensor

2 material: (housing)

VA = stainless steel

3 connection:

G = thread

4 connection size:

4 = G¾

2. Technical data:

measuring range: saturation level: 0 -100 %

temperature: - 25... +100°C / - 13°F... 212°F

accuracy: saturation level: 2 %

temperature: 0,4 %

operating pressure: 0... 25 bar / 0... 362,5 psi

tip velocity: 2 m/s / 6,6 ft/s

ambient temperature: - 25... + 85 °C / - 13°F...185°F

temperature range of fluid: - 40... + 90°C / - 40°F... 194°F

temporary +100 °C / 212 °F

survival temperature: 90 / 194°F

storage temperature: - 40... + 100°C / - 40°F... 212°F

power supply: 12... 30 V DC

analogue outputs: 2x 4... 20 mA

protection class: IP 65

ohmic resistance:

3. Pin assignment:

Pin 1 + 12... 30 V DC

Pin 2 output 4... 20 mA

(saturation)

Pin 3 + 12... 30 V DC

Pin 4 output 4... 20 mA

(temperature)

Cable color (connection cable)

1: brown (+ 12... 30 V DC)

2: white (4... 20 mA) saturation

3: blue (+ 12... 30 V DC)

4: black (4... 20 mA) temperature

1 (3)

+ 12...30 V DC

WSPS 05

mA 0 V DC

2 (4)

The maximum acceptable ohmic resistance at 24 V DC is 600

(current source).

Changes of measures and design are subject to alteration!

EDV 06/11

Friedensstrasse 41, 68804 Altlussheim, Germany

phone +49 (0)6205 2094-0 e-mail info-internormen@eaton.com

fax +49 (0)6205 2094-40 url www.eaton.com/filtration

3.1 Application areas - Compatibility

- hydraulic oils H, HL, HLP and HV

- gear oils C, CL, CLP

- motor oils, gas oils

- MIL-H-5606 E

- vegetable oils (HTG, Triglyceride)

- synthetic ester (HEES)

4. Description:

4.1. Effects of water in hydraulic oil

Due to its negative effects on the hydraulic and lubricating characteristics of a fluid, water is a type of contamination, which has to be

restricted unconditionally.

Some of the effects are for example

- the loss of additives,

- early aging,

- increase of acid value,

- or aggravation of the fluid’s filterability.

The manifold consequences for the hydraulic or the lubrication system may be significantly heavy wear, an immense increase in the risk

of failure as well as malfunctions.

But these influences do not depend on the total amount of water in a fluid. It is of decisive importance whether or not the water within the

system is free or emulsified.

Only free water is capable of causing these biological and chemical reactions.

Therefore it is of great importance to show whether free water is present in a hydraulic or lubrication system or not.

4.2. Measuring principle

The WSPS 05 does utilize a capacitive sensor for measurements. It uses polymeric foil as dielectric for interelectrode capacitance.

This foil is capable of absorbing water molecules due to its microporous structure. This absorption causes a change in capacity of this

element, which is converted into the output signal between 4 and 20 milli amps. Measurements are the saturation level (water

saturation) of the fluid in percent.

In addition to that a temperature sensor is integrated to determine the exact temperature of the fluid while measuring (4...20 mA).

The WSPS 05 – Sensor gives the saturation level of the fluid with water in percent.

The indication 100 % means that the fluid is saturated totally.

Saturation values depend on the temperature!

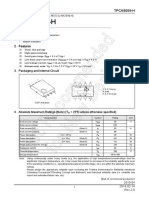

5. Sensor characteristic:

Sensor - Kennline/ sensor - characteristic Temeratur - Kennlinie / temperture - charateristic

20

20

18

18

Ausgangsssignal in mA/

Ausgangssignal in mA/

16 16

output signal in mA

output signal in mA

14 14

12 12

10 10

8 8

6 6

4

4

2

2

0

0

0 10 20 30 40 50 60 70 80 90 100

-25 -15 -5 5 15 25 35 45 55 65 75 85 95

% Sättigung/ saturation °C Temperatur/ °C temperature

6. Maintenance/sensor cleaning:

Cleaning the WSPS 05 sensor is necessary from time to time, especially if the sensor is being used for different fluids..

As cleaning fluid, clean petroleum benzin or even clean isopropanol can be used.

When cleaning the sensor, please remove the protective cap and proceed with extreme caution.

E 1638 A

You might also like

- BMXAMI0410: Product Data SheetDocument5 pagesBMXAMI0410: Product Data Sheetمحمد امين التشغيل الآليNo ratings yet

- Modicon X80 Modules - BMXAMI0410Document5 pagesModicon X80 Modules - BMXAMI0410Reibi VillarrealNo ratings yet

- PresostatosDocument5 pagesPresostatosOzias CruzNo ratings yet

- BMXAMI0410Document5 pagesBMXAMI0410Fath Indo PerkasaNo ratings yet

- Modicon X80 Modules - BMXAMI0810 PDFDocument5 pagesModicon X80 Modules - BMXAMI0810 PDFRahul Raj SinghNo ratings yet

- IP Conveter Norgen - 100XDocument2 pagesIP Conveter Norgen - 100XAnkit RedkarNo ratings yet

- BMXAMO0210Document1 pageBMXAMO0210anakhost2877No ratings yet

- Modicon X80 I - Os - BMXAMI0810Document5 pagesModicon X80 I - Os - BMXAMI0810vanesaNo ratings yet

- Modicon X80 Modules - BMXAMI0810Document5 pagesModicon X80 Modules - BMXAMI0810Prasad ReddyNo ratings yet

- Modicon X80 Modules - BMXAMI0800 - Modulo Entradas AnalogicasDocument5 pagesModicon X80 Modules - BMXAMI0800 - Modulo Entradas AnalogicasEdwin RincónNo ratings yet

- Bmxami0800 PDFDocument2 pagesBmxami0800 PDFJaanvi NanakNo ratings yet

- Kde en 923 0862Document32 pagesKde en 923 0862joseloaiza378No ratings yet

- Modicon x80 I Os Bmxami0810Document5 pagesModicon x80 I Os Bmxami0810ISLAMIC LECTURESNo ratings yet

- Sensor Array With Load Valve: Simultaneously Measures Flow, Pressure and TemperatureDocument2 pagesSensor Array With Load Valve: Simultaneously Measures Flow, Pressure and TemperatureraptorebooksNo ratings yet

- Radar Level Meter CatalogueDocument15 pagesRadar Level Meter CatalogueagusNo ratings yet

- 26Ghz High Frequency Radar Level Meter: Guangdong Kaidi Energy Technology Co., LTDDocument4 pages26Ghz High Frequency Radar Level Meter: Guangdong Kaidi Energy Technology Co., LTDJayesh SanganiNo ratings yet

- Epever Datasheet Vs BNDocument3 pagesEpever Datasheet Vs BNVinícius BastosNo ratings yet

- STB 120 N 4 LF 6Document18 pagesSTB 120 N 4 LF 6Manuel QuirozNo ratings yet

- Piezorresistive Transmitters: Model: 21R - 21 SR / MRDocument2 pagesPiezorresistive Transmitters: Model: 21R - 21 SR / MRMarcelo PellizzaNo ratings yet

- 2p en Uds3v3Document2 pages2p en Uds3v3Mantenimiento Trety T2No ratings yet

- Technical Data Sheet EP..R+MP: Type OverviewDocument10 pagesTechnical Data Sheet EP..R+MP: Type OverviewJoao MoreiraNo ratings yet

- TST PM82 enDocument2 pagesTST PM82 endawitNo ratings yet

- En Hygromil'sDocument1 pageEn Hygromil'sYersson MesiasNo ratings yet

- DB18Document2 pagesDB18taleb 6269No ratings yet

- Analog InputDocument4 pagesAnalog InputElektrik SkNo ratings yet

- Lab TransductorDocument6 pagesLab TransductorDie GueinsNo ratings yet

- TPCP8010 TPCP8010 TPCP8010 TPCP8010Document9 pagesTPCP8010 TPCP8010 TPCP8010 TPCP8010Valentin IFSNo ratings yet

- Epever Datasheet Vs BNDocument3 pagesEpever Datasheet Vs BNMartha ortega izquierdoNo ratings yet

- D4240 Manual I56-3936Document8 pagesD4240 Manual I56-3936Lynk DnNo ratings yet

- Electronic Pressure Transducers: Upa2 Upa2Document2 pagesElectronic Pressure Transducers: Upa2 Upa2Qatar home RentNo ratings yet

- Data Sheet: Waveseries Was5 OlpDocument7 pagesData Sheet: Waveseries Was5 OlpMich SpikeNo ratings yet

- Data Sheet of MonitorDocument3 pagesData Sheet of MonitorNilesh ChavanNo ratings yet

- Modicon TM3 - TM3TI4Document9 pagesModicon TM3 - TM3TI4kpeNo ratings yet

- Brochure-Universal Relays V2.1 ENGaDocument12 pagesBrochure-Universal Relays V2.1 ENGaCheng Kean KeongNo ratings yet

- DPDocument6 pagesDPAhmed MoharramNo ratings yet

- HPT604 Level Sensor Datasheet-Fuel Application - RS485Document6 pagesHPT604 Level Sensor Datasheet-Fuel Application - RS485Md ShNo ratings yet

- DS SP6014 GB 51924Document6 pagesDS SP6014 GB 51924dennyyusufNo ratings yet

- Radar Level Meter Data SheetDocument14 pagesRadar Level Meter Data Sheetamir kamaliNo ratings yet

- LCDDocument26 pagesLCDdozer_kamilNo ratings yet

- Tecsis P3276Document4 pagesTecsis P3276benNo ratings yet

- Tk58e06n1 Tk58e06n1 Tk58e06n1 Tk58e06n1Document9 pagesTk58e06n1 Tk58e06n1 Tk58e06n1 Tk58e06n1AllianceNo ratings yet

- FBRXS00005 1Document5 pagesFBRXS00005 1KholilNo ratings yet

- Product Data Sheet: Earth-Leakage Relay RH10M - 30 Ma - 240 VDocument3 pagesProduct Data Sheet: Earth-Leakage Relay RH10M - 30 Ma - 240 VDarwin LibrandaNo ratings yet

- Link NetDocument3 pagesLink Netsasa hhNo ratings yet

- Process Indicators: Ordering InformationDocument3 pagesProcess Indicators: Ordering InformationRajesh KumarNo ratings yet

- Gran Transmisor de PresionDocument4 pagesGran Transmisor de PresionАнтони Морено СавельёсNo ratings yet

- TK56E12N1Document9 pagesTK56E12N1tirekNo ratings yet

- TD RWG Ewg Poti enDocument3 pagesTD RWG Ewg Poti enJanko PekoljNo ratings yet

- Humidity/temperature Transmitter Duct MountingDocument2 pagesHumidity/temperature Transmitter Duct Mountingkristyan kawayNo ratings yet

- Belimo EP..R MP Datasheet En-GbDocument11 pagesBelimo EP..R MP Datasheet En-GbNoah MusundiNo ratings yet

- DS KM11 enDocument7 pagesDS KM11 enOmar EldrwanyNo ratings yet

- TPCA8059-H Datasheet en 20140214Document9 pagesTPCA8059-H Datasheet en 20140214vinuNo ratings yet

- EPEVER Datasheet XTRADocument3 pagesEPEVER Datasheet XTRAGem RNo ratings yet

- Logo Tech Data Expansion en PDFDocument6 pagesLogo Tech Data Expansion en PDFDezső LőcseiNo ratings yet

- BMXAMI0410: Product Data SheetDocument2 pagesBMXAMI0410: Product Data SheetJaanvi NanakNo ratings yet

- CRI P 340 - EngDocument4 pagesCRI P 340 - EngJerNo ratings yet

- Bühler Condition Monitor BCM-LS: Continuous Condition and Liquid Level Monitor For Lubricating and Hydraulic OilsDocument3 pagesBühler Condition Monitor BCM-LS: Continuous Condition and Liquid Level Monitor For Lubricating and Hydraulic Oilsseve1No ratings yet

- Datasheet RevPi AIODocument2 pagesDatasheet RevPi AIOsebadansNo ratings yet

- TK-PS EnclosureDocument3 pagesTK-PS EnclosureMichael Dela CruzNo ratings yet

- S-Convert Ownman v1sDocument8 pagesS-Convert Ownman v1sMichael Dela CruzNo ratings yet

- Soundcheckchecklist 1 1Document2 pagesSoundcheckchecklist 1 1Michael Dela CruzNo ratings yet

- QES1319 02141 DrawerDocument1 pageQES1319 02141 DrawerMichael Dela CruzNo ratings yet

- Product Data Sheet: Acti9 iC60H 2P 6A C Miniature Circuit BreakerDocument3 pagesProduct Data Sheet: Acti9 iC60H 2P 6A C Miniature Circuit BreakerMichael Dela CruzNo ratings yet

- Analog Power Meter 90deg WQDocument4 pagesAnalog Power Meter 90deg WQMichael Dela CruzNo ratings yet

- Using 4-20 Ma Sensors With 0-20 Ma InputsDocument1 pageUsing 4-20 Ma Sensors With 0-20 Ma InputsMichael Dela CruzNo ratings yet

- Kymco Kpipe 125Document57 pagesKymco Kpipe 125Michael Dela CruzNo ratings yet

- Mmse ProofDocument2 pagesMmse ProofQaddafi KhanNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- 4.1overview of Preventive MaintenanceDocument32 pages4.1overview of Preventive MaintenanceVANESSA ESAYASNo ratings yet

- Con-E-Co Lopro 427cm SpecsheetDocument1 pageCon-E-Co Lopro 427cm SpecsheetGrupo remcoNo ratings yet

- EC-II SyllabusDocument1 pageEC-II SyllabusThiyagarajan VelayuthamNo ratings yet

- CCM8 5 D Information SheetDocument1 pageCCM8 5 D Information SheetBalder LambertNo ratings yet

- FT2000 E1421t A4 0116Document28 pagesFT2000 E1421t A4 0116Niladri Bihari PatraNo ratings yet

- Wall Mounted: Split Type Room Air ConditionerDocument18 pagesWall Mounted: Split Type Room Air ConditionerGenstargazerNo ratings yet

- Widmann Mig Tig Mma-160 ManualDocument24 pagesWidmann Mig Tig Mma-160 ManualCleive Santos100% (1)

- 1-NKT Katalog Cable Accessories 7.2 42kV EnglishDocument76 pages1-NKT Katalog Cable Accessories 7.2 42kV EnglishlatifNo ratings yet

- CM2 User Manual, Magnetometer Supplement 1 - 1Document10 pagesCM2 User Manual, Magnetometer Supplement 1 - 1quangNo ratings yet

- Cordless Drill Motor DesignDocument11 pagesCordless Drill Motor DesignstephenNo ratings yet

- FILE - 20191119 - 154107 - LTE Training FL16ADocument137 pagesFILE - 20191119 - 154107 - LTE Training FL16ATuan Pham100% (1)

- Ics Telecom NG EngDocument6 pagesIcs Telecom NG EngzakibahliwahNo ratings yet

- TES P 122 10 R0 Transmission Lines GroundingDocument28 pagesTES P 122 10 R0 Transmission Lines GroundingPrabhi ThomasNo ratings yet

- CM 8880Document8 pagesCM 8880Pravat SatpathyNo ratings yet

- Physics O Level Definition and Law and Principles ListDocument9 pagesPhysics O Level Definition and Law and Principles ListTien Wai NgNo ratings yet

- GE Series RatingDocument12 pagesGE Series RatingdanshitNo ratings yet

- Dq0 Transform - Open Electrical PDFDocument3 pagesDq0 Transform - Open Electrical PDFb33lawNo ratings yet

- AutotransformerDocument85 pagesAutotransformerbalaeee123No ratings yet

- Esq - p1 - Ifc - qf103 - Foodservice Electrical Spot Connection PlanDocument1 pageEsq - p1 - Ifc - qf103 - Foodservice Electrical Spot Connection PlanMiguel MartinezNo ratings yet

- Evaluation of Impedance Parameters in Transmission LinesDocument72 pagesEvaluation of Impedance Parameters in Transmission Linesjwsmith60No ratings yet

- Question Bank Digital ElectronicsDocument12 pagesQuestion Bank Digital ElectronicsUrvin MistryNo ratings yet

- Eaton Harmonic Correction Unit Brochure PA157001ENDocument4 pagesEaton Harmonic Correction Unit Brochure PA157001ENmohsin shaikhNo ratings yet

- 033Document5 pages033hiddenhidden16No ratings yet

- Catalogue Channel Master Offset AntennaDocument2 pagesCatalogue Channel Master Offset Antennaazertd2No ratings yet

- Orcad LayoutDocument21 pagesOrcad LayoutjeepschuleNo ratings yet

- 6800+ Series: Safety Instructions and Standards (For Use With FR6800+MB)Document18 pages6800+ Series: Safety Instructions and Standards (For Use With FR6800+MB)Techne PhobosNo ratings yet

- Carbon Brush OnlyDocument11 pagesCarbon Brush OnlyPrashant SinghNo ratings yet