Professional Documents

Culture Documents

Yamato Fume Hood LDS Brochure

Uploaded by

armanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yamato Fume Hood LDS Brochure

Uploaded by

armanCopyright:

Available Formats

Fume Hood

LDS Series

Fume hood with fixed exhaust air volume

Main unit is made of steel, chemical resistant powder coating

applied; excellent fire resistance

Non-asbestos, non-combustible veneer interior with excellent

chemical and heat resistance

Selectable work surface material

Storage located in the lower base (not applicable to benchtop type)

Equipped with multi-slit baffle to efficiently exhaust harmful gas in

the fume hood

Safety features include door drop prevention stopper, ventilator

delay timer and exhaust blower activation monitor

Outlets and switches are located at an easy operating height

Selectable air speed meter, which digitally displays the front air

speed and exhaust air volume (option)

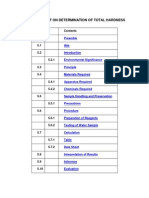

Model Guide

LDS - 150 S A

Shape

None: Standard

A: Air curtain

LDS150 T: Benchtop

J: Low-ceiling

Common specifications Working surface material

Exterior Cool-milling steel, chemical-resistant baked paint finish S: Ceramitite

E: Epoxy resin

Interior Non-asbestos, non-combustible decorative board (baffle

plate: multi-slit type) K: Ceramic steel plate

Glass window Reinforced glass, 6mm thickness, balance weight type Width dimension

Water faucet Single goose neck type, 1pc. 120: 1200mm

Outlet AC115V 15A with dual grounding wire (dropout prevention) 1pc. 150: 1500mm

Fluorescent lamp 120/150 model 32W, 180 model 40W, 1pc. each 180: 1800mm

Safety feature Door drop prevention stopper, ventilator delay timer, exhaust Model name

blower activation monitor

Individual Specifications

Standard type LDS-120 LDS-150 LDS-180

Standard discharge air quantity (m3/min) 12 16 19

Static pressure within the machine Pa (mmH2O) 30 (3) 59 (6) 79 (8)

External dimensions (W x D x H mm) 1200 x 750 x 2400 1500 x 750 x 2400 1800 x 750 x 2400

Weight (kg) ~290 ~330 ~370

Air curtain type LDS-120A LDS-150A LDS-180A

Standard discharge air quantity (m3/min) 12 16 19

Static pressure within the machine Pa (mmH2O) 30 (3) 59 (6) 79 (8)

Air flow (m3/min) 8.4 11.2 13.3

Air flow pressure within the machine Pa (mmH2O) 20 (2) 35 (3.6) 49 (5)

Air flow duct Each duct PVC with I.D.400mm O.D.100mm, connected with a half flange

Applicable air supply duct PVC with I.D.211mm O.D.216mm

External dimensions (W x D x H mm) 1200 x 750 / 1020 x 2600 1500 x 750 / 1020 x 2600 1800 x 750 / 1020 x 2600

Weight (kg) ~340 ~380 ~440

Benchtop type LDS-120T LDS-150T LDS-180T

Standard discharge air quantity (m3/min) 12 16 19

Static pressure within the machine Pa (mmH2O) 30 (3) 59 (6) 79 (8)

External dimensions (W x D x H mm) 1200 x 750 x 1550 1500 x 750 x 1550 1800 x 750 x 1550

Weight (kg) ~130 ~150 ~170

Low-ceiling type LDS-120J LDS-150J LDS-180J

Standard discharge air quantity (m3/min) 10 13 16

Static pressure within the machine Pa (mmH2O) 25 (2.5) 39 (4) 59 (6)

External dimensions (W x D x H mm) 1200 x 750 x 2100 1500 x 750 x 2100 1800 x 750 x 2100

Weight (kg) ~280 ~320 ~360

Yamato Scientific America Inc. LDS Series www.yamato-usa.com

CATV1-201701

277

85

Frontage : A

1200 : 960

211

1500 : 1260

Frontage 1800 : 1560

277

277

211

220

B B B B

210

210

ExhaustExhaust

duct duct Dimension drawing (mm) Exhaust duct plan 750

Piping 750

plan

ø261-ø267(PVC)

ø261-ø267(PVC) Exhaust Exhaust

Frontage

duct :A 277 : B

Frontage W: Water supply (1/2B)

duct

1200 : 600

1200 : 600 D: Drainage (11/2B)

210

Intake duct

Intake duct 1200 : 960 1500 : 750

1200 : 600

220

1500 : 750

665

665

400×100(PVC)

400×100(PVC) 1500:1260 1800 : 900

1800 : 900

1500:750 E1: Electricity1ø 100V

Intake

1800:1560 Intake 1800:900 E2: Electricity3ø 200V

duct duct

753

200

350

685 B B 100

200

B 150 B 200

210

100 100

150

A 200 200

150 150 300 300

210

Exhaust duct

~974

1200

150

865

2400

ø261-ø267(PVC)

737

Standard Exhaust

: 給水(1/2B)

W~530 W : 給水(1/2B) E1 E2duct

DW

type E1 E2 DE1

W E2 D W

D : 排水(1-1/2B)

D : 排水(1-1/2B) 1200 : 600

Intake duct

150

150

E1 : 電気1φ100V 1500 : 750

665

E1 : 電気1φ100V

E2 : 電気3φ200V

E2 : 電気3φ200V

Frontage : A 400×100(PVC) 1800 : 900

850

Intake

850

1200 : 960

1500 : 1260 duct

100

1800 : 1560 Exhaust duct dia.: ø261~ø267 (PVC)

200

Frontage 750 150 200

277 1020 1020

80

80

150

E1 E2 D W

211

320

550

320

100

550

B B B B B B 200

B

210

885

885

210

B

B BB B 150 300

Exhaust duct Exhaust duct

150

150

間口 B間口 ø261-ø267(PVC)

B Exhaust ø261-ø267(PVC) Exhaust

~974

210~974

A A

277 1200B: 600 duct Frontage:B

1200

duct W : 給水(1/2B)

1200

Air curtain 間口 1200 : B600

間口 1200 : 600 E1 E2 D W 1200 : 600

210

1500 : 1200

750

865

2600

Intake

1500 : 750 duct

865

1200 : 600 : 600 D : 排水(1-1/2B)

2600

Intake1500

duct: 750

737

220

737

665

type ~530 ~5301800 : 1500

900 1500 : 750

150

210

210

665

1500 : 750 1800:400×100(PVC)

: 900

750

1800 : 900

400×100(PVC) E1 : 電気1φ100V

ダクト径ダク : φ261-φ267(PVC) 1800 : 900 1800 : 900 1800 : 900

ト径 : φ261-φ267(PVC) Intake

Intake E2 : 電気3φ200V

ダクト径 : ダク φ261-φ267(PVC)

ト径 : φ261-φ267(PVC) duct

Frontage :A

Frontage :A duct

850

850

1200 : 960

850

850

1200 : 960

750 750 1500 : 1260

1500 : 1260 Exhaust duct dia.: ø261~ø267 (PVC)

1800 : 1560

1800 : 1560 Intake duct: 400 x 100 (PVC)

Frontage 750

210

Frontage 750

100 100

200 200

150 300 753

753

200

200

150 300 100 B B 1020

200

80

150 300 100

W : 給水(1/2B) 200

B B

350

350

200

100

E1 E2 DE1

W E2 D W W : 給水(1/2B) 150 300

685

685

D : 排水(1-1/2B)

D : 排水(1-1/2B) 間口 B

150

150 200

320

~974 150

550

E1 : 電気1φ100V

E1 : 電気1φ100V W : 給水(1/2B) 1200 : 600

150

150

E2 : 電気3φ200V E1 E2 D W

1550

1550

885

Benchtop E2 : 電気3φ200V D : 排水(1-1/2B)

間口 B W : 給水(1/2B)

210

1500 : 750

150

A A

~974

E1 E2 D W

150

1200

1200

type E1 E2 D W E1 : 電気1φ100V D : 排水(1-1/2B)

1200 : 600 1800 : 900

150

865

865

E2 : 電気3φ200V E1 : 電気1φ100V

150

210

770

770

~530 ~530 間口 A 間口 A 1500 : 750

1200 : 9601200 : 960 ダクト径 : φ261-φ267(PVC) E2 : 電気3φ200V

~974

1800 : 900A

1200

1500 : 1260

1500 : 1260

Frontage Frontage 750 750 1800 : 1560

1800 : 1560 ダクト径 : φ261-φ267(PVC)

865

2600

Exhaust duct dia.: ø261~ø267 (PVC)

737

~530

100

1020

100

Fro

80

850

850

B B 1020

100 12

250

80

250

200

500

15

500

150 300

320

550

Low-ceiling 753 18

150

200

~774

150

A

885

~774

A

間口 Frontage

B

1000

750

320

550

1000

type

750

1200 : 600 W : 給水(1/2B

750

587

885

~530 E1 E2 D W

587

2100

~530

2100

150

D : 排水(1-1/

210

1500 : 750

350

~974 150

~974

A 1800 : 900 E1 : 電気1φ1

865685

1200

150

間口 A間口 A E2 : 電気3φ2

ダクト径 : φ261-φ267(PVC)

2600

A

850

850

150

1200 : 960

737

Exhaust duct dia.: ø261~ø267 (PVC)

850

850

1200 : 960 ~530

1200

1550

1500 : 1260

1500 : 1260

A

~974

865

2600

1200

1800 : 1560

1800 : 1560

737

Frontage 750 ~530

850865

Frontage 750

Frontage :A

770

~530 間口 A

850

1200 : 960

1200 : 960

1500 : 1260 Fro

Airflow 1500: 1560

1800 : 1260

850

Frontage 100750

850

1800 : 1560 12

Frontage 200 750 15

150 300 18

100

Frontage 750

W : 給水(1/2B)

E1 E2 D W

D : 排水(1-1/2B)

250

150

E1 : 電気1φ100V

500

E2 : 電気3φ200V

150

Attention

~774

A

1000

750

587

Please select exhaust fan according to operating

~530

2100

location and conditions.

Not explosion-proof structure, please pay attention

間

to conditons to be used.

Window open: Window narrow open:

850

850

1

Interior material and chemical resistance of the

Efficient exhaust with Front air velocity is faster. working surface, please refer to selection table. 1

constant air velocity at Exhaust air volume is Keep electric heating lower than 2kW. 1

100

front opening controlled by air bypass at Frontage

Avoid perchloric acid. 750

top gallery

250

500

www.yamato-usa.com

150

Yamato Scientific America Inc. LDS Series

~774

A

000

CATV1-201701

0

You might also like

- LM-D-LMFM-004M Rev00Document2 pagesLM-D-LMFM-004M Rev00harimar0nNo ratings yet

- Technical Details - Ecology UnitDocument9 pagesTechnical Details - Ecology Unitprashant.jadhavNo ratings yet

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- FT Manejadora DDM0808-E5Document2 pagesFT Manejadora DDM0808-E5Will AqNo ratings yet

- Wadbros CatelogueDocument36 pagesWadbros Cateloguepistolfire99No ratings yet

- Fan Coil Connection Hoses Data SheetDocument2 pagesFan Coil Connection Hoses Data SheetROBERTO RAFAELNo ratings yet

- TAN HUE VIEN-Technical AHU-op2Document72 pagesTAN HUE VIEN-Technical AHU-op2Cao Son DuongNo ratings yet

- Tesla Ac - Specificații TehniceDocument1 pageTesla Ac - Specificații TehniceMoraru MihaelNo ratings yet

- Diaphragm Sensing Pressure Gauges 1Document2 pagesDiaphragm Sensing Pressure Gauges 1Wency JavateNo ratings yet

- 190W TDP: Highlights Ideal ApplicationsDocument2 pages190W TDP: Highlights Ideal ApplicationsTomaNo ratings yet

- PD-1250 Pressure Relief BackdraftDocument4 pagesPD-1250 Pressure Relief BackdraftDo MinhNo ratings yet

- KD-T Non Return Damper: MaterialsDocument2 pagesKD-T Non Return Damper: Materialssuan170No ratings yet

- Cat TD Silent 1300 2000 en Fid5660Document12 pagesCat TD Silent 1300 2000 en Fid5660Jhon DiazNo ratings yet

- Tdb Vrf Dvm s Desert Standard r410a 50hz Hp for Me Ver.1.31 170913Document76 pagesTdb Vrf Dvm s Desert Standard r410a 50hz Hp for Me Ver.1.31 170913edincastro955No ratings yet

- LED weatherproof exit signDocument1 pageLED weatherproof exit signTSNo ratings yet

- Fleetlife Moisture Master BrochureDocument6 pagesFleetlife Moisture Master BrochureFL Paul BNo ratings yet

- Brakel Optima: Thermally Separated Louvred VentilatorDocument4 pagesBrakel Optima: Thermally Separated Louvred VentilatorhjduarteNo ratings yet

- AHU_Selection ( Djibouti )Document2 pagesAHU_Selection ( Djibouti )fuad aliNo ratings yet

- PIR Dämmung - ENDocument2 pagesPIR Dämmung - ENBorisNo ratings yet

- Sanitary Diaphragm Valve: Type 612Document6 pagesSanitary Diaphragm Valve: Type 612Hilux PabloNo ratings yet

- ASHRAE Separator Box FilterDocument1 pageASHRAE Separator Box Filter漢克林No ratings yet

- About Sewon-Giyeon PDFDocument56 pagesAbout Sewon-Giyeon PDFPrasath SNo ratings yet

- CM YSMB Air Handling Unit CatalogueDocument18 pagesCM YSMB Air Handling Unit CatalogueNestorLagosNo ratings yet

- technical-data-sheet-alublockDocument1 pagetechnical-data-sheet-alublocklasNo ratings yet

- Schuco ASS 70 FD Bi Fold Door - Product Specification Sheet-Jan - 18Document3 pagesSchuco ASS 70 FD Bi Fold Door - Product Specification Sheet-Jan - 18HariNo ratings yet

- Cooling SystemDocument10 pagesCooling Systemundeadkyojin18No ratings yet

- Tds-Manual DamperDocument4 pagesTds-Manual Dampersabir hussainNo ratings yet

- Hudetech Spring IsolatorDocument28 pagesHudetech Spring IsolatorThanh DoNo ratings yet

- Vibration Isolation Product GuideDocument22 pagesVibration Isolation Product GuideLợi TrầnNo ratings yet

- Dac 0812 GDocument2 pagesDac 0812 GDarrenkjcNo ratings yet

- ROM Catalog 10-12-21Document8 pagesROM Catalog 10-12-21sergio poloNo ratings yet

- Easy Duct PDFDocument8 pagesEasy Duct PDFSameera Sri VidurangaNo ratings yet

- Ventilator Filter Unit BrochureDocument2 pagesVentilator Filter Unit BrochureChia Sze KiatNo ratings yet

- Astm E84Document4 pagesAstm E84Amro Metwally El HendawyNo ratings yet

- Technical Manual For Modular Air Handling Unit FAS03 201819Document22 pagesTechnical Manual For Modular Air Handling Unit FAS03 201819JAY ROD AWITNo ratings yet

- Elmasonic EASY 120 H: Ultrasonic CleanerDocument1 pageElmasonic EASY 120 H: Ultrasonic Cleanermarlon granadaNo ratings yet

- SHPDDocument32 pagesSHPDManuel Alvarez MNo ratings yet

- Double OffsetDocument10 pagesDouble Offsetkrbabu1969No ratings yet

- HS212T - Full Range Horn Speaker 12 100V AUDACDocument1 pageHS212T - Full Range Horn Speaker 12 100V AUDACBambang KaryantoNo ratings yet

- Design and Installation Guide: KLIP-LOK® 700Document8 pagesDesign and Installation Guide: KLIP-LOK® 700Er S Thirumarai NathanNo ratings yet

- D DS 01 Smard LRD 2019 10 enDocument2 pagesD DS 01 Smard LRD 2019 10 enJoost PostNo ratings yet

- Hi Wall DC Inverter 50Hz 2018 PDFDocument9 pagesHi Wall DC Inverter 50Hz 2018 PDFAymen AyedNo ratings yet

- SpecDocument2 pagesSpecMSNo ratings yet

- Tank Shell Design - LATESTDocument12 pagesTank Shell Design - LATESThgagNo ratings yet

- Pre-Insulated Aluminium Duct: Cutting MachineDocument2 pagesPre-Insulated Aluminium Duct: Cutting MachineFaza Farid100% (1)

- Pure Base 500DX Datasheet enDocument2 pagesPure Base 500DX Datasheet engilya357No ratings yet

- Air Measuring Station With VCD-42 Control Damper: Velocity: LeakageDocument5 pagesAir Measuring Station With VCD-42 Control Damper: Velocity: LeakageAnkit JainNo ratings yet

- L-BD CompuertasDocument3 pagesL-BD CompuertasEduardo RivasNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- EN Double Offset 2E SmallDocument12 pagesEN Double Offset 2E SmallEduardo TapiaNo ratings yet

- Airtech Biological Safety CabinetsDocument14 pagesAirtech Biological Safety CabinetsThabetNo ratings yet

- Performance Data: Schedule of Technical Data Genius Cooling Tower Model: GPC 125M Project: Afc Bukit JalilDocument1 pagePerformance Data: Schedule of Technical Data Genius Cooling Tower Model: GPC 125M Project: Afc Bukit JalilJeghiNo ratings yet

- 7800 Spec PDFDocument2 pages7800 Spec PDFxnbsxNo ratings yet

- Irits 0818 082 Oil Flooded 90 160kw Datasheet 60hzDocument2 pagesIrits 0818 082 Oil Flooded 90 160kw Datasheet 60hzDANIELANo ratings yet

- PP Elmasonic s100h enDocument1 pagePP Elmasonic s100h enrod macNo ratings yet

- Metal Mesh Air FilterDocument1 pageMetal Mesh Air FilterBuat AgrovatioNo ratings yet

- Accs r407c CatalogueDocument16 pagesAccs r407c CatalogueMohd FirdhausNo ratings yet

- ACCS R407C 50Hz - MS0316C 1213 CatalogDocument16 pagesACCS R407C 50Hz - MS0316C 1213 CatalogPratikno SajaNo ratings yet

- YORK Inverter 19 SEER Thames 12-24KDocument4 pagesYORK Inverter 19 SEER Thames 12-24KKevin LópezNo ratings yet

- Hdcvi-Preview-How To Set Encode Parameters in RecorderDocument2 pagesHdcvi-Preview-How To Set Encode Parameters in RecorderarmanNo ratings yet

- Summary of NSF ANSI 49 Changes Rev May 2021Document121 pagesSummary of NSF ANSI 49 Changes Rev May 2021armanNo ratings yet

- Preview NSF+ANSI+49-2016Document11 pagesPreview NSF+ANSI+49-2016armanNo ratings yet

- TC 09.10 Faq 69Document1 pageTC 09.10 Faq 69armanNo ratings yet

- NVR1B04HS-4PL Datasheet 201804132Document3 pagesNVR1B04HS-4PL Datasheet 201804132armanNo ratings yet

- Xvr5104hs I2 PortDocument1 pageXvr5104hs I2 PortarmanNo ratings yet

- Health Alert Card Ministry of Health Republic of IndonesiaDocument1 pageHealth Alert Card Ministry of Health Republic of IndonesiaarmanNo ratings yet

- Lampiran Photo Karpet Lab AirDocument1 pageLampiran Photo Karpet Lab AirarmanNo ratings yet

- Dahua Product Security White Paper V2.0Document44 pagesDahua Product Security White Paper V2.0armanNo ratings yet

- DH XVR5104HS I2 - A&eDocument8 pagesDH XVR5104HS I2 - A&earmanNo ratings yet

- Part Catalog All New Byson FI PreviewDocument10 pagesPart Catalog All New Byson FI PreviewWawan Eko DewantoroNo ratings yet

- Part Catalog All New Byson FI PreviewDocument10 pagesPart Catalog All New Byson FI PreviewWawan Eko DewantoroNo ratings yet

- TDS-Oxygen CHEMets® Kit - Rhodazine MethodDocument1 pageTDS-Oxygen CHEMets® Kit - Rhodazine MethodSorinNo ratings yet

- Watreatpath 3Document26 pagesWatreatpath 3bhaleshNo ratings yet

- BEL Technical Manual 4 End Port LDocument27 pagesBEL Technical Manual 4 End Port LarmanNo ratings yet

- SGT AbleDocument5 pagesSGT AbleYudha PrastyaNo ratings yet

- Came Searmen T Method Color I MetricDocument4 pagesCame Searmen T Method Color I MetricarmanNo ratings yet

- Exp5 PDFDocument13 pagesExp5 PDFRahimi ShahimiNo ratings yet

- File Guntara001Document1 pageFile Guntara001armanNo ratings yet

- Came Searmen T Method Color I MetricDocument4 pagesCame Searmen T Method Color I MetricarmanNo ratings yet

- Came Searmen T Method Color I MetricDocument4 pagesCame Searmen T Method Color I MetricarmanNo ratings yet

- Came Searmen T Method Color I MetricDocument4 pagesCame Searmen T Method Color I MetricarmanNo ratings yet

- Physics Investigatory ProjectDocument19 pagesPhysics Investigatory ProjectKrish KaushikNo ratings yet

- Entropy and The UniverseDocument33 pagesEntropy and The UniverselykaonasNo ratings yet

- Rggupta Chapter 1 To 3Document72 pagesRggupta Chapter 1 To 3Krishan Pal SinghNo ratings yet

- Axial Thrust Balancing in PumpsDocument4 pagesAxial Thrust Balancing in PumpsBorisNo ratings yet

- 1998 Formation and Physical Properties of Acid MilkDocument14 pages1998 Formation and Physical Properties of Acid MilkТаро и Астрология с Anatoly KartNo ratings yet

- Avogadro's Law and Ideal Gas CalculationsDocument1 pageAvogadro's Law and Ideal Gas Calculationsmel vinNo ratings yet

- Radiation Heat Transfer Mathcad SolutionsDocument176 pagesRadiation Heat Transfer Mathcad SolutionsThebe HanyaneNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSNo ratings yet

- 9 Science Imp ch2 1Document6 pages9 Science Imp ch2 1Er- WALTAR Sir, INNOVATIVE & SMART CLASSESNo ratings yet

- Detailed Meanings of The Scientific Words in The Scientific Verses in The Holy Quran Using Lisan Al-Arab (The Arabs' (Of Old) Tongue) Dictionary and Other Similar Dictionaries1Document102 pagesDetailed Meanings of The Scientific Words in The Scientific Verses in The Holy Quran Using Lisan Al-Arab (The Arabs' (Of Old) Tongue) Dictionary and Other Similar Dictionaries1JamshaidzubaireeNo ratings yet

- ANEXO Quotation Pipe AccesoriesDocument2 pagesANEXO Quotation Pipe AccesoriesJavierEnriquePalominoMendozaNo ratings yet

- Precision and Laboratory EquipmentsDocument33 pagesPrecision and Laboratory EquipmentsTone RatanalertNo ratings yet

- Protein FoldingDocument9 pagesProtein FoldingAyush ZalaNo ratings yet

- Photoelectric Effect ExplainedDocument8 pagesPhotoelectric Effect ExplainedNG WEI LONG MoeNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- Flutter Analysis of A Low Aspect Ratio Swept-Back Trapezoidal Wing at Low Subsonic FlowDocument6 pagesFlutter Analysis of A Low Aspect Ratio Swept-Back Trapezoidal Wing at Low Subsonic FlowAli BaigNo ratings yet

- SindxbDocument51 pagesSindxbImad-eddine. GuiraNo ratings yet

- Lab Report: PH 1020 Thermal Conductivity of Glass in The Form of A TubeDocument27 pagesLab Report: PH 1020 Thermal Conductivity of Glass in The Form of A TubeSudesh DinamithraNo ratings yet

- 2015-11-02 Seminar - Siruri Si Serii de FunctiiDocument2 pages2015-11-02 Seminar - Siruri Si Serii de FunctiiȘtefan RăzvanNo ratings yet

- Earth Pressure at Rest Rankine's Theory of Earth PressureDocument27 pagesEarth Pressure at Rest Rankine's Theory of Earth PressureDrSuman ManandharNo ratings yet

- Structural Steel Trusses Analysis and DesignDocument39 pagesStructural Steel Trusses Analysis and DesignSai Sasank CHNo ratings yet

- 3 Unit EMDocument5 pages3 Unit EMS.Sampath Chemistry Ghss GurubarapalliNo ratings yet

- LiquefactionDocument10 pagesLiquefactionMaria Fernanda CastilloNo ratings yet

- Catalogo de CouplingsDocument32 pagesCatalogo de CouplingsjoravicaNo ratings yet

- Std12 Chem EM 1 PDFDocument259 pagesStd12 Chem EM 1 PDFSenthil Kumar100% (1)

- Boiler performance and input/output relationshipsDocument6 pagesBoiler performance and input/output relationshipsAPINo ratings yet

- Roaster Design, Process Controls, and Flavor DevelopmentDocument9 pagesRoaster Design, Process Controls, and Flavor Developmentjacastillo68No ratings yet

- EML 6155 Convection Heat TransferDocument4 pagesEML 6155 Convection Heat TransfermasumehtfNo ratings yet