Professional Documents

Culture Documents

Crane Attention

Uploaded by

peng wangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crane Attention

Uploaded by

peng wangCopyright:

Available Formats

I operating instructions

(1) warning and notes

1、 Everyone who work with the truck should read this instructions first.

2、 Before operating the truck, you should carefully observed the operation site. within

the radius of the arm movement ,make sure there is no any obstacles.

3、 When the arm on operating, no one shall enter the radius.

4、when the vehicle is parked on a slope greater than 12 °, the wheel brake pads must

be used.

5 、 the hydraulic system pressure can not out of manual specified value range; the

system maintenance must be under a person who have experience in the hydraulic test.

before it is set in accordance with the requirements of loading.

6、only when the leg support to road and lifting the vehicle than can start to operating, or

risk unexpected will happen!

7、must strictly abide by the rules, operation mechanism motion abnormalities are found,

immediately stop work and promptly identify the cause before continuing the work of

troubleshooting.

II Operation requirements

1, observe the operating field whether it is comply with the request before the job.

2, when parking the truck, tightened hand brake, use the hand throttle to control pump

speed.

3, confirmation the legs have support to road, then you can start to loading or unloading

the goods.

4, the operation is completed, when transport the goods, Crane must fixed and in non

working station.

III Hydraulic System

Oil pump Right handed rotation

Economic speed 1500-1800

Oil system rated pressure 26Mpa

Hydraulic Oil Flow 25L/MIN

Max Lifting Moment 6.72T.M

Outrigger Number 2 sets

IV Care and maintenance

Care and maintenance

1,when the work is done, truck and crane must be in non working position.

2, each worker should check their vehicles before work, check all the mechanical parts,

hydraulic system with or without oil, and other signs of loosening.

3, should always check the height of the hydraulic oil , filling should be timely and make

sure the oil is enough,When the hydraulic oil get dark or black,please replace the oil.

In winter please use L-HM32# , low temperature hydraulic oil, In summer please use

L-HM68# hydraulic oil, usually in simple please, if mild climate you can always use

L-HM46# hydraulic oil. Please use suitable oil according your local temperature or take

advise of local maintenance engineer.

4, In the truck all the moving parts with oil cup, should always raise calcium-based

lubricants.

5, when the hydraulic oil cleanliness lower than the national standard, it is necessary to

replace all semi-cleaning filters

V Spare Parts

Hoisting winch assembly 1

Repair kits 1

Sun gear 1

Planetary gear 1

Forehead pulley 1

SQ3.2SK

Rotary gear 1

turbine 1

Worm 1

Rotary tines 1

Steel cable 1

VI lubricant and Hydraulic system requirements

Lubricant or grease part Lubricant material Grease periods

(Every Week)

Out Rigger left shaft Grease Once

Out Rigger Right shaft Grease Once

Boom section 1 Grease Once

Boom Section 2 Grease Once

Boom Turing shaft Grease Twice

Rotation Base Grease Twice

Attention:

All the moving parts and turning parts need lubricant, check regularly.

Be attention the working condition of the crane and truck, stop immediately

once any abnormal status occur.

Hydraulic Oil should change when the crane in non working station, use

suitable hydraulic oil according local temperature.

You might also like

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- CBC MOI EIM NCII Migrated 2017 Vhens 4 18 20Document65 pagesCBC MOI EIM NCII Migrated 2017 Vhens 4 18 20Khael Angelo Zheus Jacla100% (5)

- Instruction Manual: Hand Stacker Pa1015 Capacity 1000kgDocument17 pagesInstruction Manual: Hand Stacker Pa1015 Capacity 1000kgEng-Mahmoud AtiaNo ratings yet

- Manual Chipeadora 18XP (059-119)Document61 pagesManual Chipeadora 18XP (059-119)Mantenimiento BiocicloNo ratings yet

- CLG 418Document46 pagesCLG 418mliugong92% (12)

- Engines 6090HDW01, 6090HDW04 770G, 772G, 770GP, and 772GP Motor Grader (S.N. 634754-)Document2 pagesEngines 6090HDW01, 6090HDW04 770G, 772G, 770GP, and 772GP Motor Grader (S.N. 634754-)Brian Careel100% (1)

- Qs332 Machine MasterDocument8 pagesQs332 Machine MasterJustice MachiwanaNo ratings yet

- Gasoline Engine Owners Maunal For H2I2Document16 pagesGasoline Engine Owners Maunal For H2I2antNo ratings yet

- Maintenance: Right Maintenance and Inspection MethodsDocument13 pagesMaintenance: Right Maintenance and Inspection MethodsPreett Rajin MenabungNo ratings yet

- 12-20T MAINTENANCE MANUAL ZoomlionDocument23 pages12-20T MAINTENANCE MANUAL ZoomlionAbas AbasariNo ratings yet

- Steering Gear SystemDocument6 pagesSteering Gear SystemMohammad Jahid AlamNo ratings yet

- Hydraulic Stacker - Model No. Mn397: Operating Instructions and Parts ListDocument9 pagesHydraulic Stacker - Model No. Mn397: Operating Instructions and Parts ListAJ MusicNo ratings yet

- Boiler Operation General Safety and SAFETY ValvesDocument4 pagesBoiler Operation General Safety and SAFETY ValvesherlyasNo ratings yet

- Steering Gear Systems On Ships Marine enDocument5 pagesSteering Gear Systems On Ships Marine enPaul PraveenNo ratings yet

- MaintenanceDocument30 pagesMaintenanceVictor HemzNo ratings yet

- Maintenance Service Check Sheet (1500Hr) : Part No Q'ty Result RemarksDocument14 pagesMaintenance Service Check Sheet (1500Hr) : Part No Q'ty Result RemarksAgus DaniNo ratings yet

- 03 - Turbine-Oil-System-2Document7 pages03 - Turbine-Oil-System-2sakera 88No ratings yet

- Model 800h Api Service Manual 1391475090Document17 pagesModel 800h Api Service Manual 1391475090Alfred HitchcockNo ratings yet

- Turbine Lube Oil System AND GENERATOR SealingDocument32 pagesTurbine Lube Oil System AND GENERATOR SealingNishant ChaudharyNo ratings yet

- Ection Aintenance and Ervice: Revision November 2009Document24 pagesEction Aintenance and Ervice: Revision November 2009ddrb23No ratings yet

- Section 5 Eci Training General MaintenanceDocument10 pagesSection 5 Eci Training General MaintenanceGlenn BholaNo ratings yet

- Lubrication ScheduleDocument1 pageLubrication ScheduleProyectil De ProyectoNo ratings yet

- 3x1600 MAINTENANCE OF CTLDocument16 pages3x1600 MAINTENANCE OF CTLDaniel GuzmanNo ratings yet

- 16-Basic Maintenace of Hoist System-20230714-ZengzhihuaDocument29 pages16-Basic Maintenace of Hoist System-20230714-Zengzhihuaكرار عمارNo ratings yet

- Fkr555.109.d4a 00apmt ManualDocument12 pagesFkr555.109.d4a 00apmt ManualJavier FernándezNo ratings yet

- Caterpillar Crawler Operators Manual CT o d9Document7 pagesCaterpillar Crawler Operators Manual CT o d9Tommy JunNo ratings yet

- ReducerDocument37 pagesReducerSubhaanNo ratings yet

- 6M7 - Gr12 JMLDocument26 pages6M7 - Gr12 JMLPyae Win MaungNo ratings yet

- 2011 Maintenance Manual of Zoomlion Mixer(中英文)Document16 pages2011 Maintenance Manual of Zoomlion Mixer(中英文)Freddy AndresNo ratings yet

- Ninja500 Uses Manual 1Document34 pagesNinja500 Uses Manual 1njkawasakiNo ratings yet

- TM-104 Main SCH-TRTDocument19 pagesTM-104 Main SCH-TRTsanjayisdonNo ratings yet

- FX-375 ServiceDocument21 pagesFX-375 ServiceMauro PerezNo ratings yet

- Instructions of Reducer Model FH1005.142.F1B-00: Shanghai Zhenhua Heavy Industry Co.,Ltd July, 2010Document12 pagesInstructions of Reducer Model FH1005.142.F1B-00: Shanghai Zhenhua Heavy Industry Co.,Ltd July, 2010Ivan MaltsevNo ratings yet

- UNIT 1 (G) IhpDocument60 pagesUNIT 1 (G) Ihpsantosh alguleNo ratings yet

- Kf22Qt Sec4 FRDDocument21 pagesKf22Qt Sec4 FRDMauro PerezNo ratings yet

- Engine Lubrication: Section 6GDocument8 pagesEngine Lubrication: Section 6GRichard Wilson Mera JaimeNo ratings yet

- All About Steering System.Document12 pagesAll About Steering System.Ramprabu Chandrasekar100% (1)

- Maintenance of Crawl CraneDocument30 pagesMaintenance of Crawl Craneminthu khitNo ratings yet

- SANY Heavy Industry Co - LTD Quality Changes The WorldDocument35 pagesSANY Heavy Industry Co - LTD Quality Changes The WorldGustavo VargasNo ratings yet

- Tyrone Gear Pump DiagnosisDocument20 pagesTyrone Gear Pump DiagnosisMohamad SaremyNo ratings yet

- 180CW 210CW Uptime Maintenance PlannerDocument2 pages180CW 210CW Uptime Maintenance PlannerAlex Sandro dos SantosNo ratings yet

- Mixing Plant Maintenance Operation ManualDocument22 pagesMixing Plant Maintenance Operation ManualGuillermo HerreraNo ratings yet

- Victor Taichung Machinery Troubleshooting and Maintenance ManualDocument9 pagesVictor Taichung Machinery Troubleshooting and Maintenance ManualFlorin MariusNo ratings yet

- Manual XQ29-1.8 Power Tong - MotDocument27 pagesManual XQ29-1.8 Power Tong - MotPedro GilNo ratings yet

- WD 615 ManualDocument43 pagesWD 615 Manualferanba100% (1)

- Check Sheet PS Pc78uu-6 EditDocument3 pagesCheck Sheet PS Pc78uu-6 EditToko SerbaNo ratings yet

- Ane1 Wet3 MX001Document35 pagesAne1 Wet3 MX001Romuel PioquintoNo ratings yet

- TA1 Test For Hydraulic System: Status Description CommentsDocument6 pagesTA1 Test For Hydraulic System: Status Description CommentsAyman EsaNo ratings yet

- Dx210wa (950106-01517e) 1412 SM en (#5001 - 2014) PDFDocument1,358 pagesDx210wa (950106-01517e) 1412 SM en (#5001 - 2014) PDFngoun mara100% (3)

- C5000SL инструкция по ремонту-01Document33 pagesC5000SL инструкция по ремонту-01Евгений ГубаревNo ratings yet

- Maintenance: PeriodicDocument24 pagesMaintenance: Periodiccarlos maradiaga100% (1)

- Maintenance Service Check Sheet (Initial.250Hr)Document1 pageMaintenance Service Check Sheet (Initial.250Hr)Agus DaniNo ratings yet

- Hx300ll SMDocument1,206 pagesHx300ll SMJosé Maria SouzaNo ratings yet

- 600 KN Towing Winch ManualDocument173 pages600 KN Towing Winch ManualMartellusNo ratings yet

- 3541RL 3541RL: Service Manual Service ManualDocument18 pages3541RL 3541RL: Service Manual Service Manualyousef ALadwanNo ratings yet

- PC 1250 Initial 100 HR Service SheetDocument4 pagesPC 1250 Initial 100 HR Service SheetJamyansuren TseveendorjNo ratings yet

- NNNDocument127 pagesNNNNeeraj maurya100% (2)

- Group 12 LubricationDocument32 pagesGroup 12 LubricationLuisTocoraNo ratings yet

- Law InternationalDocument7 pagesLaw InternationalnebaNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Saturated Salt Solutions and %RHDocument2 pagesSaturated Salt Solutions and %RHsamman149686100% (1)

- Ibvtm User Guide MAN400Document27 pagesIbvtm User Guide MAN400Javier MontañezNo ratings yet

- CI170A, C ManualDocument120 pagesCI170A, C ManualAris van RaiserNo ratings yet

- Esc120 12Document2 pagesEsc120 12AnuradheNo ratings yet

- G41M05 Schematic Foxconn Precision Co. Inc.: Fab.A Data: 2008/7/30 Page IndexDocument36 pagesG41M05 Schematic Foxconn Precision Co. Inc.: Fab.A Data: 2008/7/30 Page IndexÔng MậpNo ratings yet

- IEC - Short-Circuit Example 2: DescriptionDocument9 pagesIEC - Short-Circuit Example 2: DescriptionFrancisco AndradeNo ratings yet

- Contractual Positions Cost Summary - CTR XXXX: Attachment 1 - Cost - Time - Resource SheetDocument13 pagesContractual Positions Cost Summary - CTR XXXX: Attachment 1 - Cost - Time - Resource SheetonlyikramNo ratings yet

- Camera Link SpecificationDocument34 pagesCamera Link Specificationmohitmangal84No ratings yet

- EdSim51 - Notes On The 8051Document16 pagesEdSim51 - Notes On The 8051Pawan KaswanNo ratings yet

- Electrical-HSE - Gov - Uk-Electrical Safety-Introduction To Electrical SafetyDocument8 pagesElectrical-HSE - Gov - Uk-Electrical Safety-Introduction To Electrical SafetyEhsan MazharNo ratings yet

- Catapult OptimEye X4Document3 pagesCatapult OptimEye X4Germán PreiszNo ratings yet

- Pioneer pdp-4280xd2 PDFDocument236 pagesPioneer pdp-4280xd2 PDFdrweb75No ratings yet

- 10Document72 pages10Dixon Javier Cortes TapiaNo ratings yet

- ABS - Troubleshooting, ImportantDocument12 pagesABS - Troubleshooting, ImportantVcads Pro100% (1)

- Electrical Power Theft DetectionDocument20 pagesElectrical Power Theft DetectionAnil KapoorNo ratings yet

- Manual Servicio JVC UX-G45BDocument41 pagesManual Servicio JVC UX-G45Bschumi_kaiserNo ratings yet

- New Holland T7: I I I I I I I IDocument28 pagesNew Holland T7: I I I I I I I ILKKNo ratings yet

- Thinkpad t480s LCFC Nm-b471Document99 pagesThinkpad t480s LCFC Nm-b471Oscar RdNo ratings yet

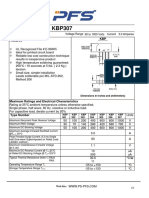

- Datasheet Puente de DiodosDocument2 pagesDatasheet Puente de DiodosEdson Rios Hamachi100% (1)

- Ficha Tecnica RAmpas Niveladoras, Mecanica e Hidraulica PAVSADocument2 pagesFicha Tecnica RAmpas Niveladoras, Mecanica e Hidraulica PAVSAEleazar HernandezNo ratings yet

- La 55pDocument3 pagesLa 55pb_dupNo ratings yet

- Final 05Document8 pagesFinal 05Taha EtemNo ratings yet

- Dressmaking7 - 8 Week5Document21 pagesDressmaking7 - 8 Week5Liam Sean HanNo ratings yet

- Standard Ac Eng PDFDocument324 pagesStandard Ac Eng PDFPranav KrishnaNo ratings yet

- C152 ManualDocument77 pagesC152 ManualyakupaksuNo ratings yet

- Moteur Translation Et Reduction R300 HYUNDAIDocument66 pagesMoteur Translation Et Reduction R300 HYUNDAIFrank BullitNo ratings yet

- Hardinge CatalogDocument8 pagesHardinge CatalogPedro VianaNo ratings yet

- 13-Air Compressor, Belt Drives - Unimog 435 Workshop ManualDocument34 pages13-Air Compressor, Belt Drives - Unimog 435 Workshop ManualJuan JapNo ratings yet