Professional Documents

Culture Documents

20007P-CRTi2-8.63 Specification Summary

Uploaded by

tibismtxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20007P-CRTi2-8.63 Specification Summary

Uploaded by

tibismtxCopyright:

Available Formats

Casing Running Tools (CRTi2-8.

63)

CRTi™ Internal Grip Casing Running Tool

Volant’s CRTi casing running tool is designed for casing running or drilling with top drive equipped rigs to

makeup, breakout, reciprocate, rotate, fill, circulate and cement casing and liner strings, reducing non-productive

time and associated costs. Casing drilling is achieved through the standard tool configuration, but if increased

flow is desired, Volant’s Highflow* option features a larger through hole for additional fluid flow. This tool is mechanically

activated in tension and both rotational directions solely by top drive control using TAWG™ wedge grip technology.

This patented architecture puts control in the hands of the driller, reducing the need for third party support to

run casing. Intuitive operations for pipe engagement and release closely emulate the familiar make and break

steps used to run drill pipe – stab, rotate to the right to engage and reverse to disengage. Similarly, rig in and

rig out steps are simple, intuitive and efficient.

Starting from the insertion diameter of the base tool (cage OD), selectable sizes of integral jaws/dies are used

to configure the CRTi to support gripping casing of increasing internal diameter. Through the use of a patented

extended reach die structure, the gripping diameter can be further increased to include casing sizes much

greater than the base tool.

Tool Model: CRTi2-8.63 Specification Summary

Tool Configuration with

Base Tool Characteristics1 Integral Slip Dies Extended Slip Dies Extended Reach Dies

Hoist ton (tonne) 690 (625) and Bumper Extension

CRTi Rated Load Capacity

Torque ft.lbs (N.m) 85,000 (115,200)

Hoist ton (tonne) 575 (521)

Combined Load Large Hoist

Torque ft.lbs (N.m) 40,000 (54,200)

Hoist ton (tonne) 475 (430)

Combined Load High Torque

Torque ft.lbs (N.m) 70,000 (94,900)

Set-Down Load Capacity 2

ton (tonne) 110 (99)

Typical Circulation Pressure Limit3

psi (MPa) 5,000 (34.4)

Maximum Pressure End Load ton (tonne) 500 (453)

Base Tool Length 4

in (mm) 65.6 (1,670)

Diametrical Stroke in (mm) 0.75 (19.0)

Through Hole in (mm) 2.0 (51)

Maximum Flow Rate 5

gpm (m /min)

3

1,161 (4.40)

Tool Joint 6.63 REG

Turns to Stroke Out 1.256 / 0.6

Give us a problem. Or just drop us a line if you want to know more.

sales@volantproducts.ca volantproducts.ca | sales@volantoiltoolsUS.com volantoiltoolsUS.com

Document No. 20007 / Revision P Printed in Canada JANUARY 2018

CRTi2-8.63 | PAGE 1

Casing Running Tools (CRTi2-8.63)

Tool Model: CRTi2-8.63 Specification Summary

Casing Seal Assembly and Tool Length4

Casing Seal Seal Type Casing Size Overall Tool Length

Description in (mm) in (mm)

Swivel Packer Cup 8.63 (219.1) - 13.38 (339.7) 78.6 (2,000)

Casing Seal Wedge Seal 13.38 (339.7) - 30.0 (762.0) 78.6 (2,000)

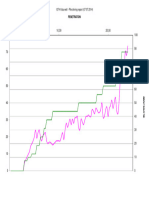

Combined Load Operation Curve

Please refer to the Base Tool Characteristics on page 1 of this Specification Summary for numeric values such

as CRTi Rated Load Capacity, Combined Load Large Hoist, and Combined Load High Torque illustrated in

the graph below:

800

700

600

Hoist Capacity (tons (short))

500

400

300

200

100

0

0 10000 20000 30000 40000 50000 60000 70000 80000 90000

Torque Capacity (ft-lbs)

Give us a problem. Or just drop us a line if you want to know more.

sales@volantproducts.ca volantproducts.ca | sales@volantoiltoolsUS.com volantoiltoolsUS.com

Document No. 20007 / Revision P Printed in Canada JANUARY 2018

CRTi2-8.63 | PAGE 2

Casing Running Tools (CRTi2-8.63)

Tool Selection Guide

Step 1: Base Tool Selection The CRTi is available in a Step 4: Die Torque Capacity Tdie = K torque x Wcasing x σYcasing

variety of dimensions and ratings. The Base Tool Characteristics

table contains the ratings and overall dimensions of the tool. The where Tdie is the torque limit due to slip die/casing interaction,

required hoist, torque, set-down load capacity and maximum K torque is the torque factor,

flow rate must be lower than or equal to the base tool rating. If Wcasing is the desired casing weight in ppf (kg/m), and

combined hoist and torque is required for the casing running job,

σYcasing is the casing yield strength in psi (MPa)

the combined hoist and torque point must fall below or on the

combined load operation curve. If no value is provided, tool rating will be limiting for all standard

casing grades. For example, for die 81756 to run 9.63 in x 40.0

Step 2: Die Selection All API casing sizes and weights with ppf L80 (244.5 mm x 59.53 kg/m L80) casing, the die torque limit

drift diameter above 7.38 in (187.4 mm) are available for this tool. is:

Find the appropriate die for casing size and weight in the die

table below. Some dies can run a range of casing weights. 0.02701 ft.lbs/psi/ppf × 40.0 ppf × 80,000 psi = 86,432 ft.lbs

Step 3: Die Hoist Capacity Tool hoist rating is based on API or

Specifications 8C; however casing load limit is further con-

3.569 N.m/MPa/(kg/m) × 59.53 kg/m × 551.6 MPa = 117,194

strained by local interaction of slip dies with casing, which must

N.m

not exceed the efficiency indicated for individual slip die sizes to

avoid excess deformation. The slip to casing interaction hoist limit Where the base tool torque capacity is lower than the die torque

(Fdie) can be found by the following formula where efficiency is the capacity, the tool is limited to base tool torque capacity.

slip to pipe body load efficiency number (listed in the following

table for every die) and Fcasing is the casing hoist limit found in API

Bulletin 5C2.

Step 5: Effect of Circulation Pressure CRTi hoist capacity

must be reduced by the pressure end load during circulation. The

Fdie = efficiency x Fcasing hoist reduction (FEndPressure) depends on circulation pressure (P),

casing nominal ID (IDcasing) and CRTi through hole (IDmandrel).

For example, from API 5C2 the pipe body yield for 9.63 in x 40.0

ppf L80 (244.5 mm x 59.53 kg/m L80) casing is 916,000 lbs FEndPressure = 0.79 × P × (ID2casing - ID2mandrel)

(415.5 tonne). The slip efficiency for slip die 81756 used to run

For example, for circulation pressure of 500 psi (3.45 MPa) and

this casing is 80%. Therefore, the die hoist limit is:

casing nominal ID of 8.84 in (224.5 mm) the hoist reduction is:

80% × 916,000 lbs = 732,800 lbs = 366.4 ton

0.79 × 500 psi × ((8.84 in)2 - (2.0 in)2) = 29,288 lbs ~ 14.6 ton

or

or

80% × 415.5 tonne = 332.4 tonne

0.79 × 3.44 MPa × ((224.5 mm)2 - (50.8 mm)2) = 129,955 N ~

In case the base tool hoist rating is smaller than the calculated 13.3 tonne

die hoist limit, the base tool hoist rating will be limiting.

Therefore, the maximum hoist for this tool reduces to 690.0 -

14.6 = 675.4 ton (612.7 tonne) or the maximum hoist for die

81756 (in step 3) must reduce to 366.4 - 14.6 = 351.8 ton (319.1

tonne).

Please contact Volant for further information.

Give us a problem. Or just drop us a line if you want to know more.

sales@volantproducts.ca volantproducts.ca | sales@volantoiltoolsUS.com volantoiltoolsUS.com

Document No. 20007 / Revision P Printed in Canada JANUARY 2018

CRTi2-8.63 | PAGE 3

Casing Running Tools (CRTi2-8.63)

Summary of Selected Slip Die Sizes7

Die P/N Nominal Max. Pipe Min. Pipe Die Curv. Max. Tool Approximate Slip to Pipe Torque Factor

Pipe Size Weight8 Weight9 Diameter Diameter Tool Weight Body Load (Ktorque)

(Wcasing) (Wcasing) Efficiency

(ft.lbs/psi/ (N.m/MPa/

(in) (mm) (ppf) (kg/m) (ppf) (kg/m) (in) (mm) (in) (mm) (lbs) (kg) (% Fy) ppf) (kg/m))

81024 8.63 219.1 36.0 53.57 24.0 35.72 8.04 204.5 20.0 510 1,350 620 80% 0.02894 3.824

82301 9.63 244.5 32.0 47.62 32.0 47.62 9.19 233.5 20.0 510 1,350 620 80% 0.02817 3.722

81756 9.63 244.5 43.5 64.74 32.0 47.62 8.91 226.5 20.0 510 1,350 620 80% 0.02701 3.569

81154 9.63 244.5 53.5 79.62 40.0 59.53 8.71 221.5 20.0 510 1,350 620 80% 0.0291 3.845

81881 9.63 244.5 58.4 86.91 47.0 69.94 8.60 218.5 20.0 510 1,350 620 80% 0.03074 4.061

82276 10.75 273.1 40.5 60.27 32.8 48.81 10.22 260.0 20.0 510 1,500 690 80% 0.02477 3.273

82275 10.75 273.1 51.0 75.90 40.5 60.27 10.02 254.5 20.0 510 1,500 690 80% 0.02554 3.374

82910 10.75 273.1 60.7 90.33 45.5 67.71 9.83 250.0 20.0 510 1,500 690 80% 0.0262 3.462

81255 10.75 273.1 65.7 97.77 51.0 75.90 9.73 247.0 20.0 510 1,500 690 80% 0.02647 3.497

81494 10.75 273.1 73.2 108.93 60.7 90.33 9.57 243.5 20.0 510 1,500 690 80% 0.02718 3.591

81138 10.75 273.1 79.2 117.86 71.1 105.81 9.40 239.0 20.0 510 1,500 690 80% 0.02785 3.680

81495 11.75 298.5 60.0 89.29 47.0 69.94 10.94 278.0 20.0 510 1,600 730 80% 0.02263 2.990

81757 11.75 298.5 71.0 105.66 60.0 89.29 10.75 273.5 20.0 510 1,600 730 80% 0.02348 3.102

100703 11.75 298.5 82.6 122.92 71.0 105.66 10.54 268.0 20.0 510 1,600 730 80% 0.02425 3.204

82039 12.75 323.9 58.4 86.91 50.0 74.41 12.03 306.0 20.0 510 1,850 840 71% 0.02012 2.658

82168 13.38 339.7 54.5 81.10 48.0 71.43 12.78 325.0 20.0 510 2,100 960 74% 0.02048 2.706

81897 13.38 339.7 61.0 90.78 48.0 71.43 12.68 322.5 20.0 510 2,100 960 74% 0.02048 2.706

82164 13.38 339.7 68.0 101.20 54.5 81.10 12.58 320.0 20.0 510 2,100 960 75% 0.02094 2.766

81150 13.38 339.7 72.0 107.15 61.0 90.78 12.52 318.0 20.0 510 2,100 960 75% 0.0213 2.814

82588 13.38 339.7 77.0 114.59 61.0 90.78 12.44 316.0 20.0 510 2,100 960 75% 0.0213 2.814

83154 13.38 339.7 86.0 127.98 72.0 107.15 12.28 312.0 20.0 510 2,100 960 76% 0.02173 2.871

81431 16.0 406.4 65.0 96.73 65.0 96.73 15.42 392.0 20.0 510 2,500 1,140 59% 0.01627 2.149

81645 16.0 406.4 84.0 125.01 75.0 111.61 15.18 386.0 20.0 510 2,500 1,140 63% 0.01757 2.321

82100 16.0 406.4 97.0 114.35 84.0 125.01 15.03 382.0 20.0 510 2,500 1,140 61% 0.01713 2.263

81758 16.0 406.4 109.0 162.21 97.0 144.35 14.88 378.0 20.0 510 2,500 1,140 64% 0.01791 2.366

82532 16.77 426.0 77.0 114.59 69.4 103.28 16.09 409.0 20.0 510 2,600 1,180 55% 0.01548 2.045

81752 17.88 454.0 105.0 156.26 93.5 139.14 16.96 431.0 20.0 510 2,650 1,210 53% 0.01485 1.962

100665 18.0 457.2 117.0 174.12 117.0 174.12 16.94 430.5 20.0 510 2,650 1,210 56% 0.01577 2.083

Give us a problem. Or just drop us a line if you want to know more.

sales@volantproducts.ca volantproducts.ca | sales@volantoiltoolsUS.com volantoiltoolsUS.com

Document No. 20007 / Revision P Printed in Canada JANUARY 2018

CRTi2-8.63 | PAGE 4

Casing Running Tools (CRTi2-8.63)

Summary of Selected Slip Die Sizes7 (continued)

Die P/N Nominal Max. Pipe Min. Pipe Die Curv. Max. Tool Approximate Slip to Pipe Torque Factor

Pipe Size Weight8 Weight9 Diameter Diameter Tool Weight Body Load (Ktorque)

(Wcasing) (Wcasing) Efficiency

(ft.lbs/psi/ (N.m/MPa/

(in) (mm) (ppf) (kg/m) (ppf) (kg/m) (in) (mm) (in) (mm) (lbs) (kg) (% Fy) ppf) (kg/m))

82976 18.63 473.1 87.5 130.21 87.5 130.21 17.88 454.5 20.0 510 2,800 1,280 45% 0.01269 1.676

81434 18.63 473.1 94.5 140.63 87.5 130.21 17.90 455.0 20.0 510 2,800 1,280 51% 0.01415 1.869

81566 18.63 473.1 97.7 145.39 87.5 130.21 17.85 453.5 20.0 510 2,800 1,280 55% 0.0152 2.008

82101 18.63 473.1 111.0 165.19 97.7 145.39 17.71 450.0 20.0 510 2,800 1,280 55% 0.01525 2.015

82675 18.63 473.1 117.0 174.12 111.0 165.19 17.63 448.0 20.0 510 2,800 1,280 56% 0.01525 2.015

81880 18.63 473.1 139.0 206.85 136.0 202.39 17.39 442.0 20.0 510 2,800 1,280 56% - -

82300 20.0 508.0 94.0 139.89 94.0 139.89 19.31 490.5 20.0 510 3,000 1,370 49% 0.01362 1.799

81759 20.0 508.0 106.5 158.49 94.0 139.89 19.19 487.5 20.0 510 3,000 1,370 49% 0.01362 1.799

81483 20.0 508.0 133.0 197.93 129.3 192.42 18.92 481.0 20.0 510 3,000 1,370 50% 0.01418 1.873

101434 20.0 508.0 147.0 218.76 129.3 192.42 18.78 477.5 20.0 510 3,000 1,370 49% 0.01387 1.832

82740 20.0 508.0 169.0 251.50 166.4 247.63 18.58 472.0 20.0 510 3,000 1,370 52% - -

82102 22.0 558.8 184.5 274.57 184.5 274.57 20.53 521.5 28.0 715 3,100 1,410 45% - -

81750 22.0 558.8 224.0 333.35 224.0 333.35 20.11 511.0 28.0 715 3,100 1,410 40% - -

100029 24.0 609.6 176.0 261.92 176.0 261.92 22.72 577.5 28.0 715 3,100 1,410 38% 0.01086 1.435

101875 24.0 609.6 186.0 276.80 171.3 254.92 22.66 576.0 28.0 715 3,100 1,410 38% 0.01086 1.435

101050 24.0 609.6 201.0 299.12 201.0 299.12 22.47 571.0 28.0 715 3,100 1,410 39% 0.01131 1.494

81462 26.0 660.4 275.0 409.24 275.0 409.24 24.09 612.0 28.0 715 3,700 1,680 37% - -

82486 28.0 711.2 222.7 331.41 222.7 331.41 26.59 675.5 32.0 815 4,400 2,000 27% 0.00783 1.034

82506 30.0 762.0 233.2 347.07 233.2 347.07 28.59 726.5 32.0 815 4,700 2,140 24% 0.00717 0.947

*For details and availability on the Highflow option contact Volant sales at +1 780.784.7099

1. Characteristics are based on standard tool components and are independent of specific limitations of cage and accessories.

2. Maximum allowable set-down load applied to the tool. Some set-down load may be reacted through the coupling. This rating does not take into account bearing load

limitations of the coupling. Minimum makeup torque requirements specified in running procedure 100027 must be followed to realise full set-down load capacity.

3. CRTi tool circulation pressure capacity is generally governed by packer cup pressure capacity. Pressure capacity may be less than indicated if alternative seal arrange-

ments are used.

4. Base tool length does not include casing seal assembly. Overall tool length depends on the casing seal arrangement.

5. Maximum flow rate is based on minimizing erosion rates when using typical fluids. Erosion rates may vary depending upon the fluid contents. Please inspect tool bore

regularly.

6. Turns to Stoke Out is the rotational limit during tool makeup (this may be exceeded in combined load scenarios). The old style cams require 1.25 turns to stroke out.

7. Common die sizes shown. All API casing sizes and weights with drift diameter above 7.38 in (186.5 mm) are available.

8. Maximum pipe weight is defined by the API Specification 5CT drift diameter of the heaviest weight casing into which the CRTi tool assembled with the specified die set will fit.

9. Indicated minimum pipe weight is based on the assumption that control of average pipe inside diameter over die grip interval does not allow pipe body area reduction less

than 3.5% from nominal and additionally takes into account tool wear allowances, die penetration, casing deformation and diametrical stroke.

Give us a problem. Or just drop us a line if you want to know more.

sales@volantproducts.ca volantproducts.ca | sales@volantoiltoolsUS.com volantoiltoolsUS.com

Document No. 20007 / Revision P Printed in Canada JANUARY 2018

CRTi2-8.63 | PAGE 5

You might also like

- Volant Specs CRTi2-5.5 PDFDocument5 pagesVolant Specs CRTi2-5.5 PDFRaymond ChuNo ratings yet

- 20009K CRTi4 7.0 Specification Summary PDFDocument5 pages20009K CRTi4 7.0 Specification Summary PDFRichard PinontoanNo ratings yet

- Volant Specs CRTi4-7.01 PDFDocument5 pagesVolant Specs CRTi4-7.01 PDFRaymond ChuNo ratings yet

- Volant Specs CRTi3-7.01 PDFDocument4 pagesVolant Specs CRTi3-7.01 PDFRaymond ChuNo ratings yet

- 05 02 18 Saturn Specifications 5.8Document1 page05 02 18 Saturn Specifications 5.8Jose FavaNo ratings yet

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- PDC Make-Up TorqueDocument1 pagePDC Make-Up TorqueSug E QalanderNo ratings yet

- LCI 550SpecSheetDocument3 pagesLCI 550SpecSheetandy131078No ratings yet

- 10P-130 Mud Pump Brochure PDFDocument2 pages10P-130 Mud Pump Brochure PDFprillaNo ratings yet

- Handing Tools CPMCDocument32 pagesHanding Tools CPMCcristinelb100% (1)

- BOP BoltsDocument5 pagesBOP BoltsHadirah DunglahNo ratings yet

- 3000 HP RigDocument1 page3000 HP RigPrakash SekarNo ratings yet

- IDS 350PE Flyer D392004983 MKT 001Document2 pagesIDS 350PE Flyer D392004983 MKT 001Juan Mata100% (1)

- CPF Maintenance ManualDocument254 pagesCPF Maintenance Manualsalman khanNo ratings yet

- Volant Crti and CrteDocument4 pagesVolant Crti and CrteSudish Bhat100% (2)

- Chap EDocument44 pagesChap ERANJITH K PNo ratings yet

- 10017Document2 pages10017Alex RamirezNo ratings yet

- Surface BOP Kill Sheet - Vertical Well (Metric/BarDocument2 pagesSurface BOP Kill Sheet - Vertical Well (Metric/BarMelnapsterDsouzaNo ratings yet

- Manual Ancora Da Linha Morta Rig 127 Jzg20型死绳固定器使用维护说明书 (英)Document7 pagesManual Ancora Da Linha Morta Rig 127 Jzg20型死绳固定器使用维护说明书 (英)Rogerio NascimentoNo ratings yet

- Workover Daily Report WQ1-039Document3 pagesWorkover Daily Report WQ1-039kareem100% (1)

- 14P220 Triplex Mud Pump Spec SheetDocument1 page14P220 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- Motor PresentationDocument23 pagesMotor PresentationVirgilioNo ratings yet

- BOP Dimensions 13stackDocument3 pagesBOP Dimensions 13stackSasan AbbasiNo ratings yet

- Drilling FormulasDocument5 pagesDrilling FormulasJoshua RosensteinNo ratings yet

- Eckel Product Catalog - English PDFDocument28 pagesEckel Product Catalog - English PDFjohangomezruizNo ratings yet

- API Casing DesignDocument2 pagesAPI Casing DesignJohnNo ratings yet

- Champ Ion PackerDocument2 pagesChamp Ion PackerCHO ACHIRI HUMPHREYNo ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- 250 HMI 475 SpecsDocument3 pages250 HMI 475 SpecsProyectil De Proyecto100% (1)

- Bomba Triplex National JWS-185 - BrochureDocument4 pagesBomba Triplex National JWS-185 - BrochureNicoFocheNo ratings yet

- 06d AppendixB4 (550HP) 1582536012902Document94 pages06d AppendixB4 (550HP) 1582536012902Harsh TiwariNo ratings yet

- Crti® & Crte® Casing Running ToolsDocument62 pagesCrti® & Crte® Casing Running ToolsLuis Arreaza BelisarioNo ratings yet

- Ton Torque ManometrosDocument16 pagesTon Torque ManometrosEliecer DiazNo ratings yet

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- Ficha Tecnica Centrifuga WFT1656Document2 pagesFicha Tecnica Centrifuga WFT1656Ricardo VillarNo ratings yet

- Hydraulic-Set Perma-Lach PHL PackerDocument2 pagesHydraulic-Set Perma-Lach PHL PackerAmrani AdelNo ratings yet

- 2M Tek Torq Tek ZIIDocument1 page2M Tek Torq Tek ZIIamghardjillali_449230% (1)

- Cement Retainer 103387896 PDFDocument1 pageCement Retainer 103387896 PDFhitesh kumarNo ratings yet

- Dampener Hydrill Dimenciones PDFDocument2 pagesDampener Hydrill Dimenciones PDFCESAR SEGURANo ratings yet

- 8-P-80 Mud Pump BrochureDocument2 pages8-P-80 Mud Pump Brochuredavorp1402No ratings yet

- HH SwivelDocument3 pagesHH SwivelHoracio LafuenteNo ratings yet

- TSH 563 dimensions and specificationsDocument4 pagesTSH 563 dimensions and specificationsjbjb2000100% (1)

- Astm A193 B7Document2 pagesAstm A193 B7groshan20No ratings yet

- DST Tools Catalog PDF FreeDocument103 pagesDST Tools Catalog PDF FreeReza AsakerehNo ratings yet

- API - Mesh ConverterDocument1 pageAPI - Mesh Convertersaa6383No ratings yet

- Varel Mining CatalogDocument24 pagesVarel Mining CatalogEmerson Phocco Yauli100% (1)

- 12 Perforating SystemsDocument79 pages12 Perforating SystemsnazgultrNo ratings yet

- Fce 3000hp RigDocument6 pagesFce 3000hp RigTimothy PopikNo ratings yet

- Duraflo Composite Oemduea Mongoose PsDocument2 pagesDuraflo Composite Oemduea Mongoose Psflasher_for_nokiaNo ratings yet

- The Most Important Is To Visually Inspect Drilling Line All TimeDocument6 pagesThe Most Important Is To Visually Inspect Drilling Line All TimeabeymechNo ratings yet

- Wedge 563 Brochure OKDocument32 pagesWedge 563 Brochure OKNico Pan100% (1)

- Cup Type TesterDocument1 pageCup Type TesterJohnsNo ratings yet

- DDR N°02 - Sydnw1 - Enf57 - 24122019Document3 pagesDDR N°02 - Sydnw1 - Enf57 - 24122019Kenaouia Bahaa100% (1)

- 355 TDS-11S Parts Manual CC Rev1 GDSDocument170 pages355 TDS-11S Parts Manual CC Rev1 GDSrig602.mechanicNo ratings yet

- AXIOMDocument3 pagesAXIOMPrejit RadhakrishnaNo ratings yet

- Coc CKMDocument127 pagesCoc CKMajayNo ratings yet

- SCM PrimaG Shaker Rev4Document2 pagesSCM PrimaG Shaker Rev4Kritbordin RintaNo ratings yet

- Cougar DLLG Solutions FaqDocument5 pagesCougar DLLG Solutions FaqLenis CeronNo ratings yet

- Volant Specs CRTi2-8.63Document5 pagesVolant Specs CRTi2-8.63Raymond ChuNo ratings yet

- Crti® Internal Grip Casing Running ToolDocument4 pagesCrti® Internal Grip Casing Running ToolArnel SolisNo ratings yet

- 20019A Bulletin CRTiPinchPointDocument2 pages20019A Bulletin CRTiPinchPointtibismtxNo ratings yet

- SCT1020HDocument17 pagesSCT1020HAndrez Zarate MerinoNo ratings yet

- 17556A TechnicalFeedback FormDocument1 page17556A TechnicalFeedback FormtibismtxNo ratings yet

- 1374 Vata Well - Pile Driving Chart (07 07 2014)Document1 page1374 Vata Well - Pile Driving Chart (07 07 2014)tibismtxNo ratings yet

- 1368 Vata Well - Pile Driving Chart (06 07 2014)Document1 page1368 Vata Well - Pile Driving Chart (06 07 2014)tibismtxNo ratings yet

- WI13-VolantCRTiRunning Procedure - Pipe HandlerDocument4 pagesWI13-VolantCRTiRunning Procedure - Pipe HandlertibismtxNo ratings yet

- Hoist and Torque CapacitiesDocument1 pageHoist and Torque CapacitiestibismtxNo ratings yet

- 36# BTC J55 Torque V PinDocument1 page36# BTC J55 Torque V PintibismtxNo ratings yet

- Helix 13625-15500-0.870-SPDocument1 pageHelix 13625-15500-0.870-SPtibismtxNo ratings yet

- Premiere patented torque ring technical specificationsDocument1 pagePremiere patented torque ring technical specificationstibismtxNo ratings yet

- CRTi Saver Sub ProposalDocument1 pageCRTi Saver Sub ProposaltibismtxNo ratings yet

- Helix 09625-10587-0.433-SP30Document1 pageHelix 09625-10587-0.433-SP30tibismtxNo ratings yet

- OWS - 5.5in 17ppf Torque V PinDocument1 pageOWS - 5.5in 17ppf Torque V PintibismtxNo ratings yet

- 47ppf Torques V Pin Nose - Premiere Torque Rings (2020 - 05 - 20 01 - 58 - 29 UTC)Document4 pages47ppf Torques V Pin Nose - Premiere Torque Rings (2020 - 05 - 20 01 - 58 - 29 UTC)tibismtxNo ratings yet

- Pred-O-Tor 7 000 Casing X 8 300 OD Single Valve L80 29ppf Tenaris BlueDocument1 pagePred-O-Tor 7 000 Casing X 8 300 OD Single Valve L80 29ppf Tenaris BluetibismtxNo ratings yet

- 9-5/8" 36# BTC Torque Ring SpecsDocument1 page9-5/8" 36# BTC Torque Ring SpecstibismtxNo ratings yet

- Reaper 7 000 Casing X 8 300 Od l80 38ppf Tenaris BlueDocument1 pageReaper 7 000 Casing X 8 300 Od l80 38ppf Tenaris BluetibismtxNo ratings yet

- Articulation Compensator Tool (ACT)Document1 pageArticulation Compensator Tool (ACT)tibismtxNo ratings yet

- Erland - Petter - Indbjo Centralizer OptiCEM DrillingDocument84 pagesErland - Petter - Indbjo Centralizer OptiCEM DrillingManuel ChNo ratings yet

- CATALOG Weatherford CentralizerDocument20 pagesCATALOG Weatherford CentralizertibismtxNo ratings yet

- Wellplan Opticem ManualDocument21 pagesWellplan Opticem ManualtibismtxNo ratings yet

- OWS - A18 A2 - WBCU Swab Surge Tripping ScheduleDocument10 pagesOWS - A18 A2 - WBCU Swab Surge Tripping ScheduletibismtxNo ratings yet

- Drill Pipe JapanDocument28 pagesDrill Pipe JapaniancathNo ratings yet

- Journal of Petroleum Technology - August 2012Document107 pagesJournal of Petroleum Technology - August 2012tibismtxNo ratings yet

- Hydraulics Report for Romania WellDocument1 pageHydraulics Report for Romania WelltibismtxNo ratings yet

- Bit HydraulicsDocument11 pagesBit HydraulicstibismtxNo ratings yet

- Logan Fishing Jar (Z Type) ManualDocument38 pagesLogan Fishing Jar (Z Type) ManualtibismtxNo ratings yet

- Roller Cone Catalog 2012Document32 pagesRoller Cone Catalog 2012tibismtxNo ratings yet

- Drilling With Casing PDFDocument69 pagesDrilling With Casing PDFtibismtxNo ratings yet

- Boq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Document4 pagesBoq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Mr. 420No ratings yet

- English 1000 Most Repeated MCQs by Learning With Rizwan - 083731Document145 pagesEnglish 1000 Most Repeated MCQs by Learning With Rizwan - 083731Athleteboy7No ratings yet

- Experiment # 04: Short-Circuit Test of Single Phase TransformerDocument5 pagesExperiment # 04: Short-Circuit Test of Single Phase TransformerNasir Ali / Lab Engineer, Electrical Engineering DepartmentNo ratings yet

- Design and Development of A Three Phase Induction Motor Drive Using Ni-MyrioDocument5 pagesDesign and Development of A Three Phase Induction Motor Drive Using Ni-MyriovinaykumaarNo ratings yet

- HPLC Determination of Caffeine in Coffee BeverageDocument7 pagesHPLC Determination of Caffeine in Coffee Beveragemuhammad ihklasulNo ratings yet

- 7Document40 pages7Felipe RichardiosNo ratings yet

- Importance of Fish in Our Daily LifeDocument3 pagesImportance of Fish in Our Daily Lifekamei321No ratings yet

- Solution Manual For Chemistry For Today General Organic and Biochemistry 8th EditionDocument37 pagesSolution Manual For Chemistry For Today General Organic and Biochemistry 8th Editionrepastgraffitie17pv100% (14)

- Letter From Springfield Mayor Sarno To License Commission Re: Late Night Hours.Document12 pagesLetter From Springfield Mayor Sarno To License Commission Re: Late Night Hours.Patrick JohnsonNo ratings yet

- District Potential Analysis of PilibhitDocument57 pagesDistrict Potential Analysis of PilibhitJasraj SinghNo ratings yet

- FT-IR Analysis of Hock ProcessDocument4 pagesFT-IR Analysis of Hock ProcessmohsengolestanzadehNo ratings yet

- Minaral and MetalDocument109 pagesMinaral and Metaldeva nesan100% (1)

- Fire Flow CalculationsDocument37 pagesFire Flow CalculationsAmy CurryNo ratings yet

- Mode of AssignmentDocument95 pagesMode of AssignmentQasim AliNo ratings yet

- PN Junction Formation and Barrier PotentialDocument9 pagesPN Junction Formation and Barrier PotentialchristlllNo ratings yet

- Global Leader: in Glass IonomerDocument2 pagesGlobal Leader: in Glass IonomerAnggini ZakiyahNo ratings yet

- Assessment Toolkit: Health InequalitiesDocument30 pagesAssessment Toolkit: Health InequalitiesAlejandro CardonaNo ratings yet

- Airworthiness Directives Record ControlDocument4 pagesAirworthiness Directives Record ControlJuan builesNo ratings yet

- MONO POWER AMPLIFIER SERVICE MANUALDocument34 pagesMONO POWER AMPLIFIER SERVICE MANUALAlexey OnishenkoNo ratings yet

- X80 Io PDFDocument446 pagesX80 Io PDFHATEM68No ratings yet

- ID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKDocument2 pagesID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKsaenuddinNo ratings yet

- EVBAT00100 Batterij ModuleDocument1 pageEVBAT00100 Batterij ModuleSaptCahbaguzNo ratings yet

- Onan RV GenSet Service ManualDocument136 pagesOnan RV GenSet Service ManualAlbert A Ghazaleh100% (2)

- 25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedDocument7 pages25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedAnonymous RVO3O6zm0No ratings yet

- Dgca Module 06 Part 02Document15 pagesDgca Module 06 Part 02Deepak Choudhary DCNo ratings yet

- CaraKumpul - Soal PAS Bahasa Inggris Kls 12Document7 pagesCaraKumpul - Soal PAS Bahasa Inggris Kls 12akusayanklenaNo ratings yet

- Nichita Stanescu - The Poet of Loneliness and LossDocument28 pagesNichita Stanescu - The Poet of Loneliness and LossEmanuelaCiocanNo ratings yet

- Proposed Plan For Increasing The Entrepreneurial Skills of Students in Food PreservationDocument13 pagesProposed Plan For Increasing The Entrepreneurial Skills of Students in Food PreservationAnonymous B0hmWBTNo ratings yet

- Glycerol PDFDocument3 pagesGlycerol PDFTushar GaikarNo ratings yet

- ProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsDocument29 pagesProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsJosephNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationFrom EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationRating: 5 out of 5 stars5/5 (1)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressFrom EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressRating: 5 out of 5 stars5/5 (1)

- SolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)From EverandSolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Rating: 4.5 out of 5 stars4.5/5 (5)

- Autodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersFrom EverandAutodesk Inventor | Step by Step: CAD Design and FEM Simulation with Autodesk Inventor for BeginnersNo ratings yet

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersFrom EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNo ratings yet

- Fusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.From EverandFusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.No ratings yet

- The Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsFrom EverandThe Geometrical Tolerancing Desk Reference: Creating and Interpreting ISO Standard Technical DrawingsRating: 4.5 out of 5 stars4.5/5 (10)