Professional Documents

Culture Documents

Workover Daily Report WQ1-039

Uploaded by

kareemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workover Daily Report WQ1-039

Uploaded by

kareemCopyright:

Available Formats

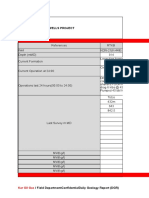

WQ1-FOD Workover Report

Well Name date Rep. No Last tagged TVD FORMATION NAME X-Mass Tree Direction

WQ1-039 19/11/2023 1 N/A 2432 Mishrif Flow line direction to the East

RIG NAME & No DM-143 FIELD NAME West Qurna 1

DAILY COST:

Xmas Tree Wellhead Type: WKM

LAST BOP TEST Next BOP Test

Valve Working

Details

Type-size Pressure

Size 7-1/16" * 11" BOP's Saturday, 18 November 2023

Master Valve WKM 4 1/16" 3K TBG-hanger Type Size (psi) & Date

Secondary Valve WKM 4 1/16" 3K Type WKM Annular BOP Cameron 13 5/8" 5K 500/1500psi 5/15mins

Swab Valve WKM 4 1/16" 3K size 7 1/16 Pipe Ram BOP Cameron 13 5/8" 5K 500/2500psi 5/15mins

Wing Valve WKM 4 1/16" 3K Thread / BPV Size 4" VAM /3.53" Blind Ram Cameron 13 5/8" 5K 500/2500psi 5/15mins

TBG & DP CSG

REMARKS: Details Old TBG

In well On derrick Production Liner

Details DP DC TBG DP HWDP DC Type LTC 9.5# VAM+7.7#VAM

Size, inch Size, inch 7 3.5''+4''

Joints, number Top depth SURFACE SURFACE

Length, meters Bottom depth 2470 2198

NPT Details on company IDC SLB HAL OT Delta Bad weather

NPT this day (hrs.)

NPT Total

Fuel (m³) Initial 40.5 Daily consumed 0.6 Remaining 39.9

OPERATIONS SUMMARY

Start - End Time

Duration Comments

(HH:MM) Class

Rig accepted at 19-Nov-2023 @ 20:00 pm

Started Well Operation:

20:00 21:30 1:30 P -HPJSM with all rig crew discussed the scope of the job and any potential hazards associated with the work.

-Connected surface lines to X-mass tree & Annulus & P/T line with 500/1500psi for 5/15min, OK.

Read SITP & SICP :

21:30 22:00 0:30 P -Read SITP =200 psi, then open the well to the waste tank there is flow of crude oil.

-Read SICP = 0psi, then open the well to waste tank to bleed off trapped gas .

Packer integrity test & cavity test:

22:00 22:30 0:30 P -Packer integrity test with 1000 psi through the annulus against the packer for 15min.. Test was Ok , then Bleed-off.

-Performed cavity test with 500/2500 psi for 5/10 min and test was ok.

Killing the well:

22:30 23:30 1:00 P -Started killing the well by bull heading through tubing with 10m³ of 1. SG Ind.water & 3 m³ Hi-vis then 13m³ of ind.water the parameter at surface

SPM 60 , Pressure at the beginning of bullheading was 300 psi then pressure dropping to zero.

Monitoring the well:

23:30 0:00 0:30 P

-After end bullheading , the well was opened for monitoring , there is no flow.

OPERATIONS SUMMARY - After mid night , 6 AM operation ,20-Nov-2023

WOWH:

-L/D surface line and flange.

-Disconnected the tree cap of x-mass tree and Installed 4" OD BPV into Tubing Hgr .

0:00 2:30 2:30 P -Remove 7 1/16",3k x 4 1/16",3k THA with wellhead Xmas tree valve.

-Checked top connection of the hanger and connected the suitable XOS to the hanger.

-Measured lock down screws of tubing hanger ( fully tightened 6 cm and when they are fully retracted 7 cm ).

-Clean the wellhead and clean the ring gasket groove and install the ring gasket.

2:30 3:30 1:00 N Stop operation due to bad weather (high wind speed with heavy rain).

WOWH:

3:30 6:00 2:30 P - N/U 7/16" 3K X 13 5/8" 5K DSA.

- N/U 13 5/8" 5K BOP. in progress...

Current Status: Cont. N/U 13 5/8'' BOP

24 Hr Summary: Rig accepted at 19-Nov-2023 @ 20:00, Read SITP&SICP and Kill the well then Monitoring the well , N/D Xmas tree and start N/U BOBs .

24 Hr Forecast: Release the anchor and Bullheading packer fluid then relatch the anchor, set 2.25'' FWG , released the anchor , POOH old completion tubing .

Received:

Other Activities:

EMIL FOD EMIL FOD EMIL FOD Well Work

IDC RM/SE IDC HSE Spy.

Well Work Subsurface Engineers Operations Superintendents

Saif Makki Haider s. Sajjad Ibrahim Bashar Lin/ Luo

Mohammed Ghazi

Osama A. / Mohammed Ali Hussein Ali Safaa Bassam A.H.

WQ1-FOD Workover Report

Well Name date Rep. No Last tagged TVD FORMATION NAME X-Mass Tree Direction

WQ1-039 20/11/2023 2 N/A 2432 Mishrif Flow line direction to the East

RIG NAME & No DM-143 FIELD NAME West Qurna 1

DAILY COST:

Xmas Tree Wellhead Type: WKM

LAST BOP TEST Next BOP Test

Valve Working

Details

Type-size Pressure

Size 7-1/16" * 11" BOP's Saturday, 18 November 2023

Master Valve WKM 4 1/16" 3K TBG-hanger Type Size (psi) & Date

Secondary Valve WKM 4 1/16" 3K Type WKM Annular BOP Cameron 13 5/8" 5K 500/1500psi 5/15mins

Swab Valve WKM 4 1/16" 3K size 7 1/16 Pipe Ram BOP Cameron 13 5/8" 5K 500/2500psi 5/15mins

Wing Valve WKM 4 1/16" 3K Thread / BPV Size 4" VAM /3.53" Blind Ram Cameron 13 5/8" 5K 500/2500psi 5/15mins

TBG & DP CSG

REMARKS: Details Old TBG

In well On derrick Production Liner

Details DP DC TBG DP HWDP DC Type LTC 9.5# VAM+7.7#VAM

Size, inch Size, inch 7 3.5''+4''

Joints, number Top depth SURFACE SURFACE

Length, meters Bottom depth 2470 2198

NPT Details on company IDC SLB HAL OT Delta Bad weather

NPT this day (hrs.) 1

NPT Total 1hr.

Fuel (m³) Initial 39.9 Daily consumed 1.25 Remaining 38.65

OPERATIONS SUMMARY

Start - End Time

Duration Comments

(HH:MM) Class

WOWH:

-L/D surface line and flange.

-Disconnected the tree cap of x-mass tree and Installed 4" OD BPV into Tubing Hgr .

0:00 2:30 2:30 P -Remove 7 1/16",3k x 4 1/16",3k THA with wellhead Xmas tree valve.

-Checked top connection of the hanger and connected the suitable XOS to the hanger.

-Measured lock down screws of tubing hanger ( fully tightened 6 cm and when they are fully retracted 7 cm ).

-Clean the wellhead and clean the ring gasket groove and install the ring gasket.

2:30 3:30 1:00 N Stop operation due to bad weather (high wind speed with heavy rain).

WOWH:

- N/U 7/16" 3K X 13 5/8" 5K DSA.

3:30 10:00 6:30 P

- N/U 13 5/8" 5K BOP.

-Connected the surface lines and hydraulic hoses then charge the accumulator unit to the normal working pressure.

BOP P/T :

-P/U , M/U (3.5" IF BOX- 4" Vam PIN XOS ) with 3.5" IF DP landing joint and RIH into tubing hanger .

10:00 11:30 1:30 P

-Closed Pipe ram then P/T the connection of the BOP with 500/2500psi for 5/15min ..hold up.

-L/D 3 1/2'' IF landing joint.

11:30 12:00 0:30 P Pumping 15m3 of ind.water inside tubing.

12:00 13:00 1:00 P R/U Kelly and connected inside tubing hanger.

Release Anchor :

-Open the Lock down screws of tubing hanger .

13:00 14:00 1:00 P

-Started released the anchor , the string weight 29 tons without buoyancy factor plus the weight of the Kelly & block 4 tons the total weight 33 tons then pulled up

the string with 2 ton over pull and rotated string 7 turns on the right the anchor got released , and noticed free string weight 29 ton.

Bullhead packer fluid:

14:00 16:30 2:30 P -Started bullheading packer fluid to the formation by pumping 3mᵌ Hi-vis & 60mᵌ of 1.0 SG ind.water through annulus with surface parameter SPM 60 , Pressure

350 psi.

Re-latch the anchor:

16:30 17:30 1:00 P -Re latch the anchor in the top of packer and then pull up the string we got 3 tons overpull that indicates good latch for the anchor.

-Tight lock down screws of tubing hanger.

R/D Kelly

17:30 18:30 1:00 P -R/D Kelly.

-P/U & M/U 3.5" vam top landing joint and connected to the hanger.

HAL SL Operation:

-HPJSM with HAL slickline and rig crew to discuss the potential hazards related to the job.

18:30 20:30 2:00 P

-R/U HAL SL equipment & PCE.

-PT Hal SL equipment with 250/500 psi for 5/15 min and test was ok

HAL SL Operation (RIH 2.25'' GC) :

20:30 21:30 1:00 P

-RIH drift run and tag at top of nipple at depth of 2192 m then POOH to the surface.

HAL SL Operation (RIH & Set 2.25" FWG plug ):

21:30 23:00 1:30 P -Connected the tool at surface and RIH and set FWG by jarring down the plug then POOH to the surface.

-PT against FWG plug with 500/1500 psi for 5/15min , test was ok.

HAL SL Operation:

23:00 0:00 1:00 P

-R/D HAL SL equipment

OPERATIONS SUMMARY - After mid night , 6 AM operation ,21-Nov-2023

Release the anchor :

- L/D 3.5" vam top landing joint

- R/U Kelly & connected into tubing hanger

0:00 3:00 3:00 P

- Retracted lock down screw of tubing hanger.

- Pull up the string to 35ton and rotated string 8 turns on the right the anchor got released

- L/D Kelly & L/D 7 1/16" tubing hanger.

Circulation the well:

-Connected FOSV and L/U line to be ready for circulation.

3:00 5:00 2:00 P

-Started Normal circulation by pumping 3m³ Hi-vis then chased by 50m³ of 1.0 SG ind.water , with surface parameter SPM 70 , Pressure 400psi , and got clean

return .

Preparing for POOH old completion :

5:00 5:30 0:30 P -Housekeeping the rig floor.

-R/U Power tongue.

5:30 6:00 0:30 P POOH old Completion:

- Started POOH & L/D 4" old tubing single by single to the pipe rack to depth 2137m.

Current Status: Cont. POOH old completion.

24 Hr Summary: Release the anchor and Bullheading packer fluid then relatch the anchor, set 2.25'' FWG , released the anchor , POOH old completion tubing .

24 Hr Forecast: Cont. POOH old completion.

Received:

Other Activities:

EMIL FOD EMIL FOD EMIL FOD Well Work

IDC RM/SE IDC HSE Spy.

Well Work Subsurface Engineers Operations Superintendents

Saif Makki Haider s. Sajjad Ibrahim Bashar Lin/ Luo

Mohammed Ghazi

Osama A. / Mohammed Ali Hussein Ali Safaa Bassam A.H.

You might also like

- Conduction From Fluids Through Pipes LectureDocument16 pagesConduction From Fluids Through Pipes Lecturech0k3 iiiNo ratings yet

- Final Year Design Project Thesis Report Session 2018Document153 pagesFinal Year Design Project Thesis Report Session 2018RiholoNo ratings yet

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Q4 WEEK 1 Gen Chem 2 Worksheet 10 THERMODYNAMICSDocument11 pagesQ4 WEEK 1 Gen Chem 2 Worksheet 10 THERMODYNAMICSMarielle TibayNo ratings yet

- Shts & RPSB, HPSRDocument8 pagesShts & RPSB, HPSRAyman100% (1)

- Master Well Log NE-85 Scale 1:200Document30 pagesMaster Well Log NE-85 Scale 1:200parama drillingNo ratings yet

- Leak-Off Test Analysis: Well: RigDocument5 pagesLeak-Off Test Analysis: Well: RigstevebeardsleyNo ratings yet

- Re Entry Work: Setting WhipstocksDocument3 pagesRe Entry Work: Setting WhipstocksAnilNo ratings yet

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysDocument2 pagesSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorreNo ratings yet

- Drill String 1 DISDocument1 pageDrill String 1 DISpiies85No ratings yet

- MR86L - Drilling MontageDocument1 pageMR86L - Drilling MontageGabriel PlazasNo ratings yet

- OOT PulsFrac Input Request - OEF-1000-001 TPN-211Document5 pagesOOT PulsFrac Input Request - OEF-1000-001 TPN-211Christian BimoNo ratings yet

- 16 BHA Tally FormatDocument2 pages16 BHA Tally FormatShraddhanand MoreNo ratings yet

- He-E10 Well MontageDocument1 pageHe-E10 Well MontageSaeid OrangiNo ratings yet

- Daily Drilling Report for HERUNEFER W-13 WellDocument3 pagesDaily Drilling Report for HERUNEFER W-13 WellIslam AtifNo ratings yet

- Goldenman Petroluem Equipment Co., Limited: Quotation ListDocument4 pagesGoldenman Petroluem Equipment Co., Limited: Quotation ListEstuardo AlvaradoNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- WFT 000483Document4 pagesWFT 000483Abboud KingNo ratings yet

- CT Coveyed PerforatingDocument4 pagesCT Coveyed PerforatingAdel Ahmed AlkhaligyNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDocument4 pagesAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNo ratings yet

- Synthetic-Based Mud Report No. 39: LLOG ExplorationDocument1 pageSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025No ratings yet

- Well DataDocument5 pagesWell Datamohamed elshemyNo ratings yet

- Job Pertamina-Petrochina East Java: Wahdanadi, ErikDocument2 pagesJob Pertamina-Petrochina East Java: Wahdanadi, Erikuli ulinuhaNo ratings yet

- Amal-18 Sta DDR#20 02-03-2020Document30 pagesAmal-18 Sta DDR#20 02-03-2020eng7mohamed7hashimNo ratings yet

- Kahraman C-181 (ST-1)Document3 pagesKahraman C-181 (ST-1)Islam AtifNo ratings yet

- Rig Crew Night Shift AttendanceDocument56 pagesRig Crew Night Shift Attendanceezi gusfiaNo ratings yet

- GEOREPORT Mudlogging ExampleDocument2 pagesGEOREPORT Mudlogging ExampleCarmen Ibeth Olivos PradaNo ratings yet

- Vertical Development Well Mud ReportDocument12 pagesVertical Development Well Mud ReportBOUBAKER LOGBINo ratings yet

- Shock Tool Manual PDFDocument23 pagesShock Tool Manual PDFAbboud KingNo ratings yet

- Notes 4Document18 pagesNotes 4Ruben ChirinosNo ratings yet

- Khurmala Field Well DGRDocument9 pagesKhurmala Field Well DGRAhmedNo ratings yet

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 pagesKhurmala Field Field Department Drilling Deve. Oil Wells Project TU Locationahmed1adnan-10No ratings yet

- 16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7Document1 page16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7javier monteroNo ratings yet

- DDR 27-10Document1 pageDDR 27-10GPCNo ratings yet

- WLL 087Document32 pagesWLL 087fauzan kartiyasaNo ratings yet

- Mizzen L-11 - End of Well Report - INV - 032042 642 PDFDocument1 pageMizzen L-11 - End of Well Report - INV - 032042 642 PDFKevin MuellerNo ratings yet

- Morning Report 19 - 24 April 2012Document3 pagesMorning Report 19 - 24 April 2012tolstoy potemkinNo ratings yet

- TCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsDocument1 pageTCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsrajafonsekaNo ratings yet

- BOP Dimensions 13stackDocument3 pagesBOP Dimensions 13stackSasan AbbasiNo ratings yet

- Chap EDocument44 pagesChap ERANJITH K PNo ratings yet

- O 1 03 01Document2 pagesO 1 03 01gplese0No ratings yet

- Make Up TorqueDocument1 pageMake Up TorqueNicasio AlonzoNo ratings yet

- Trex 01157Document17 pagesTrex 01157OSDocs2012No ratings yet

- ADM III Rig Safety Report 28-03-2018Document1 pageADM III Rig Safety Report 28-03-2018Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Detailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestDocument9 pagesDetailed Working Instruction: South Azadegan Oil Field Epd Project AZNS-163/ 7" Liner Lap Inflow TestMehdi NorouziNo ratings yet

- Programa Completo Completacion InicialDocument23 pagesPrograma Completo Completacion InicialAlejandro JaramilloNo ratings yet

- SOP 829-019 Rig Out The Mud Tanks and Pumps.Document2 pagesSOP 829-019 Rig Out The Mud Tanks and Pumps.Anonymous XbmoAFtINo ratings yet

- AM DRLG Report 19-12-2017Document336 pagesAM DRLG Report 19-12-2017Islam AtifNo ratings yet

- CLJOC Well SD-24P Bit RecordDocument1 pageCLJOC Well SD-24P Bit RecordThem Bui XuanNo ratings yet

- DDR N°02 - Sydnw1 - Enf57 - 24122019Document3 pagesDDR N°02 - Sydnw1 - Enf57 - 24122019Kenaouia Bahaa100% (1)

- Stab-in Cementing Job Risk AssessmentDocument2 pagesStab-in Cementing Job Risk AssessmentIbnu HasanNo ratings yet

- Pos North1 - Basic WCR Rev0Document874 pagesPos North1 - Basic WCR Rev0Felipe RamírezNo ratings yet

- Vibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter MeasureDocument1 pageVibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter Measuresaeed65No ratings yet

- BP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Document42 pagesBP Shell Chevron Conocophillips Marathon Total Schlumberger Imperial College, London Heriot Watt University, Edinburgh (Anywhere in Article)Doppler KenzoNo ratings yet

- Field Fluids QaqcDocument38 pagesField Fluids QaqcscrbdgharaviNo ratings yet

- 7 X 9.625 With TSP, DWPDocument5 pages7 X 9.625 With TSP, DWPRahima RahoumaNo ratings yet

- 05 Trip Sheet - IPM - QuartzDocument7 pages05 Trip Sheet - IPM - QuartzRebarNo ratings yet

- Bit BallingDocument18 pagesBit BallingGPC100% (1)

- BHA and Running ProcedureDocument5 pagesBHA and Running ProcedureRANJITH K PNo ratings yet

- Fishing Operation to Remove Stuck ToolsDocument1 pageFishing Operation to Remove Stuck ToolsIvan Dario Benavides BonillaNo ratings yet

- 4 1/2Document1 page4 1/2Hassan ZakeriNo ratings yet

- Optimizing bit hydraulics and hole cleaning calculationsDocument1 pageOptimizing bit hydraulics and hole cleaning calculationsDian SikumbangNo ratings yet

- Daily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqDocument18 pagesDaily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqkareemNo ratings yet

- Po 4510089832Document2 pagesPo 4510089832kareemNo ratings yet

- BOP Configuration 9.625inch Mud CrossDocument2 pagesBOP Configuration 9.625inch Mud CrosskareemNo ratings yet

- Po 4510089832Document2 pagesPo 4510089832kareemNo ratings yet

- Waiting On Daylight Waiting On Mast Leg Pad InspectionDocument1 pageWaiting On Daylight Waiting On Mast Leg Pad InspectionkareemNo ratings yet

- Daily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqDocument18 pagesDaily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqkareemNo ratings yet

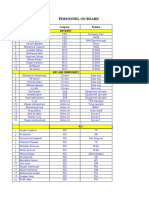

- Personnel On Board: No. Full Name Company Position LocationDocument4 pagesPersonnel On Board: No. Full Name Company Position LocationkareemNo ratings yet

- Dor 19-11-2019 FH#5 Idc45 18Document1 pageDor 19-11-2019 FH#5 Idc45 18kareemNo ratings yet

- Waiting On Daylight Waiting On Mast Leg Pad InspectionDocument1 pageWaiting On Daylight Waiting On Mast Leg Pad InspectionkareemNo ratings yet

- Iraqi Drilling Company Daily Report Integrated Mangement System (IDCP08F4)Document1 pageIraqi Drilling Company Daily Report Integrated Mangement System (IDCP08F4)kareemNo ratings yet

- Iraqi Drilling Company SOP Risk AssessmentDocument4 pagesIraqi Drilling Company SOP Risk AssessmentkareemNo ratings yet

- IDC SOP # XX Laying Down Drill Pipe From DerrickDocument4 pagesIDC SOP # XX Laying Down Drill Pipe From DerrickkareemNo ratings yet

- IDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)Document4 pagesIDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)kareemNo ratings yet

- IDC Pipe Spinner SOPDocument2 pagesIDC Pipe Spinner SOPkareemNo ratings yet

- IDC SOP # 11 POOH With DP, DC's and BitDocument3 pagesIDC SOP # 11 POOH With DP, DC's and Bitkareem100% (1)

- IDC SOP #1 Press. Test of The Standpipe in The Direction of Flow (Downstream) - MPs To TDSDocument3 pagesIDC SOP #1 Press. Test of The Standpipe in The Direction of Flow (Downstream) - MPs To TDSkareemNo ratings yet

- Testing Pressure of Standpipe and Mud PumpsDocument5 pagesTesting Pressure of Standpipe and Mud PumpskareemNo ratings yet

- Mahler AGS Gas PurificationDocument1 pageMahler AGS Gas PurificationremeenNo ratings yet

- Order of Degeneration +M First Method-Initial RateDocument9 pagesOrder of Degeneration +M First Method-Initial RateZeina Abi FarrajNo ratings yet

- Ammonia Destruction in The Reaction Furnace - Optimized Gas TreatingDocument9 pagesAmmonia Destruction in The Reaction Furnace - Optimized Gas TreatingAlejandro PedezertNo ratings yet

- Thermodynamic Analysis of Optimal Condensing Temperature of Cascade-Condenser in CO /NH Cascade Refrigeration SystemsDocument9 pagesThermodynamic Analysis of Optimal Condensing Temperature of Cascade-Condenser in CO /NH Cascade Refrigeration Systemslog duongNo ratings yet

- Tur Bulat or WebDocument13 pagesTur Bulat or WebBakkiyarajNo ratings yet

- Mb3 - Bp1: Hella Romania S.R.L. Compressed Air Preparation Zbv-Automation GMBHDocument9 pagesMb3 - Bp1: Hella Romania S.R.L. Compressed Air Preparation Zbv-Automation GMBHREMUSNo ratings yet

- аналоги к компрессорам - 2009Document77 pagesаналоги к компрессорам - 2009Andrej SobolevNo ratings yet

- Enhancing Rotary Vacuum Drum Filter PerformanceDocument8 pagesEnhancing Rotary Vacuum Drum Filter PerformanceSiska MilalaNo ratings yet

- PSV Sizing Blocked OutletDocument1 pagePSV Sizing Blocked OutletJamie RapajonNo ratings yet

- Process Synthesis 1 - IntroductionDocument30 pagesProcess Synthesis 1 - Introductionemartey62No ratings yet

- Manufacturing Processes UNIT Test-I - Series A With SolutionsDocument1 pageManufacturing Processes UNIT Test-I - Series A With SolutionsAnand KesarkarNo ratings yet

- Material Borrow From F&DDocument1 pageMaterial Borrow From F&DRizkiHusniNo ratings yet

- Process Simulation and Control Using Aspen 117 200Document84 pagesProcess Simulation and Control Using Aspen 117 200Geovanny J.No ratings yet

- Final ReportDocument19 pagesFinal Reportapi-610895314No ratings yet

- Saththasivam 2016Document10 pagesSaththasivam 2016Jesus PerezNo ratings yet

- AE8503 Aerodynamics IIDocument70 pagesAE8503 Aerodynamics IIthandialNo ratings yet

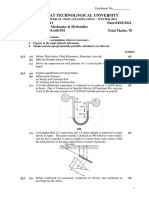

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- P 414 ED tcm72 7423Document7 pagesP 414 ED tcm72 7423Denis ReisNo ratings yet

- Improving Descale Performance With The Descalejet ProDocument7 pagesImproving Descale Performance With The Descalejet ProAdmiral FighterNo ratings yet

- Compression and SolidsDocument23 pagesCompression and SolidsHUSNAIN MURTAZA GHULAMNo ratings yet

- CHEMICAL EQUILIBRIA Part 1Document24 pagesCHEMICAL EQUILIBRIA Part 1ongkikoNo ratings yet

- DepressuringDocument23 pagesDepressuringbimo wahyuNo ratings yet

- Cheat Sheet Chemistry Chapter 6 Rate of Reaction 2Document41 pagesCheat Sheet Chemistry Chapter 6 Rate of Reaction 2yinkaNo ratings yet

- الزبدهDocument6 pagesالزبدهgeologistgeologist50No ratings yet

- Chapter 5-Fundamentals of Fluid FlowDocument26 pagesChapter 5-Fundamentals of Fluid FlowJerico Torres AdajarNo ratings yet

- Y12 April Assessment 2019Document10 pagesY12 April Assessment 2019Anela XVIINo ratings yet