Professional Documents

Culture Documents

#402 Valve Overhauling in A Cargo Tank

Uploaded by

Tolias EgwOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

#402 Valve Overhauling in A Cargo Tank

Uploaded by

Tolias EgwCopyright:

Available Formats

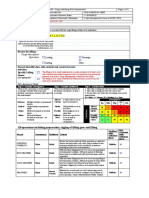

AKRON RISK ASSESSMENT R/A NO : 402

TYPE OF ACTIVITY: ROUTINE / NON- DESCRIPTION OF ACTIVITY : VALVE OVERHAULING IN A CARGO TANK

ROUTINE

RISK ASSESSMENT GUIDE : RISK MUST BE REDUCED TO AS LOW AS REASONABLY PRACTICABLE (ALARP)

STEP 1 : CONSIDER SEVERITY OF HARM (S) STEP 2 : CONSIDER LIKELIHOOD (L) STEP 3:CALCULATE RISK

1: NEGLIGIBLE: Near Miss or Simple First Aid/ Simple Repairs by ship staff/ Spill within spill trays 1: IMPROBABLE-Event not expected to occur RISK RATING RR = S x L

2: MINOR : Injury require Medical Treatment; MTC/ Repair need external assistance / Spill on deck < 1 m3 2 : RARE: Expected to occur in exceptional situations RR RISK CATEGORY

MODERATE: Serious injury or multiple minor injuries; LTI / Repairs affecting seaworthiness of ship leading to CoC / Spill on

3: 3: POSSIBLE: May occur at some time / occurred in the past

deck > 1 m3 1- 5 L - LOW

CRITICAL : Single fatality, Serious injuries, permanent disability / Requires lay up repairs or extensive drydockings, 3rd

4: 4: LIKELY : Possibility of occurrence of isolated incidents

party claims/ Spill overboard < 100L 6 - 10 M - MEDIUM

CATASTROPHIC : Mutiple Fatalaities or Long Term disabilities/ Total Loss of ship or immediate layup/dry-docking for major

5: 5: CERTAIN: Is expected to occur in most situations

repairs / Major overboard spill > 100 L 11 - 25 H - HIGH

NO HAZARD DESCRIPTION RISK EXISTING CONTROLS RISK RATING RISK ADDITIONAL CONTROLS RESIDUAL RISK RESI-

(WITH CONTROLS IN CATEG (IF NOT REQUIRED, WRITE "N". RATING DUAL

PLACE)

L/M/H IF REQUIRED, LIST OUT THE ADDITIONAL (WITH ADDIT'L RISK

CONTROLS ) CONTROLS)

CAT.

( S x L= RR) (S x L = RR) L/M/H

S L RR S L RR

1. Exposure to flammable/toxic gases. Explosion, Fire, 1. The person in charge of the work in the tank 4 2 8 M 1.Each person working in the tank 4 1 4 L

Lack of oxygen. Asphyxiation should wear a personal multi-gas detection should carry an EEBD.

instrument.

2. It should be ensured that I.G.S main isolating 2. Check the effectiveness of IG

valve of the working tank is secured / locked in valve isolation. If required the line

closed position. should be blanked.

3. The I.G. pressure of the remaining cargo tanks to

be kept at minimum positive pressure (200 mmwg).

2. Inadequate ventilation/illumination. Trips, Slips, 1. Adequate ventilation should be ensured by the 4 2 8 M 1.Any alarm on the personal meter, 4 1 4 L

Injury, Fainting use of a portable water-driven fan and flexible air- all persons to evacuate the space

duct. immediately.

2. Adequate illumination should be ensured by the 2. Sufficient portable intrisically safe

use of portable gastight/Ex lights torches to be provided and used.

FORM NO: S-20 / REV. 0 / 01 MAR 2010 Page 1 / 4 R/A NO :402

NO HAZARD DESCRIPTION RISK EXISTING CONTROLS RISK RATING RISK ADDITIONAL CONTROLS RESIDUAL RISK RESI-

(WITH CONTROLS IN CATEG (IF NOT REQUIRED, WRITE "N". RATING DUAL

PLACE)

L/M/H IF REQUIRED, LIST OUT THE ADDITIONAL (WITH ADDIT'L RISK

CONTROLS ) CONTROLS)

CAT.

( S x L= RR) (S x L = RR) L/M/H

S L RR S L RR

3. Contact with hazardous substances. Chemical burns, 1. MSDS of the previous cargo should be 2 2 4 L N

skin irritation Consulted.

2. Skin contact with oil residues to be avoided by

ensuring that all body parts are fully covered with

protective clothing.

4. Pipeline leakage. Slips, trips, 1. All suction-cross over V/Vs to be closed and 3 2 6 M All the concerned valves should be 3 1 3 L

drowning, toxic marked as appropriate to eliminate any possibility of locked and tagged out, confirmaed

vapours leakage due to accidentally openings of the valves. by a responsible officer.

2. The stripping pump should be ready for Continuous monitoring of concerned

immediate use (to strip any leakage). line. Any sign of leakages,

immediately evacuate

5. Pressurized media. inadvertant 1. Hydraulic system to the working tank should be 3 1 3 L N

operation of the isolated to avoid any inadvertent operation. A

valve. relevant warning label (NOT TO OPERATE) should

be posted.

2. During the work any operation of the cargo and

hydraulic valves should be prohibited and a relevant

WARNING should be posted in the CCR. If possible

the system to be made inopperable for the duration

of job.

6. High temperature/ humidity in the Dehydration, 1. See 3A. 2 2 4 L N

working area. fainting, injury

2. Adequate work rest periods should be

provided and precautions against dehydration

should be taken.

7. Fatigue. Injury 1. See above measures. 2 2 4 L N

2. Any involved personnel showing signs of fatigue

should be released from duty and replaced at once.

FORM NO: S-20 / REV. 0 / 01 MAR 2010 Page 2 / 4 R/A NO :402

NO HAZARD DESCRIPTION RISK EXISTING CONTROLS RISK RATING RISK ADDITIONAL CONTROLS RESIDUAL RISK RESI-

(WITH CONTROLS IN CATEG (IF NOT REQUIRED, WRITE "N". RATING DUAL

PLACE)

L/M/H IF REQUIRED, LIST OUT THE ADDITIONAL (WITH ADDIT'L RISK

CONTROLS ) CONTROLS)

CAT.

( S x L= RR) (S x L = RR) L/M/H

S L RR S L RR

8. Lifting/transferring heavy objects. Injury, damage to 1. The lifting/securing procedure to be applied 2 2 4 L N

equipment should be properly planned and communicated to

the involved personnel.

2. Securing-lifting arrangements /blocks

/slings/wires must be placed in position prior

dismantling of the valve.

3. During lifting heavy objects, all personnel

should keep clear from the “dangerous zone.

4. During lowering/transferring tools in the tank from

the cargo hatch, it should be ensured that nobody is

underneath.

9. Manual handling Injury 1. Equipment/tools to be used to be cleaned from 3 1 3 L

any oil residues so as to ensure proper/steady

grasp/hold.

10. Slippery surface. Injury, slip, trips, 1. Working area to be free of oil and well cleaned. 2 2 4 L

fall 2. Wiping rags to be available ready for use so as to

keep clean the working area.

3. The passage way from the cargo tank hatch to

the working area should be cleaned and kept free of

any oil residues

11. Adverse weather/sea condition. Injury, slip, trips, 1. The work should not be carried in adverse 2 2 4 L

fall weather.

2. Weather conditions-forecast to be monitored and

in case of deterioration the Master/Chief Officer

should be advised.

FORM NO: S-20 / REV. 0 / 01 MAR 2010 Page 3 / 4 R/A NO :402

NO HAZARD DESCRIPTION RISK EXISTING CONTROLS RISK RATING RISK ADDITIONAL CONTROLS RESIDUAL RISK RESI-

(WITH CONTROLS IN CATEG (IF NOT REQUIRED, WRITE "N". RATING DUAL

PLACE)

L/M/H IF REQUIRED, LIST OUT THE ADDITIONAL (WITH ADDIT'L RISK

CONTROLS ) CONTROLS)

CAT.

( S x L= RR) (S x L = RR) L/M/H

S L RR S L RR

12. Failure to follow repair/maintenance 1. Dismantling–overhauling procedures to be well 3 1 3 L

instructions. discussed-understood and the work should be

carried out in accordance with instructions issued by

the Chief Engineer.

2. Following the valve overhauling, the valve’s

remote operation should be checked (open/close)

ensuring that no hydraulic leakage exists.

3. Following the above operation check, a pressure

test should be carried out with the involved

personnel keeping a safe distance from the

overhauled valve.

13. Inadequate operation 1. A work planning/safety meeting should be carried 2 2 4 L

planning/coordination/supervision. out with the participation of all involved personnel

with the aim of discussing, amongst others: (a) job

procedure; (b) tool transferring arrangements; (c)

lifting arrangements; (d) safety procedures/work

permits; (e) individual work responsibilities; (f)

means of communication.

2. The Chief Officer should be in charge supervising

the job.

3. All required spare parts must be verified that are

available onboard.

4. All required tools must be verified that are

available onboard and in good condition.

14. Inadequate communication 1. It should be ensured that involved personnel are 2 2 4 L

well familiar with the Code of Hand Signals.

2. All walkie-talkies to be used should be in good

operational condition and fully charged.

Final Asesssment : Provided no deviations from the recommended control measures, the residual risk assessed is As Low As Resonably Practicable (ALARP).

Supplementary measures include correct use of PPE & Tool Box talks that ensure all workers are fully aware of the control measures.

Residual risk - HIGH : If RR is "High" category, written instructions for conducting the job and approval shall be obtained from the shore office to commence the operation.

Residual risk - MEDIUM: If RR is "Medium" , a constant monitoring of events shall be maintained and ensure all identified preventative and mitigating measures are always in place.

PREPARED BY: TECH. DEPT , S & Q DEPT. APPROVED BY: S & Q MANAGER

01 03 2010

FORM NO: S-20 / REV. 0 / 01 MAR 2010 Page 4 / 4 R/A NO :402

You might also like

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- A Beautiful Mind - Psychology AnalysisDocument15 pagesA Beautiful Mind - Psychology AnalysisFitto Priestaza91% (34)

- #405 Maintenance of Emergency GeneratorDocument2 pages#405 Maintenance of Emergency GeneratorTolias EgwNo ratings yet

- 02.1 - HSE - Policy-01 03 16 PDFDocument1 page02.1 - HSE - Policy-01 03 16 PDFTolias EgwNo ratings yet

- Allianz ZeusDocument2 pagesAllianz Zeuslulu fitriyaniNo ratings yet

- #411 Work On Pipelines or Systems Under Pressure or Flammable MediumDocument2 pages#411 Work On Pipelines or Systems Under Pressure or Flammable MediumTolias EgwNo ratings yet

- Mathematics Into TypeDocument114 pagesMathematics Into TypeSimosBeikosNo ratings yet

- Shipboard Oil Pollution Emergency Plan (Sopep)Document35 pagesShipboard Oil Pollution Emergency Plan (Sopep)setiawan agusNo ratings yet

- #404 Emergency Fire Pump Maintenance (Revised)Document4 pages#404 Emergency Fire Pump Maintenance (Revised)Tolias EgwNo ratings yet

- Hazard Identification, Risk Assessment and Control Record Register For Offshore ActivitiesDocument4 pagesHazard Identification, Risk Assessment and Control Record Register For Offshore Activitiespvs12684100% (2)

- #308 Cargo Operations - Failure of No . Cot Remote Ullaging and Temperature MonitoringDocument1 page#308 Cargo Operations - Failure of No . Cot Remote Ullaging and Temperature MonitoringTolias EgwNo ratings yet

- Echeverria Motion For Proof of AuthorityDocument13 pagesEcheverria Motion For Proof of AuthorityIsabel SantamariaNo ratings yet

- #016 Underwater OperationsDocument3 pages#016 Underwater OperationsTolias Egw100% (1)

- MOC FormDocument1 pageMOC FormahmedNo ratings yet

- AnnulmentDocument9 pagesAnnulmentHumility Mae FrioNo ratings yet

- #305 Tank Cleaning Operations - Cargo TanksDocument3 pages#305 Tank Cleaning Operations - Cargo TanksTolias EgwNo ratings yet

- #406 Maintenance On Main EngineDocument3 pages#406 Maintenance On Main EngineTolias Egw100% (1)

- #501 Bunkering OperationsDocument5 pages#501 Bunkering OperationsTolias EgwNo ratings yet

- #101 Anchoring & Weighing AnchorDocument6 pages#101 Anchoring & Weighing AnchorTolias Egw100% (1)

- #303 Cargo Operation - LoadingDocument3 pages#303 Cargo Operation - LoadingTolias EgwNo ratings yet

- #103 Mooring-Unmooring TermnalDocument3 pages#103 Mooring-Unmooring TermnalTolias EgwNo ratings yet

- #304 Cargo Operation - DischargingDocument3 pages#304 Cargo Operation - DischargingTolias EgwNo ratings yet

- PTSB (Jsa Form)Document5 pagesPTSB (Jsa Form)hanujaNo ratings yet

- Concept of HalalDocument3 pagesConcept of HalalakNo ratings yet

- Wide Communication Project Risk Register: ID Risk Factor Qualitative Risk Ranking LOW Medium HighDocument6 pagesWide Communication Project Risk Register: ID Risk Factor Qualitative Risk Ranking LOW Medium HighAIDO SEGUNNo ratings yet

- #201 Navigation in Heavy Marine Traffic ChannelDocument4 pages#201 Navigation in Heavy Marine Traffic ChannelTolias EgwNo ratings yet

- #412 Identification of Critical Equipment and Spares LevelsDocument3 pages#412 Identification of Critical Equipment and Spares LevelsTolias EgwNo ratings yet

- Europe Landmarks Reading Comprehension Activity - Ver - 1Document12 pagesEurope Landmarks Reading Comprehension Activity - Ver - 1Plamenna Pavlova100% (1)

- Australian Biofouling Management RequirementsDocument18 pagesAustralian Biofouling Management RequirementsRitesh ChandraNo ratings yet

- D-104 Emergency Operation of Cargo Ballast Bilge ValvesDocument1 pageD-104 Emergency Operation of Cargo Ballast Bilge ValveszainavNo ratings yet

- Security Plan PDFDocument101 pagesSecurity Plan PDFAbood AburassNo ratings yet

- #403 Aux - Engine MaintenanceDocument3 pages#403 Aux - Engine MaintenanceTolias EgwNo ratings yet

- Emcy Resp PlanDocument40 pagesEmcy Resp PlanredchaozNo ratings yet

- Example Report SSA E Ver1Document20 pagesExample Report SSA E Ver1Cenk ÇobanNo ratings yet

- Job Safety Analysis (JSA)Document4 pagesJob Safety Analysis (JSA)Wisnu WicaksonoNo ratings yet

- #106 Embarkation or Disembarkation Via LaunchesDocument4 pages#106 Embarkation or Disembarkation Via LaunchesTolias EgwNo ratings yet

- #401 Odme Mal Operation Due To Lack of Maintenace (Revised)Document2 pages#401 Odme Mal Operation Due To Lack of Maintenace (Revised)Tolias EgwNo ratings yet

- #401 Odme Mal Operation Due To Lack of Maintenace (Revised)Document2 pages#401 Odme Mal Operation Due To Lack of Maintenace (Revised)Tolias EgwNo ratings yet

- Learner's Material: ScienceDocument27 pagesLearner's Material: ScienceCarlz BrianNo ratings yet

- TN Vision 2023 PDFDocument68 pagesTN Vision 2023 PDFRajanbabu100% (1)

- SSRBDocument145 pagesSSRBRizky Aulia PratamaNo ratings yet

- Turky PPT PDFDocument30 pagesTurky PPT PDFSanjai bhadouriaNo ratings yet

- #502 Tank Cleaning Operations - Engine DeptDocument3 pages#502 Tank Cleaning Operations - Engine DeptTolias EgwNo ratings yet

- BMP West AfricaDocument71 pagesBMP West AfricaBrian DuttonNo ratings yet

- Appendix 7 To Chapter 5 Sms Gap Analysis Checklist and Implementation PlanDocument8 pagesAppendix 7 To Chapter 5 Sms Gap Analysis Checklist and Implementation PlanCahaya Yg TerpujiNo ratings yet

- #202 Navigation in Restricted VisibilityDocument2 pages#202 Navigation in Restricted VisibilityTolias EgwNo ratings yet

- Manning Agent Debriefing FormDocument8 pagesManning Agent Debriefing FormAbhilashNo ratings yet

- Reply To Pieta MR SinoDocument9 pagesReply To Pieta MR SinoBZ RigerNo ratings yet

- #204 Navigation Through High Risk Piracy AreaDocument2 pages#204 Navigation Through High Risk Piracy AreaTolias EgwNo ratings yet

- C T 7 0901a RACI Chart WHS Plan AppendixDocument14 pagesC T 7 0901a RACI Chart WHS Plan AppendixKathleen S. OrtizNo ratings yet

- #014 Working AloftDocument4 pages#014 Working AloftTolias EgwNo ratings yet

- M0010 Risk Assessment ManualDocument51 pagesM0010 Risk Assessment ManualnivasmarineNo ratings yet

- #104 Abondonship Drill - Davit Type LifeboatsDocument3 pages#104 Abondonship Drill - Davit Type LifeboatsTolias EgwNo ratings yet

- #004 Hot Work Cutting-Poop Deck Aft-01-03-10Document4 pages#004 Hot Work Cutting-Poop Deck Aft-01-03-10Tolias EgwNo ratings yet

- #107 Manual Handling - Deck DeptDocument6 pages#107 Manual Handling - Deck DeptTolias EgwNo ratings yet

- #206 UKC Policy BreachDocument2 pages#206 UKC Policy BreachTolias EgwNo ratings yet

- #409 Electrical Equipment MaintenanceDocument3 pages#409 Electrical Equipment MaintenanceTolias EgwNo ratings yet

- #015 Working OversideDocument2 pages#015 Working OversideTolias EgwNo ratings yet

- #302 Gas Freeing of A Cargo TankDocument4 pages#302 Gas Freeing of A Cargo TankTolias EgwNo ratings yet

- #011 Hotwork-Welding Machinery Spaces - 01-03-10Document4 pages#011 Hotwork-Welding Machinery Spaces - 01-03-10Tolias EgwNo ratings yet

- Mitchell Capt AndrewDocument150 pagesMitchell Capt AndrewOSDocs2012No ratings yet

- DKO04-Small Craft Alongside - Incl Bunker Barge, Slop BargeDocument2 pagesDKO04-Small Craft Alongside - Incl Bunker Barge, Slop BargeNang D. VuNo ratings yet

- Hazard Identification 2. Risk Evaluation 3. Risk ControlDocument4 pagesHazard Identification 2. Risk Evaluation 3. Risk ControlCarmilyn Joy TapelNo ratings yet

- CM 03 - Cargo Handling Risk AssessmentDocument3 pagesCM 03 - Cargo Handling Risk AssessmentDmitriy100% (1)

- BOMMI-PRD-07.0011-Rev.00 - Personnel Transfer OperationsDocument11 pagesBOMMI-PRD-07.0011-Rev.00 - Personnel Transfer Operationsfundatia_gaudeamusNo ratings yet

- Risk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09Document2 pagesRisk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09sizwe0% (1)

- LSA & FFA MaintenanceDocument32 pagesLSA & FFA Maintenanceajinkyachaubal2No ratings yet

- CP Noc 014Document32 pagesCP Noc 014le huyNo ratings yet

- SP-40-03 Rev 2Document15 pagesSP-40-03 Rev 2Henno Traut0% (1)

- Generic RA Gas CylindersDocument6 pagesGeneric RA Gas CylindersShahid RazaNo ratings yet

- 01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFDocument5 pages01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFTolias EgwNo ratings yet

- #007 Hot Work Welding On Cargo Tank & Main Deck-01-03-10Document6 pages#007 Hot Work Welding On Cargo Tank & Main Deck-01-03-10Tolias EgwNo ratings yet

- 3.1.4 - EM CK 01 D - Fire in EngineroomDocument1 page3.1.4 - EM CK 01 D - Fire in EngineroomTolias EgwNo ratings yet

- 1-DD-Akron-CORA-9519705-PROP-60 Months Technical Specification 2018-07-18 PDFDocument8 pages1-DD-Akron-CORA-9519705-PROP-60 Months Technical Specification 2018-07-18 PDFTolias EgwNo ratings yet

- 2 Ballast Level Flowchart PDFDocument1 page2 Ballast Level Flowchart PDFTolias EgwNo ratings yet

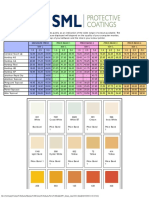

- 2.PC Jotun Chart1011 PDFDocument3 pages2.PC Jotun Chart1011 PDFTolias EgwNo ratings yet

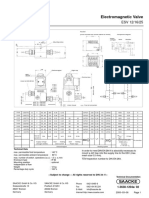

- 1 3638 5012a 02 PDFDocument2 pages1 3638 5012a 02 PDFTolias EgwNo ratings yet

- 2 Threshold Voltage PDFDocument8 pages2 Threshold Voltage PDFTolias EgwNo ratings yet

- 3.6 - EM CK 06 - Man Overboard and Recovery From WaterDocument1 page3.6 - EM CK 06 - Man Overboard and Recovery From WaterTolias EgwNo ratings yet

- 1-DD-Akron-CORA-9519705-PROP-60 Months Commercial Paint Delivery 2018-07-18 PDFDocument3 pages1-DD-Akron-CORA-9519705-PROP-60 Months Commercial Paint Delivery 2018-07-18 PDFTolias EgwNo ratings yet

- Onomatologia Kata IACS Double Hull TankerDocument5 pagesOnomatologia Kata IACS Double Hull TankerTolias EgwNo ratings yet

- 1.unimarine Equivalent List PDFDocument3 pages1.unimarine Equivalent List PDFTolias EgwNo ratings yet

- 1 3638 1204a 02 PDFDocument1 page1 3638 1204a 02 PDFTolias EgwNo ratings yet

- 1..FLOW DRAW MT CHER SW600 Kalooo PDFDocument1 page1..FLOW DRAW MT CHER SW600 Kalooo PDFTolias EgwNo ratings yet

- Heavy Oil or Similar Firing Systems With Rotary Cup Atomizer BurnersDocument2 pagesHeavy Oil or Similar Firing Systems With Rotary Cup Atomizer Burners徐玉坤No ratings yet

- 01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFDocument5 pages01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFTolias EgwNo ratings yet

- 1.apexior 3 PDFDocument1 page1.apexior 3 PDFTolias EgwNo ratings yet

- 1 3638 3074a 02 PDFDocument1 page1 3638 3074a 02 PDFTolias EgwNo ratings yet

- 02.2 - D&A Policy-01 03 16 PDFDocument1 page02.2 - D&A Policy-01 03 16 PDFTolias EgwNo ratings yet

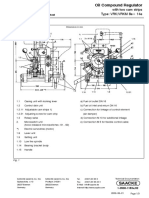

- 1 3500 1183a 02 PDFDocument3 pages1 3500 1183a 02 PDFTolias EgwNo ratings yet

- AG Hardtop XP GB English ProtectiveDocument7 pagesAG Hardtop XP GB English ProtectiveShabir ShuhoodNo ratings yet

- 1 Cot Slop Level Flowchart PDFDocument1 page1 Cot Slop Level Flowchart PDFTolias EgwNo ratings yet

- 01 General Conditions PDFDocument5 pages01 General Conditions PDFTolias EgwNo ratings yet

- 1 3500 4109a 02 PDFDocument3 pages1 3500 4109a 02 PDFTolias EgwNo ratings yet

- Oxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDFDocument1 pageOxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDFTolias EgwNo ratings yet

- 00 ContentsDocument6 pages00 ContentsTolias EgwNo ratings yet

- 1st Page PDFDocument1 page1st Page PDFTolias EgwNo ratings yet

- #408 Steering Gear Overhaul or MaintenanceDocument3 pages#408 Steering Gear Overhaul or MaintenanceTolias EgwNo ratings yet

- 1634313583!Document24 pages1634313583!Joseph Sanchez TalusigNo ratings yet

- PCI Bank V CA, G.R. No. 121413, January 29, 2001Document10 pagesPCI Bank V CA, G.R. No. 121413, January 29, 2001ademarNo ratings yet

- IndianJPsychiatry632179-396519 110051Document5 pagesIndianJPsychiatry632179-396519 110051gion.nandNo ratings yet

- HTTP Parameter PollutionDocument45 pagesHTTP Parameter PollutionSpyDr ByTeNo ratings yet

- Gastric Emptying PresentationDocument8 pagesGastric Emptying Presentationrahul2kNo ratings yet

- SET UP Computer ServerDocument3 pagesSET UP Computer ServerRicHArdNo ratings yet

- Account Statement From 1 Jan 2017 To 30 Jun 2017Document2 pagesAccount Statement From 1 Jan 2017 To 30 Jun 2017Ujjain mpNo ratings yet

- Port of Surigao Guide To EntryDocument1 pagePort of Surigao Guide To EntryNole C. NusogNo ratings yet

- Outline - Criminal Law - RamirezDocument28 pagesOutline - Criminal Law - RamirezgiannaNo ratings yet

- IBM Unit 3 - The Entrepreneur by Kulbhushan (Krazy Kaksha & KK World)Document4 pagesIBM Unit 3 - The Entrepreneur by Kulbhushan (Krazy Kaksha & KK World)Sunny VarshneyNo ratings yet

- Sarcini: Caiet de PracticaDocument3 pagesSarcini: Caiet de PracticaGeorgian CristinaNo ratings yet

- Engineeringinterviewquestions Com Virtual Reality Interview Questions Answers PDFDocument5 pagesEngineeringinterviewquestions Com Virtual Reality Interview Questions Answers PDFKalyani KalyaniNo ratings yet

- Veritas CloudPoint Administrator's GuideDocument294 pagesVeritas CloudPoint Administrator's Guidebalamurali_aNo ratings yet

- The BreakupDocument22 pagesThe BreakupAllison CreaghNo ratings yet

- Berrinba East State School OSHC Final ITO For Schools Final 2016Document24 pagesBerrinba East State School OSHC Final ITO For Schools Final 2016hieuntx93No ratings yet

- Conrad John's ResumeDocument1 pageConrad John's ResumeTraining & OD HRODNo ratings yet

- Harvard ReferencingDocument7 pagesHarvard ReferencingSaw MichaelNo ratings yet

- ED Tox PGS.2021Document4 pagesED Tox PGS.2021Jm uniteNo ratings yet

- Motion Exhibit 4 - Declaration of Kelley Lynch - 03.16.15 FINALDocument157 pagesMotion Exhibit 4 - Declaration of Kelley Lynch - 03.16.15 FINALOdzer ChenmaNo ratings yet

- Kofax Cross Product Compatibility MatrixDocument93 pagesKofax Cross Product Compatibility MatrixArsh RashaNo ratings yet

- Project Report On ICICI BankDocument106 pagesProject Report On ICICI BankRohan MishraNo ratings yet