Professional Documents

Culture Documents

Generic RA Gas Cylinders

Uploaded by

Shahid RazaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generic RA Gas Cylinders

Uploaded by

Shahid RazaCopyright:

Available Formats

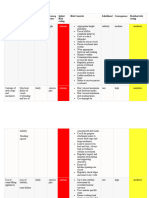

Risk Assessment for Storage and Use of Gas Cylinders Ref.

Project: Date:

Gas cylinders’ storage, use and movement. Gas cylinder regulator use.

Overview of activity / location /

equipment / conditions being A separate COSHH assessment will be needed to address hazardous substances related to gas cylinder use (such as toxic or harmful gasses).

assessed: Gas cylinder/regulators/hoses and other attachments also work equipment and must be used in compliance with PUWER and the work equipment risk

assessment.

Generic or specific assessment? Context of assessment:

Generic risk assessment Generic risk assessment

A Additional

# Hazard(s) identified Persons affected Existing controls & measures A B x controls

B required

Explosion, sudden gas or

fluid release, exposure to

cylinder contents and fire.

In general, the main causes of gas cylinder accidents and incidents that need

Impact from the blast of a to be addressed are:

gas cylinder explosion or

Inadequate training and/or supervision;

rapid release of

Poor installation and/or maintenance;

compressed gas;

Faulty equipment and/or design

Impact from parts of gas

Persons using the Poor storage

cylinders that fail or any

cylinders. Poor handling; and

1 flying debris;

Persons in the vicinity of Poor ventilation

Contact with the release

the cylinders. Specific control measures are considered below, under specific

of gas or fluid from a

cylinder (e.g. chlorine); elements/aspects of using gas cylinders. Poor ventilation is not addressed;

this would be a hazard more likely to be considered in a COSHH assessment.

Fire resulting from the

escape of flammable

gasses or fluids (e.g.

methane) or the release

of oxidising gasses (e.g.

oxygen)

RA-Gas Cylinders Rev: 01 Issued: April 2019 Page 1 of 6

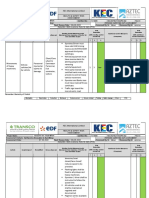

A Additional

# Hazard(s) identified Persons affected Existing controls & measures A B x controls

B required

Struck by a cylinder or

suffering a manual handling

injury

Impact from the falling

cylinder;

Manual handling injuries

from moving or handling

cylinders

Cylinder maintenance / Cylinders must be inspected at least annually:

Persons using the

inspection If departments own gas cylinders, then they must arrange for them

cylinders.

2 Explosion, sudden gas or to be inspected annually by a competent authorised person.

Persons in the vicinity of

fluid release, exposure to Most gas cylinders will be owned by the gas supplier, who as the

the cylinders.

cylinder contents and fire. owners of the cylinder will arrange for an annual inspection.

Ensure that regulators are labelled such that individual regulators can be

identified and matched to their service history.

Ensure that the gas regulator is subject to an inspection and maintenance

regime as follows:

Pre-use visual inspection – check for rating, type, fitting,

contamination and obvious damage;

Annual visual inspection and function check; and

Gas cylinder regulators

Persons using the Periodic full service by a competent person as recommended by

cylinders. the manufacturer or replacement. Most manufacturers

3 Explosion, sudden gas or

Persons in the vicinity of recommend a full service/replacement five years after

fluid release, exposure to

the cylinders. manufacture. Note that some components in a regulator will

cylinder contents and fire.

deteriorate even if a regulator remains unused.

Ensure that the gas regulator rating exceeds the maximum pressure of the

gas cylinder.

Note: Regulators will have manufacturer markings stamped into them from

which their age can be determined, but markings vary between

manufacturers’. The BCGA has published guidance on interpreting

manufacturer markings.

RA-Gas Cylinders Rev: 01 Issued: April 2019 Page 2 of 6

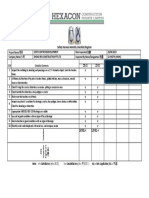

A Additional

# Hazard(s) identified Persons affected Existing controls & measures A B x controls

B required

Gasses should preferably be piped to the point of use from outside the

building, eliminating the need to house cylinders in the workrooms.

However, this is not always possible or practical.

Before a gas cylinder is attached to any equipment:

Double-check that the right gas is being used;

Double-check that the regulator and other equipment are suitable

for the gas and the pressure to be used.

During use

Cylinders must only be used in an upright position unless the

supplier has specified otherwise.

Unless a cylinder has been designed to be free-standing, it must

Gas cylinders in use

be secured in position.

Oil and grease must not be used on valves, regulators or another

Explosion, sudden gas or Persons using the

fitting. Doing so may cause an explosion.

fluid release, exposure to cylinders.

4 During downtime:

cylinder contents and fire. Persons in the vicinity of

Close the cylinder valve to reduce the chance of unintentional gas

Struck by a cylinder or the cylinders

release and replace dust caps.

suffering a manual

Cylinders must only be used for their intended purpose; they must not be

handling injury

used as rollers, supports or props as this may damage the cylinder or

cause the valve to open.

Cylinders and attachments must be regularly inspected to ensure that gas

is not leaking.

RA-Gas Cylinders Rev: 01 Issued: April 2019 Page 3 of 6

A Additional

# Hazard(s) identified Persons affected Existing controls & measures A B x controls

B required

Rotate stocks of cylinders, so that older cylinder are used first.

Gas cylinders must suitably be segregated:

Flammable and oxidising gasses must be separated from each

other; they must be either at least three metres apart or separated

by firewalls;

Gas cylinders in storage

Incompatible gasses must be stored apart; and

Empty and full gas cylinders must be stored apart.

Explosion, sudden gas or Persons using the

Gas cylinder stores must:

fluid release, exposure to cylinders.

5 Be well ventilated;

cylinder contents and fire. Persons in the vicinity of

Be sheltered from indirect heating;

Struck by a cylinder or the cylinders

Be a naked flame and smoke-free area;

suffering a manual

Be well-drained; so that cylinders do not have to sit or lie in water;

handling injury

and

Be secured to prevent unauthorised entry and access to the

cylinders.

Gas cylinders must be stored in an upright position and secured so that

they cannot fall over.

Consider:

Eliminating or reducing manual handling hazards by piping gas to

the point of use; and/or

Gas cylinder movement on Reducing the manual handling hazard by automating cylinder

Persons moving the handling using a crane or mobile hoist; and/or

campus

cylinders. Reducing the manual handling hazard by specifying and using

Persons with existing smaller gas cylinders in preference to larger cylinders; and/or

Explosion, sudden gas or

injuries/disabilities or of Reducing the manual handling hazards by using handling aids,

6 fluid release, exposure to

small stature will be more such as a cylinder trolley.

cylinder contents and fire.

vulnerable. When moving a cylinder:

Struck by a cylinder or

Persons in the vicinity of Make sure that the person handling the cylinder is equipped with

suffering a manual

the cylinders personal protective equipment

handling injury

Safety shoes with steel toe caps; and

Safety gloves to protect from mechanical damage

Make sure that the cylinder valve has been closed.

Make sure that regulators and hoses have been removed, unless

RA-Gas Cylinders Rev: 01 Issued: April 2019 Page 4 of 6

A Additional

# Hazard(s) identified Persons affected Existing controls & measures A B x controls

B required

the equipment has been designed to be moved in this way (e.g.

portable welding equipment in a trolley)

Make sure that a suitable route has been identified that takes into

account the stability and requirements of any equipment used.

If using a cylinder trolley:

Make sure that the cylinder trolley is in good order. Loose or

damaged hand grips can cause the trolley to be dropped. Loose

or damaged trolley wheel can cause the trolley to tip over.

Make sure that the cylinder is secured to the trolley.

If using a crane or hoist:

Make sure that suitable slings and/or clamps are used. Chain

slings can damage a cylinder or its markings and should not be

used. Magnetic lifting devices should not be used.

Do not lift cylinders by valves, shrouds or caps for lifting unless

designed for the purpose.

Do not lift cylinders on the fork of forklift trucks unless precautions

are taken to stop them falling or rolling.

If moving by hand only:

Do not roll horizontal cylinders along the floor; this can cause

cylinder valves to open and can damage cylinder markings and

labels.

Only ‘churn’ a cylinder over flat, smooth surfaces and then only for

short distances (<two metres).

The Carriage of Dangerous Goods and Use of Transportable Pressure

Equipment Regulations 2009 regulate the transportation of ‘dangerous

Gas cylinder movement by goods’ by road or rail. This includes the carriage of both full and empty

7

road or rail off campus gas cylinders.

This risk assessment does not cover the carriage of gas cylinders by road

or rail.

8

RA-Gas Cylinders Rev: 01 Issued: April 2019 Page 5 of 6

A Additional

# Hazard(s) identified Persons affected Existing controls & measures A B x controls

B required

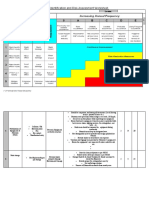

1

0

1

1

Severity

Likelihood

Insignificant (1) Minor (2) Moderate (3) Major (4) Catastrophic (5)

Rare (1) 1 2 3 4 5

Possible (2) 2 4 6 8 10

Likely (3) 3 6 9 12 15

Often (4) 4 8 12 16 20

Frequent/ Almost Certain (5) 5 10 15 20 25

15 - 25 Extreme Risk Activity or industry should not proceed in the current form.

Activity or industry should be modified to include remedial planning and action and be subject to detailed OSH

8 - 12 High Risk

assessment.

4-6 Moderate Risk Activity or industry can operate subject to management and /or modification.

1-3 Low Risk No immediate action required unless escalation of risk is possible.

Assessor signature: Print name: Review date:

RA-Gas Cylinders Rev: 01 Issued: April 2019 Page 6 of 6

You might also like

- Risk AssesmentDocument4 pagesRisk AssesmentShahd JaberNo ratings yet

- Risk AssesmentDocument9 pagesRisk Assesmentfirdashan86No ratings yet

- Hazard Identification and Risk Assessment Worksheet.: Zubair New Degassing Station Project Caravan LiftingDocument2 pagesHazard Identification and Risk Assessment Worksheet.: Zubair New Degassing Station Project Caravan LiftingNaveed AhmedNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocument1 pageSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordNo ratings yet

- 015 CH 10 Tool InspectionDocument3 pages015 CH 10 Tool InspectionLinda BooysenNo ratings yet

- Risk Assessment For Sand Blasting PaimtingDocument4 pagesRisk Assessment For Sand Blasting PaimtingRawoofuddin ChandNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Risk Assessment - House and Office CleaningDocument6 pagesRisk Assessment - House and Office CleaningVimal Thomas100% (1)

- Job Hazard Analysis Worksheet: Page 1 of 2Document2 pagesJob Hazard Analysis Worksheet: Page 1 of 2Lourdes Marianne MenesesNo ratings yet

- IRON ORE Risk AssessmentDocument5 pagesIRON ORE Risk AssessmentMamunNo ratings yet

- Gas Cylinders Risk AssessmentDocument3 pagesGas Cylinders Risk AssessmentMAB AliNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Task Risk AssesmentDocument3 pagesTask Risk Assesmentafsalkareem100% (1)

- Toolbox Talk - Permit To WorkDocument1 pageToolbox Talk - Permit To WorkrajNo ratings yet

- FORM 3 For Maintaining Records of Hazardous Waste at FacilityDocument1 pageFORM 3 For Maintaining Records of Hazardous Waste at Facilitysandeep MNo ratings yet

- Safety Harness Monthly Checklist-Register JAN23Document1 pageSafety Harness Monthly Checklist-Register JAN23Iqbal HossainNo ratings yet

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- Risk Assessment For Installation of Enclosed Switches IsolatorsDocument7 pagesRisk Assessment For Installation of Enclosed Switches IsolatorsADIL AL-AQABYNo ratings yet

- 02 - R.A. Working On ScaffoldsDocument2 pages02 - R.A. Working On ScaffoldspremNo ratings yet

- RMH HiraDocument12 pagesRMH HiraShirley SetshediNo ratings yet

- Suspended Load SafetyDocument3 pagesSuspended Load Safetymy_agautamNo ratings yet

- Risk Assessment - Portable Ladders - 2021Document3 pagesRisk Assessment - Portable Ladders - 2021Asakundwi MukhwaNo ratings yet

- Permit To Work ProcedureDocument2 pagesPermit To Work ProcedureMuhammad Tahus Al-QahtaniNo ratings yet

- 03a-306a3 - Pilling Machine ChecklistDocument2 pages03a-306a3 - Pilling Machine ChecklisttanoycometNo ratings yet

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 pagesCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Project Potential HazardsDocument10 pagesProject Potential Hazardsmichael nortonNo ratings yet

- PPE Request Form (New)Document1 pagePPE Request Form (New)Syafrial AnasNo ratings yet

- F023A General Work PermitDocument2 pagesF023A General Work PermitvladNo ratings yet

- JSA Form - Installation of ATS atDocument4 pagesJSA Form - Installation of ATS atDarren OscarNo ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Monthly Statistical Report #32 UP03, March, 2022Document4 pagesMonthly Statistical Report #32 UP03, March, 2022yasirali43No ratings yet

- R-16 Safety Management Review MeetingDocument2 pagesR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- HSE FRM-24 H & S Risk Assessment and Control FormDocument2 pagesHSE FRM-24 H & S Risk Assessment and Control Formmazen fakhfakhNo ratings yet

- SWP Fire PumpDocument6 pagesSWP Fire PumpbsynnottNo ratings yet

- 675Document2 pages675Rameese MuhammedNo ratings yet

- Safe Lifting Procedure 2Document6 pagesSafe Lifting Procedure 2angelaNo ratings yet

- JHA Soil InvestigationDocument7 pagesJHA Soil InvestigationRyan100% (1)

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocument17 pagesThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaNo ratings yet

- Risk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityDocument5 pagesRisk Assessment Record: 5 4 3 2 1 1 2 3 4 5 SeverityEmilNo ratings yet

- 8) SWP-08 Working at HeightsDocument3 pages8) SWP-08 Working at HeightsRachel NoraNo ratings yet

- k3 Bore Pile DenganBIMDocument6 pagesk3 Bore Pile DenganBIMrhoewiebNo ratings yet

- Ra For Transpo and LiftingDocument5 pagesRa For Transpo and LiftingEdsel RosalesNo ratings yet

- Safety Training PassportDocument2 pagesSafety Training PassportAbhaySngh100% (1)

- PPS HSE Internal PolicyDocument25 pagesPPS HSE Internal PolicyPioneer Power SystemsNo ratings yet

- Health, Safety & Environmental (HSE) 1/3/2022 Management SystemDocument13 pagesHealth, Safety & Environmental (HSE) 1/3/2022 Management SystemNZ NZ100% (1)

- Lifting Operations Planning Risk Assessment PDFDocument1 pageLifting Operations Planning Risk Assessment PDFulisses costaNo ratings yet

- Sand Blasting & Painting Risk AssessmentDocument6 pagesSand Blasting & Painting Risk AssessmentNaveed Ahmed Get-Info100% (1)

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli HassanNo ratings yet

- Survey Work HSE Risk AssessmentsDocument2 pagesSurvey Work HSE Risk AssessmentsSarfraz RandhawaNo ratings yet

- Paint WorkDocument1 pagePaint WorkNarender BhardwajNo ratings yet

- Installation and Repair of Fibre Optic Cable PDFDocument3 pagesInstallation and Repair of Fibre Optic Cable PDFBento BoxNo ratings yet

- Lifting Fixing of Cross BracingDocument2 pagesLifting Fixing of Cross BracingShahid RazaNo ratings yet

- FM Co KillerDocument35 pagesFM Co KillerShahid RazaNo ratings yet

- Kimanis Power Project: Job Safety AnalysisDocument9 pagesKimanis Power Project: Job Safety AnalysisShahid RazaNo ratings yet

- Welding and Gas Cutting TechnologyDocument42 pagesWelding and Gas Cutting TechnologyShahid RazaNo ratings yet

- Firstaid AwarenessDocument11 pagesFirstaid AwarenessShahid RazaNo ratings yet

- Checklist of Welding MachineDocument2 pagesChecklist of Welding MachineShahid RazaNo ratings yet

- 75 Full Body Harness - F-75Document2 pages75 Full Body Harness - F-75Shahid RazaNo ratings yet

- M/S. New Vishal Engineering & Co: Inspection Checklist For Gas Gutting SetDocument2 pagesM/S. New Vishal Engineering & Co: Inspection Checklist For Gas Gutting SetShahid RazaNo ratings yet

- Orange Stripe # 51 EnglishDocument2 pagesOrange Stripe # 51 EnglishShahid RazaNo ratings yet

- 5S Routine Audit Form: SO RTDocument1 page5S Routine Audit Form: SO RTShahid RazaNo ratings yet

- Orange Stripe#12 EnglishDocument2 pagesOrange Stripe#12 EnglishShahid RazaNo ratings yet

- Health & Safety Safety Alert Red Stripe: 01/FY21Document2 pagesHealth & Safety Safety Alert Red Stripe: 01/FY21Shahid RazaNo ratings yet

- Site Safety Audit Plan & Compliance For Tata Steel JodaDocument10 pagesSite Safety Audit Plan & Compliance For Tata Steel JodaShahid Raza100% (1)

- Jha For Painting of EquipmentDocument1 pageJha For Painting of EquipmentShahid RazaNo ratings yet

- Red & Orange Stripe Master ListDocument2 pagesRed & Orange Stripe Master ListShahid RazaNo ratings yet

- JHA For Pneumatic Conveying OperationDocument1 pageJHA For Pneumatic Conveying OperationShahid RazaNo ratings yet

- JHA ForHitaching Movement For Raw Material StackingDocument1 pageJHA ForHitaching Movement For Raw Material StackingShahid RazaNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- JHA For Positive IsolationDocument1 pageJHA For Positive IsolationShahid RazaNo ratings yet

- JHA For Belt Conveyor MaintenanceDocument2 pagesJHA For Belt Conveyor MaintenanceShahid RazaNo ratings yet

- Jsa For Hydro Test Activites GenericDocument4 pagesJsa For Hydro Test Activites GenericShahid RazaNo ratings yet

- JHA For Test WT ShiftingDocument1 pageJHA For Test WT ShiftingShahid RazaNo ratings yet

- E-Pass JharkhandDocument2 pagesE-Pass JharkhandShahid RazaNo ratings yet

- JHACarbon Brush CheckingDocument8 pagesJHACarbon Brush CheckingShahid RazaNo ratings yet

- Reed Relay and Crossbar ExchangeDocument15 pagesReed Relay and Crossbar ExchangeRanish Lloyd TauroNo ratings yet

- Catalog Richpeace Vertical Cutting PlotterDocument2 pagesCatalog Richpeace Vertical Cutting PlotterBella SuizaNo ratings yet

- EVS032 Instrumentation and Lab Techniques PDFDocument331 pagesEVS032 Instrumentation and Lab Techniques PDFRahulNo ratings yet

- AI 4500 Revita Air ManualDocument12 pagesAI 4500 Revita Air ManualRobert TuckerNo ratings yet

- Lab 2 - Exercise 1 - Use and Care of The MicroscopeDocument40 pagesLab 2 - Exercise 1 - Use and Care of The MicroscopeAyman ElkenawyNo ratings yet

- Sylvania Mercury Reflector Lamps Bulletin 1966Document2 pagesSylvania Mercury Reflector Lamps Bulletin 1966Alan MastersNo ratings yet

- Deck Machinery TTS-KocksDocument63 pagesDeck Machinery TTS-KocksBui Duy Thanh50% (2)

- User Manual Control JT-901 Smart Eng ED 23.08.02Document28 pagesUser Manual Control JT-901 Smart Eng ED 23.08.02prueba12345100% (1)

- Item 18Document1 pageItem 18Omar ShNo ratings yet

- Sri986 Electro-Pneumatic Positioner: Quick Guide QG EVE0102 (En)Document6 pagesSri986 Electro-Pneumatic Positioner: Quick Guide QG EVE0102 (En)herysyam1980No ratings yet

- SNMP ParametersDocument13 pagesSNMP ParametersJanReyAltivoNo ratings yet

- Process Flow Chart - PVC Insulated Cables, Is: 694 Raw MaterialsDocument2 pagesProcess Flow Chart - PVC Insulated Cables, Is: 694 Raw Materialsshruti sharmaNo ratings yet

- Ab Plastic Injectors Parts List PDFDocument4 pagesAb Plastic Injectors Parts List PDFAlejandroCoila0% (1)

- Machine Tool Metrology28march23Document62 pagesMachine Tool Metrology28march23meghanaNo ratings yet

- TIOGA Pipe ChartDocument2 pagesTIOGA Pipe Chartvinothkumar50% (4)

- Ipecs Lik: RSGM Installer GuideDocument43 pagesIpecs Lik: RSGM Installer GuideSufianAbukoushNo ratings yet

- 46854853229Document3 pages46854853229Abhinav AgarwalNo ratings yet

- Laser Diode Combi Controller ITC502 (-IEEE) ITC510 (-IEEE) : Operation Manual Thorlabs InstrumentationDocument123 pagesLaser Diode Combi Controller ITC502 (-IEEE) ITC510 (-IEEE) : Operation Manual Thorlabs InstrumentationFreedomNo ratings yet

- Activator 903-CIS0195-PA7 PDFDocument7 pagesActivator 903-CIS0195-PA7 PDFmahdimecarniNo ratings yet

- MTL 5018Document1 pageMTL 5018Jagadesh C S NadarNo ratings yet

- Electrical Schedule and WiringDocument1 pageElectrical Schedule and WiringJeremy BuelbaNo ratings yet

- Mp10000142 Parts BookDocument59 pagesMp10000142 Parts BookRaul quispe quispe0% (1)

- Portable Containers Booklet R3Document28 pagesPortable Containers Booklet R3abhi6784No ratings yet

- ENG DS PCF Series Relay Data Sheet E 0411Document3 pagesENG DS PCF Series Relay Data Sheet E 0411chuNo ratings yet

- 12165-70 - 2 Sundry Instr.Document300 pages12165-70 - 2 Sundry Instr.kodrysNo ratings yet

- Di650i Maintenance Planner EnglishDocument2 pagesDi650i Maintenance Planner EnglishPablo Luis Ojeda Paez0% (2)

- 02 enDocument146 pages02 enCorui BogdanNo ratings yet

- Module2maintopicce0053 1Document50 pagesModule2maintopicce0053 1Alliyah AvellanaNo ratings yet

- Nikon F55 ManualDocument61 pagesNikon F55 ManualAlex Vodnicear100% (1)

- SICK Foto-Elektriniai SensoriaiDocument96 pagesSICK Foto-Elektriniai SensoriaietecsantoNo ratings yet