Professional Documents

Culture Documents

RMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - Signed

Uploaded by

Nirmal WiresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - Signed

Uploaded by

Nirmal WiresCopyright:

Available Formats

STERLITE POWER TRANSMISSION LIMITED

RAW MATERIAL SPECIFICATION: Date- 23.03.2022 REV. :00

Item: ULTRA High Strength Class A, Zinc–5% Aluminum-Mischmetal Alloy-Coated Steel Core, (Code MA5)

(19 /2.49mm)

s.no Parameter Sterlite’s Specification Reference Standard

UHS Misch Metal Steel Core Wire Properties: 19/ 2.49 mm (After Stranding)

1 Diameter (mm) 2.49 mm ( + 0.051 / - 0.051 mm) ASTM B958/Cust.Req

* Core diameter and tolerance will be as per S. No.21

Accordingly plan for wire size.

2 Tensile strength of Core wire (Mpa) Min. :1900 ASTM B958 / Cust.Req

3 Breaking Load of Strands (KN) Min: 9.25 KN (After stranding) ASTM B958 / Cust.Req

4 Stress at 1.0% extension MPa Min.: 1550 ASTM B958 / Cust.Req

5 Elongation at break (250 mm gauge length) 3.0 (Min)p ASTM B958 / Cust.Req

6 Adherence of Coating Test Mandrel dia.: 4 times of specified wire diameter ASTM B958 / Cust.Req

Turns: 8 nos (wire shall not crack or flaking the Zn–5Al–MM

alloy-coated coating)

7 Wrap test Mandrel dia.: 4 times of specified wire diameter ASTM B958 / Cust.Req

Turns: 8 nos. (wire shall not fracture or break)

8 Density (g / cm3) 7.78 ASTM B958 /

Cust.Req

9 Modulus of Elasticity (GPa) 190 (Min.) IEC 63248/Cust.Req.

10 Co-efficient of Thermal Expansion (/degC) 11.5 X 10-6 (Max.) IEC 63248/Cust.Req

11 Length (Mtrs.) Intimated later Cust.Req.

12 Weight (Kg/km) 37.89 (Nominal) ASTM B

958/Cust.req.

13 Mass of zinc coating (g/m2) 252 ASTM B958 /

Cust.Req

14 Chemical Composition Carbon 0.50 to 1.00 % ASTM B958 /

Manganese 0.40 to 1.30 % Cust.Req

Phosphorus, max 0.035 %

Sulfur, max 0.045 %

Silicon 0.15 to 0.60 %

15 A Resistivity of steel wire (Ω·mm2/m) 0.19157 Cust. Req./ Reference

15 B Conductivity 9 % IACS purpose .

15 C Max. DC Resistance of steel wire (ohm/km) 39.34

16 Minimum No. of torsion 8 Nos. (after standing) Cust.Req./ IEC

63248

17 Purity of Aluminum used for coating (%) NA NA

18 Zn–5Al–MM composition (%) Aluminum - 4,2 – 6,2 % Cust.Req./ IEC

Cerium and lanthanum, total -0.0 – 0.10 % 63248

Iron -0.075, max

Silicon – 0.015, max

Lead, cadmium – 0.005, max

Tin – 0.002, max

Others, each – 0.02 max

Others, total – 0.04 max

Zinc – Remainder

19 Purity of Zinc (%) NA --

20 Coating heat resistance test Sample shall be kept in oven for 20 hrs at 330 Deg.C IEC63248/Cust.Req

(upto & including 250Deg.C) The specimen shall be wrapped 8Turns as per S. No.

7.

The coating shall remain firmly adherent to the steel

& shall not crack or flake to such an extent that any

coating can be removed by rubbing with the bare

fingers

STERLITE POWER TRANSMISSION LIMITED

Core properties: 19/2.49 mm (After Stranding)

21 Diameter of Core (mm) 12.45 (±1%) Cust.Spec.

22 Weight (Kg/km) 724 (Nominal) ±2% BS EN 50540

23 Lay ratio Outer layer (12 strands) 17 --- 21 (Right Hand) EN 50540/ ASTM

Inner layer (6 strands) 19 --- 25 (Left Hand) 500

24 Core UTS (kN) Min. – 175.8 KN ASTM B958/ EN

50540

25 Lay direction Outer layer of steel core -Right direction Cust.Spec.

(Two layer ACSS conductor)

26 Joints -Joints/welding is not allowed ASTM B 958/IEC

-No joints shall be made in the finished wire 63248

27 Workmanship, Finish, and Appearance The Zn–5Al–MM alloy-coated shall be reasonably ASTM B 958/IEC

smooth, continuous, of reasonably uniform thickness, and 63248/Cust.Spec.

free of imperfections not consistent with good commercial

practice.

- The finished stranded core shall be uniform in diameter and

shall be free from imperfections not consistent with good

commercial stranding practice. The stranded core shall be

free from waviness and kinks.

28 Enclosure of Quality Documents 1.Computerized Test Certificates should be sent along with

the consignment with all certifications. As per above ---

requirements.

2.Raw Material Spec No, batch no, date of Mfg, product no.,

weight and all other parameters or core as well as individual

wires to be mentioned on every Test Certificate.

3. There should not be any weld or joint in the wire OR

Joint/Weld declaration certificate/confirmation

4. Manufacturing warranty certificate.

5.Test certificate of Raw material which is used for UHS Zn–

5Al–MM alloy-coated steel wire/core manufacturing (Batch

wise details)

6.Test certificate for chemical composition UHS Zn–5Al–MM

alloy-coated steel wire/core.

7. Third Party Analysis Report for Zinc & Aluminium purity,

used for misch metal coating with test certificates of core

with traceability.

29 Core Inertness -All steel wires shall lie naturally in their position in the ---

stranded core, and where the core is cut, the wire ends shall

remain in position.

-There should be no looseness, the core should be compact.

-The steel wires shall be so stranded that when the stranded

core is cut the individual wires can be readily regrouped.

30 Identification/Packing The core should be wound on proper ---

wooden/Steel/Hybrid drums. Each drums should

have a tag showing clearly the following details:-.

-Manufacturer’s name or trade mark

- Net/ Gross weight

-Length & Batch no.

-Date of Manufacturing

- ISI Mark (if any)

31 Sealing The drum should be sealed properly to avoid any ---

theft/pilferage.

32 Special care during transportation The drum should be properly protected with suitable ---

water proof packing to avoid any water/moisture

ingress during handling and transportation.

33 Material Safety Data Sheet (MSDS) MSDS must be supplied prior to first delivery of a new ---

material and reissued whenever necessary.

34 Confidentiality This specification is the confidential, commercially ----

sensitive Property of Sterlite Power Transmission Ltd.

It may not be used for any purpose, copied or

disclosed to third parties without prior written

consent from SPTL.

STERLITE POWER TRANSMISSION LIMITED

Note:-

Coating Test The Zn–5Al–MM alloy-coated wire shall conform to the coating requirements of relevant standards.

The parameters which are not covered in this RMS will be governed by the relevant standards & Technical

specification & Customer requirements.

In case of any length shortage discrepancy and material defect found during manufacturing should be sole

responsibility of supplier.

The acceptance of any quantity of material shall in no way relieve the Supplier of any of his responsibilities for

meeting all requirements of the specification and shall not prevent subsequent rejection if such material is found

defective later in plant, inspection, site etc.

The wire diameter should not be less than the minimum specified diameter at any point of wire The UHS Zn–

5Al–MM alloy-coated steel wire/core, Carbon Wire rod, Zinc & Aluminium ,should be procured from Approved

sources only and TC should include ISI mark (if any)

The incoming good inspection will be done on random basis.If even any single component rejection found whole

lot will be rejected. The acceptance in IGI will not absolve the supplier responsibility of any rejection later during

manufacturing ,inspection or at site. The supplier need to absorb all rejection related cost and provide

replacement in specified time frame.

-Any wire break due to material defect the core has to be replaced by the supplier.

Manufactures Guarantee Certificate required or Material conformity certificate/deceleration with the relevant

standards as mentioned in the RMS.

Prepared by -NPD Reviewed by-Quality Approved by-NPD & Quality

PRASAD Jamil Khan Anantha & Prabhat

You might also like

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- GTP Drake Acsr (Aw)Document1 pageGTP Drake Acsr (Aw)PM PandianNo ratings yet

- TPG Acsr As 450Document1 pageTPG Acsr As 450donlot onliNo ratings yet

- ACSR Rail ZTTDocument6 pagesACSR Rail ZTTAntony Cesar Caballero IbarraNo ratings yet

- CuAl10Ni HCC EDocument1 pageCuAl10Ni HCC EDeepak DasNo ratings yet

- Technical Data Sheet for ROCKINSUL RB SLABSDocument1 pageTechnical Data Sheet for ROCKINSUL RB SLABSDushyant SharmaNo ratings yet

- TPG Acsr 435 PDFDocument2 pagesTPG Acsr 435 PDFNurlita Dewi UtamiNo ratings yet

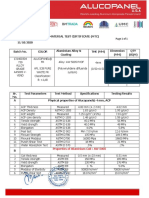

- Aludecor Al 45 Firewall En13501-1 Class A2 Technical SpecificationDocument2 pagesAludecor Al 45 Firewall En13501-1 Class A2 Technical Specificationsoham senNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Section 6.0-Particular Techn. Req. 132 KV NET-2 2013Document1 pageSection 6.0-Particular Techn. Req. 132 KV NET-2 2013Dawood Najem SalehNo ratings yet

- Selectrode: 317L Flux Coated TigDocument3 pagesSelectrode: 317L Flux Coated TigUta GilangNo ratings yet

- Martin Zhu: Technical SpecificationDocument5 pagesMartin Zhu: Technical SpecificationalfredoNo ratings yet

- Technical Specification: Aluminum Conductors, Aluminum Clad Steel Reinforced (ACSR/AS-Drake (795MCM) )Document5 pagesTechnical Specification: Aluminum Conductors, Aluminum Clad Steel Reinforced (ACSR/AS-Drake (795MCM) )alfredoNo ratings yet

- TDS Certificate09052022131255Document3 pagesTDS Certificate09052022131255SK Emran AliNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- 903 Datasheet 17Document1 page903 Datasheet 17Fred Duarte CaldeiraNo ratings yet

- Hangzhou Easy Electric Wire Spec SheetsDocument4 pagesHangzhou Easy Electric Wire Spec SheetsErnesto Antonio Astorga FloresNo ratings yet

- Nas 329J3L: (Uns S32205, S31803)Document4 pagesNas 329J3L: (Uns S32205, S31803)harry nataldoNo ratings yet

- 400PX3CHT33UEFLATDocument2 pages400PX3CHT33UEFLATjayesh95395No ratings yet

- Dual Shield 9000-B3 Flux Cored Wire for 2.25% Cr-1% Mo SteelsDocument1 pageDual Shield 9000-B3 Flux Cored Wire for 2.25% Cr-1% Mo SteelsqaNo ratings yet

- Conductor & IPS Tube - SpecificationDocument9 pagesConductor & IPS Tube - Specificationbalaeee123100% (1)

- ASTM A536 Grade 80-55-06 (2021 - 03 - 22 20 - 48 - 50 UTC)Document2 pagesASTM A536 Grade 80-55-06 (2021 - 03 - 22 20 - 48 - 50 UTC)Milton Pereira JúniorNo ratings yet

- Materilas-An Overview: 3.1 Austenitic Stainless Steel 316LDocument13 pagesMaterilas-An Overview: 3.1 Austenitic Stainless Steel 316LRS CreationsNo ratings yet

- Fsis09cxswyl004c006sa (FR LSH)Document1 pageFsis09cxswyl004c006sa (FR LSH)pkNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- Carraro India LTD Steel Mill Standard Rev 08Document7 pagesCarraro India LTD Steel Mill Standard Rev 08SUNDARNo ratings yet

- ASTM A536 Grade 60-40-18 Ductile Cast IronDocument2 pagesASTM A536 Grade 60-40-18 Ductile Cast IronbaladiroyaNo ratings yet

- LM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsDocument3 pagesLM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsSohail ShaikhNo ratings yet

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- c95500 Spec SheetDocument2 pagesc95500 Spec SheetOrnella MancinelliNo ratings yet

- GTP TogoDocument6 pagesGTP TogoRamphani NunnaNo ratings yet

- B 910 - B 910M - 02 Qjkxmc9cotewts1sruqDocument5 pagesB 910 - B 910M - 02 Qjkxmc9cotewts1sruqJuan Sebastián Londoño MartínezNo ratings yet

- Er100s GDocument1 pageEr100s GAhmed Abdel NabiNo ratings yet

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- LF GZTACSR 420-50 TW Data SheetDocument1 pageLF GZTACSR 420-50 TW Data SheetTú Trần TuấnNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetDocument2 pagesPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESNo ratings yet

- Nickel Aluminium Bronce SB-148 C95800Document2 pagesNickel Aluminium Bronce SB-148 C95800matteo_1234No ratings yet

- 3SFL 2core Power Cable SpecsDocument1 page3SFL 2core Power Cable Specssandeep bagulNo ratings yet

- Performace Evaluation of Slag Aggregates As Construction MaterialDocument49 pagesPerformace Evaluation of Slag Aggregates As Construction MaterialMd Ashiqur RahmanNo ratings yet

- En 353Document3 pagesEn 353anush_swaminathanNo ratings yet

- 18crnimo7-6: Steel GradeDocument3 pages18crnimo7-6: Steel GradeAndré Luiz NogueiraNo ratings yet

- Zamak 5 Data SheetDocument1 pageZamak 5 Data SheetLittle ChimpunksNo ratings yet

- LT XLPE Cable Data SheetDocument2 pagesLT XLPE Cable Data SheetAteebNo ratings yet

- ER-410NiMo MIG Wire Data SheetDocument2 pagesER-410NiMo MIG Wire Data SheetAnonymous skBAwexNo ratings yet

- Roxul Comfortboard 80: Insulated SheathingDocument1 pageRoxul Comfortboard 80: Insulated SheathingMark RauNo ratings yet

- Performance of Slag Aggregates in ConcreteDocument49 pagesPerformance of Slag Aggregates in ConcreteMd Ashiqur RahmanNo ratings yet

- Aac 500, Aac 1267, Acsr 60Document5 pagesAac 500, Aac 1267, Acsr 60Rahmat IzaiziNo ratings yet

- Typical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/FormDocument2 pagesTypical Uses: Product Description: Solids: Tubes: Rectangles: Standard Lengths: Shape/FormPEPENo ratings yet

- LT XLPE Cable Technical DataDocument1 pageLT XLPE Cable Technical DataVishal SharmaNo ratings yet

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocument7 pagesMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNo ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- Technical Delivery Condition: LBST Specification Code: LB 304Document2 pagesTechnical Delivery Condition: LBST Specification Code: LB 304Prasenjit PuriNo ratings yet

- Automig 70S A1 - Tigfil 70S A1Document1 pageAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNo ratings yet

- TPG Xiii.2.4 - Opgw 60 MMDocument5 pagesTPG Xiii.2.4 - Opgw 60 MMALVINNo ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- Product List - Alu and Steel ConductorDocument1 pageProduct List - Alu and Steel ConductorNirmal WiresNo ratings yet

- SLS 7 Sri LankaDocument14 pagesSLS 7 Sri LankaNirmal WiresNo ratings yet

- ASL TLDocument9 pagesASL TLNirmal WiresNo ratings yet

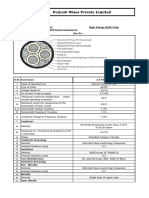

- Mill Test Certificates: TSN Wires Co., LTDDocument1 pageMill Test Certificates: TSN Wires Co., LTDNirmal WiresNo ratings yet

- Specification - GL Wires - MESPL May 2021Document2 pagesSpecification - GL Wires - MESPL May 2021M. I. BhadiNo ratings yet

- Packing List For GI Plant Packing Details For ACSRDocument2 pagesPacking List For GI Plant Packing Details For ACSRNirmal WiresNo ratings yet

- Astm 856Document3 pagesAstm 856Nirmal Wires100% (1)

- is.2599.1983 (1)Document13 pagesis.2599.1983 (1)Nirmal WiresNo ratings yet

- CESC - ESG Supplier Performance & Evaluation QuestionnaireDocument31 pagesCESC - ESG Supplier Performance & Evaluation QuestionnaireNirmal WiresNo ratings yet

- RRVPNL - Latest SpecificationDocument6 pagesRRVPNL - Latest SpecificationNirmal WiresNo ratings yet

- CIN: U28909WB1981PTC034204: Head (Works) Head (Q.A.)Document3 pagesCIN: U28909WB1981PTC034204: Head (Works) Head (Q.A.)Nirmal WiresNo ratings yet

- Pgcil SpecsDocument90 pagesPgcil SpecsNirmal Wires100% (1)

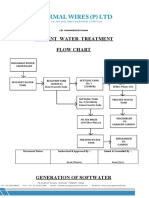

- Effuent Water Treatment Flow Chart: CIN: U28909WB1981PTC034204Document3 pagesEffuent Water Treatment Flow Chart: CIN: U28909WB1981PTC034204Nirmal WiresNo ratings yet

- Norma ASTM-A641Document5 pagesNorma ASTM-A641Dilmer CV100% (2)

- Contract AgreementDocument15 pagesContract AgreementNirmal WiresNo ratings yet

- Mechanical Testing SOP for Spiral PC WireDocument3 pagesMechanical Testing SOP for Spiral PC WireNirmal WiresNo ratings yet

- % Moisture : CIN: U28909WB1981PTC034204Document3 pages% Moisture : CIN: U28909WB1981PTC034204Nirmal WiresNo ratings yet

- Wire DrawingDocument47 pagesWire DrawingKamlesh Kumar100% (3)

- Cables PretensadoDocument12 pagesCables PretensadoFelipe CantillanoNo ratings yet

- 003 SOP of Phosphate BathDocument1 page003 SOP of Phosphate BathNirmal WiresNo ratings yet

- ASTM E340-95 Standard Method of Macroetch Metal AlloyDocument11 pagesASTM E340-95 Standard Method of Macroetch Metal Alloynearmiss82100% (1)

- Pgcil SpecsDocument90 pagesPgcil SpecsNirmal Wires100% (1)

- Determination of Chlorides Exp4 - PDFDocument12 pagesDetermination of Chlorides Exp4 - PDFSusheel Talreja100% (1)

- 003 SOP of Phosphate BathDocument1 page003 SOP of Phosphate BathNirmal WiresNo ratings yet

- BS 5896Document33 pagesBS 5896Nirmal WiresNo ratings yet

- ASTM A475 Standard Specification For Zinc-Coated Steel Wire StrandDocument5 pagesASTM A475 Standard Specification For Zinc-Coated Steel Wire StrandAdam JonesNo ratings yet

- Astm B 498Document5 pagesAstm B 498Nirmal WiresNo ratings yet

- Metallic Coated Stranded Steel Core For Aluminum Conductors, Steel Reinforced (ACSR)Document3 pagesMetallic Coated Stranded Steel Core For Aluminum Conductors, Steel Reinforced (ACSR)alanetnNo ratings yet

- Astm B857Document7 pagesAstm B857Nirmal WiresNo ratings yet

- Relative Density and Load Capacity of SandsDocument14 pagesRelative Density and Load Capacity of SandsgatotNo ratings yet

- CS401 Mcqs For Final TermDocument20 pagesCS401 Mcqs For Final Termsara.arshad.ch4No ratings yet

- Ipra IrrDocument58 pagesIpra IrrMac Manuel100% (1)

- Chapter 1 - Quiz 2 Form A: A. B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. 1. 2. 3. 4. 5. 6. 7. 8Document2 pagesChapter 1 - Quiz 2 Form A: A. B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. 1. 2. 3. 4. 5. 6. 7. 8Olalekan Oyekunle0% (1)

- New American Paintings - December-January, 2019Document180 pagesNew American Paintings - December-January, 2019Fabio Nagual100% (1)

- AEIOU Framework - Case Study On Agriculture Domain (Automatic Drip Tube Irrigation System)Document30 pagesAEIOU Framework - Case Study On Agriculture Domain (Automatic Drip Tube Irrigation System)Kunal TalegaonkarNo ratings yet

- JAOP Progress ReportDocument36 pagesJAOP Progress ReportnidhisasidharanNo ratings yet

- Shell Marine Pocketbook For International MarineDocument60 pagesShell Marine Pocketbook For International MarineGage Cendk HNo ratings yet

- Ajuste IAC and TPSDocument17 pagesAjuste IAC and TPSLuis Ignacio SilvaNo ratings yet

- Wiring Harness Installation Instructions: For InstallersDocument12 pagesWiring Harness Installation Instructions: For Installersnirut_niceguyNo ratings yet

- AP Calculus AB 4.1A Worksheet Key ConceptsDocument44 pagesAP Calculus AB 4.1A Worksheet Key ConceptsDavid Joseph100% (1)

- Hoist by TechnologyDocument6 pagesHoist by TechnologyAnonymous ntE0hG2TPNo ratings yet

- ABR College Mechanical Mid Exam Questions on MetrologyDocument1 pageABR College Mechanical Mid Exam Questions on MetrologySrinu ArnuriNo ratings yet

- Analyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphDocument13 pagesAnalyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphRamil NacarioNo ratings yet

- Ic F3022SDocument36 pagesIc F3022SEfren.galNo ratings yet

- Revisiting The Irish Royal Sites: Susan A. JohnstonDocument7 pagesRevisiting The Irish Royal Sites: Susan A. JohnstonJacek RomanowNo ratings yet

- AmadiDocument18 pagesAmadijawad bello aNo ratings yet

- GynecologyDocument24 pagesGynecologylovelots1234No ratings yet

- Zaldivar Et Al. 2017 (Dopamine Is Signaled by Mid-Frequency Oscillations and Boosts Output Layers Visual Information in Visual Cortex)Document30 pagesZaldivar Et Al. 2017 (Dopamine Is Signaled by Mid-Frequency Oscillations and Boosts Output Layers Visual Information in Visual Cortex)FRANCISCO ELI LEZAMA GUTIERREZNo ratings yet

- OK - EndUserGuideHoseSafetyInstituteDocument8 pagesOK - EndUserGuideHoseSafetyInstituteSunil GhosalkarNo ratings yet

- DSBV87ALP Two-Stage Differential Pressure Control Valve SpecsDocument2 pagesDSBV87ALP Two-Stage Differential Pressure Control Valve SpecsadrianioantomaNo ratings yet

- Hazardous Waste Identification GuidanceDocument105 pagesHazardous Waste Identification GuidanceMiguel TorresNo ratings yet

- Hydrocarbon ReactionsDocument2 pagesHydrocarbon ReactionsJessa Libo-onNo ratings yet

- Vammika Sutta - Mahasi SayadawDocument108 pagesVammika Sutta - Mahasi SayadawtravelbootsNo ratings yet

- Viscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Document40 pagesViscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Majid KhanNo ratings yet

- Process Modeling in The Pharmaceutical Industry Using The Discrete Element MethodDocument29 pagesProcess Modeling in The Pharmaceutical Industry Using The Discrete Element MethodRonaldo MenezesNo ratings yet

- Soal UAS Bahasa Inggris Kelas 2 SD Semester 1 (Ganjil) : A. Choose The Correct Answer by Crossing (X) A, B or C!Document7 pagesSoal UAS Bahasa Inggris Kelas 2 SD Semester 1 (Ganjil) : A. Choose The Correct Answer by Crossing (X) A, B or C!Hamizan ShopNo ratings yet

- The Emerald Tablets of Thoth Toth The Atlantean - Table 05Document5 pagesThe Emerald Tablets of Thoth Toth The Atlantean - Table 05Georgiana BealcuNo ratings yet

- Parts of the Globe: Prime Meridian, Equator and Climate ZonesDocument18 pagesParts of the Globe: Prime Meridian, Equator and Climate Zonesmelgazar tanjayNo ratings yet

- The Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierDocument1 pageThe Efficient Way To Prevent Water Carryover and Keep Your Indoor Air HealthierAzrinshah Abu BakarNo ratings yet