Professional Documents

Culture Documents

Polyurethane Pneumatic Tubing Shore 98 A Data Sheet PDF

Uploaded by

nikhilnv123Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyurethane Pneumatic Tubing Shore 98 A Data Sheet PDF

Uploaded by

nikhilnv123Copyright:

Available Formats

Polyurethane pneumatic tubing Shore 98 A

Applications

•Pneumatic control lines

•Machine manufacturing

Properties

•lightweight

•high flexibility at low temperatures

•UV-resistant

•high elasticity

•good damping behaviour

•excellent abrasion

excellent resistance

•kink resistant

resistance against tear propagation

•oil and grease resistant

•ideally suited for push-in-connectors

•easily fitted

•available in a range of colours

•small bending radius

•

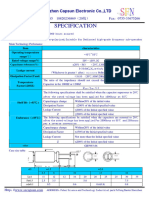

•unplasticized, no embrittlement Diagramm of pressure for PUR 98 Shore A

Degree of utilisation of the permissable pressure resistance (%) in dependence on

Temperature Range

•-40°C to +85°C temperature (°C)

Standard colours

•nature

•black

•blue

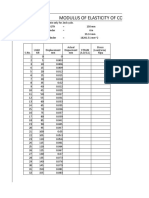

ID* Wall thickness OD* Tolerance ID & Weight Max. op. pressure Min. bending radius

mm mm mm OD mm m/g resistance at 23°C mm

bar

2 1 4 ± 0,10 11 20 20

2,7 0,65 4 ± 0,10 9 11 20

3 1 5 ± 0,10 15 15 25

4 1 6 ± 0,10 19 12 30

5 1,5 8 ± 0,10 37 13 40

5,5 1,25 8 ± 0,10 32 11 40

5,7 1,15 8 ± 0,10 30 10 40

6 1 8 ± 0,10 27 8 40

6,5 1,75 10 ± 0,10 55 12 50

7 1,5 10 ± 0,10 49 10 50

8 1 10 ± 0,10 34 6 50

8 2 12 ± 0,15 77 12 60

9 1,5 12 ± 0,15 60 8 60

11 2,5 16 ± 0,20 129 11 80

All data refers to a medium and ambient temperature of +23 °C

* Refers to the inner hose lining

Subject to technical changes and colour deviations.

Masterflex Technical Hoses Limited Tel +44 161 626 8066 Email: info@masterflex-uk.com

Units G & H, Prince of Wales Business Park, Vulcan Street, Oldham. OL1 4ER Fax +44 161 626 9066 Web site: www.masterflex-uk.com

You might also like

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- NORME NFT 58-000: Tolérances Applicables Aux Pièces Moulées en PlastiqueDocument1 pageNORME NFT 58-000: Tolérances Applicables Aux Pièces Moulées en PlastiqueDaniele RussoNo ratings yet

- Tubi Senza Saldatura Trafilati A Freddo Per Circuiti Oleodinamici. E235+N - EN10305-4 - DIN 2391Document7 pagesTubi Senza Saldatura Trafilati A Freddo Per Circuiti Oleodinamici. E235+N - EN10305-4 - DIN 2391djmattmNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Hot-Rolled Products TolerancesDocument3 pagesHot-Rolled Products TolerancesAndrew TanNo ratings yet

- Series 25L: Mechanical EncodersDocument2 pagesSeries 25L: Mechanical EncodersCasey FriendNo ratings yet

- Tolerances To ISO 9445 For Cold Rolled Narrow and Wide StripDocument8 pagesTolerances To ISO 9445 For Cold Rolled Narrow and Wide StripBurak KececiNo ratings yet

- En 10060 - TolerancesDocument3 pagesEn 10060 - TolerancesAyush Jain100% (3)

- T14 Conductor ResistanceDocument1 pageT14 Conductor ResistancebcostiucNo ratings yet

- JIS B 1351 Ref. : Applicable Shafts R 2dDocument1 pageJIS B 1351 Ref. : Applicable Shafts R 2dPedroFarfanMartelNo ratings yet

- Mosfet FS10KM-5Document2 pagesMosfet FS10KM-5Abel RodriguezNo ratings yet

- Tolerancije Limova I CeviDocument4 pagesTolerancije Limova I CeviZoran Tanja JarakovićNo ratings yet

- Epoxy Conformal Coated, Axial Leaded: Vishay DaleDocument2 pagesEpoxy Conformal Coated, Axial Leaded: Vishay DaleWilson Yecit OrtizNo ratings yet

- Modemikoo - Çalışma Sayfası1-1Document1 pageModemikoo - Çalışma Sayfası1-1TC Sezgin AkmanNo ratings yet

- IRF-36 Inductors: Vishay DaleDocument1 pageIRF-36 Inductors: Vishay DaleWilson Yecit OrtizNo ratings yet

- ISO/FDIS 8434-1:2018 (E) : Figure 10 - Weld On Nipple (WDNP)Document2 pagesISO/FDIS 8434-1:2018 (E) : Figure 10 - Weld On Nipple (WDNP)Enzo Fantoni100% (1)

- Split PinDocument1 pageSplit PinLuis CarlosNo ratings yet

- Tubo de Precision 2010 03 30 15 31 34Document3 pagesTubo de Precision 2010 03 30 15 31 34Leonardo SarriaNo ratings yet

- En Ag2100marinesmoothDocument2 pagesEn Ag2100marinesmootheloy marroquinNo ratings yet

- Laboratorio 9 Efecto Joule DatosDocument4 pagesLaboratorio 9 Efecto Joule Datosmichael marinNo ratings yet

- Combined PDF TensionBushesDocument6 pagesCombined PDF TensionBusheslogan95No ratings yet

- Resistencias SMD WIN-1524917Document4 pagesResistencias SMD WIN-1524917Ignacio Barriga NuñezNo ratings yet

- Sei SMDocument4 pagesSei SMwijeesf797No ratings yet

- FS3KMDocument5 pagesFS3KMpepe sanchezNo ratings yet

- Capsun (Radial Thru-Hole) SFN SeriesDocument2 pagesCapsun (Radial Thru-Hole) SFN Serieshes545No ratings yet

- Thickness & Dimensional Tolerances: Die-CutDocument1 pageThickness & Dimensional Tolerances: Die-Cuttripathi prashantNo ratings yet

- Copia de Flujo - JC LucasDocument37 pagesCopia de Flujo - JC LucasALEJANDRA GUTIERREZ SAAVEDRANo ratings yet

- Mechanical Dimensions: PackageDocument3 pagesMechanical Dimensions: PackageSec!No ratings yet

- Features: Mau200 SeriesDocument4 pagesFeatures: Mau200 SeriesdinhdtdNo ratings yet

- Paswara RCTDocument1 pagePaswara RCTAkash MittalNo ratings yet

- General Data SheetDocument8 pagesGeneral Data SheetGerman Ramirez LuqueNo ratings yet

- Soil Test BasicDocument17 pagesSoil Test BasicSamwailNo ratings yet

- Figure 1. The Chart of Methanol Fraction and Clindamycin Toward Propionibacterium AcnesDocument1 pageFigure 1. The Chart of Methanol Fraction and Clindamycin Toward Propionibacterium Acneswahdanie anieNo ratings yet

- R4 Relay Coil DataDocument1 pageR4 Relay Coil Datashyam_krishnan_16No ratings yet

- LM555 6Document2 pagesLM555 6Jomar SartoNo ratings yet

- 3.pipetman ClassicDocument6 pages3.pipetman ClassicLab Instruments AnalytikaNo ratings yet

- Alpha TW-700171 PDFDocument1 pageAlpha TW-700171 PDF3degreesNo ratings yet

- DRW 0002Document1 pageDRW 0002karpagavalli NNo ratings yet

- A Complete Smith Chart: '.9'1e-"'Fi: Q %Document1 pageA Complete Smith Chart: '.9'1e-"'Fi: Q %azertyNo ratings yet

- QF N CompareDocument1 pageQF N CompareDeniz GülerNo ratings yet

- TM21 Service-ManualDocument48 pagesTM21 Service-ManualRômulo MagalhãesNo ratings yet

- Irf 46Document1 pageIrf 467 SECOND RIDDLESNo ratings yet

- IRF-46 Inductors: Epoxy Conformal Coated, Axial LeadedDocument1 pageIRF-46 Inductors: Epoxy Conformal Coated, Axial LeadedWilson Yecit OrtizNo ratings yet

- JIS G3452: Carbon Steel Pipes For Ordinary PipingDocument1 pageJIS G3452: Carbon Steel Pipes For Ordinary PipingHoJienHauNo ratings yet

- 30x30x10 MM: BearingDocument1 page30x30x10 MM: Bearingkuyku3097No ratings yet

- Bending DevelopmentDocument1 pageBending DevelopmentANVNo ratings yet

- 1N4057 Thru 1N4085A: 22 Corey Street, Melrose, Massachusetts 02176 PHONE (781) 665-1071 FAX (781) 665-7379Document2 pages1N4057 Thru 1N4085A: 22 Corey Street, Melrose, Massachusetts 02176 PHONE (781) 665-1071 FAX (781) 665-7379radioscribdNo ratings yet

- Lab-1 PRC ReportDocument4 pagesLab-1 PRC ReportShanzayNo ratings yet

- Counter WeightDocument1 pageCounter WeightAvish100% (1)

- Lab 1 MelcDocument3 pagesLab 1 MelcMaria Alejandra Cortes PinzonNo ratings yet

- Hematology Controls: Assay Values and Expected RangesDocument2 pagesHematology Controls: Assay Values and Expected RangesHalan Dyego DiasNo ratings yet

- Table Kinetic ModelsDocument2 pagesTable Kinetic ModelsUvoBubaNo ratings yet

- LM337 (1) 2Document3 pagesLM337 (1) 2Sec!No ratings yet

- SPEC-DMM7510B Oct 2016 0Document25 pagesSPEC-DMM7510B Oct 2016 0SantonioNo ratings yet

- BBD ReportDocument76 pagesBBD ReportARTI PALEKARNo ratings yet

- Mantenimiento Motor Honda GXV620Document1 pageMantenimiento Motor Honda GXV620Daniel Lorenzo AgrazNo ratings yet

- DIN 128 A - Split Spring Washers, Curved, Form ADocument6 pagesDIN 128 A - Split Spring Washers, Curved, Form ASantosh100% (1)

- Multilayer SMD Ceramic Capacitors: DescriptionDocument42 pagesMultilayer SMD Ceramic Capacitors: DescriptionSetyawanNo ratings yet

- Uct IDocument1 pageUct I24Putriku 1B MPKNo ratings yet

- Biofuels Bioprod Bioref - 2022 - Ghumra - Technologies For Valorization of Municipal Solid Wastes PDFDocument14 pagesBiofuels Bioprod Bioref - 2022 - Ghumra - Technologies For Valorization of Municipal Solid Wastes PDFnikhilnv123No ratings yet

- Machine Learning Methods in Electronic Nose Analysis: Irene Rodriguez-Lujan Jordi Fonollosa Ramon HuertaDocument6 pagesMachine Learning Methods in Electronic Nose Analysis: Irene Rodriguez-Lujan Jordi Fonollosa Ramon Huertanikhilnv123No ratings yet

- 03jul2015030754paper 9Document3 pages03jul2015030754paper 9nikhilnv123No ratings yet

- Final Schedule PDFDocument4 pagesFinal Schedule PDFnikhilnv123No ratings yet

- Li2013 PDFDocument5 pagesLi2013 PDFnikhilnv123No ratings yet

- 896d PDFDocument12 pages896d PDFnikhilnv123No ratings yet

- Student Counsellor 1Document1 pageStudent Counsellor 1nikhilnv123No ratings yet

- Sports Officer Not Shortlisted 25012023 PDFDocument3 pagesSports Officer Not Shortlisted 25012023 PDFnikhilnv123No ratings yet

- P3 10 PDFDocument6 pagesP3 10 PDFnikhilnv123No ratings yet

- Sports Officer Finally Shortlisted 4745 17022023 PDFDocument1 pageSports Officer Finally Shortlisted 4745 17022023 PDFnikhilnv123No ratings yet

- Academic Calendar A.Y. 2021-22 Sem I Executive M.Tech. in CPS and DCS (1) - 01102021Document2 pagesAcademic Calendar A.Y. 2021-22 Sem I Executive M.Tech. in CPS and DCS (1) - 01102021nikhilnv123No ratings yet

- Report On Industrial VisitDocument3 pagesReport On Industrial Visitnikhilnv123100% (2)

- Broadband Access - DSL Technique (Up To 24Mbps)Document3 pagesBroadband Access - DSL Technique (Up To 24Mbps)nikhilnv123No ratings yet

- Practical Training Report 1Document72 pagesPractical Training Report 1nikhilnv123No ratings yet

- Biomedical Engineer QuoraDocument6 pagesBiomedical Engineer Quoranikhilnv123No ratings yet

- Measurement of Antenna Radiation Patterns: Laboratory ManualDocument44 pagesMeasurement of Antenna Radiation Patterns: Laboratory ManualMoBilbeisiNo ratings yet

- Sociological Question: How Is Some Degree of Order To Be Maintained in A Society?Document10 pagesSociological Question: How Is Some Degree of Order To Be Maintained in A Society?nikhilnv123No ratings yet

- Report On Industrial VisitDocument3 pagesReport On Industrial Visitnikhilnv123100% (2)

- Sandy Fire Staffing MemoDocument2 pagesSandy Fire Staffing MemoKUTV 2NewsNo ratings yet

- Shelf Drilling Pareto Conference Sep 2023 VFDocument34 pagesShelf Drilling Pareto Conference Sep 2023 VFAhmed Arabi AldeebNo ratings yet

- CashDocument3 pagesCashDahirNo ratings yet

- Postgraduate PG Mba Semester 1 2019 November Entrepreneurship Development 2019 PatternDocument2 pagesPostgraduate PG Mba Semester 1 2019 November Entrepreneurship Development 2019 PatternIVYNo ratings yet

- ACCELSA 1T 2020 EstadosFinancierosDocument18 pagesACCELSA 1T 2020 EstadosFinancierosYamis VillegasNo ratings yet

- Prepare 5 - Review 1-4Document28 pagesPrepare 5 - Review 1-4Bao NguyenNo ratings yet

- EXTRA QUESTIONS ANSWERS ch-3Document3 pagesEXTRA QUESTIONS ANSWERS ch-3Sarita ChopraNo ratings yet

- Sodium Sulphate Manufacturing Feasibility Study Project Proposal Business Plan in Ethiopia Pdf. - Haqiqa Investment Consultant in EthiopiaDocument1 pageSodium Sulphate Manufacturing Feasibility Study Project Proposal Business Plan in Ethiopia Pdf. - Haqiqa Investment Consultant in EthiopiaSulemanNo ratings yet

- Download pdf Economics 13Th Edition Roger A Arnold ebook full chapterDocument53 pagesDownload pdf Economics 13Th Edition Roger A Arnold ebook full chapterjohn.marshall425100% (2)

- Social Contract in Situations of Conflict and FragilityDocument36 pagesSocial Contract in Situations of Conflict and FragilityRinku BalwadaNo ratings yet

- Aikyam Brochure PDFDocument16 pagesAikyam Brochure PDFMeghana BezawadaNo ratings yet

- HUAYE Product CatalogueDocument24 pagesHUAYE Product CatalogueOnkar NarawadeNo ratings yet

- Principles of Microeconomics 7th Edition Gregory Mankiw Solutions Manual 1Document36 pagesPrinciples of Microeconomics 7th Edition Gregory Mankiw Solutions Manual 1ashleygeorgetifkcpmsag100% (27)

- SAP Currency TransactionsDocument1 pageSAP Currency TransactionsYazeed_GhNo ratings yet

- Knitcraft Christmas Advent Cal - Day00Document4 pagesKnitcraft Christmas Advent Cal - Day00Abigail CrisyellaNo ratings yet

- Agriculture Seminar 2Document3 pagesAgriculture Seminar 2Babe'sNo ratings yet

- Tender Details: MIS ReportsDocument2 pagesTender Details: MIS ReportsDescon Infrastructures Pvt. Ltd.No ratings yet

- Macroeconomics Principles and Applications 5th Edition Hall Lieberman Solution ManualDocument9 pagesMacroeconomics Principles and Applications 5th Edition Hall Lieberman Solution Manualjared100% (26)

- Supply & DemandDocument4 pagesSupply & DemandMichael HarrisNo ratings yet

- Textbook Chapter 10 Managing Change: Q What Is Personal Change?Document8 pagesTextbook Chapter 10 Managing Change: Q What Is Personal Change?Yashasvi SharmaNo ratings yet

- Ba0508 19-20 1Document8 pagesBa0508 19-20 1ccNo ratings yet

- Contract To Lease 8 SignedDocument3 pagesContract To Lease 8 SignedBill Turco0% (1)

- Term One Accountancy 12 QP & MSDocument13 pagesTerm One Accountancy 12 QP & MSVarun HurriaNo ratings yet

- Pc101 Applicationactivity Managingfinances TemplateDocument3 pagesPc101 Applicationactivity Managingfinances TemplateGabriel SchmidtNo ratings yet

- POABLDocument3 pagesPOABLWACK A RAMANo ratings yet

- TDS Vaxo - XLDocument1 pageTDS Vaxo - XLMikey MikslNo ratings yet

- 2017 AFR National Govt Volume IDocument706 pages2017 AFR National Govt Volume IPhilip JameroNo ratings yet

- AVSSH CablesDocument1 pageAVSSH CablesVijay KarthikeyanNo ratings yet

- DR - Bharucha Pay Bill May-11Document22 pagesDR - Bharucha Pay Bill May-11Nayan BharuchaNo ratings yet

- Ledger - Ms Vizin India PVT LTDDocument3 pagesLedger - Ms Vizin India PVT LTDgaurav narnoliaNo ratings yet