Professional Documents

Culture Documents

530AID01 DS en PDF

Uploaded by

Hatem LaadhariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

530AID01 DS en PDF

Uploaded by

Hatem LaadhariCopyright:

Available Formats

Remote Terminal Units - Data sheet

Analog input 530AID01

RTU530 product line

Analog input with 8 channels

• AD converter resolution: 16 bit

• Measuring ranges:

– 0... 2 mA, ± 2 mA

– 0... 5 mA, ± 5 mA

– 0... 10 mA, ± 10 mA

– 0... 20 mA, 4... 20 mA, ± 20 mA

– 0... 40 mA, 4... 40 mA, ± 40 mA

Application

The 530AID01 is a module of the RTU530 product line

I01

and records up to 8 analog measured values.

Resistor network

The module 530AID01 is able to process the following

Protection

ADC

types of signals: Micro -

A

• Analog measured values (AMI) controller

I02

• Measured floating point information (MFI)

RTU530 I/O bus

Multiplexer

...

RAM

Input circuit

Following measurement ranges can be configured:

• 0... 2 mA, ± 2 mA Signal-

conditioning

I03

I04

Flash

• 0... 5 mA, ± 5 mA Signal- I05

conditioning I06

• 0... 10 mA, ± 10 mA

D

IOC

Signal- I07

• 0... 20 mA, 4... 20 mA, ± 20 mA conditioning I08

• 0... 40 mA, 4... 40 mA, ± 40 mA

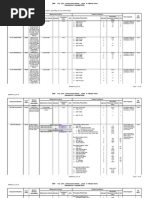

The module is available in two versions (rubrics): Figure 1: Block diagram 530AID01

• 530AID01 R0001

• 530AID01 R1001 conformal coated

Characteristics The module provides a data buffer for temporally

storing of up to 50 event messages including time

stamps. The events are stored in chronological order

Analog inputs designated for transmission to the communication

Basic signal checks and cyclic processing functions unit (CMU).

are already be done locally in order to unburden the

During initialization and operation the module

communication unit. The module transmits relevant

carries out a number of tests. If a fault occurs it is

changes as event via the RTU I/O bus.

reported to the communication unit. A failure of the

The 8 differential inputs are galvanically connected to connected module(s) is detected and signalized by the

the power supply. communication unit.

Single-ended or differential input values are resolved

Power supply input

by up to 65536 steps (16 bit including sign) for 100 %

measurement amplitude. The required power for the module is supplied via the

RTU530 I/O bus connector.

The differential inputs are protected against static

and dynamic over-voltages by a protection circuit.

A low-pass filter suppresses unwanted frequency

components.

The internal high resolution of the AD converter

allows to scan all measuring ranges with the same

resolution. An additional measurement channel is used

for automatic zero calibration. This compensates the

longterm drift of the components.

For elimination of tolerances a calibration is done

during production.

Measuring range and line frequency are easily to

configure by the RTUtil500 configuration tool.

The synchronization of the scan cycle with the line

frequency is used to increase the line frequency

interference suppression of the DC input signal.

Frequency Conversion time Scan cycle time

per channel (same for all

channels)

60 Hz 70 ms 630 ms

50 Hz 70 ms 630 ms

16.7 Hz 170 ms 1530 ms

I/O controller (IOC)

The micro-controller on the module processes

all time critical I/O tasks of the parameterized

processing functions. Moreover it carries out the

interactive communication with the RTU530 I/O bus.

All configuration data and processing parameters are

loaded by the communication unit via the RTU530 I/O

bus.

In connection with an I/O adapter (e. g. 530ADD01)

or the RTU530 communication unit the module is

interfaced to the RTU530 I/O bus.

The analog input unit can execute the following

processing functions on the measured values:

• Scan cycle and line frequency interference

suppression

• Zero value supervision and switching detection

• Smoothing

• Threshold value monitoring on absolute value or

with accumulation

• Periodic transmission and background cycles

Technical data Emission test

In addition to the RTU500 series general technical

Radiated emissions - EN 55011/ CISPR 11 class A

data, the following applies: enclosure ports (30 Mhz to

1 GHz), CISPR 16-2-3/ EN

55016-2-3

General standards

Safety tested according to • IEC 61010-1

• IEC 61010-2-201 Immunity test

Environmental conditions • IEC 60255-21-1 class 1 Electrostatic discharge, 8 kV air / 6 kV contact

tested according to • IEC 60255-21-2 class 1 IEC 61000-4-2 (level 3), criterion A

• IEC 60870-2-2 class Bm Radiated radio-frequency 80 MHz to 1 GHz: 10 V/m

and C1 electromagnetic field, (level 3), criterion A

Electromagnetic compat- • IEC 61000-6-2 IEC 61000-4-3

ibility (EMC) tested 1 GHz to 2.7 GHz: 10 V/m

• IEC 61000-6-4

according to (level 3), criterion A

• IEC 61000-6-5

Power frequency magnetic 100 A/m (level 5), criterion

Insulation classification IEC 60664-1 field, IEC 61000-4-8 A

according to • Pollution degree 2

Impulse magnetic field, 100 A/m (level 3), criterion

• Overvoltage category

IEC 61000-4-9 A

II

• Altitude: ≤ 3,000 m

Mean time between failure (MTBF)

Environmental conditions - climatic Calculation according to 2,160,000 h

Telcordia III 40°C

Operating temperature -25 °C ... 70 °C

EN 60068-2-14

Start up -40 °C Mechanical layout

EN 60068-2-1

Dimensions 30 mm x 125 mm x 85 mm

Max. operating temper- +85 °C (Width x Height x Depth)

ature, max. 96h

EN 60068-2-2 Housing type Plastic housing (V-2), RAL

7035 light gray

Relative humidity 5 ... 95 %

EN 60068-2-30 (non condensing) Mounting DIN rail mounting (EN

50022 TS35: 35 mm x 15

mm or 35 mm x 7.5 mm)

Environmental conditions - mechanical Enclosure protection class IP30

Vibration sinusoidal, Test 3.5 mm (3...9 Hz) Weight 0.15 kg

Fc , IEC 60068-2-6 10 m/s² (9...35 Hz)

1 octave/ min, 1 cycle per

axis Conformal coating

IEC 60255-21-3 class 1 Material base Acrylate resins (AR)

3 mm (3...9 Hz) Standards • IPC-CC-830B

10 m/s² (9...200 Hz) • MIL-I-46058C

15 m/s² (200...500 Hz) • UL 94

1 octave/ min, 10 cycles • UL 746E

per axis

Noxious gas protection noxious gas test

IEC 60870-2-2 class Bm

(coating material) according to DIN EN

0.035 mm (10 Hz...60 Hz) 60068-2-60 or BMW GS

5 m/s² (60 Hz...150 Hz) 95003-4

1 octave/ min, 1 cycle per Dielectric strength 60 kV/ mm according to

axis (coating material) IPC-TM-650 or DIN EN

IEC 60255-21-1 class 1 60243-1

Shock and Bump, Test Ea, 250 m/s², 10 ms Resistance to conden- 1.0 x 1010 Ohm based on

IEC 60068-2-27 4 shocks per direction sation (coating material) DIN EN ISO 6270-2

IEC 60721-3-3 class 3M5

150 m/s², 11 ms Connection type

3 shocks per direction

IEC 60255-21-2 class 1 Process connector (X4) 1 x 17 pole 5.08 mm

IEC 60870-2-2 class Bm pluggable screw terminals

(included in delivery), 0.2...

100 m/s², 16 ms 2.5 mm²/ AWG 24 - AWG 12

1000 shocks per direction Connector from CMU/ADD 2 x 6 pin, male

IEC 60255-21-2 class 1 or other I/O module (X2)

Connection type Analog inputs - EMC tests

Connector to next I/O 2 x 6 pin, female Conducted, common 30 V continuous distur-

module (X3) mode disturbances in the bance/ 300 V short

frequency range 0 Hz to duration disturbance

150 kHz, IEC 61000-4-16 (level 4), criterion A

Current consumption for power supplied via RTU530 Damped oscillatory wave, 2.5 kV (level 3), criterion A

I/O bus IEC 61000-4-18

5 V DC 75 mA

24 V DC --

Ordering information

530AID01 R0001 1KGT050100R0001

Analog input channels 530AID01

Inputs 8 differential inputs 530AID01 R1001 1KGT050100R1001

Configurable measuring • 0... 2 mA, ± 2 mA conformal coated

range • 0... 5 mA, ± 5 mA

• 0... 10 mA, ± 10 mA

• 0... 20 mA, 4... 20 mA, ±

20 mA

• 0... 40 mA, 4... 40 mA, ±

40 mA

Input impedance 50 Ω

Max. load 80 mA continuous

Resolution 16 bit including sign

AD converter resolution 16 bit

Accuracy at 25 °C ≤ 0.1 %

Linearity error at 25 °C ≤ 0.1 %

Temperature drift ≤ 100 ppm/K (0... 70 °C)

Max. common mode input ±150 V DC (electrical limit)

voltage

Max. differential input ± 4 V DC (current input)

voltage

Common mode rejection > 70 dB @ 25 °C

> 60 dB @ 0… 25 °C

Configurable line • 16.7 Hz

frequency fN • 50 Hz

• 60 Hz

Line frequency inter- > 100 dB @ fN ±2 %

ference suppression

> 45 dB @ fN ±10 %

Analog inputs - EMC tests

Electrical fast transient / 4 kV (level 4), criterion A

Burst, IEC 61000-4-4

Surge 1.2/50 µs, 2 kV (level 3), criterion A

IEC 61000-4-5

Conducted distur- 10 V (level 3), criterion A

bances, induced by

radio-frequency fields,

IEC 61000-4-6

Ring wave, IEC 61000-4-12 2 kV (level 3), criterion A

ABB Power Grids Germany AG We reserve the right to make technical We reserve all rights in this document and in ABB is a registered trademark of ABB

changes or modify the contents of the subject matter and illustrations contained Asea Brown Boveri Ltd. Manufactured

P.O. Box 10 01 64 this document without prior notice. therein. Any reproduction, disclosure to third by/for a Hitachi Power Grids company.

1KGT151075 V002 1

68128 Mannheim, Germany With regard to purchase orders, the parties or utilization of its contents – in whole

agreed particulars shall prevail. Hitachi or in parts – is forbidden without prior written

ABB Power Grids does not accept any consent of Hitachi ABB Power Grids.

responsibility whatsoever for potential © 2020 Hitachi Power Grids

errors or possible lack of information in All rights reserved

hitachiabb-powergrids.com/rtu this document.

You might also like

- OYO Case Study SolutionDocument4 pagesOYO Case Study SolutionVIKASH GARGNo ratings yet

- Analog Modules: SiemensDocument8 pagesAnalog Modules: SiemensSofiane Benseghir100% (1)

- COVID-19 and Flu Vaccination Walgreens Immunization ServicesDocument1 pageCOVID-19 and Flu Vaccination Walgreens Immunization ServicesAitana MaldonadoNo ratings yet

- 530aid02 DSDocument4 pages530aid02 DSBhageerathi SahuNo ratings yet

- 23AE23 DS enDocument4 pages23AE23 DS enBhageerathi SahuNo ratings yet

- Aeat 9955 DS103Document27 pagesAeat 9955 DS103skymax1337No ratings yet

- t49171 EngDocument7 pagest49171 EngPendonlot TanNo ratings yet

- Tds 0005Document2 pagesTds 0005computerparadise1993No ratings yet

- Flexible Control. Precise Monitoring. Safe Switch-Off.: Tailored Motor Management - Now Also With Safety IntegratedDocument4 pagesFlexible Control. Precise Monitoring. Safe Switch-Off.: Tailored Motor Management - Now Also With Safety IntegratedseñorbmxNo ratings yet

- Rtu Ai - 560air01Document4 pagesRtu Ai - 560air01Hormoz MehrNo ratings yet

- MLX90393 Product Flyer MelexisDocument2 pagesMLX90393 Product Flyer MelexisLigiutza IzabelutzaNo ratings yet

- Osixca5121a DatasheetDocument1 pageOsixca5121a DatasheetWilliam Medina GómezNo ratings yet

- Bm1422agmv eDocument28 pagesBm1422agmv ecalltokamalNo ratings yet

- 560AIR02 CS enDocument6 pages560AIR02 CS enUmutNo ratings yet

- e2_DP2200_DP1222_e_19-20_nDocument2 pagese2_DP2200_DP1222_e_19-20_nfzin khhsNo ratings yet

- SITRANS T Measuring Instruments For TemperatureDocument5 pagesSITRANS T Measuring Instruments For TemperatureCapacitacion TodocatNo ratings yet

- Opto-Switch: DimensionsDocument2 pagesOpto-Switch: DimensionsDewi AgustinaNo ratings yet

- 11 IO-Link ENDocument12 pages11 IO-Link ENPedro GodoiNo ratings yet

- AVM14Document4 pagesAVM14Adel AhmedNo ratings yet

- Ia6 12GM50 Iu V1Document2 pagesIa6 12GM50 Iu V1Pipe CastilloNo ratings yet

- 560AIR01 DS enDocument4 pages560AIR01 DS enبوحميدة كمالNo ratings yet

- s7 Plcs and Applications - Lesson 3 - Analog ProcessDocument69 pagess7 Plcs and Applications - Lesson 3 - Analog Processdtran2354No ratings yet

- Color Sensor: 12-Bit Digital OutputDocument6 pagesColor Sensor: 12-Bit Digital OutputgabiNo ratings yet

- M4066BP Mitsubishi PDFDocument5 pagesM4066BP Mitsubishi PDFDeivys VargasNo ratings yet

- Fronius Symo GEN24 5.0 Plus - Quick Installation Quide - ENDocument2 pagesFronius Symo GEN24 5.0 Plus - Quick Installation Quide - ENsimonNo ratings yet

- Overload Relay Specifications: MT Type Thermal Overload RelaysDocument12 pagesOverload Relay Specifications: MT Type Thermal Overload RelaysWOLFGANG84No ratings yet

- Ficha Tecnica 1181-M25a INSIZEDocument1 pageFicha Tecnica 1181-M25a INSIZERenua spaNo ratings yet

- Indicator I 65-S: Area of Use General PresentationDocument2 pagesIndicator I 65-S: Area of Use General PresentationKhalidNo ratings yet

- REM630 Broch 756825 LRENdDocument6 pagesREM630 Broch 756825 LRENdsihamuNo ratings yet

- Goodwe GM3000 Smart Meter User ManualDocument2 pagesGoodwe GM3000 Smart Meter User ManualDruga CatalinNo ratings yet

- Flow Monitoring MK96 For Flow Sensors MK96-LI01Document1 pageFlow Monitoring MK96 For Flow Sensors MK96-LI01chikkamNo ratings yet

- Circuit Note: 12-Bit, 4-20ma Loop-Powered Thermocouple Measurement System Using ARM Cortex-M3Document7 pagesCircuit Note: 12-Bit, 4-20ma Loop-Powered Thermocouple Measurement System Using ARM Cortex-M3Srinivasa MuralidharaNo ratings yet

- Abb Utilities GMBH: ApplicationDocument2 pagesAbb Utilities GMBH: Applicationantlsm733No ratings yet

- Microprocess Rate & Totalizer Controller Meter Model MRT: (Features)Document1 pageMicroprocess Rate & Totalizer Controller Meter Model MRT: (Features)Waqar AliNo ratings yet

- Оптический датчик Leuze Electronic LSE 318K N (Receiver)Document2 pagesОптический датчик Leuze Electronic LSE 318K N (Receiver)imaginshieldNo ratings yet

- M30 Series AC/DC 2-Wire Inductive SensorsDocument1 pageM30 Series AC/DC 2-Wire Inductive Sensorsany3000No ratings yet

- Inductive Sensors With Analogue Output Series 10 - IL: Made in GermanyDocument1 pageInductive Sensors With Analogue Output Series 10 - IL: Made in GermanydhineshretnaNo ratings yet

- PM 3sa SVDocument1 pagePM 3sa SVLeandro AriasNo ratings yet

- Compressed Air Manual Tcm44-1249312Document8 pagesCompressed Air Manual Tcm44-1249312Osama Kamel ElghitanyNo ratings yet

- ProReact Digital LHD DiMM DataSheetDocument3 pagesProReact Digital LHD DiMM DataSheetAlexandru CraiovanNo ratings yet

- Plano Eléctrico - TRACTOR D10T PDFDocument4 pagesPlano Eléctrico - TRACTOR D10T PDFHéctorReyesPinedaNo ratings yet

- M30 Series AC/DC 2-Wire Inductive Sensors with 15mm Sensing RangeDocument1 pageM30 Series AC/DC 2-Wire Inductive Sensors with 15mm Sensing Rangeany3000No ratings yet

- M30 Series AC 2-Wire/AC-DC 2-Wire SN 15mm: Inductive Sensors FeaturesDocument1 pageM30 Series AC 2-Wire/AC-DC 2-Wire SN 15mm: Inductive Sensors Featuresany3000No ratings yet

- Optical Distance Sensor - GP2Y0D810Z0F Gp2y0d810z - e PDFDocument9 pagesOptical Distance Sensor - GP2Y0D810Z0F Gp2y0d810z - e PDFLodewyk KleynhansNo ratings yet

- DataDocument1 pageDataAndrei CatanaNo ratings yet

- MP2497 r1.12-371637Document15 pagesMP2497 r1.12-371637SavouretNo ratings yet

- 1 General Description: 360 Step (8.5 Bit) Programmable High Speed Magnetic Rotary EncoderDocument27 pages1 General Description: 360 Step (8.5 Bit) Programmable High Speed Magnetic Rotary EncoderMikhailNo ratings yet

- Plume P6 Pro-PGN518 Diagram 2Document15 pagesPlume P6 Pro-PGN518 Diagram 2Life PowerNo ratings yet

- LTC 1605 CSWDocument16 pagesLTC 1605 CSWalaa delewarNo ratings yet

- Proximity SwitchDocument4 pagesProximity SwitchMohamed MekkyNo ratings yet

- AWAF AWAX AWDX AWUX eDocument8 pagesAWAF AWAX AWDX AWUX eZamuel Torres GarcíaNo ratings yet

- Motec: Adl / Adl2Document1 pageMotec: Adl / Adl2Mohammed 216No ratings yet

- Zz-Gy-S0119b, Zl-Z24bwc13-Ygg 2Document4 pagesZz-Gy-S0119b, Zl-Z24bwc13-Ygg 2EiligamNo ratings yet

- CATALOG No. E4184 High-accuracy Real Absolute Sealed Linear EncoderDocument2 pagesCATALOG No. E4184 High-accuracy Real Absolute Sealed Linear EncoderNathan ChenNo ratings yet

- CT Series: Instruction ManualDocument2 pagesCT Series: Instruction ManualHelton ClarindoNo ratings yet

- P115Document9 pagesP115ridho kusumaNo ratings yet

- AS5145H/AS5145A/AS5145B: 1 General DescriptionDocument37 pagesAS5145H/AS5145A/AS5145B: 1 General DescriptionsekoNo ratings yet

- WT Micro Temperature Controller CatalogueDocument7 pagesWT Micro Temperature Controller CataloguepngchanhNo ratings yet

- Inductive Sensor NBB15-U1-Z2: DimensionsDocument3 pagesInductive Sensor NBB15-U1-Z2: DimensionsYolteotl ReynaNo ratings yet

- Compact PLC with Built-in HMIDocument3 pagesCompact PLC with Built-in HMIkoprol_14No ratings yet

- 1KGT033300R1002 520bod01 r1002 8 Binary Outputs RelaysDocument2 pages1KGT033300R1002 520bod01 r1002 8 Binary Outputs RelaysHatem LaadhariNo ratings yet

- 1KGT033200R0001 520bid01 r0001 16 Binary Inputs 24 60 VDCDocument2 pages1KGT033200R0001 520bid01 r0001 16 Binary Inputs 24 60 VDCHatem LaadhariNo ratings yet

- Iec 60870 5 101 104 Intop PTS EngDocument44 pagesIec 60870 5 101 104 Intop PTS EngHatem LaadhariNo ratings yet

- 530BID01 DS en PDFDocument4 pages530BID01 DS en PDFHatem LaadhariNo ratings yet

- 530CID02 DS en PDFDocument8 pages530CID02 DS en PDFHatem LaadhariNo ratings yet

- 530ADD01 DS enDocument4 pages530ADD01 DS enHatem LaadhariNo ratings yet

- 530CID01 DS en PDFDocument8 pages530CID01 DS en PDFHatem LaadhariNo ratings yet

- 530PTD01 DS en PDFDocument4 pages530PTD01 DS en PDFHatem LaadhariNo ratings yet

- E560 RTU560 Security Deployment Guide LineDocument46 pagesE560 RTU560 Security Deployment Guide LineHatem LaadhariNo ratings yet

- 530IOD01 DS en PDFDocument6 pages530IOD01 DS en PDFHatem LaadhariNo ratings yet

- Industrial Control Systems Security and Supervisory Control and Data Acquisition (Scada)Document10 pagesIndustrial Control Systems Security and Supervisory Control and Data Acquisition (Scada)Feleke AfeworkNo ratings yet

- Chapter 11 RespirationDocument2 pagesChapter 11 Respirationlock_jaw30No ratings yet

- Compiler Design and Linux System AdministrationDocument47 pagesCompiler Design and Linux System AdministrationGouri ShankerNo ratings yet

- Ffective Riting Kills: Training & Discussion OnDocument37 pagesFfective Riting Kills: Training & Discussion OnKasi ReddyNo ratings yet

- Consumer Notebook Price List For September 2010Document4 pagesConsumer Notebook Price List For September 2010Anand AryaNo ratings yet

- Combining Singing and PsycologyDocument6 pagesCombining Singing and PsycologyAna luciaNo ratings yet

- A Daily Morning PrayerDocument8 pagesA Daily Morning Prayerjhustine05100% (1)

- GCS Activity 2003Document33 pagesGCS Activity 2003donnottryNo ratings yet

- Carbon Disulfide: Hazard SummaryDocument5 pagesCarbon Disulfide: Hazard SummaryAlyssa ZerlinaNo ratings yet

- The Secret Science of Shaktipat - Guide To Initiation 13 September 2020Document77 pagesThe Secret Science of Shaktipat - Guide To Initiation 13 September 2020Patrick JenksNo ratings yet

- The Impact of Spiritual Intelligence, Gender and Educational Background On Mental Health Among College StudentsDocument22 pagesThe Impact of Spiritual Intelligence, Gender and Educational Background On Mental Health Among College StudentsBabar MairajNo ratings yet

- Nursing Care Plans for ChildrenDocument4 pagesNursing Care Plans for ChildrenAlexander Rodriguez OlipasNo ratings yet

- Self-Sustainable Village: Dharm Raj Jangid 16031AA015Document2 pagesSelf-Sustainable Village: Dharm Raj Jangid 16031AA015Dharm JangidNo ratings yet

- Carbon Emission and Battery Monitoring SystemDocument17 pagesCarbon Emission and Battery Monitoring SystemIJRASETPublicationsNo ratings yet

- New Translation and Deciphering of ChineDocument14 pagesNew Translation and Deciphering of ChineRémyNo ratings yet

- The Korean MiracleDocument20 pagesThe Korean MiracleDivya GirishNo ratings yet

- 2006fileaveo MTDocument63 pages2006fileaveo MTeurospeed2100% (1)

- But Virgil Was Not There": The Lasting Impact of Dante's Homosocial HellDocument7 pagesBut Virgil Was Not There": The Lasting Impact of Dante's Homosocial HellЮлия ЧебанNo ratings yet

- Thermo Safety Cabinets MSC-Advantage - User ManualDocument53 pagesThermo Safety Cabinets MSC-Advantage - User ManualAhmed SalamaNo ratings yet

- Presentation on Indentured LabourersDocument10 pagesPresentation on Indentured LabourersAshis karmakar100% (1)

- Mobile Assisted Language Learning (MALL) Describes An Approach To Language LearningDocument7 pagesMobile Assisted Language Learning (MALL) Describes An Approach To Language Learninggusria ningsihNo ratings yet

- Cultures of Learning: Language Classrooms in China: Martin Cortazzi Lixian JinDocument54 pagesCultures of Learning: Language Classrooms in China: Martin Cortazzi Lixian JinyhoulhandhariNo ratings yet

- AAPD Reference Manual - Pediatric Dentistry 2010-2011Document336 pagesAAPD Reference Manual - Pediatric Dentistry 2010-2011Tiara100% (1)

- Clone CDDocument2 pagesClone CDavk.oracleNo ratings yet

- Fee Structure 2023-2024Document10 pagesFee Structure 2023-2024Emmanuel NjogellahNo ratings yet

- Bharathidasan University UG/PG Exam ApplicationDocument2 pagesBharathidasan University UG/PG Exam ApplicationOppili yappanNo ratings yet

- 2020 Exam-Sample-Questions-Computer-ScienceDocument8 pages2020 Exam-Sample-Questions-Computer-ScienceNesrine LaradjiNo ratings yet

- 5.test Report - RFU-C-7Ghz IP10 Extract VersionDocument42 pages5.test Report - RFU-C-7Ghz IP10 Extract Versionminhdung.pham4713No ratings yet

- Articulos 2022-2Document11 pagesArticulos 2022-2Nilser Enrique Valle HernandezNo ratings yet