Professional Documents

Culture Documents

Hetronic-Irc Instruction Manual

Uploaded by

Krum KashavarovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hetronic-Irc Instruction Manual

Uploaded by

Krum KashavarovCopyright:

Available Formats

HMF-IRC Instruction Manual - GB

HMF- IRC

INSTRUCTION MANUAL

01.01 HMF TECHNICAL SERVICE DEP.

HMF-IRC Instruction Manual - GB

Contents

Chapter Page

1. Introduction 3

2. The Components of the IRC-system 4

3. Description of the system 5

3.1 The IRC-system, general Description 5

3.2 IRC-Remote Control Box 6

3.2.1 General Description of the Remote Control Box 6

3.2.2 Control Levers 7

3.2.2.1 Operating Symbols 7

3.2.2.2 Lever Sequence, 6 Loader Functions 8

3.2.2.3 Lever Sequence, 5 Loader Functions 8

3.2.2.4 Lever Sequence, 4 Loader Functions 9

3.2.2.5 Lever Sequence, 6+2 Loader Functions 9

3.2.3 Press Buttons and Tumbler Switches 10

3.2.3.1 Remote Control of RCL functions 10

3.2.3.2 Engine Throttle Control (Option) 11

3.2.3.3 Engine start-stop (Option) 12

3.2.3.4 Electric Reverser Function, 7 or 8 Loader Functions 13

3.2.3.5 Choice of Engine Revolutions (Option) 15

3.2.4 The Remote Control Box in Stand-by Mode 16

3.3 IRC-Electronic Box 16

3.4 IRC-battery and battery Charger 17

3.4.1 Replacement of the battery 17

3.4.2 Charging of the Battery 18

3.4.3 Good Advice about the Battery 18

3.5 Remote control cable (option) 19

3.6 Transmitter System, frequencies 19

4. Safety Regulations 20

5. Starting Up of the Loader 21

5.1 Starting Up from the Indicator Panel of the RCL 21

5.2 Starting Up of the IRC-System 22

5.3 Starting Up from the IRC-Remote Control Box 22

6. Signalling during Loader Operation 23

7. Emergency Stop during Loader Operation 23

8. Stopping the IRC-system 23

01-01 HMF TECHNICAL SERVICE DEP.

1

HMF-IRC Instruction Manual - GB

9. Emergency Operation of the Loader 24

10. The HDL-system (Option) 24

10.1 Proportional HDL 25

10.2 Micro Operation 25

11. Troubleshooting 26

12. Maintenance 27

13. Technical Data 28

01-01 HMF TECHNICAL SERVICE DEP.

2

HMF-IRC Instruction Manual - GB

1. Introduction

This instruction manual on HMF-IRC radio remote control is meant for the user

of the loader and must be considered as a supplement to:

• the Instruction Manual for the individual Loader Series and

• the RCL Instruction Manual

It is important to read these instruction manuals before starting up and using the

radio remote control. This should give the best starting point for an

unproblematic use of the system.

The designation IRC is short for Integrated Radio Control, which means that the

transmission of data from the radio remote control is an integrated part of the

loader’s RCL safety system.

During loader operation, the IRC-system sends signals to the RCL 5100/5200

controller which monitors which loader functions that are activated.

The RCL safety system is thus monitoring the following parameters:

• The load moment of the loader

• The operation of the loader

• The functional conditions

and stops the loader if critical situations occur.

01-01 HMF TECHNICAL SERVICE DEP.

3

HMF-IRC Instruction Manual - GB

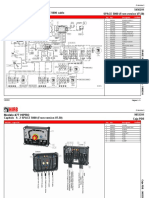

2. The Components of the IRC-System

The IRC system consists of the following components:

Remote control box with radio transmitter

Electronic box with radio receiver

Battery for the remote control box (2 pcs.)

Remote control cable (option)

Battery Charger

01-01 HMF TECHNICAL SERVICE DEP.

4

HMF-IRC Instruction Manual - GB

3. Description of the System

3.1 The IRC-System, general Description

The electronic box is connected to the electric activations on the valve block by

means of electric cables.

During loader operation, the control levers on the remote control box are

operated. Digitally coded control information is thus sent via radio signals to the

electronic box. The radio signals are converted to electric voltage, which is sent

to the electric activations of the valve block.

In the electric activations the electric voltage controls small hydraulic solenoid

valves. These solenoid valves control a hydraulic oil pressure, which activates

the control levers of the valve block.

The control levers on the valve block move at the same speed and in the same

direction as the control levers on the remote control box.

01-01 HMF TECHNICAL SERVICE DEP.

5

HMF-IRC Instruction Manual - GB

3.2 IRC-Remote Control Box

3.2.1 General Description of the Remote Control Box

The remote control box can be equipped with up to 6 control levers (pos. 1)

depending on how many loader functions are to be operated.

The left tumbler switch (pos. 2) and the right tumbler switch (pos. 3) for

operating extra functions are placed in front of the control levers. Please note:

extra functions related to the engine control of the vehicle, are only active when

the vehicle body builder has carried out the necessary electric connections.

In front of the control levers there is also a stop button (pos. 4) as well as an

indicator lamp (pos. 5). The indicator lamp as well as the built-in buzzer

currently keep the operator informed of the functional condition of the system.

On the right side of the remote control box is built in a key switch (pos. 6). The

press buttons (pos. 7) remote control functions in the RCL controller.

On the left side of the remote control box are built in some press buttons (pos.

8) for extra functions.

The remote control box is powered by a battery (pos. 9) placed at the bottom of

the box.

01-01 HMF TECHNICAL SERVICE DEP.

6

HMF-IRC Instruction Manual - GB

3.2.2 Control Levers

The control levers have stepless activation to both sides. They are spring-

loaded and therefore they automatically go back into neutral position when they

are released.

The control levers on the valve block move at the same speed and in the same

direction as the control levers on the remote control box.

The signal from a control lever is proportional, i.e. the more it is operated

towards the extreme position, the more speed is increased on the loader

function in question.

Please note that all control levers must be in neutral position before starting up

the system.

The number of control levers depends on the number of loader functions, which

are to be remote controlled. From HMF the positioning of the individual control

lever as well as the direction of travel of the loader in relation to the direction of

travel of the control levers are determined as standard configurations.

A standard configuration can be changed by an HMF service point, if required.

3.2.2.1 Operating Symbols

Loaders equipped with IRC-system are delivered from HMF with operating

symbols labelled on the remote control box.

When changing a standard configuration, the operating symbols must be

labelled on the remote control corresponding to the lever sequence in question.

At the same time, you must state the change in this Instruction Manual by

changing one of the below sketches.

In the following pages are indicated the different standard configurations of the

remote control boxes with their corresponding operating symbols.

01-01 HMF TECHNICAL SERVICE DEP.

7

HMF-IRC Instruction Manual - GB

3.2.2.2 Lever Sequence, 6 Loader Functions

3.2.2.3 Lever Sequence, 5 Loader Functions

01-01 HMF TECHNICAL SERVICE DEP.

8

HMF-IRC Instruction Manual - GB

3.2.2.4 Lever Sequence, 4 Loader Functions

3.2.2.5 Lever Sequence, 6 + 2 Loader Functions

01-01 HMF TECHNICAL SERVICE DEP.

9

HMF-IRC Instruction Manual - GB

3.2.3 Press Buttons and Tumbler Switches

All press buttons and tumbler switches on the remote control box only control

“ON/OFF”-functions in the IRC-system.

3.2.3.1 Remote Control of RCL Functions

On the RCL controller, different functions can be operated by means of the

three press buttons; red, yellow and green. These functions can also be remote

controlled by means of the press buttons on the right side of the remote control

box. However, there are only two press buttons.

The functions of the green and red press buttons are operated directly, while

the function of the yellow press button is operated by pushing the left tumbler

switch to the right (opt. 1) and at the same time pushing the red press button.

The following functions are operated by means of the press buttons:

Green press button: Activation of the RCL-system / Deactivation of buzzer

Red press button: Override / Manual activation of HDL / Indication of errors

Yellow press button: Alternative function mode.

These RCL functions are thoroughly described in the RCL Instruction Manual.

01-01 HMF TECHNICAL SERVICE DEP.

10

HMF-IRC Instruction Manual - GB

3.2.3.2 Engine Throttle Control (Option)

Throttle control of the engine of the vehicle can be carried out from the remote

control box. The regulation area is between idling and a max. number of

revolutions fixed by the HMF service point and programmed in the EDC-engine

control by the supplier of the vehicle.

Operate the throttle control in the following way:

• The left tumbler switch must be in central position

• By pushing the right press button several times, the number of revolutions is

increased (+ RPM) stepwise

• By pushing the left press button several times, the number of revolutions is

decreased (- RPM) stepwise

01-01 HMF TECHNICAL SERVICE DEP.

11

HMF-IRC Instruction Manual - GB

3.2.3.3 Engine Start-Stop (Option)

The engine of the vehicle can be started and stopped from the remote control

box as follows:

• Push the left tumbler switch to the right (opt 1). The tumbler switch must be

kept in this position because it is spring-loaded and automatically goes back

into neutral position

• The engine is started by pushing the right press button

• The engine is stopped by pushing the left press button

01-01 HMF TECHNICAL SERVICE DEP.

12

HMF-IRC Instruction Manual - GB

3.2.3.4 Electric Reverser Function, 7 or 8 Loader Functions

The remote control box has 6 proportionally acting control levers for operating 6

loader functions.

By means of an electric reverser function it is possible to operate up to two

more loader functions. I.e. one of the control levers can control three different

loader functions (or loader equipment).

By means of the left tumbler switch and the press buttons on the left side of the

remote control box, it is possible to change between up to three loader functions

on the control lever.

Example:

The loader is fitted with Fly-Jib. The 5th control lever operates the jib function of

the Fly-Jib and the 6th control lever operates the extension function (the two

levers to the extreme right) .

The Fly-Jib is fitted with extra valves for grab and rotator (7th and 8th function).

Operate the grab and rotator in the following way:

• Push the left tumbler switch to the left (opt. 2).

• While holding down the left press button (A), the 6th control lever changes

from Fly-Jib “extension”-function to “rotator”-function.

• While holding down the right press button (B), the 6th control lever changes

from Fly-Jib “extension”-function to “grab”-function.

01-01 HMF TECHNICAL SERVICE DEP.

13

HMF-IRC Instruction Manual - GB

If you require the 7th or 8th loader function to be activated permanently, carry out

as follows:

• Push the left tumbler switch to the left (opt. 2).

• Hold down the left press button (A) or the right press button (B) while

pushing the left tumbler switch into central position again.

Now the “grab”- or “rotator”-function is a direct function in the 6th control lever.

By repeating the procedure, the functions of the control levers are changed

back to their original functions.

01-01 HMF TECHNICAL SERVICE DEP.

14

HMF-IRC Instruction Manual - GB

3.2.3.5 Choice of Engine Revolutions (Option)

During loader operation, the number of engine revolutions must be increased to

a fixed level (e.g. 900-1000 RPM) to optimise the capacity of the engine as well

as the working speed of the loader.

The change from the engine running idle to its number of revolutions being

increased into working level, can be remote controlled.

By means of the right tumbler switch on the remote control box, you can choose

between two types of engine revolutions.

• If the right tumbler switch is in central position, the engine revolutions are not

activated and the engine is running idle.

• If the right tumbler switch is pushed to the left (FULL RPM), the engine is

continuously running at high working speed.

• If the right tumbler switch is pushed to the right (AUTO RPM), the high

engine revolutions are automatically engaged and disengaged.

I.e. when one of the control levers is being operated, the high engine

revolutions are engaged. When the control levers are back in neutral

position, the high engine revolutions are disengaged and the engine is

running idle.

01-01 HMF TECHNICAL SERVICE DEP.

15

HMF-IRC Instruction Manual - GB

3.2.4 The Remote Control Box in Stand-By Mode

To optimise the running time of the battery as well as for safety reasons, the

remote control box is pre-programmed to go into stand-by mode after approx.

10 minutes. At the same time the indicator lamp turns off.

I.e. if there has been no operation from the remote control box for the last 10

minutes, it goes into stand-by mode, where the power consumption is very

limited.

Please note! To reactivate the remote control box, push the green press

button.

3.3 IRC-Electronic Box

A radio receiver is built into the electronic box, which by means of the external

antenna receives radio signals from the remote control box.

The electronic box is connected to either 12 or 24 volts power supply from the

accumulator of the vehicle. There are outputs for cable connection to the

electric activations of the valve block as well as to the RCL-system.

On the right side of the electronic box there is a small square with four diodes

signalling whether or not the system functions

correctly.

Diode Function

OPERATION The diode is flashing when the hydraulic pump of the vehicle has been

(yellow diode) activated and the electric system is powered.

SIGNAL The diode is flashing when the remote control box is activated and the

(green diode) decoder in the electronic box receives a correct radio signal.

NORMAL The diode indicates that the system is ready for operation. The diode is

(yellow diode) lit while the SIGNAL diode is flashing.

ERROR When the system functions normally, the diode must be turned off. In

(red diode) connection with system errors, the diode is flashing at the same

interval as the OPERATION diode. Please see chapter on

troubleshooting.

01-01 HMF TECHNICAL SERVICE DEP.

16

HMF-IRC Instruction Manual - GB

3.4 IRC-Battery and Battery Charger

Together with the IRC-system there are two rechargeable batteries. The battery

is placed at the bottom of the remote control box and can be replaced by one

single movement.

Please note: A completely charged battery works for approx. 8 hours of remote

control operation.

The battery charger must by mounted in the driver’s cab where it is protected

against dirt and humidity. The charger must via a fuse be connected to 12 or 24

volts power supply directly to the battery of the vehicle. This is how charging is

made possible, also when the ignition is turned off.

Please note: It takes approx. 3.5 hours to recharge a battery that has been

completely discharged.

3.4.1 Replacement of the Battery

The transmitter electronics in the remote control box currently monitor the

battery voltage. When the voltage comes below a certain value after approx. 8

hours of operation, the following is indicated:

• The buzzer in the remote control box gives a periodic signal during 30

seconds.

• Then the remote control box is disconnected

Now the battery has to be replaced by a recharged battery from the battery

charger.

Follow the procedure below:

• Move the loader into a safe position within the 30 seconds of the periodic

signal from the buzzer

• Turn the key switch on the right side of the remote control box into position

“0”

• Take out the discharged battery from the remote control box

• Clean the battery compartment and make sure that the pole connectors are

normally spring-loaded and not corroded

• Put a recharged battery from the battery charger up into the battery

compartment and press it into position so that it is fixed and has a good

electric connection

• Start up the remote control box according to the chapter: “Starting Up of the

IRC-System”

The radio remote control is now ready for operation.

01-01 HMF TECHNICAL SERVICE DEP.

17

HMF-IRC Instruction Manual - GB

3.4.2 Charging of the Battery

Right after a discharged battery has been taken out of the remote control box, it

has to be recharged in the battery charger according to the following procedure:

• Put the battery into the battery compartment of the battery charger and press

it into position so that it is fixed and has a good electric connection.

• The green diode on the charger is lit, indicating that the battery is being

charged.

• The battery charger registers when the battery is completely charged

• After approx. 3.5 hours the charging is completed, and the green diode starts

flashing

• The battery charger now change to “maintenance charging”, ensuring that

the battery does not discharge after some time

• A completely charged battery is thus always available in the battery charger

3.4.3 Good Advice about the Battery

To ensure the longest possible working time of the batteries, the following must

be respected:

• The battery must be completely discharged before recharging it

• Do not replace the battery before the buzzer indicates that the battery has to

be recharged

• In case of low temperatures the capacity and working time of the battery are

reduced

• When at rechargeable battery is discarded, dispose of it as special waste

01-01 HMF TECHNICAL SERVICE DEP.

18

HMF-IRC Instruction Manual - GB

3.5 Remote control cable (option)

The remote control box can be connected to the electronic box by means of a

remote control cable.

Please note! The cable is not delivered together with the IRC-system as

standard.

The remote control cable can be used if the remote control box cannot

communicate with the electronic box in case of battery failure, interruption in the

radio communication, errors in radio transmitter/receiver, or the like,

The cable has an adapter in one end, which is inserted in the battery

compartment on the remote control box.

3.6 Transmitter System, Frequencies

Every time the IRC-system is started up, one out of 16 frequencies in the ISM-

band is chosen.

In the self-test phase during start up of the remote control box, the system is

testing whether the chosen frequency can be used or whether it collides with

other radio transmitters. If it cannot be used, repeat the starting up procedure

and the next frequency will be chosen.

A coded data telegram is now transmitted from the remote control box with an

address that must be in accordance with a corresponding data telegram with its

address in the electronic box at the frequency in question.

When the radio receiver has accepted the coded data telegram of the radio

transmitter, the IRC-system is ready for operation.

01-01 HMF TECHNICAL SERVICE DEP.

19

HMF-IRC Instruction Manual - GB

4. Safety Regulations

The IRC-system makes it possible to control the loader via radio signals, and

therefore there are certain safety regulations that have to be respected:

• Only personnel, who have been instructed in operating the equipment, must

work with a remote controlled loader.

• The loader operator must read the instruction manuals delivered together

with the loader before starting up loader operation, and follow the instructions

during loader operation.

• When the remote control box is not being used, disconnect it, and pull out

the key from the key switch.

• For safety reasons, keep the remote control box inside the driver’s cab when

not in use.

• Before carrying out mounting, maintenance or repair work, turn off the power

supply to the system

• Do not change or remove anything from the safety devices.

• When cleaning the loader, avoid spraying on water and never use high-

pressure rinsing for cleaning the electronic components.

Before loader operation, the loader operator must check as follows:

• that the remote control box belongs to the loader that is to be operated

• whether there are any cracks on or damage to the IRC-system

• that the operating symbols on the remote control box are intact

• that the loader is stopped when pushing the stop button

• that the remote control system functions correctly

• that no other person stays on or near the loader

• that the parking brake of the vehicle has been applied before starting the

engine by means of the remote control box.

During loader operation the operator must:

• stand in a suitable distance from the hook and the load, have a good

visibility, and see to it that no unauthorised persons enter into the working

area.

• be aware that it is not permitted to move the load over himself or anybody

else

• be ready to let go of the control levers and push the stop button, if he looses

control over the loader movements.

01-01 HMF TECHNICAL SERVICE DEP.

20

HMF-IRC Instruction Manual - GB

After loader operation the operator must:

• push the stop button on the remote control box and on the loader.

• put the remote control box in a place inaccessible to others

• report any errors, damage or defects on the equipment to the person

responsible for the loader

5. Starting Up of the Loader

Before starting up, the essential safety regulations have to be respected, just as

the general procedure in connection with starting up of the loader has to be

followed.

Please see the Instruction Manual of the loader as well as the RCL Instruction

Manual.

Before loader operation, extend the stabilizer beams and lower the stabilizer

legs to the surface.

5.1 Starting Up from the Indicator Panel of the RCL

When the loader is equipped with an IRC-system, the diodes on the RCL

indicator panel have different indications than a manually operated loader

during start up.

• Connect the pump (PTO); the controller is thus powered

• All stop buttons must be pulled out (there is a stop button at each control

position).

• Push the green press button on the RCL indicator panel.

• The RUN and FUNC diodes are flashing

• Push the yellow press button twice to choose the stabilizer function

• When the stabilizer legs have been lowered, start up the IRC-system

Loader operation can start.

Please note: During stabilizer operation, a change of the load moment of the

loader exceeding 10% will entail that the system automatically changes into

loader operation mode.

01-01 HMF TECHNICAL SERVICE DEP.

21

HMF-IRC Instruction Manual - GB

5.2 Starting Up of the IRC-System

Starting up of the IRC-System from the remote control box:

• The key switch must be in position “0”

• The stop button on the remote control box must be pulled out (turn it to the

right).

• All control levers must be in neutral position

• Turn the key switch into position “I”

• The buzzer indicates: signal for approx. 3 sec. - pause for approx. 3 sec. – a

short signal

• The indicator lamp starts to flash

• Push the green press button (starting up the RCL).

The following is indicated:

Remote control box The indicator lamp is flashing

Electronic box The OPERATION diode is flashing

The SIGNAL diode is flashing

The NORMAL diode is constantly lit

RCL indicator panel The RUN diode is constantly lit

The RCL/IRC-system is ready and loader operation can start.

5.3 Starting Up from the IRC-Remote Control Box

Alternatively the RCL/IRC-system can be started up from the remote control

box:

• Connect the pump (PTO); the controller is thus powered

• All stop buttons must be pulled out (there is a stop button at each control

position).

• Start up the IRC system (see that item)

• Push the yellow press button twice

• Extend the stabilizer beams and lower the stabilizer legs

Loader operation can start.

01-01 HMF TECHNICAL SERVICE DEP.

22

HMF-IRC Instruction Manual - GB

6. Signalling during Loader Operation

When the loader is remote controlled, the operator must keep an eye on the

indications of the RCL indicator panel. Please see the RCL Instruction Manual

of the loader.

To avoid unexpected stops of the loader movements, it is important to pay

attention to the indications from the buzzer of the remote control box. A periodic

signal from the buzzer during 30 seconds indicates that the battery has to be

changed (recharged).

Move the loader into a safe position within the 30 seconds of the periodic signal

from the buzzer.

If the indicator lamp on the remote control box turns off and the loader cannot

be remote controlled, it may be due to radio interference or system errors.

Please see chapter on troubleshooting.

7. Emergency Stop during Loader Operation

If a dangerous situation occurs, where you are about to loose control of the

loader, push the stop button on the remote control box and stop the loader.

When the stop button is pushed on the remote control box, the RCL controller

registers this as an error. The RUN and FUNC diodes start flashing.

Start up the IRC-system again according to the procedure and continue loader

operation.

Please note! Every time the IRC-system is started up, always test the

functioning of the stop button. When pushing the stop button, it must not be

possible to remote control the loader.

8. Stopping the IRC-System

After loader operation, interrupt the IRC-system according to the following

procedure:

• Push the stop button.

• Turn the key switch into position “0”, pull out the key and keep it with you.

• Stop the hydraulic pump, the power to the system is thus interrupted

01-01 HMF TECHNICAL SERVICE DEP.

23

HMF-IRC Instruction Manual - GB

9. Emergency Operation of the Loader

In case of IRC-system errors the following is indicated:

• The ERROR diode on the electronic box flashes

• The RUN and FUNC diodes on the RCL indicator panel are flashing

In this fault condition it is not possible to remote control the loader.

However, it is possible to change into emergency operation of the loader in the

following way:

• On the RCL indicator panel, hold down the yellow press button while pushing

the red press button

• The RUN and FUNC diodes on the RCL indicator panel are still flashing

Now emergency operation of the loader is possible by using the control levers

on the valve block of the loader.

As a control of whether the system is set for emergency operation, it is possible

to push the red press button and the 100% diode will flash. If not, then change

into emergency operation again according to the above-mentioned procedure.

Please note: In case of manual emergency operation of the loader, the

loader’s lifting capacity is reduced (the loader is derated) to 90% of its normal

capacity.

To change back into remote control mode, repeat the procedure stated above:

push/hold down the yellow press button and push the red press button.

10. The HDL-System (Option)

If the loader is equipped with an HDL system (Heavy Duty Lifting), it offers the

possibility of an increase of the loader’s nominal load by approx. 10 % while the

working speed is reduced.

01-01 HMF TECHNICAL SERVICE DEP.

24

HMF-IRC Instruction Manual - GB

10.1 Proportional HDL

In connection with the IRC-system, activation of the HDL-system is proportional,

i.e. step-less.

Example:

A heavy load is extended at max. speed at a longer out-reach by means of the

“extension out”-function.

When the loader has reached 80% of its capacity limit, the HDL is automatically

activated independent of the operator’s doings.

Now the speed of the “extension out” movement is reduced proportionally down

to 20% of the nominal working speed.

Correspondingly the working speed is increased proportionally to 100%, if the

load is retracted to a shorter reach by means of the “extension in”- function.

The example describes how the HDL-system works in connection with the

extension-function. The proportional HDL-activation functions in the same way

in connection with all other loader functions, which increase or reduce the load

moment of the loader.

When the HDL-system is activated, this is indicated on the RCL indicator panel

by the FUNC diode flashing.

10.2 Micro Operation

If the loader is to make positioning tasks, it will be possible to reduce the

working speed of the loader by means of the HDL-system.

Irrespective of the loader’s load moment, the working speed of the loader can

be reduced to approx. 20% by pushing the red press button on the remote

control box, thus activating the HDL.

By pushing the red press button once again, the HDL-system is deactivated

again. However, this implies that all control levers have been into neutral

position at the same time as the load moment is below the loader’s normal

lifting capacity limit.

01-01 HMF TECHNICAL SERVICE DEP.

25

HMF-IRC Instruction Manual - GB

Troubleshooting

In case of an error in the radio communication or the transmission of data

between the electronic box and the RCL controller, the system comes up with

the following error messages:

• The ERROR diode on the electronic box flashes

• The RUN and FUNC diodes on the RCL indicator panel are flashing

It will now be possible to troubleshoot by pushing and holding down the red

press button on the RCL indicator panel.

Now a diode indicates where to find the error in the system.

Flashing diode Type of error Remedy

85% diode The IRC-system has not Re-start the IRC-System

been started up

90% diode Start up error in the Can-bus Re-start the IRC-System

communication

100% diode The RCL controller has been Change back into remote

set for emergency operation control mode. Please see

chapter on Emergency

Operation.

80%, 85% diodes The stop button on the Pull out the stop button (turn

remote control box is it to the right)

activated (pushed in)

80%, 90% diodes Error at the cable connection Please contact an authorised

for the dump valve input in HMF service point.

the RCL

If problems continue, contact immediately an authorised HMF service point.

01-01 HMF TECHNICAL SERVICE DEP.

26

HMF-IRC Instruction Manual - GB

Maintenance

It is important to check and maintain the IRC-system both currently and when

the loader has its regular service overhaul at an authorised HMF service point.

The following items must be respected:

• When cleaning the loader, avoid spraying on water and never use high-

pressure rinsing for cleaning the electronic components.

• Before carrying out mounting, maintenance or repair work, turn off the power

supply to the system.

• Check whether there are any cracks on or damage to the IRC-system. If yes,

the equipment must be repaired immediately.

01-01 HMF TECHNICAL SERVICE DEP.

27

HMF-IRC Instruction Manual - GB

Technical Data

General System Data

Frequency: the 70 cm band

Range: approx. 100 meters

Adress: 16 bit. 65536 possibilities

Operating temperature: -20° through + 70°C

Transmission rate: 4800 Baud

Hammingdistance: 4

Electronic box

Degree of protection: IP 65

System: Synthesizer technics

Operating voltage: 12 to 24 VDC (-50% - +20%)

Decoding: Multi bit activation and comparison

Fuse: 7,5A / 80V Kfz.

Output: Intrinsically safe emergency stop with two MOS-FET-

transistors

12 digital outputs, potential free 250V/8A,

6 analog outputs,

2 speed ranges

Static current: 260mA, Stand by

Antenna connection: TNC-socket

Dimensions: approx. (LxWxH) 265mm x 161mm x 111mm

Weight 2.5kg

Remote Control Box

Degree of protection: IP 65

Battery: Design Nova 6L: 3.6V / 300mAh (NiCd)

Transmitting power <10mW

Current rating, self test: approx. 75mA

Current rating, transmission: approx. 83mA

Dimensions: approx. (LxWxH) 230mm x 106mm x 170mm

Weight (incl. battery and strap): 1.8kg

Battery Charger

Operating voltage: 12 / 24VDC

Charging current: Design Nova 6L, 100mA

Open circuit voltage: 15 - 22V

01-01 HMF TECHNICAL SERVICE DEP.

28

You might also like

- Bronto+5th Basic Training Book USBDocument288 pagesBronto+5th Basic Training Book USBxhdsnsxyqsNo ratings yet

- CTL 00Document3 pagesCTL 00jose luisNo ratings yet

- Hiab 288 #28802486Document84 pagesHiab 288 #28802486Cedric SeppeyNo ratings yet

- W Olsbergs DLHV enDocument2 pagesW Olsbergs DLHV enMike Guerreros0% (1)

- rc400 Presentazione g2b EngDocument36 pagesrc400 Presentazione g2b Engtsdcn100% (1)

- Scanreco-IRC Instruction ManualDocument54 pagesScanreco-IRC Instruction ManualMgc Elektronik0% (1)

- LTM 1060Document4 pagesLTM 1060ayman akrabNo ratings yet

- Service Manual: Colour LCD TelevisionDocument14 pagesService Manual: Colour LCD TelevisionВиталий КозакNo ratings yet

- Paltronic 50Document2 pagesPaltronic 50Juan Young50% (4)

- Digital Level - Display DA13Document16 pagesDigital Level - Display DA13Sergio Belmar CrisostoNo ratings yet

- j12 PDFDocument778 pagesj12 PDFOliveira eletricidade100% (2)

- Zoom - Us - How It Works With DAWs and Audio Collaboration (2020-0331)Document77 pagesZoom - Us - How It Works With DAWs and Audio Collaboration (2020-0331)Marcelo Rojo100% (1)

- ScanrecoP1 2015 01 A e en PDFDocument20 pagesScanrecoP1 2015 01 A e en PDFtsdcnNo ratings yet

- The Safety System 4.12: Cylinder Pressure LED'sDocument17 pagesThe Safety System 4.12: Cylinder Pressure LED'sMARCO HernándezNo ratings yet

- 07-08, Survey, Electric Diagrams, RCL 5300Document2 pages07-08, Survey, Electric Diagrams, RCL 5300Ivailo ZapryanovNo ratings yet

- Hetronic V CardsDocument12 pagesHetronic V CardsTezso JacobNo ratings yet

- Service Manual C Electric Section 2 (25 46)Document22 pagesService Manual C Electric Section 2 (25 46)Геннадий Дармоедов100% (2)

- TSS - RX 22-HLDocument1 pageTSS - RX 22-HLMedo MedooNo ratings yet

- Catalog Effer 3504S Hydraulic TankDocument1 pageCatalog Effer 3504S Hydraulic Tankary fauzi rahmanNo ratings yet

- Fs9qiwltbkdf4dg8demag Ac 40 City 40-Ton All Terrain Crane NetworkDocument13 pagesFs9qiwltbkdf4dg8demag Ac 40 City 40-Ton All Terrain Crane NetworkTornvald MNo ratings yet

- PDFDocument4 pagesPDFGatonext100% (1)

- XCMG Iflex5 Operators ManualDocument69 pagesXCMG Iflex5 Operators ManualIslam AttiaNo ratings yet

- Catálogo 8 F DisplayDocument20 pagesCatálogo 8 F Displaybenjamin100% (2)

- Installation: Imt Manual #Document16 pagesInstallation: Imt Manual #Arkadiusz ArkadiuszNo ratings yet

- Kidolgozott PeldakDocument26 pagesKidolgozott PeldakDankos IstvanNo ratings yet

- Receptor Multidrive 2Document8 pagesReceptor Multidrive 2benjamin100% (3)

- RCL 5300 Instruction Manual 20090219Document71 pagesRCL 5300 Instruction Manual 20090219Marin Rebić100% (1)

- 7600012-011 Data 7600012-012 Op Manual HETRONIC-Tecnord GA610 03-02Document20 pages7600012-011 Data 7600012-012 Op Manual HETRONIC-Tecnord GA610 03-02Sorin Bode100% (1)

- ECOS Error Codes TMS 9000EDocument27 pagesECOS Error Codes TMS 9000EMinh TúNo ratings yet

- Load Moment Indicator System: Operation & Installation ManualDocument28 pagesLoad Moment Indicator System: Operation & Installation ManualMDParthibanNo ratings yet

- LicconDocument475 pagesLicconPeter TharwatNo ratings yet

- 38-17, Software Version 61 - 51Document5 pages38-17, Software Version 61 - 51nacho006No ratings yet

- TMS900EECOS ErrorcodesDocument29 pagesTMS900EECOS ErrorcodesMiguel Del Valle AlonsoNo ratings yet

- Error Code P2Document2 pagesError Code P2Mochamad fandi Dharmawan0% (1)

- SLC FullcatalogDocument37 pagesSLC FullcatalogAna Luz MartinezNo ratings yet

- GROUP 8 TRANSMISSION (Up To #0978) : 1. StructureDocument14 pagesGROUP 8 TRANSMISSION (Up To #0978) : 1. StructureVladimir ParamonovNo ratings yet

- PreviewDocument254 pagesPreviewIgor OkNo ratings yet

- 4075 ECOS ComponentsDocument27 pages4075 ECOS ComponentsStanislas Massengo Londe100% (1)

- Radio Remote Controls - BMS GA610: - Operator ManualDocument20 pagesRadio Remote Controls - BMS GA610: - Operator ManualsergeyNo ratings yet

- Válvula Contrabalanza HiabDocument2 pagesVálvula Contrabalanza HiabEdwing GuerreroNo ratings yet

- Bison Lifting PlatformsDocument8 pagesBison Lifting PlatformsAnonymous mcCJYBoNo ratings yet

- PACWIN EnglischDocument5 pagesPACWIN EnglischGuilherme_PagaNo ratings yet

- Fassi Crane: Use and MaintenanceDocument14 pagesFassi Crane: Use and MaintenanceДенис ЧерныйNo ratings yet

- Grúa Tadano Faun - ATF 130G - Menú de Servicio Del ChasisDocument197 pagesGrúa Tadano Faun - ATF 130G - Menú de Servicio Del ChasisReinaldo ZorrillaNo ratings yet

- Paltronic 50 EN PDFDocument2 pagesPaltronic 50 EN PDFJhon Syalfiandy0% (1)

- OEMterexRT 130SSC Manual er22301RevDDocument40 pagesOEMterexRT 130SSC Manual er22301RevDadan felipe romanNo ratings yet

- Catálogo 6 F Display PDFDocument20 pagesCatálogo 6 F Display PDFbenjaminNo ratings yet

- Kabel XSDriveDocument1 pageKabel XSDriveDozer KamilNo ratings yet

- Danfoss - PVG32: Linear LeversDocument2 pagesDanfoss - PVG32: Linear LeversNovakurniawanNo ratings yet

- Repair Instruction Hydraulic Loader Crane: Exchange Scanreco Radio Remote Control RC400/P1 To RC400/P2Document23 pagesRepair Instruction Hydraulic Loader Crane: Exchange Scanreco Radio Remote Control RC400/P1 To RC400/P2Paweł B100% (1)

- MicroGuard 500 Series - New BackgroundDocument11 pagesMicroGuard 500 Series - New Backgroundjulio cesarNo ratings yet

- EWPC 974: Freezer ControlDocument3 pagesEWPC 974: Freezer ControlFlávio MatosNo ratings yet

- Yamaha RX-V2067, HTR-9063, RX-A2000 PDFDocument190 pagesYamaha RX-V2067, HTR-9063, RX-A2000 PDFboroda24100% (1)

- Demag 5 Axle Family 1.3Document3,666 pagesDemag 5 Axle Family 1.3DraganNo ratings yet

- P1 e enDocument22 pagesP1 e entsdcn100% (1)

- XCMG Qay180: Construction Machine BrochureDocument16 pagesXCMG Qay180: Construction Machine BrochureGuilherme Leal100% (1)

- Technical Specifications: Zoomlion Ztc1100V Truck CraneDocument92 pagesTechnical Specifications: Zoomlion Ztc1100V Truck CraneKiller boyNo ratings yet

- Instruction Manual Scanreco IRCDocument54 pagesInstruction Manual Scanreco IRCJose GodoyNo ratings yet

- TRG Manual For Avr With Maxdna PLC PDFDocument65 pagesTRG Manual For Avr With Maxdna PLC PDFRukma Goud Shakkari0% (1)

- Instruction Manual Safety SystemDocument99 pagesInstruction Manual Safety SystemAndrey AndreyNo ratings yet

- ABB ACS 1000 Tech Catalog RevDDocument161 pagesABB ACS 1000 Tech Catalog RevDElena Koneva50% (2)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- PC 2 PDFDocument2 pagesPC 2 PDFOliveira eletricidade100% (1)

- RZ dh608 Engl Web PDFDocument2 pagesRZ dh608 Engl Web PDFOliveira eletricidadeNo ratings yet

- Hydraulic Spare Parts - PC1055J-07052012 PDFDocument4 pagesHydraulic Spare Parts - PC1055J-07052012 PDFOliveira eletricidadeNo ratings yet

- Document PDFDocument1 pageDocument PDFOliveira eletricidadeNo ratings yet

- s130 PDFDocument603 pagess130 PDFManuel Pedro Inácio50% (4)

- Hydraulic Spare Parts - PC1055J-07052012 PDFDocument4 pagesHydraulic Spare Parts - PC1055J-07052012 PDFOliveira eletricidadeNo ratings yet

- Hydraulic Piece List - PC1055J-07052012 PDFDocument1 pageHydraulic Piece List - PC1055J-07052012 PDFOliveira eletricidadeNo ratings yet

- HFO GB 0607 PDFDocument8 pagesHFO GB 0607 PDFOliveira eletricidadeNo ratings yet

- Electric Piece List - PC1055 PDFDocument2 pagesElectric Piece List - PC1055 PDFOliveira eletricidadeNo ratings yet

- Dokumen - Tips - s1x Tamper Control System Description Tamper Control System Descriptions1xDocument8 pagesDokumen - Tips - s1x Tamper Control System Description Tamper Control System Descriptions1xOliveira eletricidadeNo ratings yet

- DeepaDocument2 pagesDeepaSitesh SmarakNo ratings yet

- Psalm 23 - The Lord Is My ShepherdDocument4 pagesPsalm 23 - The Lord Is My ShepherdElizabeth HyltonNo ratings yet

- Anathema Curse Theocracy StateDocument17 pagesAnathema Curse Theocracy StateSaad shamimNo ratings yet

- Estudio in A Minor (Moderato) by Dionisio AguadoDocument2 pagesEstudio in A Minor (Moderato) by Dionisio Aguadolang chenNo ratings yet

- Fccidio User Manual 3235352 Schindler CompressDocument8 pagesFccidio User Manual 3235352 Schindler CompressslottyNo ratings yet

- Chapter 1 - Information TheoryDocument55 pagesChapter 1 - Information TheoryBoruto69No ratings yet

- My DLPDocument3 pagesMy DLPApril BuenoNo ratings yet

- ParazitiiDocument2 pagesParazitiiAna DumitruNo ratings yet

- Dark Knight - Main ThemeDocument14 pagesDark Knight - Main Thememacabre5679No ratings yet

- Lesson Plan - DynamicsDocument2 pagesLesson Plan - DynamicsUnibelle Joy Lachica50% (2)

- Brenda K Star - I Still BelieveDocument14 pagesBrenda K Star - I Still Believejoel_2014_joelNo ratings yet

- DBX2 GOO PiviGames - BlogDocument1 pageDBX2 GOO PiviGames - BlogJhonatan Jimmy Obeso CernaNo ratings yet

- My Mother Said (Teacher Resource)Document18 pagesMy Mother Said (Teacher Resource)alioliver9No ratings yet

- Your Latest Trick Alto SaxophoneDocument8 pagesYour Latest Trick Alto SaxophoneMiga Sergio0% (1)

- Q4 Music Lecture 24 WK 1 2Document6 pagesQ4 Music Lecture 24 WK 1 2dianne sulaNo ratings yet

- 6.4 Digital Transmission: Pulse Amplitude Modulation (PAM) and Pulse Code Modulation (PCM)Document13 pages6.4 Digital Transmission: Pulse Amplitude Modulation (PAM) and Pulse Code Modulation (PCM)Khairil Azwan TugimanNo ratings yet

- MH - Ad-2.mhlm Iac Rwy22 Ils ZDocument2 pagesMH - Ad-2.mhlm Iac Rwy22 Ils ZNelson HernandezNo ratings yet

- Antonio VivaldiDocument19 pagesAntonio VivaldiMario A. Baltazar0% (2)

- Re Going On A Bear HuntDocument13 pagesRe Going On A Bear HuntKristine Fhae Rico100% (1)

- Mued 211 Observation Form 1 DodsonDocument3 pagesMued 211 Observation Form 1 Dodsonapi-549702919No ratings yet

- Wonderful Tonight: Музыка: Eric Clapton Аранжировка: Дашкевич ПавелDocument2 pagesWonderful Tonight: Музыка: Eric Clapton Аранжировка: Дашкевич ПавелancaluNo ratings yet

- 1ST MIDTERM 2nd Year 2023Document4 pages1ST MIDTERM 2nd Year 2023Lu EncinasNo ratings yet

- February 2024 Monthly Current AffairsDocument89 pagesFebruary 2024 Monthly Current Affairsdd4802163No ratings yet

- Here I Am To Worship-Partitura e PartesDocument22 pagesHere I Am To Worship-Partitura e PartesKarol Guimarães100% (1)

- Write Your Answers On The Space Before The Number: Oggayam, and D-HudhudDocument3 pagesWrite Your Answers On The Space Before The Number: Oggayam, and D-HudhudDiosie Ganzon VeradioNo ratings yet

- 32nd Sunday, 6th Nov 2022Document2 pages32nd Sunday, 6th Nov 2022Henry KaweesaNo ratings yet

- What's Your Name? How Do You Spell Your Surname?: Examiner Booklet I. Answer The Following QuestionsDocument10 pagesWhat's Your Name? How Do You Spell Your Surname?: Examiner Booklet I. Answer The Following QuestionsShirley Delgado CatpoNo ratings yet

- East 17 Stay Another DayDocument54 pagesEast 17 Stay Another DayMustafa Eren TurnaNo ratings yet

- A Convict's Twilight By: Arturo Belleza RotorDocument9 pagesA Convict's Twilight By: Arturo Belleza RotorLadyNareth MierdoNo ratings yet