Professional Documents

Culture Documents

Calc Co2

Uploaded by

ArdhianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calc Co2

Uploaded by

ArdhianCopyright:

Available Formats

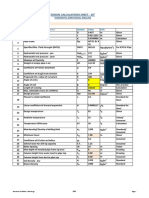

No Prep by Chkd by App'd By Date

PT. BAHTERA MAKMUR REJEKI

Komplek Pertokoan Bukit Citra Mas RB-12, Driyorejo

Gresik, Jawa Timur

www.ptbmr.biz.id

Client: PT. PLN Equipment: Kubikel

Location: Bali Tag Number: INCOMING FEEDER 1 kubikel

Project: CO2 fire protection Quantity: 1 Ref No 84

CALCULATION SUMMARY

1 Type of Enclosure Electric Panel 9 CO2 req for surface fire 6,54 kg

2 Specific Hazard Dry electrical hazards in general 10 Minimum flow rate for surface fire 11,90 kg/min

3 Hazardous Material NaN 11 Extinguishing period for deep seated fire 0,00 minute

4 Surface Area Condition Flat surfaces 12 CO2 req for deep seated fire 0,00 kg

3

5 Enclosure volume 3,24 m 13 Minimum flow rate for deep seated fire 0,00 kg/min

2

6 Total opening area 0,00 m 14 Final requirement of CO2 6,54 kg 13 litre

7 Design Concetration of CO2 43,00 % 15 Selected CO2 cylinder volume 10 kg 0 kg

8 Time to reach design concentration 0,50 minute 16 No of required cylinder 1 bottle 0 bottle

Notes

a

b

c

d

e

f

g

h

i

j

k

l

m

n

Parameter Value Unit Parameter Value Unit

17 DESIGN PARAMETER

3

18 Type of Enclosure Electric Panel 31 Forced ventilation (i.e. Fan) Fv 0,00 m /min

19 Specific Hazard Dry electrical hazards in general 32 Normal Working Temperature Nwt 25,00 C

20 Hazardous Material NaN 33 Enclosure internal pressure Ep 1,00 bar

21 Surface Area Condition Flat surfaces 34 Density of CO2 at STP ρ 1,87 kg/m3

22 Enclosure Height H 1,75 m 35 Density of surrounding air at 21 C ρ2 1,20 kg/m3

23 Enclosure Width W 1,95 m 36 Time to reach design concentration Trf 0,50 minute

24 Enclosure Depth D 0,95 m 37 Gravitational constant g 9,81 m/sec2

25 Opening 1 Width Ow1 0,00 m 38 Specific vol. of CO2 vapor @30C s 0,56 m3/kg

26 Opening 1 Height Oh1 0,00 m 39 CO2 cylinder pressure Pcyl 58,75 bar

27 Opening 1 Distance from ceiling Od1 0,00 m 40 Machine deceleration period Td 0,00 minute

28 Opening 2 Width Ow2 0,00 m 41 Extinguishing period for deep seated Tds 0,00 minute

fire ( if not considered = 0; if

considered = 20 minute minimum)

29 Opening 2 Height Oh2 0,00 m 42 No of panel partition / doors Par 1,00 ea

30 Opening 2 Distance from ceiling Od2 0,00 m 43

44 DESIGN CALCULATION 51

3

45 Enclosure volume Ve 3,24 m 52 Percent of opening area to wall 0,00 %

2

46 Opening 1 area Ao1 0,00 m 53 Percent perimeter enclosed Ppe 0,00 %

2 3

47 Opening 2 area Ao2 0,00 m 54 Assumed volume Va 9,29 m

2

48 Total opening area Aotot 0,00 m 55 Concentration for specific hazard Csh 43 %CO2

2 3

49 Total wall area Awtot 10,15 m 56 Floading factor FL 1,35 kg CO2/m

50 Percent of opening area to volume 0,00 % 57 Concentration for hazardous material Chm 34 %CO2

58 Surface Fire 72 Deep Seated Fire

59 Material conversion factor MCF 1,35 73 Design basis of CO2 Cb 0,00 kg

3

60 Density of atmosphere ρ1 1,49 kg/m 74 Added CO2 for unclosed opening Co 0,00 kg

61 Design basis of CO2 Cb 4,39 kg 75 Added CO2 for forced ventilation Cfv 0,00 kg

62 Added CO2 for MCF Cmcf 5,95 kg 76 Added CO2 for temp. correction Ctc 0,00 kg

63 Added CO2 for unclosed opening Co 0,00 kg 77 Total CO2 required Ctot 0,00 kg

Flow rate for maintaining 30%

64 Added CO2 for forced ventilation Cfv 0,00 kg 78 concentration for 0 minutes Q03 0,00 kg/min

Added CO2 for maintaining 30%

65 Added CO2 for temp. correction Cmcf 0,00 kg 79 concentration for 0 minutes C03 0,00 kg

NFPA 12 CO2 CALCULATION 1 of 2

No Prep by Chkd by App'd By Date

PT. BAHTERA MAKMUR REJEKI

Komplek Pertokoan Bukit Citra Mas RB-12, Driyorejo

Gresik, Jawa Timur

www.ptbmr.biz.id

Client: PT. PLN Equipment: Kubikel

Location: Bali Tag Number: INCOMING FEEDER 1 kubikel

Project: CO2 fire protection Quantity: 1 Ref No 84

CALCULATION SUMMARY

1 Type of Enclosure Electric Panel 9 CO2 req for surface fire 6,54 kg

2 Specific Hazard Dry electrical hazards in general 10 Minimum flow rate for surface fire 11,90 kg/min

3 Hazardous Material NaN 11 Extinguishing period for deep seated fire 0,00 minute

4 Surface Area Condition Flat surfaces 12 CO2 req for deep seated fire 0,00 kg

3

5 Enclosure volume 3,24 m 13 Minimum flow rate for deep seated fire 0,00 kg/min

2

6 Total opening area 0,00 m 14 Final requirement of CO2 6,54 kg 13 litre

7 Design Concetration of CO2 43,00 % 15 Selected CO2 cylinder volume 10 kg 0 kg

8 Time to reach design concentration 0,50 minute 16 No of required cylinder 1 bottle 0 bottle

Notes

66 Total CO2 required Ctot 5,95 kg 80 Final requirement of CO2 Creq 0,00 kg

67 Added 10% C04 0,59 kg 81 Time to reach 30% of concentration Tr0.3 0,00 minute

68 Final requirement of CO2 Creq 6,54 kg 82 Max. time to reach concentration Trd 0,00 minute

69 Flow rate to reach concentration Q 11,90 kg/min 83 Design flow rate to reach T rd Qtrd 0,00 kg/min

70 Discharging period Tdis 0,55 minute 84 Design flow rate to reach T r03 Qtr03 0,00 kg/min

2 2

71 Minimum enclosure vent area Av 0,00028 m 85 Minimum enclosure vent area Av 0,00000 m

NFPA 12 CO2 CALCULATION 2 of 2

You might also like

- HDD Calculation - CH 15Document23 pagesHDD Calculation - CH 15Binay Kumar100% (1)

- 100-T-1100 Methanol Tank SampleDocument3 pages100-T-1100 Methanol Tank SampleSachinl PatelNo ratings yet

- DEST Pipeline Calculation Rev.1 (By Hasan Asif)Document11 pagesDEST Pipeline Calculation Rev.1 (By Hasan Asif)Saqib LaeeqNo ratings yet

- Line Sizing (SI) Gas PhaseDocument10 pagesLine Sizing (SI) Gas PhaseRian Intan SaputraNo ratings yet

- Tata Consulting Engineers Limited: Compressor House Wind Loading Wind Loading at ColumnsDocument12 pagesTata Consulting Engineers Limited: Compressor House Wind Loading Wind Loading at ColumnsVed Vrat AryaNo ratings yet

- Heat Exchanger Design and HT Coefficent Calculation From RC-6 BookDocument20 pagesHeat Exchanger Design and HT Coefficent Calculation From RC-6 BookJag KhadseNo ratings yet

- Pipeline Calculations - ASAB Gas Lift LinesDocument11 pagesPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqNo ratings yet

- PHE DesignDocument53 pagesPHE Designchgourishankar2000100% (1)

- Pile Capacity CalculationDocument3 pagesPile Capacity CalculationBharathi ThadigotlaNo ratings yet

- V Method As Per API 650 App KDocument182 pagesV Method As Per API 650 App KSiva baalanNo ratings yet

- CS-74 - MAND RIVER HDD Design CalculationDocument6 pagesCS-74 - MAND RIVER HDD Design CalculationG. BalamuruganNo ratings yet

- Shell and Tube Multipass Heat Exchanger Design - Tubular Juice HeaterDocument3 pagesShell and Tube Multipass Heat Exchanger Design - Tubular Juice HeaterGovinda DeshmukhNo ratings yet

- MBBP00044 Process Data Sheet R3Document3 pagesMBBP00044 Process Data Sheet R3Hina ImranNo ratings yet

- Data Sheet EjectorDocument4 pagesData Sheet EjectorGunturMudaAliAkbarNo ratings yet

- CHE 631: Chemical Reaction Engineering: Animangsu GhatakDocument5 pagesCHE 631: Chemical Reaction Engineering: Animangsu GhatakPankaj Kumar SainiNo ratings yet

- Design Calculation PDFDocument6 pagesDesign Calculation PDFJWC Sales & Services :No ratings yet

- Design CalculationDocument6 pagesDesign Calculationbinay kumar100% (1)

- Fire Protection Engineering PrinciplesDocument19 pagesFire Protection Engineering PrinciplesHenry Humberto Mesa JimenezNo ratings yet

- SESCO.L90.D.501-03 - Basic Calculation of Machinery - Rev00Document65 pagesSESCO.L90.D.501-03 - Basic Calculation of Machinery - Rev00Quyet PhungNo ratings yet

- Design Calculations Sheet - 12.75": SL .No. Symbol Value UnitDocument6 pagesDesign Calculations Sheet - 12.75": SL .No. Symbol Value UnitASHOK SWAMINo ratings yet

- Agn 2019Document4 pagesAgn 2019lidiNo ratings yet

- HD RFT Mty Ope 003Document5 pagesHD RFT Mty Ope 003Anonymous AtAGVssJNo ratings yet

- HDD Design Calculation: A. Input Values and Parameters: 21.91Document6 pagesHDD Design Calculation: A. Input Values and Parameters: 21.91G. BalamuruganNo ratings yet

- Useful Equations For Kiln & CoolerDocument7 pagesUseful Equations For Kiln & CoolerAbul Qasim100% (2)

- Calc Reformer Skin Max Temp PDFDocument3 pagesCalc Reformer Skin Max Temp PDFirfanlarikhotmailcomNo ratings yet

- TD HE S&T v2020.00Document29 pagesTD HE S&T v2020.00Claudia BonocoreNo ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- Sizing A Subsonic Flare StackDocument3 pagesSizing A Subsonic Flare Stackadewunmi olufemiNo ratings yet

- AQ10T-BFM, 363PL 2335kWDocument2 pagesAQ10T-BFM, 363PL 2335kWLiviu ConstantinNo ratings yet

- Power CalculationDocument4 pagesPower CalculationGunasekaranNo ratings yet

- DIN 93 - Tab Washers With Long Tap PDFDocument1 pageDIN 93 - Tab Washers With Long Tap PDFFernando ColomboNo ratings yet

- Perhitungan Anaerobik Digester, Floating Dome, Fixed DomeDocument51 pagesPerhitungan Anaerobik Digester, Floating Dome, Fixed DomesehonoNo ratings yet

- Column Diameter and Hetp CheckDocument6 pagesColumn Diameter and Hetp Checkmayur1980100% (1)

- EAc4Calculator LEED-V4 PROTECTED IPCCv4 GWPsDocument16 pagesEAc4Calculator LEED-V4 PROTECTED IPCCv4 GWPsThanhNo ratings yet

- Datasheet - Compressor - StarterDocument4 pagesDatasheet - Compressor - StarterAudhinna ZuffyNo ratings yet

- 19.design 102.00Document5 pages19.design 102.00Fredin FrancisNo ratings yet

- Journal Utilitas GenapDocument6 pagesJournal Utilitas GenapDidi WardoyoNo ratings yet

- Refractory Thickness CalculationsDocument9 pagesRefractory Thickness CalculationsHsein WangNo ratings yet

- Shell and Tube Heat ExchangerDocument19 pagesShell and Tube Heat ExchangerMangesh MandgeNo ratings yet

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Document4 pagesDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- HE Pressure DropDocument43 pagesHE Pressure DropNitin KurupNo ratings yet

- Pipeline Pressurisation & de Pressurisation CalculationDocument4 pagesPipeline Pressurisation & de Pressurisation Calculationhatakerobot50% (2)

- ECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemDocument9 pagesECS002 - Calculation For The Orifice Plate On The AC Lube Oil SystemPaul CarlyNo ratings yet

- Earthmat Calculation FOR 132/25Kv Quazigund TSS: Northern RailwayDocument4 pagesEarthmat Calculation FOR 132/25Kv Quazigund TSS: Northern RailwayRaj-Kanishk SharmaNo ratings yet

- Integrated Gasification Combined Cycles: Go Slow With Irreversible Process . The Combustion !!!Document55 pagesIntegrated Gasification Combined Cycles: Go Slow With Irreversible Process . The Combustion !!!ABHAY PARASHARNo ratings yet

- Thermo-Kinetics Thermowell Calculation Program: Tag #: Date: Rev: Company: Project NoDocument1 pageThermo-Kinetics Thermowell Calculation Program: Tag #: Date: Rev: Company: Project NoDeni MulyawanNo ratings yet

- Compressor Trial 1Document5 pagesCompressor Trial 1sahil bonganeNo ratings yet

- Ball Mill Calculation SheetDocument3 pagesBall Mill Calculation Sheetniladri.jagaty100% (2)

- CCT ShellAndTubeReportDocument2 pagesCCT ShellAndTubeReportLuthfi LegooNo ratings yet

- All Right Machinery All Right Machinery - 44000 000: SpecificationsDocument1 pageAll Right Machinery All Right Machinery - 44000 000: SpecificationsAlan_andasaNo ratings yet

- Plate Heat Exchanger Data SheetDocument2 pagesPlate Heat Exchanger Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Case 2 - Tank Heat LossDocument84 pagesCase 2 - Tank Heat Lossahmad santosoNo ratings yet

- DMM Foundation Design Design of Strip Footing: Project: Air Compressor Shed Client: ONGC Rev: R1 Date: 15/07/06Document7 pagesDMM Foundation Design Design of Strip Footing: Project: Air Compressor Shed Client: ONGC Rev: R1 Date: 15/07/06mvap2856No ratings yet

- National University of Singapore Department of Mechanical Engineering ME2134 Fluid Mechanics I Tutorial 2 SolutionsDocument19 pagesNational University of Singapore Department of Mechanical Engineering ME2134 Fluid Mechanics I Tutorial 2 SolutionsCl SkyeNo ratings yet

- Dàn NgưngDocument2 pagesDàn Ngưngba phongNo ratings yet

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- Fundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringFrom EverandFundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringNo ratings yet