Professional Documents

Culture Documents

BS5930-2015 208 PDF

Uploaded by

Ford cell0 ratings0% found this document useful (0 votes)

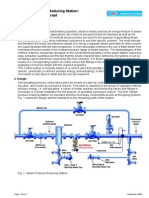

7 views1 page1. The document describes a Ridley-type flushable piezometer, which is a device used to measure pore water pressure.

2. It consists of a fully grouted borehole with a porous ceramic tip connected by pipes to a pressure sensor and pump used to circulate and de-air water.

3. Pneumatic piezometers are also discussed, which measure pore water pressure using gas-filled tubes connecting a measuring point to a valve near a porous element.

Original Description:

Original Title

BS5930-2015_208.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document describes a Ridley-type flushable piezometer, which is a device used to measure pore water pressure.

2. It consists of a fully grouted borehole with a porous ceramic tip connected by pipes to a pressure sensor and pump used to circulate and de-air water.

3. Pneumatic piezometers are also discussed, which measure pore water pressure using gas-filled tubes connecting a measuring point to a valve near a porous element.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageBS5930-2015 208 PDF

Uploaded by

Ford cell1. The document describes a Ridley-type flushable piezometer, which is a device used to measure pore water pressure.

2. It consists of a fully grouted borehole with a porous ceramic tip connected by pipes to a pressure sensor and pump used to circulate and de-air water.

3. Pneumatic piezometers are also discussed, which measure pore water pressure using gas-filled tubes connecting a measuring point to a valve near a porous element.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Figure 20 Schematic of a Ridley-type flushable piezometer

Key

1 Pump for circulating water and 7 50 mm diameter UPVC pipe

removing air 8 Hydraulically operated valve

2 Flush de-aired water (in) 9 О-ring seal

3 Flush air and water (out) 10 Water chamber

4 Pressure sensor 11 Porous ceramic (1 bar air entry)

5 70 mm diameter fully grouted

borehole

6 50 mm diameter UPVC pipe

52.7 Pneumatic piezometers

COMMENTARY ON 52.7

Pneumatic piezometers consist of two gas-filled tubes connecting a measuring

point to a valve located close to a porous element (see Figure 21). When the gas

pressure in the input line equals the water pressure in the porous element, the

valve opens, the gas flows around the system and can be detected as it

emanates from the return tube. The gas supply is then shut off and the pressure

in the supply tube is monitored as it decays. The pore water pressure is taken to

be the final steady pressure developed when the valve closes. The operation of

the valve requires a small volume change in the porous element, and in stiff low

permeability clays this can lead to difficulties. Pneumatic piezometers are simple

to install, but they can be slow to respond because the operator has to wait for

the gas pressure to equalize. They cannot be used for in-situ permeability

measurements (see Penman, 1960 [121]).

Dirt entering the tubes can prevent the valve operating properly and, therefore,

the operating system should be kept scrupulously clean. Care should be taken to

include coils in the cables when laying them in trenches, to avoid them being

stretched when strains (e.g. settlements) are encountered.

You might also like

- Oil and Gas Separation ProcessDocument13 pagesOil and Gas Separation ProcessRome John Francisco100% (2)

- Pipeline Design for Water EngineersFrom EverandPipeline Design for Water EngineersRating: 5 out of 5 stars5/5 (1)

- BS5930-2015 206Document1 pageBS5930-2015 206Ford cellNo ratings yet

- Pipe Friction LossDocument6 pagesPipe Friction LossHoongNo ratings yet

- Technical Notes: Air Vents, Vacuum Relief Valves, and Pressure Relief Valves in Pressurized PipelinesDocument10 pagesTechnical Notes: Air Vents, Vacuum Relief Valves, and Pressure Relief Valves in Pressurized PipelinesKyriakos MichalakiNo ratings yet

- Petroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesDocument14 pagesPetroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesUnknown Gamer467No ratings yet

- Method of Flow Measurement ..Document12 pagesMethod of Flow Measurement ..anuj kanadeNo ratings yet

- Dorot Plastic Air Valve - DAV-PDocument12 pagesDorot Plastic Air Valve - DAV-PShai Ben-ArieNo ratings yet

- Erhard Sewage Air Valve BrochureDocument12 pagesErhard Sewage Air Valve BrochureSivaprasad SasidharanNo ratings yet

- Method Statement of Hydraulic Pressure Testing: 1. Machinery / Equipment and ToolsDocument9 pagesMethod Statement of Hydraulic Pressure Testing: 1. Machinery / Equipment and Toolskevin JiaoNo ratings yet

- Coin Box Based Automatic WheelDocument52 pagesCoin Box Based Automatic WheelAakash DindigulNo ratings yet

- Air Ingestion and Transport Testing in A Rotating Drum Raw Water Strainer-HaberDocument12 pagesAir Ingestion and Transport Testing in A Rotating Drum Raw Water Strainer-HaberSai Shankar LakshminarayananNo ratings yet

- MIT-EL-80-017-09574615 Steam Bubble Collapse Water Hammer and Piping Network Response Volume 1 PDFDocument51 pagesMIT-EL-80-017-09574615 Steam Bubble Collapse Water Hammer and Piping Network Response Volume 1 PDFhamadaniNo ratings yet

- Mechanics of Fluids: TechnologyDocument3 pagesMechanics of Fluids: TechnologyrmuhumuzaNo ratings yet

- Triaxial Testing Machine - 10knDocument31 pagesTriaxial Testing Machine - 10knAldo Villacorta DiazNo ratings yet

- Electromechanically Valve Electric Current SolenoidDocument11 pagesElectromechanically Valve Electric Current SolenoidLoga NathanNo ratings yet

- DryPipeSystems RevDocument24 pagesDryPipeSystems RevCostel BalasoiuNo ratings yet

- Dry ValveDocument12 pagesDry ValveSayed MohamedNo ratings yet

- Im316 Flow MeasurementDocument67 pagesIm316 Flow MeasurementSelvarajNo ratings yet

- Pages From 1053-15610-Primary Cooling Equipment - Ch-1, Ch-2, Ch-3, Ch-4, Ch-5, & Ch-6 - I, O,&mDocument3 pagesPages From 1053-15610-Primary Cooling Equipment - Ch-1, Ch-2, Ch-3, Ch-4, Ch-5, & Ch-6 - I, O,&mtranhkl2012No ratings yet

- Computational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveDocument4 pagesComputational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveMax KocourNo ratings yet

- 1172132997-Oe Combined Prds ValvesDocument21 pages1172132997-Oe Combined Prds ValvesmayurjannuNo ratings yet

- Reverse Osmosis System Installation Diagram Highlighting: Flow ControlDocument1 pageReverse Osmosis System Installation Diagram Highlighting: Flow ControlMeu nomeNo ratings yet

- SUMMARYDocument71 pagesSUMMARYDale Iverson LacastreNo ratings yet

- Common Reference Guide To Piping EngineeringDocument32 pagesCommon Reference Guide To Piping EngineeringSteve WanNo ratings yet

- Aerisitor Subteran Ape Reziduale 9827-9828Document2 pagesAerisitor Subteran Ape Reziduale 9827-9828Simona AdrianaNo ratings yet

- Flowmeter DEMONSTRATIONDocument20 pagesFlowmeter DEMONSTRATIONAfiq IkhwanNo ratings yet

- 07 Fluid Transports EquipmentsDocument12 pages07 Fluid Transports EquipmentsarfpowerNo ratings yet

- Venturi and OrificemeterDocument10 pagesVenturi and OrificemeterVikrant KumarNo ratings yet

- Sensitivity Analysis On Surge Analysis of Water Supply SystemDocument4 pagesSensitivity Analysis On Surge Analysis of Water Supply SystemSanjeev Kumar DasNo ratings yet

- Liquid Process Piping - Part 6 Ancillary Equipment & Corrosion Protection PDFDocument17 pagesLiquid Process Piping - Part 6 Ancillary Equipment & Corrosion Protection PDFnitin guptaNo ratings yet

- REPORTpp 1Document16 pagesREPORTpp 1gajulavamshikrishna02No ratings yet

- Robinet de Retinere FlowserveDocument8 pagesRobinet de Retinere FlowservemartinandreiNo ratings yet

- Piping AuxiliariesDocument12 pagesPiping AuxiliariesarchitNo ratings yet

- PrdsDocument0 pagesPrdssandi1111No ratings yet

- A R INewDocument28 pagesA R INewBhavesh TandelNo ratings yet

- Addis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringDocument10 pagesAddis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringEskiasNo ratings yet

- Q105 - RSW#3 - Bautista, Aljon Mar, LDocument26 pagesQ105 - RSW#3 - Bautista, Aljon Mar, LaljonNo ratings yet

- Piping Eveporative COndensersDocument12 pagesPiping Eveporative COndensersscribd99190No ratings yet

- Reliableb1acc 1Document6 pagesReliableb1acc 1salajeanuNo ratings yet

- FM & HM Lab Lab ManualDocument75 pagesFM & HM Lab Lab ManualvenkiteshksNo ratings yet

- Well Testing and Evaluation: Well Flow (Production) Test - Physical CharacteristicsDocument12 pagesWell Testing and Evaluation: Well Flow (Production) Test - Physical Characteristicsyadi_supriyadiNo ratings yet

- Low Vacuum Levels PDFDocument2 pagesLow Vacuum Levels PDFbalaNo ratings yet

- BOPs and Their ControlDocument59 pagesBOPs and Their ControlYoun Seok Choi100% (1)

- BOPs and Their ControlDocument59 pagesBOPs and Their Controlelflaco79No ratings yet

- Sewage Air ValveDocument10 pagesSewage Air ValveAhmed TalaatNo ratings yet

- Pulse Valves For Dust Collector SystemsDocument4 pagesPulse Valves For Dust Collector SystemsUrip S. SetyadjiNo ratings yet

- t000005801 PDFDocument7 pagest000005801 PDFMohammed Hassan B KorainaNo ratings yet

- Group 6 Andrie Dave AiraDocument24 pagesGroup 6 Andrie Dave AiraReginald VelanoNo ratings yet

- Pressure Testing in Main PipelineDocument7 pagesPressure Testing in Main PipelineChintamani KuralkarNo ratings yet

- Water Hammer Calculation FormulasDocument6 pagesWater Hammer Calculation FormulasAvinash Vasudeo100% (1)

- Flow MeasurementDocument11 pagesFlow MeasurementRaj Ven100% (1)

- Well Testing StudyDocument29 pagesWell Testing StudyDavid LutmangNo ratings yet

- Product Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Document21 pagesProduct Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Gỗ MộcNo ratings yet

- Control Valves in Process PlantDocument8 pagesControl Valves in Process Plantmukramah.yusufNo ratings yet

- BS5930-2015 238Document1 pageBS5930-2015 238Ford cellNo ratings yet

- BS5930-2015 305Document1 pageBS5930-2015 305Ford cellNo ratings yet

- BS5930-2015 236Document1 pageBS5930-2015 236Ford cellNo ratings yet

- BS5930-2015 234Document1 pageBS5930-2015 234Ford cellNo ratings yet

- BS5930-2015 235Document1 pageBS5930-2015 235Ford cellNo ratings yet

- BS5930-2015 233Document1 pageBS5930-2015 233Ford cellNo ratings yet

- BS5930-2015 311Document1 pageBS5930-2015 311Ford cellNo ratings yet

- BS5930-2015 308Document1 pageBS5930-2015 308Ford cellNo ratings yet

- BS5930-2015 307Document1 pageBS5930-2015 307Ford cellNo ratings yet

- BS5930-2015 306Document1 pageBS5930-2015 306Ford cellNo ratings yet

- BS5930-2015 312Document1 pageBS5930-2015 312Ford cellNo ratings yet

- BS5930-2015 230Document1 pageBS5930-2015 230Ford cellNo ratings yet

- BS5930-2015 310 PDFDocument1 pageBS5930-2015 310 PDFFord cellNo ratings yet

- BS5930-2015 224Document1 pageBS5930-2015 224Ford cellNo ratings yet

- BS5930-2015 231Document1 pageBS5930-2015 231Ford cellNo ratings yet

- BS5930-2015 225Document1 pageBS5930-2015 225Ford cellNo ratings yet

- BS5930-2015 232Document1 pageBS5930-2015 232Ford cellNo ratings yet

- BS5930-2015 223Document1 pageBS5930-2015 223Ford cellNo ratings yet

- BS5930-2015 226Document1 pageBS5930-2015 226Ford cellNo ratings yet

- BS5930-2015 220Document1 pageBS5930-2015 220Ford cellNo ratings yet

- BS5930-2015 221Document1 pageBS5930-2015 221Ford cellNo ratings yet

- BS5930-2015 227Document1 pageBS5930-2015 227Ford cellNo ratings yet

- BS5930-2015 217Document1 pageBS5930-2015 217Ford cellNo ratings yet

- BS5930-2015 218Document1 pageBS5930-2015 218Ford cellNo ratings yet

- BS5930-2015 215Document1 pageBS5930-2015 215Ford cellNo ratings yet

- BS5930-2015 222Document1 pageBS5930-2015 222Ford cellNo ratings yet

- BS5930-2015 219Document1 pageBS5930-2015 219Ford cellNo ratings yet

- BS5930-2015 216Document1 pageBS5930-2015 216Ford cellNo ratings yet

- BS5930-2015 210Document1 pageBS5930-2015 210Ford cellNo ratings yet

- BS5930-2015 212Document1 pageBS5930-2015 212Ford cellNo ratings yet