Professional Documents

Culture Documents

Moment Connection - Design of Steel Strucuture-Subramanian

Uploaded by

MANOJ0 ratings0% found this document useful (0 votes)

33 views2 pagesSolved Example

Original Title

Moment connection -Design of Steel Strucuture-Subramanian

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSolved Example

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views2 pagesMoment Connection - Design of Steel Strucuture-Subramanian

Uploaded by

MANOJSolved Example

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

gome

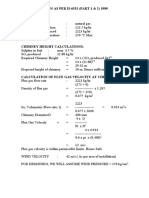

example 5.23 Design a bolted end plate connection between an ISMB 300 beam

sai an ISHB 200 column, to transfer a vertical factored shear of 120 kN and a

sored hogging bending moment of 120 kNm. Use HSFG bolts of diameter 20

a: The connection is as shown in Fig. 5.75.

400 mm.

forces

* ang moment about the centre of the bottom flange

120 10? + 20 x (300/2 ~ 13.1/2) = (2F, + 2F,) x (300 — 13.1)

122869 + 2Fy x 63.45

= (2F;/286.9) [2 x 286.9? + 63.45*]

$69 = 1,175.67F,

cures

n of Steel StU

420, esis

s 51KN

FoF, = 1045

ie (63.45/286.9)F = 23.11 KN

jon at bottom flange

as = 1045 + 104.51 + 23.11) — 20

= 444.26 kN ‘A

city of beam flange = (fy%mo

eee) = (250/1.1) x 13.1 x 140 x 10 = 416.8 gy

This is only 6.2% less than F.. Hence the connection is safe.

End plate and bolts

Conder the portion of end plate above top flange (assume 10-mm fillet Welds to

flange and 180-mm wide end plate)

Distance from the centre line of the bolt to the toe of the fillet weld

1,= 40-10 = 30 mm

Adopted end distance /, = 50 mm

Effective length of end plate per bolt = 180/2 = 90 mm

Tension capacity of M20 bolt (Table 5.11) = 141 KN

Allowable prying load Q = 141 - 104.51 = 36.49kN

Moment at the toe of the weld = Tl, — Ql,

= 104.51 x 30 - 36.49 x 50 = 1,310.8 Nm

Moment capacity of the plate = (f/1.10)(w77/4)

= 27

Therefore, Jt car

T= Vbb.3108% 10 1.10% 4725090) = 16mm

Adopt T = 20 mm

Proof stress =

9.Tfyy = 0.7 x 800/100 = 0.56 kN/mm?

2= UPL) IT. ~ yf PAO)

= (3012 x 50)] [104.51 — 2 x LS x 0.56 x 90 x 204427 x 50x30]

= 0.3(104,5) — 19.91) =

25.38 KN < 36,49 KN ( ssumed)

2 for non-pre-loade . ee

d and y= 1.5 for fac

combined shear and pate 1.5 for factored load)

(Note: f=

141 kN 00

S14 25.38)/1417 = 0.145 + 0,848 = 0.993 =!

: i

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Extended End Plate Connection (IS-800-2007 LSM) - 2019.08.26Document11 pagesExtended End Plate Connection (IS-800-2007 LSM) - 2019.08.26MANOJNo ratings yet

- Asce7-10 Wind Load CalculationDocument14 pagesAsce7-10 Wind Load CalculationMANOJNo ratings yet

- ASCE 7 10 Vs ASCE 7 16 1657453966Document53 pagesASCE 7 10 Vs ASCE 7 16 1657453966MANOJNo ratings yet

- End Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22Document11 pagesEnd Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22MANOJNo ratings yet

- AISC (LRFD) Shear Connection - Cleat AngleDocument14 pagesAISC (LRFD) Shear Connection - Cleat AngleMANOJNo ratings yet

- Chimney Calculations, Dia 400 MM, 30 M HeightDocument15 pagesChimney Calculations, Dia 400 MM, 30 M HeightMANOJNo ratings yet

- GRATING CATALOG - MetricDocument20 pagesGRATING CATALOG - MetricMANOJNo ratings yet

- AISC (ASD) Shear Connection - Cleat AngleDocument15 pagesAISC (ASD) Shear Connection - Cleat AngleMANOJNo ratings yet

- Load Bearing ClaculationDocument9 pagesLoad Bearing ClaculationMANOJNo ratings yet