Professional Documents

Culture Documents

Is 1865 - 8

Is 1865 - 8

Uploaded by

Svapnesh ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1865 - 8

Is 1865 - 8

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

IS 1865 : 1991

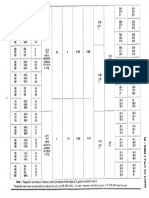

Table 2 Mecbrraica) Properties Measured on Test Pieces from Cast on Test Samples

( Clause 12.1.2 )

Grade Typical Minimum Minimum Minimum For Information Only

CP ‘og Tensile 0~2pw~feot Elon- r---_----rr--_?

Th,ik- Strength, gatioo, Brine11 P:edominant

oess, MPal) Stress, Perce’ota) Hardness, Constituent

mm MPa’) HBS of Structure

SG 70012~ 30 to 60 700 400 2 22d to 320 Pea&e

61 to 200 650 380 1

_____ --p--

SG 600/3A 30 to 60 600 360 2 180 to 270 Pearlite

61 to 200 5.50 340 1 + Ferrite

SG 500/7A 30 to 60 450 300 7 170 to 240 Ferrite

__ ___.

61 to 200 420 290 5 + Pearlitc

SG w/15A 30 to 60 390 250 15 130 to 180 Ferrite

61 to200 370 240 12

SG 400N8A 30 to 60 390 250 15 130 to 180 Ferrite

61 to 200 370 240 12

SG 350/22A 30 to 60 330 220 18 2 150 Ferrite

61 to 220 320 210 15

1) 1 MPa = 1 N/mm2 = 10’2 kgf/cm’.

*) Elongation is measured on an initial gauge length L = 5 d, where d is the diameter of the gauge length

of the test pie&( see Fig. 5 ).

Table 3 Minimum Impact Values Measured oo Test Pieces from Separately Cast Test Samples

( Clauses 12.2.1, 12.2.2 and 13.3.1 )

Grade Minimum Impact Values in Joules oo V-Notch Test Pieces at Ambient Temperature of

c------------ A - -_-----,

Mean ( 23 * ‘&?vidual MeaA - 20 f Indwdual

2 1O.C. M(ez 4o * 2 )izdividual

Value Value Value Value Value Value

from from from

3 Tests 3 Tests 3 Tests

SG 400/l 8 14 11

SG 400/18L 12 9

-

SG 350122 17 14

SG 350/22L 12 9

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- SG Iron Casting Grades and StandardsDocument4 pagesSG Iron Casting Grades and Standardsvkhavate100% (1)

- TESDocument4 pagesTESkgaria79No ratings yet

- LBB Single-PotDocument1 pageLBB Single-PotWalas ribeiro da silvaNo ratings yet

- Geology in Civil EngineeringDocument108 pagesGeology in Civil EngineeringKnowell Jan PartozaNo ratings yet

- Material Data Sheet: Ductile Iron in DIN 1693Document4 pagesMaterial Data Sheet: Ductile Iron in DIN 1693Leandro de BittencourtNo ratings yet

- Catalogo Bombas NETZSCHDocument1 pageCatalogo Bombas NETZSCHJesus BolivarNo ratings yet

- Chemical Composition and Grades of Ductile Cast IronDocument7 pagesChemical Composition and Grades of Ductile Cast Ironparth50% (2)

- Norma ISO 12240-4 Horquillas Articuladas PDFDocument39 pagesNorma ISO 12240-4 Horquillas Articuladas PDFNemoz ZrNo ratings yet

- En 1563 - Spheroidal Graphite Cast IronsDocument4 pagesEn 1563 - Spheroidal Graphite Cast Ironsvamsi patnalaNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Is 1865 - 7Document1 pageIs 1865 - 7Svapnesh ParikhNo ratings yet

- Test Plan Is 2062Document2 pagesTest Plan Is 2062GOPAL MaityNo ratings yet

- Gjs GGG AstmDocument17 pagesGjs GGG AstmmakmuntohirNo ratings yet

- Spheroidal GraphiteDocument1 pageSpheroidal GraphiteS.Mohana sundaramNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- B - Boehler FOX SPE - Se - en - 5Document1 pageB - Boehler FOX SPE - Se - en - 5panait trofinNo ratings yet

- Supercito E: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito E: MMA Electrodes C-MN and Low-Alloy Steelsantonio111aNo ratings yet

- BL L189xxWDocument3 pagesBL L189xxWcorazzaedwardNo ratings yet

- B - Boehler FOX EV 60 - Se - en - 5Document1 pageB - Boehler FOX EV 60 - Se - en - 5Juan Bedolla FloresNo ratings yet

- Böhler Fox CM 2 KB: Classifi CationsDocument1 pageBöhler Fox CM 2 KB: Classifi CationsBranko FerenčakNo ratings yet

- En 10139Document2 pagesEn 10139releone11No ratings yet

- SG Iron Charts2Document4 pagesSG Iron Charts2bbaskaran100% (3)

- Properties FCD 50Document5 pagesProperties FCD 50dwi Kuntoro100% (1)

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Features: Finishing-Purpose of Negative Chip Breaker For Steel TurningDocument4 pagesFeatures: Finishing-Purpose of Negative Chip Breaker For Steel TurningArdeleana TisaNo ratings yet

- Chemical Composition of Welding Wire % (Typical) StandardsDocument1 pageChemical Composition of Welding Wire % (Typical) StandardsAli KayaNo ratings yet

- Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFDocument4 pagesData Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFchristos032No ratings yet

- SSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enDocument4 pagesSSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enchristos032No ratings yet

- Böhler Fox Ev 50: &odvvlàfdwlrqvDocument1 pageBöhler Fox Ev 50: &odvvlàfdwlrqvHAMITOUCHENo ratings yet

- 055 PDFDocument1 page055 PDFantonio111aNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- Böhler Fox Eti: Rutile Stick Electrode, UnalloyedDocument1 pageBöhler Fox Eti: Rutile Stick Electrode, UnalloyedMiroslav MiladinovićNo ratings yet

- 4G 2G 2F 3G UphillDocument1 page4G 2G 2F 3G Uphillamit singhNo ratings yet

- MS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)Document10 pagesMS-M-07-MATERIAL SUBMITTAL - (Galvanized Duct)khalilNo ratings yet

- THG Hooks Forged Hooks Catalogue SheetDocument5 pagesTHG Hooks Forged Hooks Catalogue SheetjhonNo ratings yet

- THG Hooks Forged Hooks Catalogue Sheet PDFDocument5 pagesTHG Hooks Forged Hooks Catalogue Sheet PDFjhonNo ratings yet

- Dual Shield Mol, Crmo1 and Crmo2: All Position Rutile Cored Wires For Creep Resisting SteelsDocument2 pagesDual Shield Mol, Crmo1 and Crmo2: All Position Rutile Cored Wires For Creep Resisting SteelsRobertoNo ratings yet

- S355JRDocument2 pagesS355JRThanh NguyenNo ratings yet

- 02112015000000B - Boehler FOX EV 70 - CeDocument1 page02112015000000B - Boehler FOX EV 70 - CeOPAZOSCNo ratings yet

- Plumbnes Strake 2 - (12 Koordinat)Document1 pagePlumbnes Strake 2 - (12 Koordinat)yuwantoniNo ratings yet

- Sepction - 3Document3 pagesSepction - 3k koradiaNo ratings yet

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- 02112015000000B - Boehler FOX EV 65 - CeDocument1 page02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General InformationGopi KrishnanNo ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Mig WiresDocument4 pagesMig Wirespipat .sNo ratings yet

- Super Flux Led Lamp, 4pin LedDocument4 pagesSuper Flux Led Lamp, 4pin Lediman wahyudinNo ratings yet

- B Boehler FOX EV 50-A Se en 5Document1 pageB Boehler FOX EV 50-A Se en 5Sun SunNo ratings yet

- POSCO HighStrength Rebar PDFDocument19 pagesPOSCO HighStrength Rebar PDFLe Phan TaNo ratings yet

- Adi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Document2 pagesAdi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Milton Pereira JúniorNo ratings yet

- Steel Grades Specifications: Grades, Properties, and Nearest EquivalentsDocument5 pagesSteel Grades Specifications: Grades, Properties, and Nearest EquivalentsBelal AhmedNo ratings yet

- 01112015000000B - Boehler FOX CEL - CeDocument1 page01112015000000B - Boehler FOX CEL - Cekapster KannourNo ratings yet

- Data Sheets Me6222 - 2023Document16 pagesData Sheets Me6222 - 2023yagnikvaidya123No ratings yet

- MURAFLEX 2020 Low RizeDocument4 pagesMURAFLEX 2020 Low RizeanisyariskiNo ratings yet

- We Care.: Hot-Dip Galvanized Steel StripDocument12 pagesWe Care.: Hot-Dip Galvanized Steel StripvictorNo ratings yet

- Applications: Type TestedDocument4 pagesApplications: Type TestedFV AllanNo ratings yet

- Böhler Fox Dcms KB: Classifi CationsDocument1 pageBöhler Fox Dcms KB: Classifi CationsBranko FerenčakNo ratings yet

- PDS Bohler+FOX+N+EV+50-1 PDFDocument1 pagePDS Bohler+FOX+N+EV+50-1 PDFserdarNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 5Document1 pageIs 12308-5 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-9 - 1993 - 1Document1 pageIs 12308-9 - 1993 - 1Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 5Document1 pageIs 12308-7 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 4Document1 pageIs 12308-6 - 1991 - 4Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 1Document1 pageIs 12308-5 - 1991 - 1Svapnesh ParikhNo ratings yet

- Is 12308-4 - 1988 - 4Document1 pageIs 12308-4 - 1988 - 4Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 4Document1 pageIs 10719 (Iso 1302) - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 11Document1 pageIs 10719 (Iso 1302) - 11Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 12Document1 pageIs 10719 (Iso 1302) - 12Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 8422-6 - 1977 - 4Document1 pageIs 8422-6 - 1977 - 4Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 2Document1 pageIs 8422-8 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 3Document1 pageIs 8422-2 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 5Document1 pageIs 8422-8 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 2Document1 pageIs 8422-3 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 2Document1 pageIs 8422-1 - 1977 - 2Svapnesh ParikhNo ratings yet

- Department of Education: Humss 12 Cluster A and B Weekly Home Learning PlanDocument4 pagesDepartment of Education: Humss 12 Cluster A and B Weekly Home Learning PlanRhomelyn AbellarNo ratings yet

- Unisilkon TK 017/200 Therm, TK 017/500 ThermDocument1 pageUnisilkon TK 017/200 Therm, TK 017/500 Thermspurwito46No ratings yet

- Ce Correl Fluid Mechanics (A) : Situation 1Document2 pagesCe Correl Fluid Mechanics (A) : Situation 1Glenn Frey LayugNo ratings yet

- VaziraniDocument100 pagesVaziranibobbyNo ratings yet

- Phase MaskDocument3 pagesPhase MaskLe Hoang NhatNo ratings yet

- Propagation of Reinforcement Corrosion: Principles, Testing and ModellingDocument26 pagesPropagation of Reinforcement Corrosion: Principles, Testing and Modellingflaco_astrozaNo ratings yet

- Approved AbstractsDocument19 pagesApproved AbstractsKapil SharmaNo ratings yet

- Earth Sci 1 - Prac 4.1.4Document1 pageEarth Sci 1 - Prac 4.1.4Mireya TorresNo ratings yet

- Physics 231 Lecture9Document11 pagesPhysics 231 Lecture9Jasper John GomezNo ratings yet

- LP Surveying-I III Sem Civil - 2Document31 pagesLP Surveying-I III Sem Civil - 2ubaid khanNo ratings yet

- امتحان الري كيمياءDocument3 pagesامتحان الري كيمياءAli KasmNo ratings yet

- Tutorial 1 - AnswersDocument8 pagesTutorial 1 - AnswersRaymond Kakala100% (6)

- Microwave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDocument28 pagesMicrowave Drying of Gelatin Membranes and Dried Product Properties CharacterizationDominico Delven YapinskiNo ratings yet

- TCISDocument34 pagesTCISChinmayee SastriNo ratings yet

- SPE 15578 Specific Mixing Energy: A Key Factor For Cement SlurryDocument8 pagesSPE 15578 Specific Mixing Energy: A Key Factor For Cement SlurryNaveed HasanNo ratings yet

- New+ISO ICAO+Photo+GuidelinesDocument7 pagesNew+ISO ICAO+Photo+GuidelinesPedro PerezNo ratings yet

- Hydrogen Induced Cracking (HIC) of Hardened and Tempered Steel Fastener Used in Space ApplicationDocument9 pagesHydrogen Induced Cracking (HIC) of Hardened and Tempered Steel Fastener Used in Space ApplicationSinan ChenNo ratings yet

- Mechanical Engineering NotesDocument216 pagesMechanical Engineering NotesvelavansuNo ratings yet

- Unit 4.2: Unit 4.2 Particle Vibrations and Wave MotionDocument61 pagesUnit 4.2: Unit 4.2 Particle Vibrations and Wave MotionhahaNo ratings yet

- FatigueDocument1 pageFatigueBipulBrahmaNo ratings yet

- JDM F17: Enterprise Specification For Paint PerformanceDocument19 pagesJDM F17: Enterprise Specification For Paint PerformanceSilenkar EscapamentosNo ratings yet

- OLGA 2015.1.2 Release Notes PDFDocument51 pagesOLGA 2015.1.2 Release Notes PDFamine bcNo ratings yet

- Imperfections in SolidsDocument47 pagesImperfections in SolidsRichel Ann CapacilloNo ratings yet

- Soild State Electronic Devices Chapter 1 SolDocument10 pagesSoild State Electronic Devices Chapter 1 Soljh010708No ratings yet

- 7 Mecanica Quantica Prof Angelo LeitholdDocument5 pages7 Mecanica Quantica Prof Angelo LeitholdANGELO ANTONIO LEITHOLDNo ratings yet

- Manoj 1Document73 pagesManoj 1ajayNo ratings yet