Professional Documents

Culture Documents

Is 2074 - 8

Is 2074 - 8

Uploaded by

Svapnesh ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 2074 - 8

Is 2074 - 8

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

IS 2074 : 1992

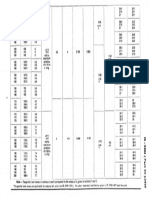

D-2.6 Dip the disc in the paint sample for 10 where

minutes and take out the disc. Allow the excess

coating material to drain off. Blot the coating W = grams of non-volatile matter in 1 g of

material off the bottom edge of the disc so that wet coating.

beads or drops do not dry on the bottom edge

of the disc. Dry the disc at 105°C for 3 hours D-2.11 Calculate the percent volume solids of

and cool. Weigh the coated disc in air. Let it be the paints as follows:

U’s grams.

D-2.7 Suspend the coated disc in water and Volume solid, v* - v

weigh again. Let it be W, grams. percent by mass = --vp X 100

D-2.8 Calculate the volume of the coated disc 0:

VI as follows:

-vd

v, 3

wa- wa = -

V,

x 100

d

where D-2.12 The percent volume solids of a paint is

d = density of the water at room temperature.

related to the covering capacity and wet Rim

thickness in the following manner:

D-2.9 Calculate the volume of the dried coating

a) Theoretical coverage ( m2/1 ) =

as follows:

Percent Volume Solids

Volume of dried coating, ( Vd ) = j/r -1/ x 10

Dry film thickness ( microns7

D-2.10 Calculate the volume of wet coating as

follows: b) Wet film thickness ( microns ) =

j/f = wa--1 Dry film thickness ( microns ) x 1oo

w Percent Volume Solids

WXP

ANNEX E

[ Table I, SZ JVO.(xi) ]

METHOD FOR ACCELERATED STORAGE STABILITY TEST

E-l PROCEDURE there shall be no evidence of seeding. The paint

shall meet the drying time requirement and shall

Store the paint sample in a closed 500-ml con- produce dry film that is uniform in appearance

tainer and keep at 60°C for 96 hours. After the and free from streaking, mottling and seediness.

test paint shall not gel, liver, curdle or increase Further, the change in gloss value from the

in efflux time by more than 20 percent. and original shall not be more than 5 units.

You might also like

- 9 BTC Hack Script From BitslerDocument19 pages9 BTC Hack Script From BitslerSandipan ChakrabortyNo ratings yet

- Experiment No. 8 Liquid LimitDocument11 pagesExperiment No. 8 Liquid LimitMelesa SimanNo ratings yet

- Homework 05-Solutions PDFDocument10 pagesHomework 05-Solutions PDFElizabeth DouglasNo ratings yet

- Pile Foundation (Part II-Group Piles)Document8 pagesPile Foundation (Part II-Group Piles)Francis Philippe Cruzana CariñoNo ratings yet

- Time Series Analysis Project - CAC 40 - 2018Document33 pagesTime Series Analysis Project - CAC 40 - 2018HofidisNo ratings yet

- CAP13Document21 pagesCAP13LIma NetoNo ratings yet

- Compaction Test. (IS: 2720 - PART - 7 & 8)Document2 pagesCompaction Test. (IS: 2720 - PART - 7 & 8)XOXOXOXO XOXOXOXONo ratings yet

- Solid of Revolution AnswersDocument8 pagesSolid of Revolution AnswersIrfan Maulana NasutionNo ratings yet

- AUTO400 Homework Assignment 4 SOLUTIONDocument6 pagesAUTO400 Homework Assignment 4 SOLUTIONHarsit Agrawal100% (1)

- Relative Density of SandDocument29 pagesRelative Density of SandMd. Saiful Islam RonyNo ratings yet

- Standard Proctor Compaction Test: Test and Is Based On The Compaction of The Soil Fraction Passing No, 4 U.S. SieveDocument8 pagesStandard Proctor Compaction Test: Test and Is Based On The Compaction of The Soil Fraction Passing No, 4 U.S. SieveRaven VergaraNo ratings yet

- Expt 10, Expt 11Document12 pagesExpt 10, Expt 11alaa AlobeidyeenNo ratings yet

- Geotechnical FormulasDocument15 pagesGeotechnical FormulasBernard de VeraNo ratings yet

- Contoh Soal Dan Jawaban Teknik Sipil: CM GR V WDocument9 pagesContoh Soal Dan Jawaban Teknik Sipil: CM GR V WThomas ArfiantoNo ratings yet

- CompactionDocument43 pagesCompactionDhankotmaNo ratings yet

- Compaction of SoilsDocument19 pagesCompaction of SoilspavanNo ratings yet

- 3 Binders For Eco FormulationsDocument80 pages3 Binders For Eco FormulationsCarolinaMaria Consonni100% (1)

- Saeed 147Document3 pagesSaeed 147Saeed RehmanNo ratings yet

- Appendix A.6 - Expansion Index TestDocument2 pagesAppendix A.6 - Expansion Index TestJerome YangaNo ratings yet

- Session 23: Post Class Test SolutionsDocument1 pageSession 23: Post Class Test SolutionsAlessio TONo ratings yet

- CH. Devi Lal State Institute of Engineering & Technology, Panniwala Mota, Sirsa. Laboratory ManualDocument2 pagesCH. Devi Lal State Institute of Engineering & Technology, Panniwala Mota, Sirsa. Laboratory ManualManik GoyalNo ratings yet

- Models - Heat.semi Infinite WallDocument18 pagesModels - Heat.semi Infinite WallsuganthNo ratings yet

- Geotechnical FormulasDocument13 pagesGeotechnical FormulasRhodhel BillonesNo ratings yet

- On The Dynamics of Distillation Processes VI Batch Distillation Doherty 1978Document7 pagesOn The Dynamics of Distillation Processes VI Batch Distillation Doherty 1978Csaba AndrásNo ratings yet

- Praticle No. 1Document6 pagesPraticle No. 1TejasNo ratings yet

- Consistency LimitsDocument10 pagesConsistency LimitsAbinavNo ratings yet

- Delft University of Technology: PagesDocument12 pagesDelft University of Technology: PagesMaria TabaresNo ratings yet

- Test For Sterength Deterioration by Dry-Wet Cycle: 1. Purpose of The TestDocument3 pagesTest For Sterength Deterioration by Dry-Wet Cycle: 1. Purpose of The TestrkNo ratings yet

- Math 55 PS2 Part 1Document1 pageMath 55 PS2 Part 1krystal.bscNo ratings yet

- Soil CompactionDocument8 pagesSoil Compactionpp hsu67% (3)

- Chapter 2. Economics: Economic JustificationDocument12 pagesChapter 2. Economics: Economic Justificationkaleem ullah janNo ratings yet

- Mechanical Properties of Fluids KeyDocument4 pagesMechanical Properties of Fluids KeyBastin SamuelNo ratings yet

- On-Demand Separation of Oil-Water MixturesDocument6 pagesOn-Demand Separation of Oil-Water MixturesSun DayNo ratings yet

- UntitledDocument9 pagesUntitleddavid giraldo lopezNo ratings yet

- Solution Physics Test Class 11 - PhysicsDocument7 pagesSolution Physics Test Class 11 - PhysicsUtkarsh VaishNo ratings yet

- Hadji Basit Study Guide 3Document8 pagesHadji Basit Study Guide 3Jayar MariquitaNo ratings yet

- Optimization in Operations Research 2nd Edition Rardin Solutions Manual DownloadDocument18 pagesOptimization in Operations Research 2nd Edition Rardin Solutions Manual DownloadLula Allen100% (23)

- ESandEPS162 Homework 1Document17 pagesESandEPS162 Homework 1SISTLA SUNDARA RAMA SARMANo ratings yet

- Gate 2020 Me QP Shift 2Document21 pagesGate 2020 Me QP Shift 2Jayanth ThammineniNo ratings yet

- Models - Cfd.elastohydrodynamic Interaction ComsolDocument18 pagesModels - Cfd.elastohydrodynamic Interaction ComsolBen FahNo ratings yet

- PT 2023 Past QuestionDocument7 pagesPT 2023 Past QuestionTSOG MHNo ratings yet

- Field Density by Sand Cone MethodDocument6 pagesField Density by Sand Cone MethodDanyar Mohammed TahirNo ratings yet

- EC-2-with-Margin (SOIL COMPACTION) HANDWRITTENDocument7 pagesEC-2-with-Margin (SOIL COMPACTION) HANDWRITTENNenia RosasNo ratings yet

- 7.2 Integration by Parts: 7.2.1 The Idea by An ExampleDocument12 pages7.2 Integration by Parts: 7.2.1 The Idea by An ExamplemarioasensicollantesNo ratings yet

- SPM Form 4 Add Math Tuition Note - Differentiation - Maximum and Minimum PointDocument5 pagesSPM Form 4 Add Math Tuition Note - Differentiation - Maximum and Minimum PointMyHomeTuition.com100% (2)

- (Soil Compaction) HandwrittenDocument6 pages(Soil Compaction) HandwrittenNenia RosasNo ratings yet

- EXP 03 - Specific Gravity and Absorption FADocument3 pagesEXP 03 - Specific Gravity and Absorption FAMarshall james G. RamirezNo ratings yet

- CE 524 TECHNICAL ELECTIVE 2 QUIZ NO. 2 - SolutionDocument3 pagesCE 524 TECHNICAL ELECTIVE 2 QUIZ NO. 2 - SolutionSamuel EsparteroNo ratings yet

- Week4 AdditionalPracticeProblems SolutionsDocument16 pagesWeek4 AdditionalPracticeProblems SolutionsBiswajeet ThakuriaNo ratings yet

- 2A4-Applied-Fluid-Mechanics-L2-Slides-Povey Blasius & Boundary LayerDocument24 pages2A4-Applied-Fluid-Mechanics-L2-Slides-Povey Blasius & Boundary LayerMoemen MetwallyNo ratings yet

- Sifat TanahDocument9 pagesSifat TanahdaniNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelDocument28 pagesUniversity of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelSaeeda KhiljiNo ratings yet

- Compiled By: Prof.B.S.Chawhan Asst - Professor, CED, Government - Engineering College, Haveri-581110 (12/4/2011-Till Date)Document17 pagesCompiled By: Prof.B.S.Chawhan Asst - Professor, CED, Government - Engineering College, Haveri-581110 (12/4/2011-Till Date)vinodh159No ratings yet

- Illustrates Flow Behaviour of Common Fluids: A. B. C. D. Solution - ADocument17 pagesIllustrates Flow Behaviour of Common Fluids: A. B. C. D. Solution - AJaspreet KaurNo ratings yet

- Strength of Materials Newsletter Important Subjects NewslettersDocument4 pagesStrength of Materials Newsletter Important Subjects NewslettersBaydaa QaidyNo ratings yet

- MECHANICAL Upda Type-Final SearchableDocument56 pagesMECHANICAL Upda Type-Final SearchablenadinemwahdanNo ratings yet

- CMTL - Group3 Lab Report 5 Moisture ContentDocument5 pagesCMTL - Group3 Lab Report 5 Moisture ContentChristian Kyle BeltranNo ratings yet

- Proctored Mock CAT-9 2012 Answers and ExplanationsDocument9 pagesProctored Mock CAT-9 2012 Answers and ExplanationsMridul PantNo ratings yet

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyFrom EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 5Document1 pageIs 12308-5 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-9 - 1993 - 1Document1 pageIs 12308-9 - 1993 - 1Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 5Document1 pageIs 12308-7 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 4Document1 pageIs 12308-6 - 1991 - 4Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 1Document1 pageIs 12308-5 - 1991 - 1Svapnesh ParikhNo ratings yet

- Is 12308-4 - 1988 - 4Document1 pageIs 12308-4 - 1988 - 4Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 4Document1 pageIs 10719 (Iso 1302) - 4Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 11Document1 pageIs 10719 (Iso 1302) - 11Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 12Document1 pageIs 10719 (Iso 1302) - 12Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 8422-6 - 1977 - 4Document1 pageIs 8422-6 - 1977 - 4Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 2Document1 pageIs 8422-8 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 3Document1 pageIs 8422-2 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-8 - 1977 - 5Document1 pageIs 8422-8 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 2Document1 pageIs 8422-3 - 1977 - 2Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 2Document1 pageIs 8422-1 - 1977 - 2Svapnesh ParikhNo ratings yet

- Clean Dumped MeDocument12 pagesClean Dumped MeLuis Antonio Arévalo SifontesNo ratings yet

- User Manual-Industry Robot Control System - LT PDFDocument113 pagesUser Manual-Industry Robot Control System - LT PDFEsteban Acosta MartinezNo ratings yet

- MSB780 & MSB780X: Digital BarometersDocument4 pagesMSB780 & MSB780X: Digital BarometersPham Van LinhNo ratings yet

- Ptfe Torque Chart Aps KitsDocument2 pagesPtfe Torque Chart Aps KitsJo KingsNo ratings yet

- Modbus in ML200Document30 pagesModbus in ML200cunconfunnyNo ratings yet

- Technical Information: Grounding in Off-Grid SystemsDocument6 pagesTechnical Information: Grounding in Off-Grid SystemsRavikumargowdaNo ratings yet

- Addmaths Kacang Form 4 Chapter 1: Functions: Notes & Past SPM QuestionsDocument17 pagesAddmaths Kacang Form 4 Chapter 1: Functions: Notes & Past SPM QuestionssanjeniNo ratings yet

- BJT 2Document14 pagesBJT 2Suguna PriyaNo ratings yet

- B.SC Syllabus 2018 Batch Onwards 1 VI SemestersDocument31 pagesB.SC Syllabus 2018 Batch Onwards 1 VI SemestersAnon writNo ratings yet

- Literature Review 3Document6 pagesLiterature Review 3api-548697085No ratings yet

- Report (9-10) - 5 - 2023Document5 pagesReport (9-10) - 5 - 2023mintuNo ratings yet

- KL 300Document4 pagesKL 300Zaheer AbbasNo ratings yet

- Venturekit Business PlanDocument29 pagesVenturekit Business Plankamilreshad89No ratings yet

- Experiment 3: Density Level Measurement DLT 912: ObjectivesDocument4 pagesExperiment 3: Density Level Measurement DLT 912: ObjectivesFBK98No ratings yet

- Truss To Beam Connection Detail: Proposed Two Storey Residential BuildingDocument1 pageTruss To Beam Connection Detail: Proposed Two Storey Residential BuildingRaymart CubidNo ratings yet

- Air Conditioning TermsDocument15 pagesAir Conditioning TermsBaby DarylNo ratings yet

- VR-3200 BrochureDocument32 pagesVR-3200 BrochureAndres Melendez HernandezNo ratings yet

- Design Aspects of Control SystemDocument3 pagesDesign Aspects of Control Systemmekeilah romaNo ratings yet

- Hyd - Cal. WTP BaggiDocument27 pagesHyd - Cal. WTP BaggiChief Engineer PMUNo ratings yet

- EAD CAD Standard Manual PDFDocument287 pagesEAD CAD Standard Manual PDFRey KelireyNo ratings yet

- IE 525: System Engineering: Interest Rate Is The Ratio of The Borrowed Money To The Fee Charged For Its Use Over ADocument20 pagesIE 525: System Engineering: Interest Rate Is The Ratio of The Borrowed Money To The Fee Charged For Its Use Over Adanielle faith jalloresNo ratings yet

- Tài Liệu Business Partner (MYENGLISHLAP)Document47 pagesTài Liệu Business Partner (MYENGLISHLAP)jqmrtcs7xbNo ratings yet

- 3GPP TS 23.122Document49 pages3GPP TS 23.122holapaquitoNo ratings yet

- Modulo Comm Valv EXDocument83 pagesModulo Comm Valv EXAgustinNo ratings yet

- Worksheet: Required DataDocument2 pagesWorksheet: Required DataKaarthicNatarajanNo ratings yet

- Working Aresnal ScriptDocument14 pagesWorking Aresnal Scriptuziahmalone9No ratings yet

- A Guide For Visatron Oil Mist Detector Users - V 1.2.3 PDFDocument64 pagesA Guide For Visatron Oil Mist Detector Users - V 1.2.3 PDFGENNIEL SABA100% (4)

- Untitled Project - Created With VisMeDocument1 pageUntitled Project - Created With VisMeZumaan KhanNo ratings yet