Professional Documents

Culture Documents

CBB Ts 161128 Babbitt Types

Uploaded by

Alejandro SanchezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CBB Ts 161128 Babbitt Types

Uploaded by

Alejandro SanchezCopyright:

Available Formats

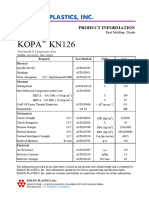

Babbitt Types & Application

Ultimate Strength in

Compression Brinell Hardness Composition %

Melting

Babbitt Type psi (Mpa) point °F

(°C)

Application

68°F (20°C) 212°F (100°C) 68°F (20°C) 212°F (100°C) Sn Sb As Cu Pb

High speed, High pressure, High temperature, Excellent corrosion

resistance, Easy bonding, Less tendency for segregation and welding,

ASTM B23 Alloy 2 14 900 (102.7) 8700 (60) 24.5 12 466 (241) 89 7.5 3.5

Good for steady load conditions in steam and gas turbines, electric

motors, blowers, and pumps

ASTM B23 Alloy 3 17 600 (121.3) 9900 (68.3) 27 14.5 464 (240) 84 8 8 Heavy duty, High Speed, High pressure, High shock

Softer than the tin based Babbitt’s, Less tendency to score a shaft,

ASTM B23 Alloy 7 15 650 (107.9) 6150 (42.4) 22.5 10.5 464 (240) 10 15 0.5 R

Lower pressure, Lower Speed, Lower thermal conductivity

ASTM B23 Alloy 15 15 500 (107) 6100 (42) 21 13 479 (248) 1 16 1 R Heavy duty, High Speed, High pressure

Same as ASTM B23 Alloy 2, without trace of Lead (meets European

REACH requirements), Max static pressure capacity up to high

Tegostar ECKA 19 300 (133) 10 300 (71) 26 14 458 (237) 81 12 6 hydrodynamic sliding speeds, Very high fatigue strength, Resistant

against high frequency vibration, Minimum strain in creep and then

optimum dimensional stability

Max static pressure capacity up to high hydrodynamic sliding speeds,

Good dynamic capacity for high frequency vibration, good capacity for

Tegostar 738 19 300 (133) 10 300 (71) 26 14 458 (237) 81 12 6

impact, minimum strain in creep and then optimum dimensional

stability (meets European REACH requirements)

Good for Steady heavy load, High speed especially with low thickness,

QQ-T-390A Alloy 10 15 100 (104) 6050 (41) 25 15 459 (237) 1 16 0.6 R

Low corrosion resistant

Canadian Babbitt Bearings Ltd., 64 Dalkeith Drive, Brantford Ontario. N3P 1N6

CBB Ts 161128 Babbitt Types +1 (519) 752-5471 | +1 800-963-9863 | sales@cbb.ca

www.cbb.ca

You might also like

- RoHS Compliant Heat Shrink Tubes for Busbar InsulationDocument2 pagesRoHS Compliant Heat Shrink Tubes for Busbar InsulationCarlos Berrospi ChacaNo ratings yet

- 2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesDocument2 pages2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesJairo BarragánNo ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- Machine Tool Slideways Oil TDSDocument3 pagesMachine Tool Slideways Oil TDSIsay Quiroga VargasNo ratings yet

- 2024-T3 ASM Material Data Sheet PDFDocument2 pages2024-T3 ASM Material Data Sheet PDFAnonymous mq0U43UsPNo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Lupox Gp1000H: Description ApplicationDocument2 pagesLupox Gp1000H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- Sikadur®-42 MP Slow - PDSDocument7 pagesSikadur®-42 MP Slow - PDSkamran abbasiNo ratings yet

- TKGR FLON (PTFE) density, properties, applicationsDocument1 pageTKGR FLON (PTFE) density, properties, applicationse.vicente.caballeroNo ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Styroflex 2G66: Styrene Butadiene Copolymer (SBC)Document3 pagesStyroflex 2G66: Styrene Butadiene Copolymer (SBC)Ronaldo CamargoNo ratings yet

- Friction Abrasion Corrosion TAC Test Tesults - Wear Test ASTM G65 PDFDocument11 pagesFriction Abrasion Corrosion TAC Test Tesults - Wear Test ASTM G65 PDFBurag HamparyanNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Principal Behind Small SagDocument1 pagePrincipal Behind Small SagAbdullah GhannamNo ratings yet

- 9851 3139 01 - Cop 1238KDocument2 pages9851 3139 01 - Cop 1238Kbundajoseph148No ratings yet

- D R S HD: Enso OCK HieldDocument4 pagesD R S HD: Enso OCK HieldPabloCesarCamargoNo ratings yet

- Ds - TECHDRAIN GTG 30.6 - enDocument1 pageDs - TECHDRAIN GTG 30.6 - enThameem SharaafNo ratings yet

- ASTM C90700 - CuSn11 - Tin Bronze AlloysDocument1 pageASTM C90700 - CuSn11 - Tin Bronze Alloysİrem Şebnem SorucuNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- Material Data Sheet: ABS+ High Grade-ABS vs ABS M30 Mechanical PropertiesDocument1 pageMaterial Data Sheet: ABS+ High Grade-ABS vs ABS M30 Mechanical PropertiesSuryas SivaNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- Qurain PP Raffia 3 Mfi Ht031Document1 pageQurain PP Raffia 3 Mfi Ht031Engr HasnainNo ratings yet

- Qurain Polypropylene Technical Data Sheet: Injection Molding Resins Film ResinsDocument1 pageQurain Polypropylene Technical Data Sheet: Injection Molding Resins Film ResinsTychNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- PC-ABS Cycoloy™ C6600Document2 pagesPC-ABS Cycoloy™ C6600countzeroaslNo ratings yet

- LED Lamp Cover Material for Light DiffusionDocument2 pagesLED Lamp Cover Material for Light DiffusionLong HomaNo ratings yet

- T700S Technical Data Sheet 1 PDFDocument2 pagesT700S Technical Data Sheet 1 PDFgk9No ratings yet

- Standard Modulus Carbon Fiber for Traditional ManufacturingDocument2 pagesStandard Modulus Carbon Fiber for Traditional ManufacturingGustavoNo ratings yet

- Foil de AluminioDocument1 pageFoil de AluminioArmando MantillaNo ratings yet

- Tairilac ABS Resin Properties and CharacteristicsDocument3 pagesTairilac ABS Resin Properties and CharacteristicsDiegoTierradentroNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- RMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - SignedDocument3 pagesRMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - SignedNirmal WiresNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- Properties of Commercially Pure Titanium and Titanium AlloysDocument27 pagesProperties of Commercially Pure Titanium and Titanium AlloysZhu DanielNo ratings yet

- TALLER PRESOSTATO 2 inglesDocument2 pagesTALLER PRESOSTATO 2 inglesedisson garzonNo ratings yet

- Aluminum 7075 Alloy Material Data SheetDocument2 pagesAluminum 7075 Alloy Material Data Sheetadam.el.polaco7881No ratings yet

- Nitoflor RT6000 UTDocument4 pagesNitoflor RT6000 UTAndrew KasanaNo ratings yet

- Ds - INTERDRAIN GM & GMG 27.6 - enDocument1 pageDs - INTERDRAIN GM & GMG 27.6 - enThameem SharaafNo ratings yet

- High Conductivity Copper, Hard, UNS C10200 (MatWeb)Document3 pagesHigh Conductivity Copper, Hard, UNS C10200 (MatWeb)jlmeseguerNo ratings yet

- TECASINT_2011_natural_14Document1 pageTECASINT_2011_natural_14e.montgomeryNo ratings yet

- Performace Evaluation of Slag Aggregates As Construction MaterialDocument49 pagesPerformace Evaluation of Slag Aggregates As Construction MaterialMd Ashiqur RahmanNo ratings yet

- Abs XR 404 LGDocument2 pagesAbs XR 404 LGLeandro LacerdaNo ratings yet

- Lexan 9034 Data SheetDocument2 pagesLexan 9034 Data SheetAdrián PonceNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- High Density Polyethylene: ASTM D 1505 G/CM 0.963-0.968 ASTM D 1238 G/10min 4.5-5.5Document1 pageHigh Density Polyethylene: ASTM D 1505 G/CM 0.963-0.968 ASTM D 1238 G/10min 4.5-5.5Oswald SolorzanoNo ratings yet

- GAP Type Conductor CatalogueDocument4 pagesGAP Type Conductor CatalogueLê An Mai CơNo ratings yet

- RT-duroid 6202 Laminate Data SheetDocument2 pagesRT-duroid 6202 Laminate Data SheetAditya Bonnerjee 21BEC0384No ratings yet

- T700S R4 - 04132018 ActualDocument2 pagesT700S R4 - 04132018 ActualVaibhav AnuseNo ratings yet

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterNo ratings yet

- TenCate BT250E-6 DatasheetDocument4 pagesTenCate BT250E-6 DatasheetGregory A KressNo ratings yet

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- ASM Material Data Sheet PDFDocument2 pagesASM Material Data Sheet PDFanne smithNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Isha Forest Flower Aug 2019Document24 pagesIsha Forest Flower Aug 2019Alejandro SanchezNo ratings yet

- Ludeca-A Practical Guide To Shaft Alignment PDFDocument0 pagesLudeca-A Practical Guide To Shaft Alignment PDFDelfinsh100% (1)

- Hidden Energy Electric Motors Savings in HotelsDocument14 pagesHidden Energy Electric Motors Savings in HotelsAlejandro SanchezNo ratings yet

- Centrifugal Pumps 2EDocument592 pagesCentrifugal Pumps 2EAlejandro Sanchez100% (1)

- Radio Wave Packet - Firstenberg - 2001Document8 pagesRadio Wave Packet - Firstenberg - 2001MA-Doc100% (1)

- Jani-King Commercial Cleaning Healthcare ServicesDocument59 pagesJani-King Commercial Cleaning Healthcare ServicesAlejandro SanchezNo ratings yet

- Isha Forest Flower Aug 2019 PDFDocument24 pagesIsha Forest Flower Aug 2019 PDFAlejandro SanchezNo ratings yet

- Isha Fore Flower Sept 2019Document24 pagesIsha Fore Flower Sept 2019aaha74No ratings yet

- Jani-King Educational Commercial Cleaning Services PDFDocument24 pagesJani-King Educational Commercial Cleaning Services PDFAlejandro SanchezNo ratings yet

- Isha USA - Isha - SadhguruDocument6 pagesIsha USA - Isha - SadhguruAlejandro SanchezNo ratings yet

- Jani-King Commercial Cleaning Healthcare ServicesDocument59 pagesJani-King Commercial Cleaning Healthcare ServicesAlejandro SanchezNo ratings yet

- Enlightenment Life The Way It Is SadhguruDocument83 pagesEnlightenment Life The Way It Is Sadhgurushivasun1100% (2)

- Bring Devi HomeDocument11 pagesBring Devi HomeAlejandro Sanchez100% (1)

- Enlightenment Life The Way It Is SadhguruDocument83 pagesEnlightenment Life The Way It Is Sadhgurushivasun1100% (2)

- Isha Forest Flower - June 2019Document24 pagesIsha Forest Flower - June 2019DeeshaNo ratings yet

- Isha Forest Flower - July 2019Document24 pagesIsha Forest Flower - July 2019Alejandro SanchezNo ratings yet

- How industrial engineering can optimize mining operationsDocument6 pagesHow industrial engineering can optimize mining operationsAlejandro SanchezNo ratings yet

- Isha Forest Flower Feb 2019Document24 pagesIsha Forest Flower Feb 2019Alejandro SanchezNo ratings yet

- Yoga Programs-Inner Transformation-Yoga Center at ISHA FoundationDocument4 pagesYoga Programs-Inner Transformation-Yoga Center at ISHA FoundationAlejandro SanchezNo ratings yet

- Deccan Chronicle 5 Jan 2019Document1 pageDeccan Chronicle 5 Jan 2019Alejandro SanchezNo ratings yet

- Deccan Chronicle 28 Jan 2019Document1 pageDeccan Chronicle 28 Jan 2019Alejandro SanchezNo ratings yet

- The Times of India 10 Feb 2019Document1 pageThe Times of India 10 Feb 2019Alejandro SanchezNo ratings yet

- Isha Forest Flower Feb 2019Document24 pagesIsha Forest Flower Feb 2019Alejandro SanchezNo ratings yet

- MahaShivRatri 2019 - 4th Mar 2019 - Cel..Document12 pagesMahaShivRatri 2019 - 4th Mar 2019 - Cel..Alejandro SanchezNo ratings yet

- The Agile Unified Process AUPDocument34 pagesThe Agile Unified Process AUPAlejandro SanchezNo ratings yet

- Enlightenment Life The Way It Is SadhguruDocument83 pagesEnlightenment Life The Way It Is Sadhgurushivasun1100% (2)

- The Agile Unified Process (AUP)Document11 pagesThe Agile Unified Process (AUP)Alejandro SanchezNo ratings yet

- AMWhiteboardEtiquetteRules PDFDocument1 pageAMWhiteboardEtiquetteRules PDFAlejandro SanchezNo ratings yet

- Introduction To Agile Model Driven Development (AMDD) : Scott W. AmblerDocument18 pagesIntroduction To Agile Model Driven Development (AMDD) : Scott W. AmblerCristi MocanuNo ratings yet

- Modern tobacco marketing fundamentalsDocument6 pagesModern tobacco marketing fundamentalsAbdus SalamNo ratings yet

- Persons Choki MotobuDocument4 pagesPersons Choki MotobuHessabi max100% (1)

- Vampire Stories in GreeceDocument21 pagesVampire Stories in GreeceΓιώργος ΣάρδηςNo ratings yet

- KCIS 2nd Semester Science Fair ProjectsDocument2 pagesKCIS 2nd Semester Science Fair ProjectsCaT BlAcKNo ratings yet

- Sat Psat Word GamesDocument166 pagesSat Psat Word Gamesapi-360773187No ratings yet

- Importers - Dry Fruits and NutsDocument5 pagesImporters - Dry Fruits and Nutsankit0% (1)

- L-1 Preparation of Gases MCQDocument31 pagesL-1 Preparation of Gases MCQapi-233604231No ratings yet

- IMU 25,26 Oct 2014 (Other) ResultDocument2,582 pagesIMU 25,26 Oct 2014 (Other) ResultMuhammadFarhanShakee100% (1)

- Coping With Frustration, Conflict, and StressDocument7 pagesCoping With Frustration, Conflict, and StressCess Abad AgcongNo ratings yet

- Indigenous Peoples SyllabusDocument9 pagesIndigenous Peoples Syllabusapi-263787560No ratings yet

- Delta ABAP Workbench 4.0 To 4.6Document313 pagesDelta ABAP Workbench 4.0 To 4.6aurber2013No ratings yet

- Refunds Maceda Law and PD957Document2 pagesRefunds Maceda Law and PD957QUINTO CRISTINA MAENo ratings yet

- Handout-Wisdom QuestionsDocument1 pageHandout-Wisdom Questionsapi-369459770No ratings yet

- Data Center Cooling Solutions That Lower Costs With High Energy SavingsDocument5 pagesData Center Cooling Solutions That Lower Costs With High Energy Savingskhamsone pengmanivongNo ratings yet

- The Routledge Handbook of Translation and Culture by Sue-Ann Harding (Editor), Ovidi Carbonell Cortés (Editor)Document656 pagesThe Routledge Handbook of Translation and Culture by Sue-Ann Harding (Editor), Ovidi Carbonell Cortés (Editor)Rita PereiraNo ratings yet

- Partnership Dissolution QuizDocument8 pagesPartnership Dissolution QuizLee SuarezNo ratings yet

- Popular Telugu Novel "Prema DeepikaDocument2 pagesPopular Telugu Novel "Prema Deepikasindhu60% (5)

- Mathematics Engagement in An Australian Lower Secondary SchoolDocument23 pagesMathematics Engagement in An Australian Lower Secondary SchoolDane SinclairNo ratings yet

- Stigmatization of Feminism: Gender Studies As "Gender Ideology" in Right-Wing Populist Political Discourse in HungaryDocument55 pagesStigmatization of Feminism: Gender Studies As "Gender Ideology" in Right-Wing Populist Political Discourse in HungaryAnubhav SinghNo ratings yet

- Hidden Divergence Reveals Profitable Trading PatternsDocument12 pagesHidden Divergence Reveals Profitable Trading PatternsSubrata PaulNo ratings yet

- 9th Science Mcqs PTB PDFDocument25 pages9th Science Mcqs PTB PDFUmar JuttNo ratings yet

- Digital Mining Technology CAS-GPS Light Vehicle System Technical SpecificationDocument5 pagesDigital Mining Technology CAS-GPS Light Vehicle System Technical SpecificationAbhinandan PadhaNo ratings yet

- Tower Scientific CompanyDocument3 pagesTower Scientific Companymaloy0% (1)

- Sun Temple, Modhera: Gudhamandapa, The Shrine Hall Sabhamandapa, The AssemblyDocument11 pagesSun Temple, Modhera: Gudhamandapa, The Shrine Hall Sabhamandapa, The AssemblyShah PrachiNo ratings yet

- Bible Walk Through - Old TestamentDocument211 pagesBible Walk Through - Old TestamentWei Wang100% (2)

- Year 11 GCSE Revision Guidance and Exam Booklet Solihull PDFDocument27 pagesYear 11 GCSE Revision Guidance and Exam Booklet Solihull PDFNoor Ulain Nabeela83% (6)

- Administrator Guide: Document Version 3.6.1Document76 pagesAdministrator Guide: Document Version 3.6.1App PackNo ratings yet

- Art of Public Speaking 11th Edition Lucas Test BankDocument25 pagesArt of Public Speaking 11th Edition Lucas Test BankBryanMillernicy100% (49)

- Perceptions of Organizational Structure in The Hospitality IndustryDocument11 pagesPerceptions of Organizational Structure in The Hospitality IndustryLeah Williams100% (1)

- Pas 220Document71 pagesPas 220JuwitaNo ratings yet