Professional Documents

Culture Documents

Operational Manual WBL 85 HR

Uploaded by

Rahul sharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operational Manual WBL 85 HR

Uploaded by

Rahul sharmaCopyright:

Available Formats

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 1 von 62 Revision 4

Single Arm Pantograph

Model: WBL 85 IR High Reach

Acc. dwg. No. 1-21210.11673

Description

Maintenance-and

Operating Manual

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 2 von 62 Revision 4

Copyright by Schunk Bahn- und Industrietechnik GmbH.

All rights reserved.

This publication may not be reproduced, stored in a retrieval system, translated into

another language, or transmitted in whole or in part, in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written

permission of Schunk Bahn- und Industrietechnik GmbH.

We are not responsible for the consequences of possible mistakes or errors in this

publication.

We reserve the right to make technical changes at any time, and without prior notice.

Schunk Bahn- und Industrietechnik GmbH

Aupoint 23

A-5101 Bergheim, Austria

Phone: +43 (0) 662 459200-0

Fax: +43 (0) 662 459200-1

e-mail: office@schunk-group.at

i-net: http://www.schunk-group.at

Rev.No. Revision Date Name

1 First edition 15.01.09 Pardeller

2 Maintainance schedule updtd and ORD added 16.10.14 seetharam

3 Maintainance schedule updtd & Must change parts 05.02.15 seetharam

list added

4 Maintainance schedule &Technical data updated 18.03.16 seetharam

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 3 von 62 Revision 4

Index

Description Maintenance-and Operating Manual ......................................................... 1

1. Introduction ..................................................................................................................... 5

2. Safety Instructions ........................................................................................................ 6

2.1. General Information ............................................................................................. 6

3. Technical Data ................................................................................................................ 7

4. Description of Pantograph Components ................................................................ 9

4.1. General Information ............................................................................................. 9

4.2. Structural Components ....................................................................................... 9

4.2.1 Base Frame ....................................................................................................10

4.2.2 Lower Frame...................................................................................................10

4.2.3 Upper Frame...................................................................................................10

4.2.4 Coupling Rod..................................................................................................11

4.2.5 Pan Head ........................................................................................................11

4.2.6 Parallel Guide Bar..........................................................................................11

4.2.7 Air Bellow ........................................................................................................11

4.2.8 Resting Bumper .............................................................................................11

4.2.9 Damper............................................................................................................11

4.2.10 Electrical Equipment......................................................................................11

4.2.11 Base- and Upper frame bearing ..................................................................12

4.2.12 Pneumatic Control .........................................................................................12

4.2.12.1 Pneumatic control box...........................................................................12

4.2.12.2 Auto drop device (ADD) ........................................................................12

4.2.13 Over reach detector (ORD)...................................................................14

4.2.14 Pneumatic diagram........................................................................................14

5. Packaging ......................................................................................................................15

5.1. Packaging for Transport ...................................................................................15

6. Storage ...........................................................................................................................15

7. Cleaning .........................................................................................................................15

8. Assembly .......................................................................................................................16

8.1. General Information ...........................................................................................16

8.2. Transport and Storage ......................................................................................16

8.3. Attachment to the Vehicle.................................................................................16

8.4. High Voltage Connection..................................................................................17

8.5. Mounting of Compressed Air Connection ......................................................17

9. Start Up...........................................................................................................................18

9.1. Check List ...........................................................................................................18

10. Maintenance ..............................................................................................................19

10.1. General Information ...........................................................................................19

10.2. Collector Strip .....................................................................................................24

10.3. Bearings ..............................................................................................................26

10.3.1 Grooved Ball Bearings ..................................................................................26

10.3.2 Plane Bearings...............................................................................................26

10.4. Screw Joints .......................................................................................................26

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 4 von 62 Revision 4

10.4.1 Torque for Stainless Steel Screw Connections ........................................27

10.4.2 Screw bonding and Screw sealing ..............................................................27

10.5. Hydraulic Oscillation Damper...........................................................................27

10.6. Insulators, Insulating Tubes .............................................................................27

10.7. Bellow Drive ........................................................................................................28

10.8. Cable with Terminals of Raising Mechanism ................................................28

10.9. Shunt Connections ............................................................................................28

10.10. Pan Head Springs..............................................................................................28

10.11. Pneumatic Control Box .....................................................................................28

10.12. Auto Drop Device (ADD)...................................................................................32

10.13 Over Reach Detector (ORD) ....................................................................25

10.14. Auxiliary Material................................................................................................33

11. Troubleshooting – Trouble List ...........................................................................35

11.1. General Information ...........................................................................................35

11.2. Trouble List .........................................................................................................35

12. Repairs .......................................................................................................................37

12.1. General Information ...........................................................................................37

12.2. Dismounting of Pantograph from Top of Vehicle Roof ................................37

12.3. Complete Disassembly of Pantograph ...........................................................37

12.4. Repairs of Component Parts............................................................................38

12.4.1 Free Bearing of Base Frame and Upper Frame .......................................38

12.4.2 Fixed Bearing of Base Frame, Coupling Rod and Upper Frame ...........39

12.4.3 Pan Head Rocker Boxes ..............................................................................39

12.4.4 Shunts..............................................................................................................40

12.4.5 Bellow Drive ....................................................................................................40

12.4.6 Other Component Parts ................................................................................41

12.4.7 Surface Coating .............................................................................................41

12.4.7.1 Pre-Treatment ........................................................................................41

12.4.7.2 Finishing Paint ........................................................................................41

12.4.7.3 Touch Up Paint.......................................................................................42

12.5. Re-Assembly after complete Disassembly ....................................................42

13. Adjustment Procedures .........................................................................................43

13.1. General Information ...........................................................................................43

13.2. Adjustment of Coupling Rod and Resting Position ......................................44

13.3. Adjusting the Bellow Drive................................................................................45

13.4. Adjustment of Pneumatic Control....................................................................46

13.4.1 Adjust Safety valve (3) ..................................................................................47

13.4.2 Adjust contact pressure ................................................................................47

13.4.3 Adjust raising time .........................................................................................47

13.4.4 Adjust Lowering time .....................................................................................48

13.5. Adjustment Curve of Contact Pressure ..........................................................49

13.6. Adjustment of Turning Capacity of Pan Head ...............................................50

13.7. Adjustment of Over reach detector ................................................................50

14. Product Data Sheets ...............................................................................................52

15. Spare Parts ................................................................................................................62

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 5 von 62 Revision 4

1. Introduction

The Single Arm Pantograph WBL 85 serves the Current Collection of electrically operated

Heavy Rail Vehicles.

Our objective was to design and manufacture a simple, light weight, and easy to maintain,

Pantograph. We further wanted to achieve an optimum in catenary contact behaviour,

even under the most basic overhead wire conditions, and combine with it a maximum of

operating safety.

The last chapter contains the Replacement Part Catalogue. We kindly request you to

describe the needed parts as accurate as possible and in accordance with this catalogue

to assure a problem free order processing, and subsequent delivery.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 6 von 62 Revision 4

2. Safety Instructions

2.1. General Information

Attention!!! Before starting any repair or maintenance work, always:

Switch off the overhead wire current and ensure, that the current

cannot be inadvertently switched back on

Lower the pantograph

Attention!!! No one is allowed underneath the pantograph while being transported

by a crane or other means.

Attention!!! After completion of every repair or maintenance:

Please assure that no tools or other loose parts are left on top of

the vehicle roof.

Attention!!! The given internal safety regulations have to be kept.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 7 von 62 Revision 4

3. Technical Data

Standard ............................................................................................................... IEC 60 494-1

Minimum height with insulators in resting position ......................................... 645 +5 mm

Insulating distance .............................................................................................. min. 250 mm

Minimum working over resting position .................................................................... 100 mm

Maximum working height over resting position .................................................... 3400 mm

Maximum extension................................................................................................... 3600 mm

Width of pan head acc 1-W08.15605 ............................................................ 2030 ± 5 mm

Height of pan head acc 1-W08.15605............................................................. 320 ± 5 mm

Profile ……………………………………………………………………………...SKEL 4992

Current collector strip - length......................................................................... 1030 +/-2 mm

Current collector strip - spacing......................................................................... 390 ± 5 mm

Current collector strip – material ................................................................... .SK85Cu

Total length in resting position ...................................................................... 3069 ± 10 mm

Total weight without insulators ..................................................................... about 165 kgs

Lateral deflection at max. working height & lateral force of 300N acc.to IEC 60494-1

………...…………………………………………………………………………….Max.30mm

Calculated height of insulators................................................................................... 363 mm

Nominal voltage ............................................................................................................... 25 kV

Nominal current ............................................................................................................... 600 A

Nominal static upward force (adjustable)...................................................................... 70 N

Pan head ............................................................... individual suspension of collector strips

Spring rate of pan suspension .................................................................. 8750 N/m ± 10%

Maximum speed under good overhead wire conditions ...................................... 200 km/h

Ambient temperature according to spec. .................................................... -10°C to +70°C

Propulsion system with air bellow

Air pressure supply from vehicle for raising of pantograph............................ min. 5,5 bar

Air pressure supply from vehicle for continuous operation ................................min. 6 bar

condition of compressed air ................... dry and oil free air for insulating characteristics

Raising time to maximum working height .....................................................................15 s

Lowering time from maximum working height............................................................ 15 s

Air pressure connection to vehicle .......................High voltage insulating hose 1000 mm

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 8 von 62 Revision 4

Forces applied to pantograph support insulators:

Conditions for calculation according UIC 566:

Acceleration longitudinal: ax=5g

Acceleration transversal: ay=1g

Acceleration vertical: az=3g

Fx (longitudinal direction) ..............................................................................................2000N

Fy (transversal direction) ................................................................................................. 400N

Fz (vertical direction) ......................................................................................................8600N

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 9 von 62 Revision 4

4. Description of Pantograph Components

4.1. General Information

Rail Vehicles, which are powered through an overhead wire system, can be equipped with

the Single Arm Pantograph WBL 85.

Main features of the Single Arm Pantograph WBL 85 are:

Low weight

Simple construction

Minimum maintenance

Excellent contact behaviour, even under basic catenary conditions

Maximum operating safety

This is mainly achieved through:

Proven bearing techniques

Patented hydraulic oscillation damping techniques

Pan head with independent suspension of carbon strips

4.2. Structural Components

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 10 von 62 Revision 4

4.2.1 Base Frame

The base is a welded structure of closed rectangular hollow steel profiles.

The following component parts are located on the base frame:

Basic bearings for the lower frame

Resting buffer for upper and lower frame

Mounting fixtures for:

- Air bellow

- Coupling rod

- Hydraulic damper

- Insulators

- High voltage hook-up

- Pneumatic hook-up

4.2.2 Lower Frame

The lower frame is a welded structure. Its seating is located on the base frame.

The following component parts are mounted to the lower frame:

Cam disks with suspension fixture for the bellow-drive cables

Parallel guide bar

Hydraulic oscillation damper

4.2.3 Upper Frame

The upper frame is a welded structure made of seamless tubes. Necessary lateral

stability is achieved through a cross wire-rope construction.

Attached to the upper frame are the following component parts:

Pan head

Coupling rod

Lower frame

Bearing blocks for the knuckle joint bearings

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 11 von 62 Revision 4

4.2.4 Coupling Rod

The coupling rod consists of the coupling rod tube made of a seamless steel round-tube

and two roller bearings with left-handed and right-handed thread. By turning of the

coupling rod tube, the geometry of the pantograph will be adjusted and fine tuned.

4.2.5 Pan Head

The pan head is located at the crest of the upper frame and uses leaf springs for the

suspension of the copper strips. They are affixed in the rocker box, and carry at each end

bearing supported mounts, to which the carbon strips are attached.

4.2.6 Parallel Guide Bar

The parallel guide bar prevents the pan head from distorting, while the pantograph is

raised or lowered.

4.2.7 Air Bellow

The pneumatic bellow drive allows the pantograph to rise. It is mounted between the base

frame and the lower frame. A pneumatic line connects the bellow drive with the pneumatic

control, and then continues via the solenoid valve on to the compressor. The contact

pressure is adjusted through the pneumatic control system.

4.2.8 Resting Bumper

The resting bumper prevents vibrating the knie section of the pantograph.

4.2.9 Damper

The pantograph damping is attained through the oscillating damper between base frame

and lower frame. This guarantees a good contact between the copper strips and the

overhead wire. The dampers are suitable for temperatures ranging from -40 to +80

degrees Celsius (approx. -40 to +176 degrees Fahrenheit).

4.2.10 Electrical Equipment

All bearing locations are by-passed by shunt connectors. These prevent the current from

flowing through the bearings. The shunts are consisting of flexible copper cables with

clamped end pieces. The current connectors are greased with copper grease to achieve

good conducting properties between the shunts and the frame parts.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 12 von 62 Revision 4

4.2.11 Base- and Upper frame bearing

The bearings of the pantograph are maintenance free and greased for life. At each

bearing two, in a certain distance on an axle arranged, ball bearings are used.

To avoid condensation the gap between the ball bearings is filled with grease. The

outside of the bearings is protected with cover plates against mechanical damage.

4.2.12 Pneumatic Control

The pneumatic control consists mainly of two parts:

Pneumatic control box.

Auto drop device (ADD), mounted inside the pneumatic control box.

For the connection to the pneumatic system is one connection available:

one for the pressure supply of the air bellow

4.2.12.1 Pneumatic control box

The pneumatic control is fixed at the base frame and consists mainly of a Air filter, two

throttle valves, two safety valves, a 3/2-Way valve,Pressure regulator and Quick Exhaust

Valve(ADD).

The main part of the unit is the pressure regulator, it is responsible for supply the

constant pressure to the air bellow during all service conditions.

The pressure regulator has a high sensitivity and is adjustable in a range of 1 to 8 bar.

4.2.12.2 Auto drop device (ADD)

The pantograph is equipped with a pneumatic carbon monitoring system to minimize

damages of catenary and pantograph through worn or damaged carbon strips (e.g.

broken carbon pieces).

For this purpose the pantograph is fitted with special suitable carbon strips, a valve unit is

fixed inside the pneumatic control box, consisting of the main parts, Quick exhaust valve,

cut off cock and an air hose leading from the base frame, lower frame and upper frame to

the carbon strips.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 13 von 62 Revision 4

Air supply

Connection

ADD

Connection

to air bellow

4.2.13 Over Reach Detector (ORD)

The pantograph is equipped with a ORD system to avoid damages to pantograph when

pantograph reaches un wired section.

The overreach detection mainly consists of a 3/2 way valve mounted on the base frame, a

clamp with a cam clamped to the lower frame

The overreach detector drops the pantograph to its resting height in the case that the

pantograph reaches to the indicated height (preferred by Cust.)

If the pantograph raises to the indicated height, the cam switches the 3/2-way valve,

Compressed air exhaust from the valve and pantograph Lowered to its resting position,air

from the valve will be exhausting continiously

Since this is push pull type valve, this process will continuously happening until panto

down command given by driver

For normal working of pantograph, valve has to reset manually on roof top,

Pantograph will starts rising after resetting of the valve only

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 14 von 62 Revision 4

4.2.14 Pneumatic diagram

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 15 von 62 Revision 4

5. Packaging

5.1. Packaging for Transport

The pantograph is mounted in an appropriate packaging (e.g. wood box) in lowered

position with pan head up.

Attention!!! Always transport the pantograph with the proper side up, the pan head

must be upside.

6. Storage

For storage please get the pantograph in a roofed room. Make sure, that this place is well

ventilated, dry and the temperatures do not exceed the temperature limits according to

the technical data (see chapter #3). The pantograph can remain in the packaging for

storage.

Attention!!! Store the pantograph always with the proper side up, the pan head

must be upside.

Do not place other parts directly on the pantograph. If the pantograph is stored out of the

packing, take care, that the ground is flat, use spacers of an appropriate length under the

pantograph feet in order to avoid damages by the floor to low and moving parts (Air

bellow, Pneumatic control). If pantographs are stored one upon the other outside the

packing, use suitable frames. Take care, that exposed part (horns, etc.) will not be

damaged.

7. Cleaning

Use only acid-free cleaning agents for cleaning!

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 16 von 62 Revision 4

8. Assembly

8.1. General Information

The pantograph is manufacturer-adjusted according to your system requirements.

8.2. Transport and Storage

3

4

For transportation and lifting purpose without packaging use ONLY the 4 transport hooks

(1,2,3 and 4)

Attention!!! No one is allowed underneath the pantograph while it is being

transported!

8.3. Attachment to the Vehicle

The base frame has to be mounted tension free onto the vehicle roof. The base tube of

the lower frame has to be horizontal. If needed washers may be placed underneath the

insulators, to act as shims.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 17 von 62 Revision 4

8.4. High Voltage Connection

The high voltage connection is to be fastened to the connection board (1,2), which is

attached to the base frame. Before establishing the connection, please make sure that the

contact surface is cleaned and greased with contact grease.

8.5. Mounting of Compressed Air Connection

The compressed air connection to lift the pantograph is made by the high voltage

insulating tube at the position (1). The insulating tube must be connected to 18mm tube

on the roof.

After assembly the compressed air connections are to be checked for tightness.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 18 von 62 Revision 4

9. Start Up

9.1. Check List

Also refer to chapter #15

Before Start Up please check the following:

Check insulating distances to vehicle according to the technical data

(see chapter #3).

Assure that the screw connection of the high voltage connection is properly

fastened and well greased (see chapter #8.4).

Check the contact pressure (see chapter #13.4.2) of the pantograph according to

the technical data (see chapter #3).

Assure that the collector strips are seated friction free.

Check that the pan head can turn freely from the horizontal position

(see chapter #13.6).

Assure that the collector strips are parallel to the overhead wire.

Assure that the raising and lowering times are in accordance with the technical

data (see chapter #3).

Assure that the coupling rod rests on the resting bumper

Check the function of the overreach detection. (see chapter #13.8)

Attention!!! No one is allowed underneath the pantograph while adjusting the

overreach detection on the train.

The overreach detection is connected to a lowering function, the pantograph

will collapse if a certain height is detected.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 19 von 62 Revision 4

10. Maintanance

10.1 General Information

The single arm pantograph WBL85HR requires a minimum of maintenance.

At the regular maintenance intervals of the vehicles, the following procedures are Must

Change:

The required maintenance is influenced by the environmental and operational conditions,

so the operator has to adapt accordingly.

10.1.1 Trip Inspection (45days±3Days)

Visual inspection of carbon strips for break and wear; Exchange carbon strips if

necessary.(see chapter #10.2, #13.4.2 & #3)

Check Contact force according technical data (70N) (see chapter #10.2)

Check Raising and Lowering time according technical data (see chapter #3)

10.1.2 Inspection IA (90/135±3Days)

The Work carried out in TI inspection should be repeated in this schedule.

In addition,

Inspection of the pneumatic components for tightness.

Visual inspection of pan head springs and support spring of base frame for

deformation,rusting/cracks (see chapter #10.10)

10.1.3 Inspection IB & IC (180/270±3Days)

The Work carried out in IA inspection should be repeated in this schedule.

In addition

Visual inspection of cable with terminals of raising mechanism; grease cable if with

AtulTop 2000 (see chapter #10.8)

Visual Inspection of Shunts.(see chapter #10.9)

Inspection of All Pneumatic Valves for any leakages

Inspection of ADD Valve for any leakages, if any leakage open the valve and clean

Diapharm and re assemble

Functional check of Air Filter, any leakages or not draining

If any leakages or filter element turn to brown color replace the filter element,

Functional check of Pressure Regulator for any leakages, if any leakage replace

with seal Kit

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 20 von 62 Revision 4

10.1.4 Medium Overhauling (MOH) (18months)

The Work carried out in IC should be repeated in this schedule.

In addition,

Functional inspection of ADD (see chapter #10.12)

Functional inspection of ORD (see chapter #10.13)

Inspection of easy motion of plane bearings,exchange parts if necessary

Visual & Functional inspection of hydraulic oscillation dampers.(see chapter #10.5)

Visual Inspection of Air bellow drive for any damages / rubbing marks / deformations.

Exchange parts if any cut marks/deep rubbing /damages /deformations

Visual inspection of shunts (see chapter #10.9)

Functional inspection of Pneumatic parts,Exchange parts if necessary

Functional check of Air filter. (see chapter #10.11.1)

Functional check of Pressure regulator (see chapter #10.11.2)

Check for friction of ball bearings of base frame ,upper frame and coupling rod.

Replace ball bearings if necessary

Replace the filter element and O rings (Must Change)

Replace of IR kit in Pressure Regulator (Must Change)

Replace of Rubber bumper & Bellow of Parallel guide bar (Must Change)

All Air hoses must be replaced in MOH (Must Change)

Replace of Air bellow in every 2 nd MOH 36 months (Must Change)

Replace of Shunts in every 2nd MOH 36 months (Must Change)

Replace of Air filter in every 2nd MOH 36 months (Must Change)

Replace leaf spring on rocker box and support spring in base frame in every

2nd MOH 36 months (Must Change)

10.1.5 Intermediate overhauling (IOH) (6 yrs)

Work carried out in MOH should be repeated in this schedule, In addition

Replace of air bellow drive.(Must Change)

Replace of Air hose,Teflon insulating hose (Must Change)

Replace of ball joint of parallel guide bar (Must Change)

Replace hydraulic oscillation damper (Must Change)

Replace cable with terminals of raising mechanism (Must Change)

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 21 von 62 Revision 4

Change grooved ball bearings of base frame upper frame and Coupling rod

(Must Change)

Replace pneumatic control unit (Must Change)

Replace rocker box of pan head (Must Change)

Visual inspection of Cams (Lower Frame). Exchange if necessary

Clean all re used parts

Renew coating of coated parts

10.1.6 Periodical overhauling (POH) (12 yrs)

The Work carried out in Intermediate Overhauling (IOH) should be repeated in this

schedule. In addition

Replace of Cams on Lower Frame.(Must Change)

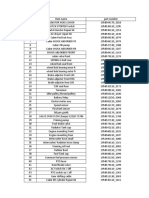

Inspection & Maintenance of WBL 85 HR Pantograph for AC Freight Electric Locomotive:

SL Every Every Every Every Every Every

Description

No TI IA IB IC MOH IOH

Visual inspection of carbon strips for

1 break, wear, Chipped off etc. Y Y Y Y Y Y

Exchange strips if necessary

2 Ensure tightness of all screw

X X X Y Y Y

connections as per torque list

3 Visual inspection of shunts condition

X X X Y Y Y

and connections

4 Visual inspection of damages/

cutting of shunt strains. Change

shunts in case more than 5% of wire

strains are broken.Whenever shunts X X Y Y Y Y

are require to replace, Clean contact

area and apply copper content

contact grease Molygraf TC-55

5 Check the contact force of the

pantograph according to the Y Y Y Y Y Y

technical data. Adjust if necessary

6 Check Raising and Lowering time,

should be within 6 to 15 Sec. Y Y Y Y Y Y

Adjust if necessary

7 Inspection of the pneumatic valves

for lock nut tightness and for any air X Y Y Y Y Y

leakages.

8 Visual inspection of pan head

springs/support spring in base frame

X X Y Y Y Y

condition for deformation, rusting,

cracks. Exchange if necessary

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 22 von 62 Revision 4

Every Every Every Every Every Every

SL Description TI IA IB IC MOH IOH

No

8 Visual inspection of pan head

springs/support spring in base frame

X X Y Y Y Y

condition for deformation, rusting,

cracks. Exchange if necessary

9 Inspection of the parallel guide bar

X X X Y Y Y

for free movement of the pan head.

Inspection of easy rotation of plane

10 X X X Y Y Y

bearings I-Gus bushes.

Visual inspection of hydraulic

11 dampers for any leakage of fluid/ X X X X Y Y

idle play.Exchange if necessary

Visual inspection of Teflon insulating

12 hose for any damage on surface. X X X X Y Y

Exchange if necessary

Functional inspection of hydraulic

dampers fix damper at one end and

13 hang 2kg weight at other end and X X X X Y Y

damper should open to max

extention in 1min ±10secs

Visual inspection of Teflon insulating

14 hose for any damage on surface. X X X X Y Y

Exchange if necessary

Visual inspection of Air hose for any X X X X Y Y

15 damages. Exchange if necessary

Visual inspections of Air bellow drive

for any damage / rubbing

16 marks/deformation. Exchange parts X X X X Y Y

if any cut marks / deep rubbing /

damages/deformations.

Visual inspection of steel wire cable

with terminal of raising mechanism

for any damage. Exchange If more

17 than ten single wires or one single X X X Y Y Y

braid broken /damaged.

Apply ATULTOP 2000 Grease on

Cable and Cam groove for cable.

Visual inspection of CAM for any

18 damages over cable rope guide X X X X Y Y

surface.

Check for friction of ball bearings of

base frame, upper frame and X X X X Y Y

19 coupling rod. Exchange if

necessary

Functional check of Pneumatic parts

Pressure Regulator,Safety Valve, X X X Y Y Y

20 Throttle valves.

Exchange if necessary

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 23 von 62 Revision 4

Every Every Every Every Every Every

SL Description

TI IA IB IC MOH IOH

No

Functional check of Air Filter

Replace the element & ‘O’ Ring

when one of the followings occurs.

21 a. Pressure drop reaches 0.1 MPa. X X X Y Y Y

b. Element operates for 1.5 years.

c. When the filter element become

brownish color

Functional check of Pressure

22 Regulator. X X X Y Y Y

Exchange IR Kit if Necessary

23 Functional inspection of ADD X X X Y Y Y

24 Functional inspection of ORD X X X Y Y Y

a. Must Change parts of Pantograph WBL85HR: 1st MOH (18Months)

Part No./Drawing

Sl.No Description No/Size Qty /Assly Units

01 SM Bumper 03 Nos

02 Filter Element AF30P-060S 01 Nos

03 IR Kit for Pressure Regulator KT-IR3000 01 Nos

04 Air hose d10/8 PA12W Black 0.4 mtrs

05 Air hose d6/4 PA12W Black 0.6 mtrs

06 Sealing Washer 4-V15.5090 02 Nos

07 Spare KIT for ADD Valve XC113443V-22383 01 Nos

08 Bellow Best Nr. 1407AW 01 Nos

09 Cable Tie 7.5x180 PA 6.6(black) 02 Nos

b. Must Change parts of Pantograph WBL85HR: 2nd MOH (36Months)

Part No./ Drawing No/

Sl.No Description Size Qty /Assly Units

01 SM Bumper 03 Nos

02 Support spring incl.shrink tube 3-G11.4488 04 Nos

03 Air Filter I-AF30-F02 BD 01 Nos

04 IR Kit for Pressure Regulator KT-IR3000 01 Nos

05 Air hose d10/8 PA12W Black DIN 74324 0.4 mtrs

06 Air hose d6/4 PA12W Black DIN 74324 0.6 mtrs

07 Sealing Washer 4-V15.5090 02 Nos

08 Spare KIT for ADD Valve XC113443V-22383 01 Nos

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 24 von 62 Revision 4

Part No./Drawing No/

Sl.No Description Size Qty /Assly Units

09 Throttle Valve (Raising) T1000C2800 01 Nos

10 Throttle Valve (Lowering) T20C2800 01 Nos

11 3/2 Way Valve V61B4D7A -X5090 G1/4” 01 Nos

12 Bellow Best Nr. 1407AW 01 Nos

13 Cable Tie 7.5x180 PA 6.6(black) 02 Nos

14 Air Bellow M31103 01 Nos

15 Shunt 4-S00.3579 04 Nos

16 Shunt 4-S00.4999 04 Nos

17 Shunt 4-12800.5848 10 Nos

18 Leaf Spring 4-1318.2224 04 Nos

c. Must Change parts of Pantograph WBL85HR: IOH (6Years)

Part No./ Drawing No /

Sl.No Description Size Qty /Assly Units

01 SM Bumper 03 Nos

02 Support spring incl.shrink tube 3-G11.4488 04 Nos

03 Air Filter I-AF30-F02 BD 01 Nos

04 IR Kit for Pressure Regulator KT-IR3000 01 Nos

05 Air hose d10/8 PA12W Black DIN 74324 0.4 mtrs

06 Air hose d6/4 PA12W Black DIN 74324 0.6 mtrs

07 Sealing Washer 4-V15.5090 02 Nos

08 Spare KIT for ADD Valve XC113443V-22383 01 Nos

09 Throttle Valve (Raising) T1000C2800 01 Nos

10 Throttle Valve (Lowering) T20C2800 01 Nos

11 3/2 Way Valve V61B4D7A -X5090 G1/4” 01 Nos

12 Bellow Best Nr. 1407AW 01 Nos

13 Cable Tie 7.5x180 PA 6.6(black) 02 Nos

14 Air Bellow M31103 01 Nos

15 Shunt 4-S00.3579 04 Nos

16 Shunt 4-S00.4999 04 Nos

17 Shunt 4-12800.5848 10 Nos

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 25 von 62 Revision 4

Part No./Drawing No/

Sl.No Description Size Qty /Assly Units

18 Leaf Spring 4-1318.2224 04 Nos

19 Air hose 3-B14.5360 01 Nos.

20 Teflon Hose 4-B09.4724 01 Nos.

21 Ball Joint ISO 12240-4 K GARSW

01 Nos

10 R C3

22 Hydraulic Damper 3-7432 02 Nos

23 Cable with Thread fitting SB-027639 01 Nos

24 Ball Bearing (base bearing) 2RS 6206 90% KLB

04 Nos

TOPAS NB152 DIN625

25 Ball Bearing (upper bearing) 2RS 6303 90% KLB

04 Nos

TOPAS NB152 DIN625

26 Ball Bearing (coupling rod 2RS 6006 90% KLB

04 Nos

bearing) TOPAS NB152 DIN625

27 Pneumatic Control Unit 1-V15.12520 01 unit

28 Rocker Box 2-W08.12507 02 Nos

d. Must Change parts of Pantograph WBL85HR: POH (12yrs)

Part No./Drawing

Sl.No Description No/Size Qty /Assly Units

01 All the items mentioned in IOH Kit (c) Sl No.01-28

02 Cam 2-UN.12400 02 Nos.

10.2 Collector Strip

Determine the intervals between visual inspections, please consider the following:

Anticipated operating and wear life.

Extreme weather conditions (ice, snow, rain, sleet, etc.)

The wear of both collector strips should happen evenly if not check the adjustment of the

parallel guide bar (see chapter #13.6) or if parts of the pan head or the parallel guide bar

are damaged.

When the collector strips wear down to the thickness indicated in the sketch below, they

must be replaced.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 26 von 62 Revision 4

They always have to be replaced as a pair.

The contact surface of the connection bracket has to be cleaned and greased with contact

grease.

After the installation the contact pressure (see chapter #13.4.2) has to be checked.

10.3 Bearings

10.3.1 Grooved Ball Bearings

When the grooved ball bearings are to be changed, the space of the ball bearings needs

completely to be filled with grease in order to avoid condensation.

Grease bearing seats before mounting new bearings in order to prevent the parts from

corrosion.

10.3.2 Plane Bearings

All plane bearings of pantograph are maintenance free. The plane bearings are:

plastic bushings

If plane bearings are slow moving, determine and eliminate the cause of this slowness.

Damaged plane bearings need to be replaced.

Dirty plane bearings require cleaning.

Grease bearing seats before mounting new bearings in order to prevent the parts from

corrosion.

10.4 Screw Joints

All mounting screws are to be checked for damage and tight fit, especially:

Mounting screws for the collector strips.

Pan Head connections.

Shunts.

Attention!!! Hex head nuts according DIN 985 / EN ISO 10511 and lock washers according

BN 208010-8 must be replaced by new ones after dismounting!

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 27 von 62 Revision 4

10.4.1 Torque for Stainless Steel Screw Connections

The table below is valid for screw connections of strength class A2-70 with using an

assembly lubricant.

Thread Size [mm] Torque [Nm] Thread Size [mm] Torque [Nm]

M3 1,0 M10 30,0

M4 1,8 M12 50,0

M5 3,5 M14 80,0

M6 6,0 M16 120,0

M8 15,0 M20 250,0

10.4.2 Screw bonding and Screw sealing

Some screw connections have to be secured with a high strength thread locker or have to

be sealed with a thread sealant.

Please see in the illustrated spare parts catalogue (see chapter #15) for these

connections.

10.5 Hydraulic Oscillation Damper

For operational test of hydraulic oscillation dampers, please disassemble. No idle play is

allowed between the draw- and the pressure stage. No liquid withdrawal should be visible.

During Every 2nd MOH(after 3yrs) the dampers have to be checked for functionality

Close the damper fully as shown in photo 1

Apply 2 kgs of load as shown in photo 2 and damper starts open freely towards down

Damper should opens to max limit in 1min ±10secs

Repeat this test for 3-4 times, if the time achieved is within the limits damper is working

Photo 1 Photo 2 Photo 3

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 28 von 62 Revision 4

10.6 Insulators, Insulating Tubes

Dirty insulators and insulating tubes need to be cleaned.

10.7 Bellow Drive

The bellow drive is maintenance free.

Check bellow drive for operation during each main inspection by lifting and lowering the

pantograph. If needed, replace damaged or bent parts.

The cables are to be greased with ATULTOP 2000/ MolygrafCC2.

10.8 Cable with Terminals of Raising Mechanism

The cable with terminals of the raising mechanism needs to be checked for breaks of

wires and braids.

The cable needs to be changed if:

more than 10 single wires or/and

1 single braid are broken.

For this examination the pantograph needs be fully raised in order to do a visual

inspection of the whole cable.

Further the cable needs to be checked if it is well greased, if necessary grease the cable

on the contact surfaces to the cam.

10.9 Shunt Connections

The shunts need to be checked for breaks of the wires and braids.

The shunts need to be changed if:

more than 5% of the wires are broken.

Before fixing new shunts the contact areas must be cleaned and greased with contact

grease.

10.10 Pan Head Springs

The pan head springs have to be checked for any deformation and corrosion. Defective

parts have to be changed.

10.11 Pneumatic Control Box

During each IC/MOH inspection the following parameters needs to be attended in

pneumatic control unit

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 29 von 62 Revision 4

Functional check of Safety Valve

Replacement of filter element

Functional test of pressure regulator, Replace seal kit

10.11.1 Functional check of Safety Valve

The safety valve needs to be tested by increasing the pressure through the

pressure regulator.

After completion of test, adjust contact pressure to required level.

10.11.2 Replacement of Filter Element

Replace the Filter element,‘O‘ Rings when one of the followings occurs

Pressure drop reaches 0.1 Mpa. or

Element operates for 1.5 years.

When Filter Element turns brownish/black color (as shown in Photo 2)

For filter element replacement , proceed according to the following process:

Pull button towards down as shown in filter bowl

Rotates the bowl to either right or left 45° as shown and the bowl is detached

Rotate baffle anti clock wise direction to unscrew and remove element assembly

Replace element with new one, Assemble the element assembly and bowl in

reverse direction

Whenever replacing filter element, replace ‘O’ ring of the bowl also

New Filter Element Filter element for replacement

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 30 von 62 Revision 4

Filter Element replacement Steps:

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 31 von 62 Revision 4

10.11.3 Functional test of Pressure Regulator

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 32 von 62 Revision 4

For Functional test of Pressure Regulator, proceed according to the

following process:

Fix the pressure gauges to in let anrd out let of Pressure regulator as shown

Connect the system to air line with solenoid valve,supply air of pressure 7 bar

Control the in let pressure to 5bar and check the oulet pressure gauge the out let

pressure should be same as set pressure.

Maintain same pressure for 5mins, and there should not be any variation in out let

pressure (means outlet pressure should be same as set pressure)

Repeat the procedure with different pressure settings.

If there is any change in set and out let pressure,check for leakages from Pressure

Regulator, replace pressure regulator seal kit

Maintain Inlet pressure between 6-7bar during testing

Circlip

Screw

Remove all the four Screws

Open the Valve

Remove Circlip

Replace all seals

10.12 Auto Drop Device (ADD)

The auto drop device (ADD) shell be checked every year for function.

Attention!!! No one is admitted underneath the pantograph, while testing the Auto

Drop Device.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 33 von 62 Revision 4

Test procedure:

Fix the pantograph in resting position.

Give the raising signal.

Open the pneumatic tube connection from the carbon strip.

The rapid ventilation valve must react.

After the test fix the pneumatic tube to the carbon strip and check proper raising.

10.13 Over Reach Detector

The over reach detector shall be checked during every year inspection

Check the wear of the 3/2 Way valve and the clamp part 1.

If the wear of the roller ball is high and not able to turn easily / cam on clamp part 1

shows too much wear they have to be replaced.

Test Procedure:

Fix the pantograph in resting position

Give the raising signal

Check the Overreach detection, means the pantograph is Lowered when the

adjusted height of the pantograph is exceeded

Measure the height from where the pantograph is Lowered, if necessary adjust the

height.

After completion of test,Check for raising and lowering

Attention!!!!

For normal working of pantograph, valve has to reset manually on roof top,

Push the lever towards Cam for resetting the Valve

Pantograph will starts rising after resetting of the valve only

Cam

Valve re-setting 3/2 way valve

Direction

Valve re-setting Lever

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 34 von 62 Revision 4

10.14 Auxiliary Material

The following auxiliary material has to be used for maintenance and repairs:

Description Product Manufacturer

Grease Atul Top 2000 / Molygraf CC2 Agip Schmiertechnik

GmbH / Fotuna Associates

Contact grease Molykote HCS plus / Moygraf Dow Corning / Fotuna

TC-55 Associates

Assembly lubricant Ceramo Paste Metallit GmbH

High strength thread Weicon Lock AN 306-38 or Weicon Lock, Loctite

locker Loctite 270

Thread sealant Loctite 577 Loctite

Grease, contact grease and assembly lubricant are specified in chapter #14.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 35 von 62 Revision 4

11. Troubleshooting – Trouble List

11.1 General Information

For adjustments: see also chapter adjustment procedures.

11.2 Trouble List

Defect Reason(s) Correction

Pantograph does not raise Air bellow damaged. Check air bellow, exchange

or lower. broken air bellow. (also see

defect: Bellow drive

defective).

Cable torn Replace cable. (also see

defect: Cable torn)

Pneumatic control unit Exchange pneumatic

defective. control.

Pneumatic tube defect. Replace pneumatic tube.

Hydraulic oscillation Replace hydraulic

dampers between base oscillation dampers.

frame and lower frame

defect.

Inner friction of pantograph Check pantograph for

is too high. damages, and eliminate

damages.

Replace defective

bearings.

Auto drop device is Check auto drop device,

activated. especially carbon strips for

air leakage or damage.

Change defective parts.

Frequent interruption of Contact pressure is poorly Check contact pressure

current transmittal (strong adjusted. and adjust. (see chapter

arcing). #13.4.2)

Inner friction of pantograph Check pantograph for

is too high. damages, and eliminate

damages.

Replace defect bearings.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 36 von 62 Revision 4

Defect Reason(s) Correction

Frequent interruption of Carbon strips show strong Replace carbon strips.

current transmittal (strong breakage.

arcing).

Pan head springs are slow Clean bearings, replace

motion. defect bearings.

Parallel guide bar is poorly Adjust turning capacity of

adjusted (pan head doesn‘t pan head. (see chapter

turn freely from horizontal #13.6)

position).

Uneven wear of carbon Parallel guide bar is poorly Adjust turning capacity of

strips. adjusted. pan head. (see chapter

#13.6)

Current flashover from Insulators between base Clean insulators between

pantograph to vehicle roof. frame and vehicle roof are base frame and vehicle.

dirty.

Cable torn. Cables are not greased Replace cable and grease

in area of cam disk with

non-water-soluble grease.

Bellow drive defective. Screws are loose. Tighten screws.

Hose line leaking. Exchange leaking hose

with new hose line.

Bellow cylinder leaking. Exchange bellow cylinder;

find reason for leakage and

check bellow joints.

Excessive air leakage. Pressure-regulator Exchange pressure

defective (normal air regulator.

leakage of pressure

regulator < 2 l / min.).

Increase of contact Pressure regulator Exchange pressure

pressure without previous defective. regulator.

adjustment of pressure

regulator.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 37 von 62 Revision 4

12. Repairs

12.1 General Information

Prior to disassembling the pantograph, please study the illustrated spare parts catalogue

(see chapter #15) be informed about the relationship of the individual component parts.

Deformed and defective component parts are to be changed.

Bearing alignment is only accurately measurable on a measuring table.

Schunk Bahn- und Industrietechnik GmbH can take no responsibility for workmanship at

repairs and maintenance carried out by other companies.

12.2 Dismounting of Pantograph from Top of Vehicle Roof

Lower pantograph into resting position.

Attention!!! Make sure that current in overhead is switched off and grounded!

Detach electrical connections between pantograph and vehicle.

Disassemble the high voltage insulating tubes between pantograph and vehicle.

Secure pantograph at the transport hooks.

Detach pantograph from insulators.

Lift pantograph off vehicle roof only by using transport hooks.

12.3 Complete Disassembly of Pantograph

Lower pantograph.

Detach shunts and collector strips.

Detach rocker boxes from apex tube.

Detach parallel guide bar.

Detach apex tube from upper Frame.

Detach pan head bearing from upper frame.

Detach hydraulic oscillation dampers from lower frame and base frame.

Detach coupling rod from upper frame and base frame.

Detach upper frame from lower frame.

Detach air bellow drive.

Detach lower frame from base frame.

Detach pneumatic control.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 38 von 62 Revision 4

12.4 Repairs of Component Parts

12.4.1 Free Bearing of Base Frame and Upper Frame

Instructions:

Remove both covers (1) (e.g. by using a screwdriver).

Push bearing (2) out of bearing housing by means of a sleeve, which only rests on

the outer ring of the grooved ball bearing.

Detach both external retaining rings (3) by using a retaining ring plier.

Detach both insulating rings (4).

Push off the grooved ball bearings (7) from bearing shaft (5), and replace by new

ones if necessary.

Replace the complete bearing shaft (5), including the insulating bushing (6).

Assembly of the bearings in reversed order - pack space between grooved ball

bearings with grease.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 39 von 62 Revision 4

12.4.2 Fixed Bearing of Base Frame, Coupling Rod and Upper Frame

Instructions:

Remove both covers (1) (e.g. by using a screwdriver).

Detach both internal retaining rings (2) by using a retaining ring plier.

Push bearing (3) out of bearing housing by means of a sleeve, which only rests on

the outer ring of the grooved ball bearing.

Push off the grooved ball bearings (6) from bearing shaft (4), and replace by new

ones if necessary.

Replace the complete bearing shaft (4), including the insulating bushing (5).

Assembly of the bearings in reversed order - pack space between grooved ball

bearings with grease.

12.4.3 Pan Head Rocker Boxes

Detach collector strip supports from rocker boxes

Detach rocker suspension, leaf springs and spring supports from rocker boxes.

Check parts and replace defective ones.

Assembly in reversed order.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 40 von 62 Revision 4

12.4.4 Shunts

For the assembly of new shunts proceed according the following procedure:

clean the contact areas,

grease contact areas with contact grease,

install shunts and align them according to the following criteria:

The shunts may neither contact each other, nor may they touch other components

of the pantograph.

The shunts must hang loosely and are not allowed to be strained.

In order to achieve this, the shunts must be turned into the appropriate position, if

necessary also the cable sockets have to be bent.

To check the adjustment the pantograph must be lifted and lowered over the whole

working height, if necessary the shunts need to be readjusted.

12.4.5 Bellow Drive

4-B0B.6957

Detach bellow drive, check parts and replace defective ones.

Fixing of bellow to pantograph.

Attention!!! Do not over torque the cable, as it otherwise may jam the bellow.

Tighten the cable (1) evenly and adjust bellow (see chapter #13.3).

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 41 von 62 Revision 4

12.4.6 Other Component Parts

If the pantograph is damaged, all components need to be checked very carefully and

replaced if needed.

Parallel guide bar including ball joints.

Upper frame including diagonal cables and bearings for pan head.

Coupling rod.

Lower frame including hydraulic oscillation dampers, bolt for parallel guide bar and

cam.

Base frame including support spring and rubber bumpers.

Screw connections.

Plane bearings.

12.4.7 Surface Coating

As a minimum standard for surface protection of coated parts we recommend powder

coating according the following procedure.

12.4.7.1 Pre-Treatment

Clean surface from oil, grease and other dirt. Sandblast steel parts according to ISO

8501-1 grade SA 2 ½ in order to remove rust and foreign particles. Afterwards the surface

has to be cleaned from dust.

Roughen aluminium by grinding, then clean surface from dust.

12.4.7.2 Finishing Paint

Powder paint on polyester base:

Binder: Polyester

Pigment: Titanium dioxide, pigments giving colour

Hardener: Triglycidilisocyanurate (TGIC)

Total layer thickness: min. 80μm

Colour: RAL 7001

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 42 von 62 Revision 4

12.4.7.3 Touch Up Paint

To repair smaller damaged areas of powder coated surface we recommend the following

procedure:

Clean parts from oil, grease and other dirt.

Grind surfaces with sandpaper.

Clean parts from dust.

Paint with ground layer based on synthetic resin.

After drying, paint with a finish coat based on synthetic resin, colour according to

requirements.

Attention!!! Current connections, bearing seats and threads MUST not be painted!

12.5 Re-Assembly after complete Disassembly

If the pantograph had been completely disassembled, the re-assembly is to be conducted

as follows:

Mount free bearings and fixed bearings for lower frame as well as rubber bumper

to the base frame.

Attach cam discs to lower frame.

Mount lower frame to base frame.

Mount pneumatic control to base frame.

Attach bellow drive to base frame.

Mount cable with terminals to lower frame and air bellow and secure with lock nuts.

Assemble coupling rod (bearing, calibration) and mount to base frame.

Install bearings of upper frame.

Mount upper frame to lower frame, and coupling rod to upper frame.

Mount diagonal cables to upper frame and tighten (caution during tightening, upper

frame may not distort).

Mount pan head bearing and apex tube to upper frame.

Install springs supports, leaf springs and rocker suspension into the rocker boxes.

Install collector strip supports on to the rocker boxes.

Attach rocker boxes to the apex tube.

Attach collector strips and shunt assemblies.

Assemble parallel guide bar.

Attach parallel guide bar between lower frame and pan head mount.

Attach air hose from pneumatic control to bellow.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 43 von 62 Revision 4

Attach air hose from pneumatic control to pan head.

Intermediate Check - verify tightness of all screws.

Adjust pantograph (see chapter #13).

Attach hydraulic oscillation dampers between lower frame and base frame.

Final inspection on pantograph.

Mount pantograph to vehicle roof.

Establish electrical connection between pantograph and vehicle.

Connect high voltage insulation tube from the pneumatic control to the vehicle roof.

Before operation follow instructions of checklist (see chapter #9.1).

13. Adjustment Procedures

13.1 General Information

Each pantograph had been calibrated by the manufacturer.

Adjustment works are to be carried out in the following order:

Adjust coupling rod and resting position

Adjust resting bumper

Adjust the air bellow drive

Adjust pneumatic control

Adjust curve of contact pressure

Adjust turning capacity of pan head

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 44 von 62 Revision 4

13.2 Adjustment of Coupling Rod and Resting Position

The resting position of the pantograph is adjusted through the coupling rod (1).

Upper Frame (3)

Coupling Rod (1)

Lower Frame (2)

Lock Nut (5)

Rubber Bumper (4)

Procedure:

Loosen the lock nuts (5)

Adjustment is made by turning the coupling rod tube (1).

After adjustment, tighten lock nuts (5).

Inspection:

Lower the pantograph.

Check the height in lowered position.

The lower frame (2) and the upper frame (3) have to rest on the resting bumpers

(4).

Attention!!! By adjusting the length of the coupling rod (1), the geometry of the

pantograph has changed as well, therefore check the curve of the

contact pressure and adjust if necessary.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 45 von 62 Revision 4

13.3 Adjusting the Bellow Drive

2 1 3

±5mm

4-B0B.6957

If fine tuning is required, proceed as follows:

Lower pantograph. Bellow has to be completely without pressure.

Loosen lock nuts (5) on both sides of the wire rope.

Strain the wire rope (1) with the hex nuts (2) that bellow (3) moves up and down as

shown in the sketch.

Attention!!! If you strain the wire rope, you have to fix the terminals of the wire

rope means that the wire rope can not be pivoted ore turned off!

Secure with lock nuts (5).

Final inspection of the fine tuning through raising and lowering of the pantograph.

Check the ±5mm motion of the cylinder support (4) again.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 46 von 62 Revision 4

13.4 Adjustment of Pneumatic Control

The pneumatic control has to be connected to the air bellow on the pantograph and to air

supply of the vehicle or from workshop. The pantograph has to be mounted on the vehicle

or to appropriate mounting legs in the workshop.

If the pneumatic control has to be adjusted complete, the following things have to be

done before:

Pressure regulation valve (1): Unscrew adjustment screw complete by turning

counter-clockwise.

Throttle valve (2): Is for the adjustment of the raising time. Unscrew adjustment

screw complete by turning counter-clockwise.

Safety valve (3): Screw in adjustment screw complete by turning clockwise.

Throttle valve (4): Is for the adjustment of the lowering time. Screw in adjustment

screw complete by turning clockwise

Quick exhaust valve (5): Is for the adjustment of the quick lowering. Screw in

adjustment screw complete by turning clockwise.

5

1

4

3

After each replacement of sliding strips the contact pressure needs to be verified.

The value of the static contact pressure can be taken from the technical data (see chapter

#3).

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 47 von 62 Revision 4

13.4.1 Adjust Safety valve (3)

Switch on compressed air.

The adjustment screw of the pressure regulation valve (1) has to be screwed in

slowly (turning clockwise) until the static contact force is 25 N higher than

indicated in the technical data (see chapter #3). Check with a spring scale.

Attention!!!: Don’t turn the adjustment screw of the pressure

regulation valve too fast, otherwise the pantograph will raise too

fast and may be damaged.

Slowly unscrew (turning counter-clockwise) the adjustment screw of the safety

valve (3), until light air outlet occurs.

Increase the static contact pressure slowly and the safety valve (3) latest has to

open completely at static contact force plus 50 N.

Secure adjustment screw with thread sealant.

13.4.2 Adjust contact pressure

The adjustment screw of the pressure regulation valve (1) has to be unscrewed

(turning counter-clockwise), until the contact pressure agrees with the value in the

technical data (see chapter #3). Check contact pressure with a spring scale.

Measurement of contact pressure with spring scale

Value 1: Measuring of contact pressure from highest working position with

slow descending motion into resting position.

Value 2: Measuring of contact pressure from resting position with slow

ascending motion into the highest working position.

Results: (Value 1 + Value 2)/2 = Average Value = Contact Pressure

Friction: Difference of contact pressure between Value # 1 and Value # 2

(ideal value lower than 20 N)

If the difference of the contact pressure is greater than 40 N, determine the reason

(e.g. defective component part, dirt in the bearings, etc.) and have it corrected.

13.4.3 Adjust raising time

Screw in (turning clockwise) complete Adjustment screw of throttle valve (2).

Switch on compressed air.

Unscrew (turning counter-clockwise) Adjustment screw of throttle valve (2) slowly,

until the raising time agrees with the value in the technical data (see chapter #3).

Attention!!!: Don’t turn the adjustment screw of the throttle valve

too fast, otherwise the pantograph will raise too fast and may be

damaged.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 48 von 62 Revision 4

13.4.4 Adjust Lowering time

Attention!!!: Make sure that nobody is below the pantograph.

Switch off compressed air.

The adjustment screw of the throttle valve (4) has to be unscrewed slowly (turning

counter-clockwise) so the pantograph lowers and touches down easily to the

support springs on the base frame.

Attention!!!: Don’t turn the adjustment screw of the throttle valve

too fast, otherwise the pantograph will lower too fast and may be

damaged.

The lowering time has to be in accordance with the upper limit mentioned in the

technical data (see chapter #3).

Switch on compressed air.

Check that pantograph raises in the time which agrees with the value in the

technical data (see chapter #3).

Switch off compressed air.

Under repeated raising and lowering of the pantograph gradual unscrew (turning

counter-clockwise) the adjustment screw of Quick exhaust valve (5) until Quick

exhaust valve (5) responds short after switching off compressed air. The Quick

exhaust valve (5) should respond so that pantograph lowers quickly for a distance

of the insulation distance shown in the technical data (see chapter #3). Raise and

lower the pantograph more times. The total lowering time now should lie in the

lower range of the value in the technical data (see chapter #3) and touch down on

the support bumpers on the base frame should happen as soft as possible.

Attention!!!: Don’t turn the adjustment screw of the Quick

exhaust valve too fast, otherwise the pantograph will lower too

fast and may be damaged.

After Adjustment, tighten all counter nuts of pressure regulation valve (1) and

throttle valve (2). Lock adjustment screws of safety valve (3) and Quick exhaust

valve (5) with thread sealant.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 49 von 62 Revision 4

13.5 Adjustment Curve of Contact Pressure

The contact pressure should be nearly constant over the entire working range.

1 4

3

Instructions:

4-B0B.6957

Loosen the four screw connections (3).

Calibration is done by means of adjustment screw (1) on the cam disc (4) of the

lower frame.

Adjustment through:

Turns clockwise = contact pressure increases in the lower working range

Turns counter clockwise = contact pressure decreases in the lower working range

Adjustment is required until curve of contact pressure is nearly constant over the entire

working range. Verification with spring balance or with the SCHUNK pantograph contact

pressure measuring gauge KM 11.

Then tighten lock nuts (2) and screw connections (3).

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 50 von 62 Revision 4

13.6 Adjustment of Turning Capacity of Pan Head

The pan head has to be able to move from its horizontal position in either direction over

the entire length of its working height range. The turning scope of the pan head in the

median working height should be the same in both directions.

The adjustment is made by adjusting the length of the parallel guide bar.

3

1

2

4-W0B.12732 4

Instructions:

Remove the parallel guide bar from lower frame.

Loosen lock nut (2).

Adjustment is accomplished through screwing in or screwing out of the parallel

guide bar at the rod end (1).

After adjustment tighten lock nut (2) and re-check adjustment.

Fix bellow (4) again with cable tie (3).

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 51 von 62 Revision 4

13.7 Adjustment of Overreach detection

The overreach detection should drops the pantograph when the Pantogarph raises

over a set height. If he does, a signal should be indicated into the Vehicle to a

pressure switch.

The adjusting is made by moving the 3/2 Way valve (1) on the base frame and

twisting and moving the Clamp (2) on the lower frame.

Attention!!! No one is allowed underneath the pantograph while adjusting the

overreach detection on the train. The overreach detection is connected to a

lowering function, the pantograph will collapse if a certain height is detected.

Instructions:

Pantograph is in resting position.

Fasten 3/2 way valve (1) at the base frame, that the area before the cam on the

clamp part 1 (2) is not affected with its rollerball. Distance should be about 1mm.

Fasten clamp part 1 (2) on lower frame, that the angle between rollerball of the 3/2

way valve and the cam on clamp part 1 (2) is about 48 degrees.

Lift the pantograph.

Check that Pantograph lowers from the set height. if not:

Check the 3/2 way valve (1) that the contact travel of it (4 -5mm) is reached. If not,

readjust and lift again.

Check the cam of the clamp part 1 (2) switches the 3/2 way valve (1) if the

pantograph reaches the wished height. If not,

Twist the clamp part 1 (2) on the lower frame in the direction you need and lift

again.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 52 von 62 Revision 4

14. Appendix

14.1 Product Data Sheets

14.1.1 Ceramo Paste Metallit GmbH, Art.-Nr:394 020

Area of Application

Application

Product Data

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 53 von 62 Revision 4

Safety text

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 54 von 62 Revision 4

14.1.2 Autol Top 2000 of Agip Schmiertechnik GmbH

Description:

Range of Application

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 55 von 62 Revision 4

Remarks

Physical properties

14.1.3 Cramolin Paste 100 HS of ITW Chemische Produkte GmbH

14.1.4 Description

Copper based greasy Paste with high Melting Point.

Cramolin Paste 100 HS is a viscous copper based grease ensuring perfect current flow

through current-carrying connections of all kinds.

The paste exhibits outstanding adherence at high ambient temperatures and retains its

consistency when temperature varies.

It protects contact surfaces from soiling, incrustations and harmful mechanical stress.

It is chemically neutral towards engineering materials.

Date: 15.01.09 Prepared: Pardeller Approved: Santner

Schunk Bahn- und Industrietechnik GmbH

4-12717-1-e Page 56 von 62 Revision 4

Application

To permanently ensure perfect current flow through current-carrying connections of all

kinds.

Particularly suitable for use on contact surfaces subjected to high temperatures.

Also reliable to prevent corrosion, incrustations and soiling on any contact metals.

Technical Data

Colour: pink-metallic