Professional Documents

Culture Documents

Hydraulic System Specification

Uploaded by

Petre LacatusuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic System Specification

Uploaded by

Petre LacatusuCopyright:

Available Formats

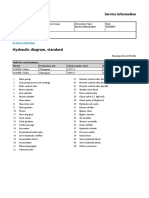

35.

1 Specification

Sec. 35.1 - pg. 1/21

Hydraulic System - Specifications

TD 60/70/80/90/95 D

Filter

Type Paper cartdridge

Location Mounted on pump body on suction side

Pump

Type Gear type with oil suction from transmission casing

Location Behind timing gear cover

Direction of rotation (as seen from drive side) Clockwise

Control Driven by timing gears

Maximum pressure (bar) 210

Pressure relief valve

Location On Auxiliary Control Valve

(discharge in top cover )

Operating pressure (bar) 190 ÷ 195

Sec. 35.1 - pg. 2/21

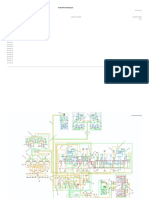

High Pressure System - Layout

Static oil

Oil in suction

Tractor brake circuit oil (brakes off)

Pressurised oil

Exhaust oil flow

1. Delivery line to control valve (3).

2. Trailer brake control valve.

3. Auxiliary control valves.

4. Auxiliary control valve lines.

5. Trailer brake control valve line.

6. Lift control valve.

7. Suction line.

8. Oil filter.

9. Hydraulic pump.

Sec. 35.1 - pg. 3/21

High Pressure System - Components

Oil outlet to high pressure

circuit

Oil intake from rear

transmission box

Sec. 35.1 - pg. 4/21

High Pressure System - Components

TD 60 - 70 D TD 80 - 90 - 95 D

Model BOSCH BOSCH

Type mechanical pump mechanical pump

Displacement 14.3 cc 19.5 cc

Nominal flow rate 35.5 l/min (2300 rpm) 45.38 l/min (2500 rpm)

Direction of rotation counter-clockwise counter-clockwise

Sec. 35.1 - pg. 5/21

High Pressure System - Components

1 Front cover 8 Rear cover 15 Bolt

2 Cover seals 9 Driving shaft seal 16 Washer

3 Pump body 10 Spacer 17 Key

4 Gear support 11 Driving shaft seal 18 Bushing

5 Gear shafts 12 Snap ring 19 Safety washer

6 Gear support 13 Safety washer 20 Nut

7 Bushing 14 Nut

Sec. 35.1 - pg. 6/21

High Pressure System - Components

SECTIONAL VIEW

PERSPECTIVE

EXPLODED VIEW

HYDRAULIC DIAGRAM

Sec. 35.1 - pg. 7/21

Lift Control Valve - Cross Section PERSPECTIVE EXPLODED VIEW

Sec. 35.1 - pg. 8/21

Lift Control Valve - Perspective SECTIONAL VIEW EXPLODED VIEW

Sec. 35.1 - pg. 9/21

Lift Control Valve - Exploded View PERSPECTIVE SECTIONAL VIEW

Sec. 35.1 - pg. 10/21

Lift control valve - in neutral

Static oil

High pressure

Discharge

Sec. 35.1 - pg. 11/21

Lift control valve - Raising

Static oil

High pressure

Discharge

Sec. 35.1 - pg. 12/21

Lift control valve - Lowering

Static oil

High pressure

Discharge

Sec. 35.1 - pg. 13/21

Lift Control Valve - In Neutral

Static oil

Pump delivery

Oil outlet

Sec. 35.1 - pg. 14/21

Lift Control Valve - Cylinder Safety Valve Operation

When the pressure of the static oil exceeds 215 bar, as a result of the implement

jolting, the valve activates by draining off the oil and resetting normal pressure.

The linkage, detecting this pressure drop, moves the pin to delivery, returning to

the initial height.

Static oil

Pump delivery

Oil outlet

Sec. 35.1 - pg. 15/21

Lift Control Valve - Raising

Neutral

Static oil

Pump delivery

Oil outlet

Sec. 35.1 - pg. 16/21

Lift Control Valve - Lowering

Neutral

Static oil

Pump delivery

Oil outlet

Sec. 35.1 - pg. 17/21

Legend

1 Control valve pin 17 Implement descent speed

2 Control valve pin seat adjustment valve

3 One-way valve and spring 18 Spring

4 Control valve pin spring 19 Descent speed adjustment pin

5 Control valve 20 Cylinder delivery union

6 O-ring and antiextrusion ring 22 Ball

8 Case

9 Pilot valve

10 Control valve and spring T Lift cylinder

11 Speed adjustment valve and T3 Speed valve oil outlet choke

spring V Overpressure valve

13 Cap with speed valve P Pump

14 O-ring F Filter

15 Cylinder safety valve F1 Control valve pin choke

(210÷215 bar)

Sec. 35.1 - pg. 18/21

Control Valve Pin Seal Control

Insert the control valve pin (2), seat (3) and spring (4)

on tool 293982 (1).

Tighten the cap (5) on the tool.

Check that the control valve pin slides in the seat.

Sec. 35.1 - pg. 19/21

Control Valve Pin Seal Control

Fit the tool and pin (2) on the pump (3).

Connect a pressure gauge (1) to the tool.

Using the pump, tighten the screw (4) on the tool

until the outgoing oil flow stops.

Zero-set the pressure gauge and tighten

the screw by a further 1.8-2 mm.

Sec. 35.1 - pg. 20/21

Control Valve Pin Seal Control

Using the pump, bring the pressure to 245 bar.

Check that the pressure takes more than six seconds

to drop from 196 to 98 bar.

If not, replace the pin and the control valve seat.

Sec. 35.1 - pg. 21/21

Cylinder Safety Valve Calibration

Fit the valve (1)

on union 290828 (2) and connect to

pump 290284 (3).

Using the pump, check that the

valve opens at a pressure (P)

of 210 ÷ 215 bar.

If P < 210 bar

tighten the calibration screw with

tool 291862.

If P > 215

loosen the calibration screw.

Sec. 35.1 - pg. 22/21

Rear Mechanical Lift Adjustments

For Rear Mechanical Lift Adjustments see Training Notes Handout

Sec. 35.1 - pg. 23/21

You might also like

- ZF 5hp 6hp Ecomat 500 590 600 Long Version Repair Manual 2Document20 pagesZF 5hp 6hp Ecomat 500 590 600 Long Version Repair Manual 2jacob100% (31)

- Full Air Brake - Parking Brake - Air DryerDocument81 pagesFull Air Brake - Parking Brake - Air DryerAngga Budi Pratama100% (1)

- دائرة المشحمة لونش مانتوكDocument138 pagesدائرة المشحمة لونش مانتوكMohamed Rashed100% (1)

- 3508b ManualDocument744 pages3508b ManualЕвгений Белоусов100% (1)

- Fuel System (G6EA - GSL 2.7) PDFDocument665 pagesFuel System (G6EA - GSL 2.7) PDFStefan AslamNo ratings yet

- Excavtor HYDDocument54 pagesExcavtor HYDTamer SalahNo ratings yet

- Main Control Valve 966Document22 pagesMain Control Valve 966Ahmed RezkNo ratings yet

- Tecnico Swing DeviceDocument21 pagesTecnico Swing DeviceSilvio RomanNo ratings yet

- Test and Adjust Transmission PressuresDocument6 pagesTest and Adjust Transmission PressuresAbdelbagiNo ratings yet

- Motor Hyundai D4eb-Diesel 2.2Document91 pagesMotor Hyundai D4eb-Diesel 2.2Igatech Diesel82% (11)

- Control valve functions guideDocument39 pagesControl valve functions guideAstrit StratiNo ratings yet

- Audi Q7 4MB 4M 2015-2017 Service ManualDocument8,540 pagesAudi Q7 4MB 4M 2015-2017 Service Manualpeter11100% (1)

- Engine SpecificationsDocument19 pagesEngine SpecificationsPetre LacatusuNo ratings yet

- Pierburg 2e3 Maintenance and RepairDocument11 pagesPierburg 2e3 Maintenance and Repairq1q1q1q1100% (2)

- Hydraulic Knowledge for Heavy Equipment OperatorsDocument35 pagesHydraulic Knowledge for Heavy Equipment OperatorsSilfia Wahyuni100% (1)

- XA(T,V)S 650-750-850 JD7 Compressors Oil Injected Systems OverviewDocument61 pagesXA(T,V)S 650-750-850 JD7 Compressors Oil Injected Systems Overviewamerica1591100% (1)

- Full Air Brake SystemDocument81 pagesFull Air Brake SystemMuhamad RifkyNo ratings yet

- Engine Specifications and Component Details for G6EA GSL 2.7Document101 pagesEngine Specifications and Component Details for G6EA GSL 2.7juanmanuel_4615958100% (1)

- 04 Hydraulic System-EnDocument44 pages04 Hydraulic System-EnCarlos GuajardoNo ratings yet

- Hanjin Db-8d Rig SpecsDocument1 pageHanjin Db-8d Rig SpecsAsif KhanzadaNo ratings yet

- AS350 Manual-HydraulicsDocument34 pagesAS350 Manual-HydraulicsJudd100% (2)

- STIHL TS410, TS420 Spare PartsDocument11 pagesSTIHL TS410, TS420 Spare PartsMarinko PetrovićNo ratings yet

- Plano Hidráulico 430-D PDFDocument4 pagesPlano Hidráulico 430-D PDFJose Alberto IzquielNo ratings yet

- 0293 594 0 Sys Hy en 144Document100 pages0293 594 0 Sys Hy en 144api-19483250100% (1)

- 6991 5374 62b Explorac E100 PDFDocument360 pages6991 5374 62b Explorac E100 PDFJoseAntonioQuintanillaPoncedeLeon75% (4)

- Autolube System (HYD) OverviewDocument21 pagesAutolube System (HYD) OverviewDaniel Alfonso Diaz FloresNo ratings yet

- Rotating Control Device Service ManualDocument24 pagesRotating Control Device Service ManualJeck MaxNo ratings yet

- MYCOM VR Series Screw Compressor Overhaul ManualDocument51 pagesMYCOM VR Series Screw Compressor Overhaul ManualWai LaiNo ratings yet

- Gearbox Clutch Driveshaft Steering PDFDocument190 pagesGearbox Clutch Driveshaft Steering PDFluisxxx1100% (1)

- Esquema Hidráulico, Transmissão Powershift (Mudança de Força)Document3 pagesEsquema Hidráulico, Transmissão Powershift (Mudança de Força)Marco OlivettoNo ratings yet

- Transmição 2+2Document12 pagesTransmição 2+2Dayvison Lúcio100% (1)

- ATR Ata - 08 - Weighing - and - LevelingDocument5 pagesATR Ata - 08 - Weighing - and - LevelingJesús Montalvo FernándezNo ratings yet

- Case 695Document22 pagesCase 695ДмитрйиNo ratings yet

- Hydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return CircuitDocument28 pagesHydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return Circuitroparts clujNo ratings yet

- Uenr6313uenr6313 01 ScoopDocument1 pageUenr6313uenr6313 01 ScoopEnzo Miguel Sarabia MontesNo ratings yet

- Hydraulic System: Systems OperationDocument28 pagesHydraulic System: Systems OperationRoberto BaierNo ratings yet

- Pneumatic Actuator FundamentalsDocument84 pagesPneumatic Actuator Fundamentalsheru hsNo ratings yet

- Valvula Selectora Trans.Document4 pagesValvula Selectora Trans.enriqueNo ratings yet

- Understanding the XAHS-186 Cud CompressorDocument203 pagesUnderstanding the XAHS-186 Cud Compressorvivek tiwariNo ratings yet

- Hydraulic System Sections ExplainedDocument34 pagesHydraulic System Sections ExplainedRafał DworakNo ratings yet

- 12 CA4250P25K2T2E5A80 DY648 BrakeDocument29 pages12 CA4250P25K2T2E5A80 DY648 BrakeJesus gomez corvalanNo ratings yet

- PTP-11.2 HandoutDocument21 pagesPTP-11.2 HandoutJayNo ratings yet

- Sistema de DireccionDocument18 pagesSistema de DireccionFredy ReyesNo ratings yet

- Ad60 Hidráulico NNWDocument1 pageAd60 Hidráulico NNWOsciel MaluendaNo ratings yet

- Auto Grease Lubrication Systems ExplainedDocument21 pagesAuto Grease Lubrication Systems ExplainedFrezgi BirhanuNo ratings yet

- Stick Hydraulic SystemDocument11 pagesStick Hydraulic SystemAllan LariosaNo ratings yet

- LubricationDocument32 pagesLubricationfulltransmissionNo ratings yet

- Jana EngineDocument38 pagesJana EngineJanaka BiyanwalaNo ratings yet

- Sistema HidráulicoDocument36 pagesSistema HidráulicoValdir AlexandreNo ratings yet

- Vacuum Pump SV300 FP - GA02346 - 002 - A0Document34 pagesVacuum Pump SV300 FP - GA02346 - 002 - A0pisit jantarasuwanNo ratings yet

- 2012-08!13!233533 Transmission Pressures - Test and Adjust 938gDocument6 pages2012-08!13!233533 Transmission Pressures - Test and Adjust 938gAbdelbagiNo ratings yet

- Group 2 Hydraulic Pump: 1. GeneralDocument8 pagesGroup 2 Hydraulic Pump: 1. GeneralJet AcostaNo ratings yet

- Hydraulic diagram 900EC480DDocument3 pagesHydraulic diagram 900EC480DAnasBahariNo ratings yet

- Boom Hydraulic SystemDocument13 pagesBoom Hydraulic SystemThein Htoon lwinNo ratings yet

- Transmission Control Valve: Shutdown SIS Previous ScreenDocument13 pagesTransmission Control Valve: Shutdown SIS Previous ScreenYudi setiawanNo ratings yet

- Hydraulic Diagram, Standard: Service InformationDocument3 pagesHydraulic Diagram, Standard: Service InformationPetrus Kanisius WiratnoNo ratings yet

- 4P10 TimingDocument15 pages4P10 TimingCrispus Karuri MwangiNo ratings yet

- Sistema Hidráulico PrincipalDocument4 pagesSistema Hidráulico Principallevinton jose tobias genesNo ratings yet

- Vortec V6 4.3LDocument127 pagesVortec V6 4.3LRicardo RomeroNo ratings yet

- Att System OperationDocument41 pagesAtt System OperationchanlinNo ratings yet

- Group 3 Pilot Circuit: Line Filter Swing Priority Solenoid ValveDocument8 pagesGroup 3 Pilot Circuit: Line Filter Swing Priority Solenoid ValveJorge zangarelliNo ratings yet

- SteeringDocument122 pagesSteeringGreg HannaNo ratings yet

- Hydraulic Diagram, Powershift Transmission: Service InformationDocument3 pagesHydraulic Diagram, Powershift Transmission: Service InformationРоман КузівNo ratings yet

- 4pilot Hydraulic System 336DDocument8 pages4pilot Hydraulic System 336DAnonymous Dq7m7Hq7arNo ratings yet

- 4.hydraulic System of B160 PDFDocument55 pages4.hydraulic System of B160 PDFDedi rahmat100% (1)

- D7G TRACTOR POWERSHIFT 65V07701-UP TROUBLESHOOTING GUIDEDocument23 pagesD7G TRACTOR POWERSHIFT 65V07701-UP TROUBLESHOOTING GUIDESteven Y.MNo ratings yet

- WJ-3A Manual Underground Loader GuideDocument64 pagesWJ-3A Manual Underground Loader GuideJopeth YoussefNo ratings yet

- Section E Section E: HydraulicsDocument1 pageSection E Section E: HydraulicsNikNo ratings yet

- A-1 HydraulicDocument27 pagesA-1 Hydraulicrich kumar sabar100% (1)

- Template Name: SM - 1 - Col Template Date: 1994 - 04 - 05 Alt To Hide Template Information Alt+ To Display Template InformationDocument1 pageTemplate Name: SM - 1 - Col Template Date: 1994 - 04 - 05 Alt To Hide Template Information Alt+ To Display Template InformationPetre LacatusuNo ratings yet

- Specifications: Sec. 21.1 - Pg. 1/28Document18 pagesSpecifications: Sec. 21.1 - Pg. 1/28Petre LacatusuNo ratings yet

- Series TD-D: For Training Purposes Only, Released On Spring 2002Document11 pagesSeries TD-D: For Training Purposes Only, Released On Spring 2002Petre LacatusuNo ratings yet

- Hydraulic System SpecificationDocument23 pagesHydraulic System SpecificationPetre LacatusuNo ratings yet

- Transmitters and Switches: Sec.1 - Pg. 1/14Document7 pagesTransmitters and Switches: Sec.1 - Pg. 1/14Petre LacatusuNo ratings yet

- TDD Top Cover SetupDocument16 pagesTDD Top Cover SetupPetre LacatusuNo ratings yet

- Brakes: Sec. 33 - Pg. 1/7Document16 pagesBrakes: Sec. 33 - Pg. 1/7Petre LacatusuNo ratings yet

- HLHP ErrorDocument5 pagesHLHP ErrorPetre LacatusuNo ratings yet

- 40 KMDocument6 pages40 KMPetre LacatusuNo ratings yet

- HLHP Passive 06.09.2014Document2 pagesHLHP Passive 06.09.2014Petre LacatusuNo ratings yet

- Trasmision Passive 06.09.2014Document1 pageTrasmision Passive 06.09.2014Petre LacatusuNo ratings yet

- Operation: Sec. 21.2 - Pg. 1/27Document23 pagesOperation: Sec. 21.2 - Pg. 1/27Petre LacatusuNo ratings yet

- AP Training EquipmentDocument36 pagesAP Training EquipmentPetre LacatusuNo ratings yet

- HLHP Parametrii 08.08.2014 Calculator VechiDocument3 pagesHLHP Parametrii 08.08.2014 Calculator VechiPetre LacatusuNo ratings yet

- TDD Pinion Setup CalculationDocument2 pagesTDD Pinion Setup CalculationPetre LacatusuNo ratings yet

- Erori HLHP Nou 08.08.2014Document1 pageErori HLHP Nou 08.08.2014Petre LacatusuNo ratings yet

- ALARM Trans Passive 11.09.2014Document1 pageALARM Trans Passive 11.09.2014Petre LacatusuNo ratings yet

- Trasmision Passive 06.09.2014Document1 pageTrasmision Passive 06.09.2014Petre LacatusuNo ratings yet

- HLHP Pasiv Erori 14.08.2014Document3 pagesHLHP Pasiv Erori 14.08.2014Petre LacatusuNo ratings yet

- Erori HLHP Nou 08.08.2014Document1 pageErori HLHP Nou 08.08.2014Petre LacatusuNo ratings yet

- HLHP Pasiv Erori 14.08.2014Document3 pagesHLHP Pasiv Erori 14.08.2014Petre LacatusuNo ratings yet

- HLHP Parametrii 08.08.2014 Calculator VechiDocument3 pagesHLHP Parametrii 08.08.2014 Calculator VechiPetre LacatusuNo ratings yet

- HLHP Passive 06.09.2014Document2 pagesHLHP Passive 06.09.2014Petre LacatusuNo ratings yet

- HLHP ErrorDocument5 pagesHLHP ErrorPetre LacatusuNo ratings yet

- ALARM Trans Passive 11.09.2014Document1 pageALARM Trans Passive 11.09.2014Petre LacatusuNo ratings yet

- VFe34S Interior CMF Specbook v1.0Document67 pagesVFe34S Interior CMF Specbook v1.0Trần Văn LynhNo ratings yet

- Traxon - Kamaz - 54901 ErrorsDocument374 pagesTraxon - Kamaz - 54901 Errorsnima grantNo ratings yet

- 2020 - YZF - R1 - Kit Manual - ENDocument82 pages2020 - YZF - R1 - Kit Manual - ENMr. TNo ratings yet

- Arctic Cat 2009 250 Utility DVX 300 Service ManualDocument10 pagesArctic Cat 2009 250 Utility DVX 300 Service Manualandrew100% (48)

- Display Monitor d3kDocument5 pagesDisplay Monitor d3kirawanNo ratings yet

- BMW 5 SiDocument14 pagesBMW 5 SiDMX ElectronicsNo ratings yet

- T105se Jupiter TaillightDocument1 pageT105se Jupiter TaillightTeguh MargiantoNo ratings yet

- Bobcat 730sh ManualDocument68 pagesBobcat 730sh ManualAngel Diaz ArenasNo ratings yet

- Commercial Faucet Wallmount Sink Faucets: Specification: (Example)Document2 pagesCommercial Faucet Wallmount Sink Faucets: Specification: (Example)jmarrero488307No ratings yet

- Illustrated Parts List: Ta-C84 For Solaris Urbino 12H November 2011Document24 pagesIllustrated Parts List: Ta-C84 For Solaris Urbino 12H November 2011Leszek MarczakNo ratings yet

- 1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulDocument29 pages1989 Nissan Sentra 1.6L Automatic Manual Transmission OverhaulRubenNo ratings yet

- Fms ScaniaDocument51 pagesFms ScaniaturpinNo ratings yet

- 8.8L Cac Parts Book 20sept13Document37 pages8.8L Cac Parts Book 20sept13Silver SilverNo ratings yet

- Camp Master Festive Product and Price Catalogue 2023Document59 pagesCamp Master Festive Product and Price Catalogue 2023Robert JonesNo ratings yet

- Sample Cutting Machine GuideDocument16 pagesSample Cutting Machine Guidefatih_hideNo ratings yet

- Cerato 1.6 2010 - Transmissão A4CF1 - Inspeção Básica e AjustesDocument5 pagesCerato 1.6 2010 - Transmissão A4CF1 - Inspeção Básica e AjustesWiterMarcosNo ratings yet

- BMW F90 V2 Installation GuideDocument13 pagesBMW F90 V2 Installation GuideOmar MahmoudNo ratings yet

- 3.4 Burner Lance ManualDocument3 pages3.4 Burner Lance ManualANTONIO MEDINA RIOSNo ratings yet

- Manual Midea SM LC 50r410a DC Inv S Au B 150105Document114 pagesManual Midea SM LC 50r410a DC Inv S Au B 150105Fidio RodriguezNo ratings yet

- Toyota InnovaDocument1 pageToyota Innovasaifshakh1994No ratings yet

- Chery-QQ S11 Transmisión Parte 4Document17 pagesChery-QQ S11 Transmisión Parte 4limadacarlos100% (1)

- SD-77DX & SD-77F: TF Series Soil CompactorsDocument2 pagesSD-77DX & SD-77F: TF Series Soil CompactorsCarlos Ediver Arias Restrepo50% (2)

- Transfer Case bm4485Document109 pagesTransfer Case bm4485Cesar Augusto GalloNo ratings yet