Professional Documents

Culture Documents

LEGGERA Installation Guide v2.1

Uploaded by

service iyadMedicalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LEGGERA Installation Guide v2.1

Uploaded by

service iyadMedicalCopyright:

Available Formats

Leggera Installation Guide v2.

0 1

LEGGERA

Installation Guide

Table of Contents

Parts

Wiring

Mounting the Panel

Grid Installation

Stand Calibration

Generator Jumper Configuration

Generator Tech Service Configuration

Generator Auto Calibration

PrestoDR Calibration

AEC Calibration

AEC Tracking Calibration

DiCom Setting Configuration

Acceptance Report

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 2

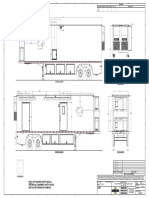

Parts:

1 – Mounting Plate (not shown)

1 - 24v Power Supply

1 - DB9 to DB9 Cable (Generator Interface Cable) L001

1 - DB9 to DB15 Cable (Panel Power Cable) L002

1 - Network Crossover Cable L003

1 - Panel Mounting Screw Kit

1 – 18x18, 215 Line, 8:1 Grid (Not Shown)

Figure 1

**Verify all components are present**

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 3

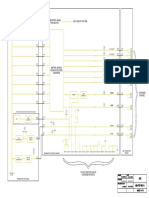

Wiring:

Generator PC

L001 GIF Card

Panel

Power

L002

Supply

NIC Card

L003

The following cables must run through the U-Arm along the same path as the AEC Cable:

L002 (DB15-DB9)(Panel Power Cable)

L003 (Network Crossover cable) If crossover cable is not long enough to

run to the PC, then a network coupler is needed and the Cat5 cable pre-

run can be used

Figure 2

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 4

From Panel

The L003 will run from the

Panel to the PC in the tech

area. (See Figures 3 & 4)

Figure 3

The Panel uses the Add-On NIC

To PC Card

(See Figure 4)

Figure 4

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 5

J4 In Generator L001 will run from J4 in the

Generator to the GIF Card in

the PC.

(See Figures 5 & 6)

Figure 5

If J4 is not in system go to

page 32 for hard wiring in

the connection.

GIF Card

Figure 6

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 6

To Power Supply

L002 will run from Panel to

Power Supply.

Figure 7 (See Figures 7 & 8)

Both DB9 plugs are 24VDC,

only one is used unless

multiple panels are being

installed.

From Panel

Figure 8

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 7

Mounting the Panel:

1. Remove the grid/Ion chamber mounting bracket. Discard the screws, keep washers and lock

washers (longer replacement screws are provided in the screw kit) Figure 9

Figure 9

Notch

Figure 10

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 8

2. Connect the power cable (L002) and the crossover cable (L003) to the panel. (Connections are

easier to make than after panel is mounted to plate) Figure 11

Figure 11

3. Mount the Panel to the adapter plate using the provided screws with the cable connectors

coming up from the foot/bottom side of the enclosure. Figure 12 & 13

Figure 12

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 9

Figure 13

4. Align the adapter plate to the holes that the grid/Ion chamber bracket was mounted with.

Figure 14

Cables must exit this side

Figure 14

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 10

5. Remount the Grid/Ion chamber bracket with the screws provided in the screw kit.

Figure 15

Figure 15

6. 3 screws are provided to mount the adapter plate to the enclosure mount on the foot end. The

holes on the plate are threaded and all screws come from the bottom up. (If plate not threaded,

use a nut and bolt) Figure 16

Figure 16

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 11

7. Remove the washers from the grid guide screws. (allows more room for top cover space)

Figure 17

Figure 17

8. Remove the grid holder on the bottom of the enclosure. Figure 18

Figure 18

9. Panel Mounting is now completed.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 12

Grid Installation:

Grid slides into grid guides (screws may have to be loosened to allow play in guide for proper fit)

Figures 19 & 20

Figure 19

Figure 20

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 13

Stand Calibration:

1 Hold the Positioning button for 5 seconds. Password: 2434 Figure 21

a. Select Configuration / Calibration

b. Select Positioner Configuration

c. Change Units from CM to Inch

d. Set Safety Distance for 3.9”, Press SET

e. Room Height to verified Room Height, Press SET

f. Detector Width Left to 10.6”, Press SET

g. Detector Width Right to 16.1”, Press SET

h. Detector Thickness to 5.9”, Press SET

All other settings should be performed as in manual

Figure 21

Verify Control Board Software is V2R1.8

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 14

Generator Jumper Configuration:

Jumpers to be installed in the Generator:

3TS1-2 to 3TS1-7

****Detector Interface may be different

AEC Adapt board TS1-7 to TS1-10

Install Jumper from

3TS1-22 to 3TS1-23 as

needed for Door Interlock

Verify SW2-3 on ATP

Board is in Service Mode

(page 3 of Configuration

Section of the Generator

Service Manual)

Verify U24 chip on ATP

Board is V7R1b13 CMT

version

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 15

Generator Tech Service Configuration:

PC Log-in is:

User Name: technician

Password: tech-*tos

Verify Date, Time, and Time Zone are correct on PC upon boot-up.

Adjust with windows settings if needed.

I. Workstation Setup

1. From the PC (MPU), select from the shortcuts window select “TechService”; the Generator

Service Mode screen appears.

Figure 22

2. On Generator Service Mode screen, choose “Configuration”; the Configuration screen appears.

Figure 22

a. WS1 must be set as:

Tube 1, Bucky 1, and which port you have selected for AEC.

b. WS3 must be set as:

Tube 1, Direct, and which port you have selected for AEC.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 16

II. Extended Memory Setup

1. Select “MANUAL CALIBRATION”

2. Select past the highest mA station.

o E02: Tube Type = (Tube chart on page 39 0f the configuration tab in the generator

manual)

FX7254 = 5, FX7884 = 6

o AEC Calibration = 70

AEC-1 calibration = E04

AEC- 2 calibration = E09

AEC- 3 calibration = E20

o E06: KV Compensation = 200

Extended Memory Location E06 contains the calibration factor for kV Loop. Each

number above or below of the indicated in the E06 memory location increases or

decreases respectively the kV gain value.

o AEC Tracking

AEC- 1 tracking = E08

AEC- 2 tracking = E10

AEC- 3 tracking = E24

You are now ready to calibrate the Generator

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 17

Generator Auto Calibration:

1. Select “Auto Calibration” button.

2. Select workstation (WS3 / Direct mode)

3. Angle Tube away from detector

4. Click “OK”.

5. Confirm or leave the Auto-calibration by pressing the respective button (“Yes” or “No”) on the

new screen.

6. Select focal spot calibration. Figure 23 (left)

7. Click “OK”.

8. Select “Yes” Figure 23 (right)

9. Confirm or leave the Auto-calibration (second confirmation) by pressing the respective button

(“Confirm” or “Dismiss”) on the calibration screen. Figure 24

10. Auto-calibration is activated when the “AutoCalibration” is shown. Figure 25

11. Press Prep and Expose from the hand switch. (Prep may take up to 45 seconds to start Calibration)

12. “AutocalOK” will replace the “AutoCalibration” once the calibration is completed for the selected

focal spot.

13. Spot check generator for calibration verification and fill in acceptance form.

Figure 23

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 18

Figure 24

Figure 25

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 19

PrestoDR Setup:

In this section it is necessary to switch between two opened windows. The calibration and tech service

screens will need to be opened throughout this section. In order to accomplish this, press the <ALT> key

(do not release) then use the <TAB> key to toggling between each opened applications until the desired

application is selected. Then release the <ALT> key to open. This must be done after step 1 is completed.

1. You must install the Detectors license into the system

a. From Detector Install CD provided with the panel go to software/pixrad-detxxxx.key.

b. Copy file.

c. Paste pixrad-detxxxx.key file into:

k:\_exe\ThirdParty\Pixrad\config\simple\config_4143\Csi folder

2. Go to the PrestoDR shortcut window and access the Calibration application

a. Double-click on the Calibration icon.

b. The Presto DR System Calibration dialog box appears. Figure 26

c. The application will alert a “No Defect Map is available” for the detector.

This is normal until calibration has been completed.

d. Verify that Buffer-A is selected for both “Buffer to Acquire” and “Buffer to Show” in the Buffer

operation section. Figure 25

e. Click Okay

Verify Buffer-A is

selected for both

“Buffer to Acquire”

and “Buffer to

Show

Figure 26

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 20

3. Detector Offset

a. From the System Calibration Main Window, choose “Offset Get Offset”

b. After a few seconds an offset image appears.

Note: Generator conditions are controlled via the “Tech Service” software. Both the Presto DR

Calibration Utility and the Tech Service software should be active during calibration. If either of these

applications is inactive, X-ray acquisition will not be possible.

4. Optimal Temperature

a. From the Installation menu,

b. select Optimal Temperature

c. change from 25 degrees C to 28 degrees C.

Note: The temperature must be monitored during the whole calibration process. If at any stage the

temperature has deviated by more than +1.0 degrees, restart the calibration.

5. Open the shortcut window again by pressing the <ALT> key (do not release) then use the <TAB> key to

now tab over allowing access the “Tech Service” application.

a. Open “Tech Service” application.

b. Select “Manual Calibration”. Figure 27

c. Select “User Mode”. Figure 28

d. Here is where all generator changes will be made during calibration.

Figure 27 Figure 28

Note: Generator conditions are controlled via the “Tech Service” software.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 21

6. Defect List Creation

a. In the Presto DR System Calibration Window,

b. From the “DM Generation” menu,

c. Select “Create Defect List”.

d. Room Preparation window will open. Figure 36

e. Exposure conditions window will open. Figure 29

f. Set the SID to 180cm (72”)

g. Remove the grid

h. Place the 1.5mm copper absorber in the collimator.

i. Set 85kV, 400mA, and 100mS from “Tech Service” User Mode.

Note: Generator settings must be controlled with “Tech Service”.

j. Make an exposure.

k. A message will appear if the set exposure meets the 25 μGray dose as required. Figure 30

Figure 29

Figure 30

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 22

The application will now guide you step-by-step through the Defect List Calibration.

l. Leave the X-ray condition values as-is, and press Resume.

m. Within 2-3 seconds “press Prep” will appear.

n. Make an exposure and continue until 10 images are acquired at this generator setting.

o. You will be prompted to change dose level.

p. The system will then display a message asking for setting X-ray to 2.5 μGray.

q. Change to the desired mA that is asked for in “Tech Service”.

r. Press resume.

Follow the proposed mA settings for the next 4 exposures

Note: you may have to adjust the mAs accordingly to achieve desired dose i.e. for 630 mA, 100mS setting

would be a 63mAs exposure. 500mA at 128mS will give you a 64mAs exposure. Using the same manipulation,

obtain the desired 80mAs dose final calibration exposure.

s. The following message will appear when calibration is completed. Figure 31

t. Press OK

Figure 31

u. The following message will appear. Figure 32

v. Insert the grid in the 4143 FPD Bucky. Figure 19 & 20

w. Press OK.

Figure 32

x. The following message will appear in the calibration screen. Figure 33

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 23

y. Set 85kV, 500mA, and 100mS from “Tech Service” User Mode.

z. Make an exposure.

Figure 33

aa. The system will detect the FPD orientation

bb. The following message will be displayed. Figure 34

cc. Press OK to finish the process.

Figure 34

7. Defect List Verification

a. From the “DM Generation” in the Main Calibration window,

b. Select “Display ECV”

c. The “Defect Classification and ECV” dialog box appears. Figure 35

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 24

Figure 35

d. Verify that the:

1) • ECV value is less than 100,000.

2) • M1 to M8 values are all zero.

e. Note values in the Acceptance Report.

8. Creating Gain Correction Matrices

a. In the PrestoDR System Calibration application.

b. Select the “Gain” menu.

c. Select “Create Gain Factors Matrices”.

d. Room Preparation window will open. Figure 36

e. Set the SID to 180cm (72”)

f. Remove the grid

g. Place the 1.5mm copper absorber in the collimator.

h. Exposure conditions window will open. Figure 37

i. Set 85kV, 400mA, and 100mS from “Tech Service” User Mode.

Note: Generator settings must be controlled with “Tech Service”.

j. Make an exposure.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 25

Figure 36

Figure 37

k. Leave the X-ray condition values as-is, and press Resume.

l. Within 2-3 seconds “press Prep” will appear.

m. Make 10 images at the set generator settings (unlike the Defect List Calibration, no

generator settings will have to be changed.)

n. The following image will appear. Figure 38

Figure 38

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 26

9. Panel calibration is now finished.

10. Create a backup of the Calibration data files to an external media device provided (USB Stick)

a. Insert the USB Device that is provided in the computer box into the PC.

b. From the shortcuts window

c. Select “Util”

d. Select Backup and restore

e. Select Registry, Databases, Correction Tables, ART Parameter Files, and Essential

production settings.

f. Select USB Device.

g. Select Capture/Report.

h. Files should now be backed up onto USB Device.

i. Remove USB Device and store in safe place with manuals.

11. Complete Thales Acceptance Report at the end of this guide and send to Viztek for warranty

information.

12. ***Check Anti-crushing Board Job Card 2.5 in Stand Service Manual page 166***

13. X-Ray Warning Room Light is wired into 3TS1-47 & 3TS1-48 (page 58 in the Installation tab of the

generator manual)

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 27

AEC Calibration:

I. Chamber Equalization

Note: Ensure a short jumper was installed in the Generator on the AEC adaptation board TB1 7 to 10. Page 14

1. SID =135 CM, Tube centered to the detector.

2. Verify center with the collimator light source.

3. Open collimator to 17” x 17” or large enough to cover all AEC cells.

4. Verify that the Grid is in its place inside the Bucky.

5. Place the 1.5 mm copper absorber in the collimator.

6. From the shortcuts window select “Tech Service”.

7. press Enter

8. The “Sedecal Generator Service Application” screen appears. Figure 39

Figure 39

9. Select “Manual Calibration”

10. Select WS 3 (Direct Mode).

11. Select Go to “User Mode”. Figure 40

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 28

Figure 40

12. Select “RAD” tab.

13. set generator for

70kV,

320mA

400 mS.

14. Select the “AEC” tab. Figure 41

Figure 41

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 29

15. From the Areas options,

16. Select Center cell.

Film Speed, select Medium.

From the Density options, select 0.

17. Take an x-ray exposure of the Center Chamber.

18. Check the post X-ray MAS reading displayed in the “Tech Service” screen.

19. Note this value.

20. Take an X-ray of the Left and Right Chambers noting the post X-ray MAS values,

21. If the MAS values differ by more than 5% between chambers, adjust the appropriate Pre-amp

potentiometer so that all chambers are in agreement to within 5%.

Note: Claymount Ion Chambers are not adjustable.

22. Repeat steps 21 and 22 until the desired MAS levels are equal in all 3 chambers.

II. AEC Gain Calibration

1. Tube centered to the detector.

2. Verify center with the collimator light source.

3. Open collimator to 17” x 17” or large enough to cover all AEC cells.

4. Verify that the Grid is in its place inside the Bucky.

5. Place the 1.5 mm copper absorber in the collimator.

6. From the Presto DR Shortcuts window.

7. Select the Calibration application.

Figure 42

8. From The “Tech Service”.

9. Select “Manual Calibration”.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 30

10. Select “User Mode”.

11. From the “AEC” tab.

12. Select Center Cell.

From the Film Speed select “Medium”.

From the Density options, select “0”.

13. From the “RAD” tab set.

70KVp

320 ma

400 ms

14. Open the Calibration Presto application from the Shortcuts window.

15. The ROI square appears on the image.

The average Gray Level value is displayed in the “Mean GL” field.

16. Check the Mean GL. It should be between 750 and 800 GL using Center Cell. If the GL

value is not in the specified range: Adjust the preamp master gain potentiometer to

achieve the specified value.

Note: Claymount pre-amp have a master adjust only

Note: The final value for reference to be used during the AEC Tracking calibration.

AEC Tracking Calibration:

1. Set the X-ray system, to the following conditions:

Tube centered to the detector.

Verify center with the collimator light source.

Open collimator to 17” x 17” or large enough to cover all AEC cells.

Verify that the Grid is in its place inside the Bucky.

Place the 1.5 mm copper absorber in the collimator.

2. Open the Tech Service application.

3. Select Manual Calibration.

4. Using the Up / down arrows, set the mA value to E08.

5. From the Calibration Value options:

Choose Read.

Change the value to 0.

Choose Store.

6. Choose Go to User Mode; the Set X-ray Values screen appears.

7. Verify that the RAD button is active and set the X-ray values as follows:

KVp = 55 KVp

mA = 320

ms = 400

8. From the TechService screen, choose AEC; the Film Settings screen appears.

From the Areas options, select Center.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 31

From the Film Speed options, select Medium.

From the Density options, select 0.

9. Take an X-ray exposure and check the average gray level by checking the ROI box in the PrestoDR

Calibration Window and looking at the Average GL field. Note this value. Setting and Calibrating

the PrestoDR System.

10. Take an exposure at 90 KVp check the average gray level in the PrestoDR Calibration Window and

adjust the value of E08 to bring the average gray level as close as possible to that achieved at 70

KVp during the gain calibration. E08 is the slope adjustment.

Note: Increasing from 0 to 1 will decrease the GL at 55 KVp. Decreasing from 0 to 255 will

increase the GL at 55 KVp and have the opposite effect at 90 KV. When returning to the User

Mode after adjusting E08 value you must re-select AEC again before taking another exposure.

11. Repeat the steps until the average gray level at 55 and 90 KVp converge as close as possible to

the gray level achieved at 70KVp (750 and 800 GL).

Note: any adjustments of the value of E08 will affect both 55 and 90 KVp.

12. Take an X-ray at 120 KVp. Check the average gray level is +/- 10% of the value achieved at 70 KVp.

If not within the specified range adjust the value of E08 until the desired gray level is achieved. If

adjustment is required it will affect the 55 KVp calibration point. Repeat step to verify that the

average gray level is +/- 10% of the value achieved at 70 KVp.

Setting DiCom Information:

1. Go to shortcut window and select Util

2. Select “DiCom configuration”,

3. In the “Store” tab change from “0” to “1” storage SCP servers positions.

4. Input PACS DiCom information asked for (AE Title, IP/Host address, Port, and the Display

Name) as provided by the site.

5. Select the MWM for the Modality Worklist …Input the information as provided by the site

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 32

Generator J4 wiring

Pin 1 - 3TS1-4 (Bucky 1 Drive Return)

Pin 2 - 3TS1-5 (Bucky 1 Motion)

Pin 3 - 3TS1-6 (Bucky 1 Motion Return)

Pin 4 - 3TS1-17 (24vdc)

Pin 5 - 3TS1-17 (24vdc)

Pin 6 - *P5-5 on HT Control PCB for 64KW Generators

Pin 6 – *P2-2 on Interface Control Board for 50 KW Generators

Pin 6 is depending on whether there is a high speed DRAC or not. (P2-2 on Interface

Control Board for no DRAC, P5-5 on HT Control Board for generators with a DRAC).

Troubleshooting

Having issues getting Tech Service to communicate

Verify that U24 Chip on ATP Board is V7R1b13 CMT, If not call Viztek to gain proper chips.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 33

Acceptance Test

Acceptance Test Procedure

Overview

Following is a Test Report that you are requested to fill out during the installation and calibration processes.

This information is required to record the system status on the day of installation.

The Acceptance Test is required to verify that the installation was performed correctly and that the system is

in nominal (and optimal) conditions.

A soft copy of this document can be found at C:\Util\ Acceptance Test.bat.

Some of the tests are to be carried out during the installation and calibration processes, and some tests are

to be carried out after completion of the process.

Note that at times during the installation and calibration processes you will be referred to the Acceptance

Test form to enter data regarding the test results. This will save time and prevent the repetition of certain

steps.

When & How

Test Section When & How

Fill out when unpacking the equipment; see

General Information 0

section Error! Reference source not found.

Visual Inspection 0

System Movements Control 0

Perform after completing hardware installation

Filtration 0 but before initiating the PrestoDR calibration

Generator Calibration 0 process; see section Error! Reference source not

found..

Tube - Bucky - Collimator Calibration 0

Half Value Layer 0

Performed in two steps:

Temperature Monitoring 0

1. Before PrestoDR calibration; see section

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 34

Error! Reference source not found..

2. After completing the calibration process; see

section Error! Reference source not found.

Pixium 4143 detector Offset 0 Perform during the PrestoDR calibration process;

see section Error! Reference source not found.

Defect Map 0 and section Error! Reference source not found..

Gain Flatness and Calibration Error 0

FPD Sensitivity 0

Spatial Resolution and Contrast Resolution 0 Perform after completing the installation and

Grid Micro Switches 0 completing the calibration process.

Automatic Collimator 0

AEC 0

Test Section When & How

Error!

Referenc

Peripheral Equipment Connectivity Test e source

not Perform after completing the installation and

found. completing the calibration process.

Monitor Calibration Data Recording 0

Test Report Files 0

Note that some Thales system types support two detectors. Therefore there are several sections that require data

from the two detectors. If you are installing a single detector system, please indicate “NA” in the “Second FPD”

sections.

When filling out the form, please enter the parameter value in the right hand column. If there is no parameter

value, enter a check mark () or ’NA’ in the appropriate box, as required.

If some or all of these tests were already completed, enter the results in the relevant tables.

If you encountered/detected any problems, please contact your local PrestoDR support for assistance.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 35

Required Applications

The applications required for this procedure are:

1. The generator software to set the generator parameters.

2. The Thales calibration program. The program’s main screen is shown in:

.

Pixel coordinates for length measurement

Averaged Gray Level of the Roi

(Rand of Interest)

Detector Temperature

Figure 0-1 Thales Calibration Program - Main Screen

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 36

The calibration program has several modes for image correction. The corrections are accessed via the Correction

section in the main screen menu:

Offset correction only

Pixel cluster defects

Ofsset+Gain correction

Pixel Clipping correction

Pixel defects

Butting correction

Echo line correction

Grid suppression correction

No corrections (raw image)

Required Test Equipment

Note

For all tests, unless otherwise specified, do not use collimator added filters.

Following is the list of required test equipment:

1. SAMIQAT Phantom Assembly (PN 91SA000500)

2. 4 Coins (no special requirements)

3. 4 mm Aluminum Layer

4. 1.5 mm Copper Absorber

5. Digital Volt Meter

6. Dose Meter

7. mAs Meter

8. kV Meter

9. Perpendicularity Test Tool

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 37

Test List

General Information…………………………. ........................................................................ 0

Visual Inspection .......................................................................................................... 0

System Movements Control ......................................................................................... 0

Filtration Check............................................................................................................. 0

Generator Calibration................................................................................................... 0

Tube – Bucky – Collimator Orientation ........................................................................ 0

X- ray Beam Test ........................................................................................................... 0

Tube – Bucky Perpendicularity ..................................................................................... 0

Collimator Visible Light Orientation ............................................................................. 0

Collimator Visible Light Orientation ............................................................................. 0

Half Value Layer............................................................................................................ 0

Temperature monitoring .............................................................................................. 0

Pixium 4143 Detector Offset ........................................................................................ 0

Defect Map ................................................................................................................... 0

Gain Flatness and Calibration Error .............................................................................. 0

FPD Sensitivity .............................................................................................................. 0

Spatial Resolution and Contrast Resolution ................................................................. 0

Grid Micro Switches ..................................................................................................... 0

Automatic Collimator ................................................................................................... Error! Reference source

not found.

AEC................................................................................................................................ 0

Peripheral Equipment Connectivity Test ...................................................................... Error! Reference source

not found.

Monitor Calibration ...................................................................................................... 0

Test Report Files ........................................................................................................... 0

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 38

Acceptance Test Form

General Information

Fill in this information during the unpacking stage; see Section Error! Reference source not found. of the

installation and maintenance manual.

Contact Details

Installed by: Signature:

Email: Phone number:

Reported by: Signature:

Installation Start date: Installation end date:

Customer Data

Customer: Address: Postal Code:

City: State: Country:

System Data

Type of system (PrestoDR 4143\PrestoDR portable 3543 only):

DR System

Optimum/Compact: Serial #: S/W version:

Brand: Serial #:

Generator Manufacture date: Model: S/W version:

S/W version:

Overhead

Brand: Model: Serial #:

(Ceiling suspension)

Tube Support

Type:

__________________ Brand: Model: Serial #:

(Ceiling\ floor

mount\U-arm)

Table Brand: Model: Serial #:

Brand: Model: Serial #:

Tube

Filtration: Total Filtration:

Brand: Model: Serial #:

Collimator

Filtration: Total Filtration:

Bucky1 Serial #: Model: U-Arm/Table/Vertical

Bucky2 Serial #: Model: U-Arm/Table/Vertical

Brand: Model: Serial #:

Grid in Bucky 1

Line per cm: Ratio:

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 39

Focal distance: Line filler:

Brand: Model: Serial #:

Grid in Bucky 2

Line per cm: Ratio:

Focal distance: Line filler:

Brand: Serial #:

AEC1

Manufacture date: Model:

Brand: Serial #:

AEC2

Manufacture date: Model:

Pixium ________ 4143/3543 Serial #:

FPD1

Manufacture date: Model:

Pixium ________4143/3543 Serial #:

FPD2

Manufacture date: Model:

Other Devices Data

Brand: Serial #:

Manufacture date: Model:

Brand: Serial #:

Manufacture date: Model:

Brand: Serial #:

Manufacture date: Model:

Visual Inspection

Fill in this information after completing system assembly and before initiating the DR system calibration process.

Visually verify the following:

There are no cables that interfere with the moving parts of the system or persons.

The cables that move the system parts are well attached and cannot strike a person when moving.

All system parts screws are well secured.

There are no broken or scratched parts.

The system is clean (no dust, etc.) and the room is clear of all materials/tools used during assembly.

Verify existence of all required labels

System Movements Control

Fill in this information after completing system assembly and before initiating the DR system calibration process

U-Arm

Vertical (up and down) Tube Rotation

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 40

Arm Rotation (-30- 90) Detector angulations (±30)

SID (40”/100cm – 72”/180 cm)

Filtration Check

After completing system assembly and before initiating the DR system calibration process, check the filtration

details (located on the component stamps or in the specifications) of the tube, collimator and any additional

equipment in the X-ray path (such as DAP).

Verify that the total filtration of the tube+ collimator + additional equipment exceeds 2.5mm AL

equivalent.

Generator Calibration

Connect a kVp meter and mA meter to the generator using Tech Service WS-3

1 Set mA =100mA.

2 Set ms = 100ms.

3 Set the kVp according to the following table and acquire images. Write the measured kVp and mAs:

kVp set kVp measured mA measured

55 kVp __________ __________

(52-58 kVp allowed) (95-105 mA allowed)

70 kVp __________ __________

(68-73 kVp allowed) (95-105 mA allowed)

100 kVp __________ __________

(96-105 kVp allowed) (95-105 mA allowed)

120 kVp __________ __________

(115-125 kVp allowed) (95-105 mA allowed)

Verify that the measured kVp and mAs is in allowed area

Tube – Bucky - Collimator Orientation

Fill in this information after completing system assembly and before initiating the PrestoDR calibration process

(For Pixium Portable 3543 the following is when the detector is inside the bucky).

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 41

Test Setup

1 Set the system values as follows from Tech Service WS-1:

kVp mA/mSec Absorber SID [cm/Inch] Calibration Correction Grid AEC

60 100mA/50mS None 100/40 “none” No Off

2 Activate the collimator light source and narrow the collimator shutters (in both axes) so that they are inside

the image (to approximately 14”x14” [35cm x 35cm] image area).

Butting lines cross

Shutters

Figure -2- Tube – Bucky - Collimator Orientation Test Example

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 42

X- Ray Beam Test

1 Acquire an x- ray image.

2 Check the gray levels in the acquired image by verifying that the lighter pixels are in a circle

in the center of the image.

If the lighter pixels are not in a circle in the center of the image, adjust the tube according to

the applicable manufacturer’s instructions and repeat the test.

3 When the test is completed, print the image that displays the light when it is centered and

attach the image to this report.

Tube – Bucky Perpendicularity

1 Set the system values as follows using Tech Service WS-1:

kVp mA/mSec Absorber SID [cm/Inch] Calibration Correction Grid AEC

70 100mA/50mS None 100/40 “none” No Off

2 Position the perpendicularity test tool on the bucky center and perform an exposure.

3 Measure the distance between the two center points in the circles of the acquired image.

The distance should be less than 135 pixels (= 20mm/0.148 pixels/mm = 2%SID).

Figure -3 Measure the Distance between the Two Center Points

3.1. Repeat the tests in horizontal orientation. If you encounter a problem you might need to calibrate the

system in such a way that the errors emerging from the bending of the U-arm will be distributed to

vertical and horizontal misalignments so the total error in each position will be within the limitations.

Note

If one or more of the measurements exceeds the limit, adjust the tube position related to the bucky

according to the applicable manufacturer’s instructions and repeat all tests in the section.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 43

Collimator Visible Light Orientation

1 Position four coins on the corners of the shuttered area (using tape) and acquire an x-ray image.

2 Note the image and position the coins at the corners of the image as follows:

The coins are fully visible.

There is no light area between the coin and the shutters.

3 Acquire an x-ray image and fine tune the position of the coins until the two conditions described in

step 2 are satisfied.

The example illustrated in the following figure does not meet the two conditions described in step 2:

The upper coins not fully visible.

The lower coins are too high relative to the lower shutter

Figure - 4: Incorrect Coin Positioning

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 44

4 Activate the collimator light source and verify that the coins are positioned at the corners of the

illuminated area. See the following figure.

Figure - 5: Correct Coin Positioning

5 If the coins are not correctly positioned in the corners, adjust the light until the required result

is obtained.

Collimator – Bucky Orientation

This test verifies collimator/FPD alignment by using the FPD’s inherent butting lines to measure the alignment.

1 Acquire an X-ray image.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 45

XLU XRU

YRU

YLU

YRD

YLD

XLD XRD

Figure -6 Shuttered Rectangular Edge Lines and Butting Lines

2 Referring to the figure above, measure the misalignment by calculating the distance (in pixels) between the

shuttered rectangular edge lines and the butting lines cross and enter these values in the following form in

vertical position:

Xup = |XLU - XRU| = ____________ Xdown = |XLD - XRD| = ____________

Xright = |XRU - XRD| = ____________ Xleft = |XLU - XLD| = ____________

Yup = |XLU - XRU| = ____________ Ydown = |XLD - XRD| = ____________

Yright = |XRU - XRD| = ____________ Yleft = |XLU - XLD| = ____________

3 Verify that all the differences (Xup, Xdown, Xright, Xleft, Yup, Ydown, Yright, Yleft) are less than 10

pixels.

4 Adjust the position of the collimator until the required alignment is obtained.

Repeat the tests in horizontal orientation. If you encounter a problem you might need to calibrate the system

in such a way that the errors emerging from the bending of the U-arm will be distributed to vertical and horizontal

misalignments so the total error in each position will be within the limitations.

Xup = |XLU - XRU| = ____________ Xdown = |XLD - XRD| = ____________

Xright = |XRU - XRD| = ____________ Xleft = |XLU - XLD| = ____________

Yup = |XLU - XRU| = ____________ Ydown = |XLD - XRD| = ____________

Yright = |XRU - XRD| = ____________ Yleft = |XLU - XLD| = ____________

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 46

Half Value Layer

Fill in this information after completing system assembly and before initiating the DR system calibration process.

1 Set the system values as follows:

kVp mA/mSec Absorber SID [cm/Inch] Calibration Correction Grid AEC

100 100mA/20mS None 100/40 Not Relevant No Off

2 Position a dosimeter on the box so it will be 10-15 mm above the bucky. Position the dosimeter on the center.

3 Measure the dose level for three exposures and average the dose values.

4 The averaged value A-4 mm (without a 4 mm aluminum layer) is: ________________.

5 Put the 4mm aluminum layer on the collimator output.

6 Repeat step 3.

7 The averaged value A+4 mm (with a 4 mm aluminum layer) is: ________________.

8 Verify that:

1.41 < (A-4mm / A+4mm) < 2.0

9 In case the collimator filter option exists repeat steps 1-10 with the filters. Verify that:

1.41 < (A-4mm / A+4mm) < 1.74

Note

1.41, 1.74 and 2.0 are equivalent to half value layer of 8, 5 and 4 respectively.

Temperature Monitoring

Record detector temperature values before and after calibration; see section Error! Reference source not found.

of the installation and maintenance manual.

Parameter value /

FPD1 Before calibration _________

FPD1 End of calibration _________

FPD2 Before calibration _________

FPD2 End of calibration _________

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 47

The temperature variance between initiating calibration and completing calibration should be

+1.0oC.

Detector Offset

Fill in this information during system calibration; see section Error! Reference source not found. of the installation

and maintenance manual

1 On the offset menu press, Display current offset.

2 With maximal ROI, verify that the average gray level is between:

For 4143G (GOS): 1500 to 2000 GL.

For 4143C (CsI): 2500 to 3300 GL

3 For a dual detector system, repeat the test for the second detector.

Defect Map

Fill in this information during system calibration; see section Error! Reference source not found. of the installation

and maintenance manual.

The Defect Map is checked by the ECV calculation. It should be less than 256,000. M2 to M8 should be zero.

Parameter value /

FPD1 ECV and M2 to M8 values _________

FPD2 ECV and M2 to M8 values _________

Gain Flatness and Calibration Error

1 Set the system values as follows:

# kVp mA/mSec Absorber SID [cm/Inch] Calibration correction Grid AEC

1 70 100mA/40mS 1.5mmCu. 100/40 All Yes Off

2 70 100mA/40mS 1.5mmCu. 100/40 All No Off

3 120 100mA/50mS 1.5mmCu. 180/72 All Yes Off

4 120 100mA/50mS 1.5mmCu. 180/72 All No Off

2 For each of the 4 test setups:

a Acquire an image.

b Using the default ROI (400 x 400 pixels, double click on the image), measure the average grey level of the

image four corners and of the image center. Record these values in the Flatness column of the table

below.

c For each line of the table below, enter the maximum and minimum values of the five ROIs in the Max and

Min columns.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 48

d For each line of the table below, calculate the mean gray level and record the result in the Mean column.

e Calculate the deviation of the Max-Mean divided by the Mean and Mean-Min divided by the Mean and

record the results in the corresponding columns.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 49

Table 1 – Gain Flatness and Calibration Error

(Max-Mean) (Mean-Min)

Gain Table Flatness Max Min Mean

Mean Mean

Short SID

Grid

Long SID

Grid

Short SID

no Grid

Long SID

no Grid

3 Verify that all the values in the two right columns ( (Max-Mean)/Mean, (Mean-Min/Mean)) are

<0.1.

4 Load the relevant gain calibration file placed in C:\_Exe\Trixell_Correction_Tables (for example

Gain_LongSID_Grid_NoSwivel_#Station1). Use a narrow windowing level (center as the image average and

width as 10% of the image average). Verify there are no clear ghost images such as collimator blades or

phantom you used before.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 50

5 Repeat the test for the table stand if exists with the following setups:

# kVp mA/mSec Absorber SID [cm/Inch] Calibration correction Grid AEC

1 70 100mA/40mS 1.5mmCu 100/40 All Yes Off

2 70 100mA/40mS 1.5mmCu 100/40 All No Off

1 120 100mA/40mS 1.5mmCu 140/55 All Yes Off

2 120 100mA/40mS 1.5mmCu 140/55 All No Off

Table 2 – Gain Flatness and Calibration Error

(Max-Mean) (Mean-Min)

Gain Table Flatness Max Min Mean

Mean Mean

Short SID

Grid

Long SID

Grid

Short SID

no Grid

Long SID

no Grid

6 Verify that all the values in the two right columns ( (Max-Mean)/Mean, (Mean-Min/Mean)) are

<0.1.

7 Load the relevant gain calibration file placed in C:\_Exe\Trixell_Correction_Tables (for example

Gain_LongSID_Grid_NoSwivel_#Station1). Use a narrow windowing level (center as the image average and

width as 10% of the image average). Verify there are no clear ghost images such as collimator blades or

phantom you used before.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 51

FPD Sensitivity Test

1 Set the system values as follows:

SID Calibration

kVp mA/mSec Absorber Grid AEC

[cm/Inch] Correction

70 200mA/50mS 1.5mmCu 100/40 All No Off

1 Place a dosimeter on a lead plate and position it above the bucky center.

2 Measure the height of the dosimeter above the bucky surface: h = ______.

3 Calculate the height correction factor: Hcf = [104/(100-h)] 2.

4 Acquire an image.

5 Measure the dose and record the result: μGy = __________

6 Position the ROI square on the middle of the image.

7 Record the average gray level: GL = __________

8 Calculate :

SGL = GL/ μGy ∙ Hcf= __________

9 Verify that value is 610±120 for CSI and 359±30 for GADOX (for the Pixium Portable

3543 the value is 610±120)

10 Repeat the same for table if exists.

Spatial Resolution and Contrast Resolution

1 Set the system values as follows:

kVp mA/mSec Absorber SID [cm/Inch] Calibration Correction Grid AEC

70 100/100 None 100/40 All No Off

2 Place the image test target in the grid position.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 52

3 Acquire an image.

Contrast

Resolution

Spatial

Resolution

Figure - 7: Image Test Target

Figure - 8: Spatial Resolution Section

4 Using full resolution view without zoom, in the spatial resolution section (marked with a circle

in Figure 9 5), locate the smallest group of lines where the black and white lines are visible.

The LP/mm number should be >3.1. Windowing is allowed.

5 Using full resolution view, in the contrast resolution section (marked with an ellipse in Figure

9 5), verify that six entire circles are visible. Windowing is allowed.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 53

Grid Micro Switches

1 Choose APR Chest PA.

a Verify that the APR requires a grid.

b Insert the grid. Verify that the Grid icon does not appear.

c Remove the grid. Verify that the Grid icon appears.

2 Insert the grid.

a Choose APR Chest Child.

b Verify that the APR does not require a grid.

c Verify that the Grid icon appears.

d Remove the grid. Verify that the Grid icon disappears.

AEC

Perform this test only after adjusting the AEC. See sections Error! Reference source not found. - 0Error! Reference

source not found. of the installation and maintenance manual

Different kVp Values and Stability

1 Set the system values as follows:

kVp mA/mSec Absorber SID [cm/Inch] Calibration Correction Grid AEC

Defined below 400/320 None 180/72 All Yes On

2 Using the kVp and absorber settings listed in the table below, acquire images.

3 In the left hand corner record the measured μGy

4 Calculate for each three lines the average value and record it in the middle column MμGy.

5 Calculate according to the equation in the right column the deviation (Dev) from average for each line.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 54

Table 3 Dev Values

MμGy

μGy

Setup Dev = (μGy/MμGy-1) 2

(mean{μGy})

1. 70kVp 1.5mmCu

2. 70kVp 1.5mmCu

3. 70kVp 1.5mmCu

1. 120kVp 1.5mmCu

2. 120kVp 1.5mmCu

3. 120kVp 1.5mmCu

6 Calculate:

(Sum(Dev)/6) = ___________. The value should be less than 0.05.

7 Repeat the same for table.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 55

Different Density Values Stability Check

1 Set the system values as follows:

kVp mA/mSec Absorber SID [cm/Inch] Calibration Correction Grid AEC

Defined below 400/320 None 180/72 All Yes On

2 Using the KvP, AEC filed selection and absorber settings listed in the table below, acquire images.

Table 4 FPD Gray Levels

KVp AEC filed and

Absorber Density, FPD1 Gray level FPD2 Gray Level

55 KV, no Al -2

0

+2

80 KV, 1.5mm Cu -2

0

+2

120 KV, 1.5mm Cu -2

3 V

0

erif

+2 y

that

all the measured gray levels are as follows:

For Density = -2 Sensitivity value * 6 * 75% +100

For Density = 0 Sensitivity value * 6 +100

For Density = +2 Sensitivity value * 6 * 125% +100

Note - For Sedecal replace 75% with 50% and 125% with 150%.

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 56

MWM/HIS/RIS

Refer to the relevant User Manual.

Receive patient list

Search by ID

Search by date

Search by name

Patient details received OK

DICOM

Refer to the relevant User Manual.

Image printed in Full Text, Portrait format

Image printed in Full Text, Landscape format

Image printed in Maximum Size, Portrait format

Image printed in Maximum Size, Landscape format

Image sent to PACS

Patient details in the PACS system are correct

Image in the PACS appears as on the monitor

Modality performed procedure Step Create sent to RIS

Modality performed procedure Step Set sent to RIS

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 57

Monitor calibration

Fill out following table after performing the monitor calibration as described in paragraph Error! Reference source

not found.

Monitor Calibration Results – PrestoDR

Monitor Serial Number S

Monitor Model

Date D M Y

Monitor Calibration Version____________

Parameter Value Unit Min Nominal Max

Brightness % - - 100

Brightness / Contrast % 55 75 85

Contrast

No Error Check

Pop-up Mark

Display Settings

Monitor

Temperature Kelvin 4700 5000 5300

Temperature

Monitor

Measurements Steps - 10 20 20

Measurements

Check

Created Performed

Mark

ICC Profile

Check

Validated Performed

Mark

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

Leggera Installation Guide v2.0 58

Test Report Files

After completing the test, please send the following:

1. A soft copy of the calibration files placed in: K:\_Exe\Trixell_Correction_Tables

2. A signed hard copy of this document.

To:

THALES ELECTRON DEVICES S.A.

460, rue du Pommarin - BP 122

38346 Moirans Cedex – France

Tel : +33 (0)4 76 57 52 80

Fax : +33 (0)4 76 57 40 85

email to: x-rayimaging.support@thalesgroup.comx-rayimaging.support@thalesgroup.com

Customer Support 1.800.366.5343 – support@viztek.net

LGDR-UG-Leggera Mobile Installation-D-190213-2.1

You might also like

- BackPlane - Description Pin OutDocument14 pagesBackPlane - Description Pin OutSanty VallNo ratings yet

- Products Affected / Serial Numbers Affected:: TP17 212.pdf 08-11-17Document4 pagesProducts Affected / Serial Numbers Affected:: TP17 212.pdf 08-11-17RudyNo ratings yet

- Wlink WL-G510 Cellular Router User ManualDocument65 pagesWlink WL-G510 Cellular Router User ManualWLINK SHENZHENNo ratings yet

- Wiring DiagramDocument4 pagesWiring Diagramgledyson gueNo ratings yet

- Wiring DiagramDocument4 pagesWiring Diagramivo rodriguesNo ratings yet

- Wimod Lite Gateway: Data SheetDocument13 pagesWimod Lite Gateway: Data SheetJulian CamiloNo ratings yet

- DSL8900GR (AC) : Product BenefitsDocument2 pagesDSL8900GR (AC) : Product BenefitsMich AltNo ratings yet

- SSGW 406Document8 pagesSSGW 406ALSAMAD V MNo ratings yet

- Cisco Catalyst IE3200 Rugged SeriesDocument16 pagesCisco Catalyst IE3200 Rugged SerieshayashiedNo ratings yet

- Quectel BG96 Hardware Design V1.6Document73 pagesQuectel BG96 Hardware Design V1.6diemariasNo ratings yet

- HP PN5966 4167E - Passively Probing Motorola IBMPowerPC 603Document12 pagesHP PN5966 4167E - Passively Probing Motorola IBMPowerPC 603sirjole7584No ratings yet

- KHDtrack Standard 7Document30 pagesKHDtrack Standard 7Aziz AzizNo ratings yet

- XM125 DatasheetDocument22 pagesXM125 DatasheetCem VardarNo ratings yet

- Ipc 2226Document63 pagesIpc 2226Benyamin Farzaneh AghajarieNo ratings yet

- Hardware Installation Guide: Imanager Neteco V600R008C10Document72 pagesHardware Installation Guide: Imanager Neteco V600R008C10Nagaraju ThangellaNo ratings yet

- Service Repair Documentation Level 2.5e - C75: S ComDocument37 pagesService Repair Documentation Level 2.5e - C75: S ComQuiteNo ratings yet

- AVR IoT WG Development Board User Guide 50002809BDocument47 pagesAVR IoT WG Development Board User Guide 50002809BPedro MorrisNo ratings yet

- DE10-Lite User Manual: June 5, 2020Document56 pagesDE10-Lite User Manual: June 5, 2020SferreiraNo ratings yet

- Products Affected / Serial Numbers Affected:: TP17 273.pdf 10-10-17Document3 pagesProducts Affected / Serial Numbers Affected:: TP17 273.pdf 10-10-17RudyNo ratings yet

- PixLite 4 Mk2 User Manual - 20230823Document24 pagesPixLite 4 Mk2 User Manual - 20230823valentinlemarquierNo ratings yet

- Amwell Standard Protocol V2.02!14!11 - 11Document30 pagesAmwell Standard Protocol V2.02!14!11 - 11Aziz AzizNo ratings yet

- Mixed DocumentDocument76 pagesMixed DocumentPongsak KungsuwunNo ratings yet

- Intellivue Patient MonitorDocument30 pagesIntellivue Patient MonitorystloveNo ratings yet

- DG Wm2003sie New UmDocument27 pagesDG Wm2003sie New Umподделкаイスラム教No ratings yet

- Catalyst Ie3100 Rugged Series DsDocument18 pagesCatalyst Ie3100 Rugged Series Dshavoc25No ratings yet

- Display Board For G2 Power ControllersDocument2 pagesDisplay Board For G2 Power ControllersHamed YazidiNo ratings yet

- DH7516 Nova Receiving Card Spec EnglishDocument7 pagesDH7516 Nova Receiving Card Spec Englishquang nguyễnNo ratings yet

- (C33561.20 B0) User ManualDocument130 pages(C33561.20 B0) User ManualrastavljeniNo ratings yet

- Aw GM320 PDFDocument10 pagesAw GM320 PDFhadiNo ratings yet

- Datasheet LT22222Document1 pageDatasheet LT22222mcarruNo ratings yet

- Nemtek CDG2 GManual Druid 2 XDocument6 pagesNemtek CDG2 GManual Druid 2 Xneumann CassienNo ratings yet

- 2-Channel Unit SUB - SUB 2x400ohm 6ch User ManualDocument130 pages2-Channel Unit SUB - SUB 2x400ohm 6ch User Manualhui liuNo ratings yet

- Product Change NotificationDocument10 pagesProduct Change NotificationAly RabahNo ratings yet

- Qig PDFDocument8 pagesQig PDFnaveen pragashNo ratings yet

- Circuit Descriptions: EN 34 QM16.4E LA 7Document3 pagesCircuit Descriptions: EN 34 QM16.4E LA 7avrelec100% (1)

- Ireland English Client Pricelist FY15Q4 PDFDocument516 pagesIreland English Client Pricelist FY15Q4 PDFAswin Lorenzo GultomNo ratings yet

- G Glensound Electronics LTD: Gsgc5G Isdn MixersDocument20 pagesG Glensound Electronics LTD: Gsgc5G Isdn MixersJohnnyNo ratings yet

- Cat Ie3200 Rugged Series DsDocument17 pagesCat Ie3200 Rugged Series Ds吳竣民No ratings yet

- KTD 00714 F Add2 Dvi Dual User ManualDocument9 pagesKTD 00714 F Add2 Dvi Dual User ManualkarllozaraujoNo ratings yet

- Opengear User ManualDocument345 pagesOpengear User ManualApple FruitworldNo ratings yet

- IM7200 Quick Start Guide: 01. Check The Kit's Contents Are CompleteDocument4 pagesIM7200 Quick Start Guide: 01. Check The Kit's Contents Are CompleteMiro JanosNo ratings yet

- Dell Latitude D630 Schematics VersionDocument67 pagesDell Latitude D630 Schematics VersionRodney RibeiroNo ratings yet

- Ion G2display DsDocument2 pagesIon G2display DsMohammed HamedNo ratings yet

- 4channel RemoteDocument15 pages4channel Remoteryan cooperNo ratings yet

- Wrtu54g TM v10 Ug B-WebDocument107 pagesWrtu54g TM v10 Ug B-WebMarcelo GiussaniNo ratings yet

- Sony VGN-NR498E SpecificationsDocument2 pagesSony VGN-NR498E SpecificationsdsromeNo ratings yet

- CF CardDocument10 pagesCF CardHùng ThanhNo ratings yet

- FPGA Applied in Hardware Computer Aided Design ofDocument8 pagesFPGA Applied in Hardware Computer Aided Design ofMangaka DomingosNo ratings yet

- Philips+22PFL3606-77+TPM8 3LDocument63 pagesPhilips+22PFL3606-77+TPM8 3Lluciano casoNo ratings yet

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardFrom EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardNo ratings yet

- 2.9.2 Lab - Basic Switch and End Device ConfigurationDocument6 pages2.9.2 Lab - Basic Switch and End Device ConfigurationSuemdzinNo ratings yet

- GT4000 LCD Topper & GT4010 LED Backlit Topper: Technical SpecificationDocument62 pagesGT4000 LCD Topper & GT4010 LED Backlit Topper: Technical SpecificationdhanysiregarNo ratings yet

- tpm8.3l La 312278519190 110930Document63 pagestpm8.3l La 312278519190 110930GMS ELECTRONICANo ratings yet

- Digital Scanner Product Reference Guide: MN-002752-12ENDocument642 pagesDigital Scanner Product Reference Guide: MN-002752-12ENOswaldo ShakurNo ratings yet

- Electronic Service ToolsDocument9 pagesElectronic Service ToolsYousuf AliNo ratings yet

- Abcdef: Meridian Digital Repeater User ManualDocument21 pagesAbcdef: Meridian Digital Repeater User Manual'Egemen KayaNo ratings yet

- 2XX-IP: Ethernet Interface OptionDocument12 pages2XX-IP: Ethernet Interface OptionDidik SudarsonoNo ratings yet

- A6V12574873 - BACnet - IP Web Interface - BR - PXG3.W100-2 PXG3.W200 - enDocument12 pagesA6V12574873 - BACnet - IP Web Interface - BR - PXG3.W100-2 PXG3.W200 - enRadu HereaNo ratings yet

- Capri - Capri+ Trouble-Shooting Guide-L3Document53 pagesCapri - Capri+ Trouble-Shooting Guide-L3Jonatan Antonio Da SilvaNo ratings yet

- Akd User GuideDocument979 pagesAkd User GuideMehdi Ben AbdallahNo ratings yet

- 1.5T 8CH Torso Coil Anterior Connector Fru - SM - Doc1118868 - 1Document6 pages1.5T 8CH Torso Coil Anterior Connector Fru - SM - Doc1118868 - 1service iyadMedicalNo ratings yet

- CBT-90-RX-L15-BN101-CBT-90 TE热增强LED芯片组-红色 平的 621 (615~627) 28mm3mm4.08mm 2.8VDocument15 pagesCBT-90-RX-L15-BN101-CBT-90 TE热增强LED芯片组-红色 平的 621 (615~627) 28mm3mm4.08mm 2.8Vservice iyadMedicalNo ratings yet

- 1.5T 16CH Sentinelle Breast Coil by Invivo Service Manual - SM - Doc1729472 - 1Document144 pages1.5T 16CH Sentinelle Breast Coil by Invivo Service Manual - SM - Doc1729472 - 1service iyadMedicalNo ratings yet

- FXRD1417W X-Ray Detector User Manual VieworksDocument125 pagesFXRD1417W X-Ray Detector User Manual Vieworksservice iyadMedicalNo ratings yet

- 1.5T 8CH Sentinelle Breast Coil by Invivo Service Manual - SM - Doc1724552 - 1Document47 pages1.5T 8CH Sentinelle Breast Coil by Invivo Service Manual - SM - Doc1724552 - 1service iyadMedicalNo ratings yet

- Internal Photos 2147563Document2 pagesInternal Photos 2147563service iyadMedicalNo ratings yet

- Internal Photos 2201148Document20 pagesInternal Photos 2201148service iyadMedicalNo ratings yet

- 1.5T Express Coil Suite Operator Manual Direction 5343815-2EN Rev 6Document37 pages1.5T Express Coil Suite Operator Manual Direction 5343815-2EN Rev 6service iyadMedicalNo ratings yet

- ACT Series Installation Manual Electrical Calibration, Integration & TestingDocument110 pagesACT Series Installation Manual Electrical Calibration, Integration & Testingservice iyadMedicalNo ratings yet

- HHS Fluoro System Tests - SM - 46-017563 - 37Document38 pagesHHS Fluoro System Tests - SM - 46-017563 - 37service iyadMedicalNo ratings yet

- ID Label 2201122Document2 pagesID Label 2201122service iyadMedicalNo ratings yet

- 通用电气GE Optima CT520Pro 全身用X射线计算机体层摄影装置7f0Document22 pages通用电气GE Optima CT520Pro 全身用X射线计算机体层摄影装置7f0service iyadMedicalNo ratings yet

- CT Somatom Go Top Brochures Stand Out in Advanced CT Procedures Hood05162002856838 152099932Document56 pagesCT Somatom Go Top Brochures Stand Out in Advanced CT Procedures Hood05162002856838 152099932service iyadMedicalNo ratings yet

- Xw8400 Service and Technical Reference Guide - SM - 5555180-1EN - 1 - 2Document224 pagesXw8400 Service and Technical Reference Guide - SM - 5555180-1EN - 1 - 2service iyadMedicalNo ratings yet

- MRI-Magnetic Resonance Imaging Tris Budiyono (ATRO CB) PPT - 翻译版Document85 pagesMRI-Magnetic Resonance Imaging Tris Budiyono (ATRO CB) PPT - 翻译版service iyadMedicalNo ratings yet

- Definium 8000 SystemDocument2 pagesDefinium 8000 Systemservice iyadMedicalNo ratings yet

- QC For FFDMDocument78 pagesQC For FFDMservice iyadMedicalNo ratings yet

- Workstation BlocksDocument70 pagesWorkstation Blocksservice iyadMedical100% (1)

- Breast Imagingand InterventionalDocument353 pagesBreast Imagingand Interventionalservice iyadMedicalNo ratings yet

- XJLink2 - USB JTAG 控制器xjtag-tech-specs - xjlink2-EnDocument1 pageXJLink2 - USB JTAG 控制器xjtag-tech-specs - xjlink2-Enservice iyadMedicalNo ratings yet

- BD FACSCelesta™ Flow Cytometer User's GuideDocument152 pagesBD FACSCelesta™ Flow Cytometer User's Guideservice iyadMedicalNo ratings yet

- 飞利浦巴基诊断 X 射线系统 DigitalDiagnost VM 2 +VM Compact-1Document57 pages飞利浦巴基诊断 X 射线系统 DigitalDiagnost VM 2 +VM Compact-1service iyadMedical100% (2)

- 加拿大CPI公司 VZW2930FJ2-40 X射线诊断高压发生装置Document37 pages加拿大CPI公司 VZW2930FJ2-40 X射线诊断高压发生装置service iyadMedicalNo ratings yet

- 1.5T Scanner Software V3.x Reinstallation Guide Operating DocumentationDocument26 pages1.5T Scanner Software V3.x Reinstallation Guide Operating Documentationservice iyadMedicalNo ratings yet

- Ophthalmic-Slit-lampMicroscope-SLM-3ER (SLR) - SLM-3ER User-ManualDocument48 pagesOphthalmic-Slit-lampMicroscope-SLM-3ER (SLR) - SLM-3ER User-Manualservice iyadMedicalNo ratings yet

- Graphics Layout Drawing - 4Document1 pageGraphics Layout Drawing - 4service iyadMedicalNo ratings yet

- KMMI Blue Moon For Integrated DRDocument2 pagesKMMI Blue Moon For Integrated DRservice iyadMedicalNo ratings yet

- Angix System3D CalibrationDocument21 pagesAngix System3D Calibrationservice iyadMedicalNo ratings yet

- Awodey, Categories For Everybody - PsDocument196 pagesAwodey, Categories For Everybody - PsΣωτήρης Ντελής100% (3)

- An FPGA Implementation of A Feed-Back Chaotic Synchronization For Secure CommunicationsDocument5 pagesAn FPGA Implementation of A Feed-Back Chaotic Synchronization For Secure Communicationslaz_chikhi1574No ratings yet

- CISCO Router Software - Configuration PDFDocument408 pagesCISCO Router Software - Configuration PDFasalihovicNo ratings yet

- Awards Gold Medals Grade VIDocument11 pagesAwards Gold Medals Grade VIBernadeth Escosora DolorNo ratings yet

- NumaticsFRLFlexiblokR072010 EsDocument40 pagesNumaticsFRLFlexiblokR072010 EsGabriel San Martin RifoNo ratings yet

- 4$20 Triangles$20 ProofsDocument23 pages4$20 Triangles$20 ProofsBaskaran SeetharamanNo ratings yet

- 15Document20 pages15Allen Rey YeclaNo ratings yet

- WhiteLED1 8Document12 pagesWhiteLED1 8Smyle KatariaNo ratings yet

- Good 1983Document352 pagesGood 1983ASDA75% (4)

- JSF + JPA + JasperReports (Ireport) Part 2 - Ramki Java BlogDocument7 pagesJSF + JPA + JasperReports (Ireport) Part 2 - Ramki Java BlogMartin MurciegoNo ratings yet

- Ruby On Rails 3 Cheat SheetDocument7 pagesRuby On Rails 3 Cheat SheetJarosław MedwidNo ratings yet

- Caterpillar Product Line 13Document7 pagesCaterpillar Product Line 13GenneraalNo ratings yet

- Astm A394 2008 PDFDocument6 pagesAstm A394 2008 PDFJavier Ricardo Romero BohorquezNo ratings yet

- Module 1 Engineering ScienceDocument38 pagesModule 1 Engineering ScienceLogan JesseNo ratings yet

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDocument5 pagesComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- Reverse Engineering Cheat SheetDocument1 pageReverse Engineering Cheat Sheetalfredhitchcock_007100% (2)

- A334 Carino, Patricia Andrea Assignment On ForecastingDocument3 pagesA334 Carino, Patricia Andrea Assignment On ForecastingPatricia Andrea CariñoNo ratings yet

- Mit BBM (Ib), Ipm-Session 2.4Document32 pagesMit BBM (Ib), Ipm-Session 2.4Yogesh AdhateNo ratings yet

- Glpi Developer DocumentationDocument112 pagesGlpi Developer Documentationvictorlage7No ratings yet

- 1922 A Textbook of Balochi LanguageDocument228 pages1922 A Textbook of Balochi LanguageAnonymous 0ywnNS29EGNo ratings yet

- Soiling Rates of PV Modules vs. Thermopile PyranometersDocument3 pagesSoiling Rates of PV Modules vs. Thermopile PyranometersAbdul Mohid SheikhNo ratings yet

- Momus Design CNC Router Manual Version 2.1Document178 pagesMomus Design CNC Router Manual Version 2.1Francisco Teruel100% (8)

- Four Bolt Unstiffened End PlateDocument7 pagesFour Bolt Unstiffened End PlateRnD2013No ratings yet

- Groundwater Flow-Chapter3FYDocument73 pagesGroundwater Flow-Chapter3FYTemesgen workiyeNo ratings yet

- T8 - Energetics IDocument28 pagesT8 - Energetics II Kadek Irvan Adistha PutraNo ratings yet

- Javascript Html5 CanavasDocument13 pagesJavascript Html5 CanavasmihailuNo ratings yet

- Nidhi ResumeDocument2 pagesNidhi ResumeabhiNo ratings yet

- Numbers (0, 1, 2, 3,... ) Are Defined To Be Natural Numbers, Including Zero, That Does Not ContainDocument9 pagesNumbers (0, 1, 2, 3,... ) Are Defined To Be Natural Numbers, Including Zero, That Does Not ContainRomela EspedidoNo ratings yet

- 8.2.2.2.1.1 Batch Operation ManagementDocument10 pages8.2.2.2.1.1 Batch Operation ManagementbernardNo ratings yet

- Basic Use of Datum Plane in Creo ParametricDocument8 pagesBasic Use of Datum Plane in Creo ParametricKartik BhararaNo ratings yet