SAP Asset Management

Uploaded by

M KASHIF IDREESSAP Asset Management

Uploaded by

M KASHIF IDREES- Introduction to SAP Asset Management: This section provides an overview of SAP's solutions in asset management, including digital twin technology and strategic operations.

- SAP's Vision for Asset Management: Presents SAP’s vision for integrating digital processes in asset management, enhancing collaboration and process efficiency.

- Global Asset Management Trends: Discusses global trends in asset management from traditional methods to smart digital connected assets.

- Network of Digital Twins: Explains how digital twins are utilized for enhanced asset management, integrating physical and digital realms.

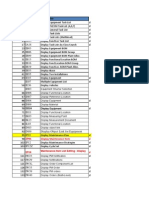

- SAP Connected Assets Portfolio: Describes the portfolio of applications for connected assets, focusing on integration and intelligence systems.

- Complementary Digital Twins: Details the three digital twins provided by SAP, enhancing operational efficiency and asset management.

- SAP Asset Intelligence Network: Introduces the asset intelligence network that connects business partners for collaborative asset management.

Common questions

Powered by AIThe SAP Asset Intelligence Network contributes to collaborative asset management by providing a global registry of equipment that is shared between multiple business partners and stakeholders, leading to new collaborative business models and true operational excellence. The key components include a cloud portal of standardized content for equipment definition, a secure network for information exchange, and various apps for performance improvement and spare parts management .

Asset Central supports data integration across IoT applications by serving as a reusable asset registry that ensures data consistency and seamless integration. The benefits it offers for EAM include improved predictive maintenance techniques and optimized business processes for greater asset availability and reduced cost, as it centralizes and harmonizes asset information .

The shift from selling compressors to selling compressed air, empowered by SAP solutions like Predictive Maintenance and Service and machine health monitoring, transforms the business model from a product-centric to a service-centric approach. This transition is enabled by IoT, enhancing equipment availability and moving maintenance from unplanned to planned, which aligns with the modern service-oriented economy .

Predictive engineering insights for Arctic Wind's remote wind farm enable real-time engineering simulation through sensor-feeds and a Finite Element Solver, which facilitates better decision support in operations and maintenance. The advantages include maintenance cost reduction due to predictive capabilities, lifetime extension via full load history, and improved operational efficiency despite the challenges of accessing remote locations .

FEDEM enhances predictive engineering insights by enabling real-time finite element analysis in cloud-based applications. It supports advanced simulation of structural behaviors, including hydro- and aerodynamics, soil stiffness, and control systems. This facilitates vibrational diagnostics, stress and strain analysis, and predictive maintenance in operational settings, bridging design and operational data .

SAP Predictive Maintenance and Service facilitates the transition from corrective to planned maintenance by integrating IT and OT data for remote diagnostics and predictive models. This predictive approach increases asset availability and passenger satisfaction while reducing maintenance effort by anticipating faults before they occur, thus allowing for planned interventions rather than reactive responses .

A centralized asset information repository at BASF Ludwigshafen improves asset effectiveness and decision-making by ensuring data consistency and availability across engineering and maintenance processes. This integration allows quick access to the latest information, leading to more informed, faster decision-making and consequently higher asset effectiveness .

Businesses applying SAP's Predictive Maintenance and Service experience enhanced maintenance efficiency by reducing unplanned outages, increasing asset availability, and providing real-time diagnostics. This shift from reactive to proactive maintenance improves service levels and asset longevity, leading to lower maintenance costs and operational downtime .

The digital twin enhances asset lifecycle management by providing a full digital representation of assets, allowing for real-time insights, optimization via prediction, and collaborative processes across the asset's lifecycle. Key applications include prescriptive maintenance, smart work instructions, and strategic asset performance management, facilitating better decision-making and operational efficiencies .

Integrating SAP Leonardo IoT for Asset Management has strategic implications by enabling a digital core for system intelligence and transformational effects on operations. It improves end-to-end business value through predictive maintenance, asset strategy, and performance management, thereby enhancing asset availability, reducing costs, and increasing operational insights across the enterprise .