Professional Documents

Culture Documents

Nitrocellulose in Finish On Leather: Standard Test Method For

Nitrocellulose in Finish On Leather: Standard Test Method For

Uploaded by

Hoem ITOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitrocellulose in Finish On Leather: Standard Test Method For

Nitrocellulose in Finish On Leather: Standard Test Method For

Uploaded by

Hoem ITCopyright:

Available Formats

--`,,```,,,,````-`-`,,`,,`,`,,`---

Designation: D 4907 – 00 (Reapproved 2005)

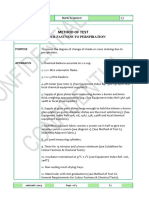

Standard Test Method for

Nitrocellulose in Finish on Leather1

This standard is issued under the fixed designation D 4907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope dark blue color, then nitrocellulose is not present in the finish.

1.1 This test method is intended for use in identifying If the indicator solution develops a dark blue color after contact

nitrocellulose in the finish on all types of leathers. This test with the finish, it indicates the presence of nitrocellulose or has

method does not apply to wet blue. developed color from colored finish components, or both.

1.2 The values stated in SI units are to be regarded as the 6.2 Repeat the above procedure except that the blank

standard. solution is employed instead of the indicator solution. If a dark

1.3 This standard does not purport to address all of the blue color does not develop, whereas it does when the indicator

safety concerns, if any, associated with its use. It is the solution is applied, then nitrocellulose is present in the finish

responsibility of the user of this standard to establish appro- and colored finishing materials do not interfere.

priate safety and health practices and determine the applica- 6.3 If colored finish material develops a dark blue color in

bility of regulatory limitations prior to use. the presence of the blank solution, then place the specimen

finish side up in a watch glass and pour acetone on the

2. Significance and Use specimen, until completely covered, for dissolving any nitro-

2.1 This test method is used to identify nitrocellulose in cellulose present in the specimen. After allowing the specimen

finishes on all types of leathers. to soak in acetone for approximately 2 min, remove the

specimen from the watch glass and the evaporate acetone in the

3. Apparatus watch glass on the steam oven to dryness. When cooled to

3.1 Borosilicate Glass Watch Glass, 100 mm diameter. room temperature, place a few drops of indicator solution on

3.2 Reagent Bottles, two, (4 fl oz each) equipped with glass one side of the watch glass near the rim and allow the drops to

joint dropping pipet. run downward. At another location on the watch glass, place a

few drops of blank solution near the rim and allow to run

4. Reagents downward. If nitrocellulose is present in the finish, a dark blue

4.1 Indicator solution prepared by dissolving 0.1 g diphe- color will develop as the indicator solution runs downward into

nylamine in solution containing 100 mL of sulfuric acid and 30 the watch glass whereas the blank solution will not show any

mL of distilled water. color development.

4.2 Blank solution comprising 100 mL of sulfuric acid and

7. Report

30 mL of distilled water.

4.3 Acetone, C.P. 7.1 The indicator method for testing the presence of nitro-

cellulose in finish on the leather shall be reported as positive or

5. Test Specimen negative.

5.1 The test specimen shall be approximately 1 cm2 of the

8. Precision and Bias

finished leather.

8.1 This test method is adopted from the procedures of the

6. Procedure American Leather Chemists Association where it has been in

6.1 Place the test specimen in the watch glass with the finish use and where it was approved for publication before the

side up. Apply one or 2 mL of indicator solution on the finish inclusion of precision and bias statements were mandated. The

and allow to run over the side of the leather on to the watch original interlaboratory test data is no longer available. The

glass. After 3 min, if the indicator solution does not develop a user is cautioned to verify by the use of reference materials, if

available, that the precision and bias of this method is adequate

for the contemplated use.

1

This test method is under the jurisdiction of ASTM Committee D31 on Leather

and is the direct responsibility of Subcommittee D31.06 on Chemical Analysis— 9. Keywords

General. This test method was developed in cooperation with the American Leather

Chemists Assn. (Method K 5-1956). 9.1 finish; nitrocellulose

Current edition approved Sept. 1, 2005. Published September 2005. Originally

approved in 1989. Last previous edition approved in 2000 as D 4907 – 00.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Reproduced by IHS under license with ASTM Copyright by ASTM Int'l (all rights reserved);

No reproduction or networking permitted without license from IHS Not for Resale

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Sep 26 13:31:29 EDT 2005

D 4907 – 00 (2005)

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Copyright by ASTM Int'l (all rights reserved);

Reproduced by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Sep 26 13:31:29 EDT 2005

You might also like

- ASTM D3723 2005 - Pigment Content of Water-Emulsion PaintsDocument2 pagesASTM D3723 2005 - Pigment Content of Water-Emulsion PaintstsalemnoushNo ratings yet

- Facilitate Learning Session: Prepared By: Wilmer J. DirectoDocument31 pagesFacilitate Learning Session: Prepared By: Wilmer J. DirectoJohn Wilner DirectoNo ratings yet

- H1.50XM (D001)Document404 pagesH1.50XM (D001)porter1980100% (6)

- LR - Phil Politics and Governance Week 1 For StudentDocument19 pagesLR - Phil Politics and Governance Week 1 For StudentErinRoelleNo ratings yet

- Vice President Information Technology in Baltimore MD Resume Jerry KingDocument2 pagesVice President Information Technology in Baltimore MD Resume Jerry KingJerryKing2No ratings yet

- Daily Lesson Log G8 TLEDocument4 pagesDaily Lesson Log G8 TLEMervin PaciaNo ratings yet

- Astm e 1135Document5 pagesAstm e 1135KEN KNo ratings yet

- Astm d3258Document2 pagesAstm d3258mynor aldanaNo ratings yet

- The Lump Sum Construction Contract What Seems To Be The ProblemDocument57 pagesThe Lump Sum Construction Contract What Seems To Be The ProblemJamalNo ratings yet

- Case Study Uber Pricing Strategy Uber PRDocument10 pagesCase Study Uber Pricing Strategy Uber PRTehreem SirajNo ratings yet

- Astm D2180-1989 (2008)Document2 pagesAstm D2180-1989 (2008)WMJNo ratings yet

- D185Standard Test Methods For Coarse Particles in PigmentsDocument2 pagesD185Standard Test Methods For Coarse Particles in PigmentsGiovanni OsorioNo ratings yet

- Piping Support Standard Specification (217-234)Document35 pagesPiping Support Standard Specification (217-234)Emilio HuertasNo ratings yet

- Network Chapter# 20: Transport Protocols Transport Protocols Transport Protocols Transport ProtocolsDocument6 pagesNetwork Chapter# 20: Transport Protocols Transport Protocols Transport Protocols Transport ProtocolsRevathi RevaNo ratings yet

- ASTM F21 Atomiser Test For Surface FilmsDocument5 pagesASTM F21 Atomiser Test For Surface Filmsazam RazzaqNo ratings yet

- Productattachments Files e - E-m-hp23-V2 14Document2 pagesProductattachments Files e - E-m-hp23-V2 14ramonNo ratings yet

- D6989 PDFDocument3 pagesD6989 PDFDeepak D MishraNo ratings yet

- D 1720 - 96 r00 - Rde3mjatotzsmdaDocument4 pagesD 1720 - 96 r00 - Rde3mjatotzsmdaRaphael CordovaNo ratings yet

- Licensed To Arun Kumar Das: (Reaffirmed 2017)Document6 pagesLicensed To Arun Kumar Das: (Reaffirmed 2017)Indira MukherjeeNo ratings yet

- D 1720 - 03 - Rde3mjaDocument4 pagesD 1720 - 03 - Rde3mjaRaphael CordovaNo ratings yet

- D 1720 - 96 - Rde3mjatotyDocument3 pagesD 1720 - 96 - Rde3mjatotyRaphael CordovaNo ratings yet

- D 1579 - 01 Rde1nzk - PDFDocument2 pagesD 1579 - 01 Rde1nzk - PDFMarceloNo ratings yet

- Gram-Color Modified (Phenol-Free) Staining Kit For Gram Staining Method On Bacteriological SmearsDocument2 pagesGram-Color Modified (Phenol-Free) Staining Kit For Gram Staining Method On Bacteriological Smearsaisyah annisa rahma hidayahNo ratings yet

- Surfactants, Anionic, (Detergents), Method 8028, 02-2009, 9th Ed PDFDocument4 pagesSurfactants, Anionic, (Detergents), Method 8028, 02-2009, 9th Ed PDFCorinne MartinNo ratings yet

- Microscopy Gram-Color: Stain Set For The Gram Staining MethodDocument3 pagesMicroscopy Gram-Color: Stain Set For The Gram Staining MethodMuhammad AdhityaNo ratings yet

- ASTM CTC Az Metileno C837 1207962-1Document2 pagesASTM CTC Az Metileno C837 1207962-1JLVriverNo ratings yet

- Solvent-Extractable Material in Black Pigments1Document2 pagesSolvent-Extractable Material in Black Pigments1Ajit SamalNo ratings yet

- Test Name Principal Apparatus/ Requirement Procedure Observation Result/ Concluison PrecautionsDocument4 pagesTest Name Principal Apparatus/ Requirement Procedure Observation Result/ Concluison PrecautionsHuzaifa KhanNo ratings yet

- D332-87 (2011) Standard Test Method For Relative Tinting StrengDocument3 pagesD332-87 (2011) Standard Test Method For Relative Tinting Strengastewayb_964354182No ratings yet

- D 4795 - 94 r98 - Rdq3otutotrsotgDocument3 pagesD 4795 - 94 r98 - Rdq3otutotrsotgalienz1988newNo ratings yet

- Solvent-Extractable Material in Black Pigments: Standard Test Method ForDocument2 pagesSolvent-Extractable Material in Black Pigments: Standard Test Method Forasma hamzaNo ratings yet

- Analysis Nitrite HIGHDocument3 pagesAnalysis Nitrite HIGHvandrake10No ratings yet

- AATCC 104 Colorfastness To Water SpottingDocument1 pageAATCC 104 Colorfastness To Water SpottingAbraham ToxtleNo ratings yet

- D 3272 - 76 (2003) PDFDocument2 pagesD 3272 - 76 (2003) PDFAl7amdlellahNo ratings yet

- Coarse Particles in Pigments: Standard Test Methods ForDocument2 pagesCoarse Particles in Pigments: Standard Test Methods ForPaula DiasNo ratings yet

- Nitrate AnalysisDocument2 pagesNitrate AnalysiskemsmartaNo ratings yet

- Ios Ebp Dma 001 Ziehl-Neelsen Staining Rev 1Document8 pagesIos Ebp Dma 001 Ziehl-Neelsen Staining Rev 1Farid TahmasebiNo ratings yet

- CT 338Document17 pagesCT 338Assane RoqueNo ratings yet

- Astm D-1343Document4 pagesAstm D-1343shikaru7114No ratings yet

- Creysl Violet Stain Neurosciencecourses PDFDocument4 pagesCreysl Violet Stain Neurosciencecourses PDFFabio CampeottoNo ratings yet

- D 1583 - 01Document2 pagesD 1583 - 01o_l_0No ratings yet

- Class 9 PracticalDocument3 pagesClass 9 Practicalkushagrayadav163No ratings yet

- Nitratos Ion SelectivoDocument8 pagesNitratos Ion Selectivosofia parraNo ratings yet

- Clau Astm PDFDocument3 pagesClau Astm PDFLezlie Berenice Serrano GalindoNo ratings yet

- Endotoxine ImpurityDocument6 pagesEndotoxine ImpurityBharat SutharNo ratings yet

- D 3279 - 97 - RdmynzktotcDocument3 pagesD 3279 - 97 - RdmynzktotcHans AbantoNo ratings yet

- D 1579 - 97 Rde1nzktotcDocument2 pagesD 1579 - 97 Rde1nzktotcMarceloNo ratings yet

- AATCC - 15 - 2002 - CF To PerspirationDocument3 pagesAATCC - 15 - 2002 - CF To PerspirationNguyễn Công ThoạiNo ratings yet

- Preparación Patrones de Calibración.Document3 pagesPreparación Patrones de Calibración.Nancy BarrantesNo ratings yet

- Total Iodine Value of Drying Oils and Their Derivatives: Standard Test Method ForDocument3 pagesTotal Iodine Value of Drying Oils and Their Derivatives: Standard Test Method ForAl7amdlellahNo ratings yet

- Core Practical 8 The Rate of Dehydrogenase Activity in Extracts of ChloroplastsDocument6 pagesCore Practical 8 The Rate of Dehydrogenase Activity in Extracts of ChloroplastsAdiNo ratings yet

- Moa Baby CleanserDocument5 pagesMoa Baby CleanserAkanksha SharmaNo ratings yet

- Evaluating The Degree of Chalking of Exterior Paint Films: Standard Test Methods ForDocument4 pagesEvaluating The Degree of Chalking of Exterior Paint Films: Standard Test Methods ForEdgarDavidDiazCamposNo ratings yet

- F 21 - 65 R02 RjixDocument5 pagesF 21 - 65 R02 RjixJuanNo ratings yet

- Analysis For Sodium Toluene Sulfonate in Detergents: Standard Test Method ofDocument3 pagesAnalysis For Sodium Toluene Sulfonate in Detergents: Standard Test Method ofShaker QaidiNo ratings yet

- RDQN MNDocument2 pagesRDQN MNOsama TaghlebiNo ratings yet

- Sidero Tec KitDocument3 pagesSidero Tec KitAidan FOONo ratings yet

- C07 - Colour Fastness To PerspirationDocument5 pagesC07 - Colour Fastness To PerspirationChandru TGNo ratings yet

- ftm25 NewDocument3 pagesftm25 NewCarlos Jorge Julio Llerena Pulido100% (2)

- Dilution and Storage of Botulinum Toxin - Klein, 1998Document2 pagesDilution and Storage of Botulinum Toxin - Klein, 1998Rafael Autran Cavalcante AraújoNo ratings yet

- Astm D2222-14Document2 pagesAstm D2222-14Gabriel Perez CruzNo ratings yet

- Acid-Insoluble Lignin in Wood: Standard Test Method ForDocument2 pagesAcid-Insoluble Lignin in Wood: Standard Test Method ForCasey RybackNo ratings yet

- Sop Gram StainDocument6 pagesSop Gram Staindavid mchembeNo ratings yet

- Physical Description Screening Analysis in Waste: Standard Test Method ForDocument2 pagesPhysical Description Screening Analysis in Waste: Standard Test Method ForAnilNo ratings yet

- Measuring and Counting Particulate Contamination On SurfacesDocument4 pagesMeasuring and Counting Particulate Contamination On SurfaceshopemarineNo ratings yet

- F 24 - 09 (2015) PDFDocument4 pagesF 24 - 09 (2015) PDFAzize RazamNo ratings yet

- Turbidity AWWA Standard Methods 22Document4 pagesTurbidity AWWA Standard Methods 22Marco AzambujaNo ratings yet

- D 2621 - 87 r95 - Rdi2mjetoddsotvfmqDocument26 pagesD 2621 - 87 r95 - Rdi2mjetoddsotvfmqjorge armandoNo ratings yet

- BS 1042 2 4 1989, Measurement ofDocument44 pagesBS 1042 2 4 1989, Measurement ofHoem ITNo ratings yet

- D 6124 - 01 - RdyxmjqDocument4 pagesD 6124 - 01 - RdyxmjqHoem ITNo ratings yet

- FDocument7 pagesFHoem ITNo ratings yet

- Austenitic Ductile Iron Castings For Pressure-Containing Parts Suitable For Low-Temperature ServiceDocument5 pagesAustenitic Ductile Iron Castings For Pressure-Containing Parts Suitable For Low-Temperature ServiceHoem ITNo ratings yet

- Corrosion-Resistant High-Silicon Iron Castings: Standard Specification ForDocument5 pagesCorrosion-Resistant High-Silicon Iron Castings: Standard Specification ForHoem ITNo ratings yet

- FDocument2 pagesFHoem ITNo ratings yet

- Martensitic Stainless Steel Forgings and Forging Stock For High-Temperature ServiceDocument4 pagesMartensitic Stainless Steel Forgings and Forging Stock For High-Temperature ServiceHoem ITNo ratings yet

- Steel Sheet, Terne (Lead-Tin Alloy) Coated by The Hot-Dip ProcessDocument5 pagesSteel Sheet, Terne (Lead-Tin Alloy) Coated by The Hot-Dip ProcessHoem ITNo ratings yet

- Evaporation and Drying of Analytical Solutions: Standard Test Method ForDocument2 pagesEvaporation and Drying of Analytical Solutions: Standard Test Method ForHoem ITNo ratings yet

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocument5 pagesStainless Chromium Steel-Clad Plate: Standard Specification ForHoem ITNo ratings yet

- Carbon and Ferritic Alloy Steel Forged and Bored Pipe For High-Temperature ServiceDocument4 pagesCarbon and Ferritic Alloy Steel Forged and Bored Pipe For High-Temperature ServiceHoem ITNo ratings yet

- Chromium-Vanadium Alloy Steel Spring Wire: Standard Specification ForDocument4 pagesChromium-Vanadium Alloy Steel Spring Wire: Standard Specification ForHoem ITNo ratings yet

- Steel Castings, Chromium-Nickel-Iron Alloy (25-12 Class), For High-Temperature ServiceDocument4 pagesSteel Castings, Chromium-Nickel-Iron Alloy (25-12 Class), For High-Temperature ServiceHoem ITNo ratings yet

- Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsDocument12 pagesChromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsHoem ITNo ratings yet

- Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesDocument12 pagesSeamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesHoem ITNo ratings yet

- g13mft MDB s1 GBDocument57 pagesg13mft MDB s1 GBPreda AndreiNo ratings yet

- Índice Mundial de Libertad ElectoralDocument72 pagesÍndice Mundial de Libertad ElectoralRoberto MuñozNo ratings yet

- How Do I Enable or Disable HDMI Audio in Windows If I Am Using An HDMI Connection Between My Nvidia Video Card or Motherboard and My Monitor?Document3 pagesHow Do I Enable or Disable HDMI Audio in Windows If I Am Using An HDMI Connection Between My Nvidia Video Card or Motherboard and My Monitor?JavadNo ratings yet

- SLR PaperDocument11 pagesSLR PaperramNo ratings yet

- CCNA 2 Discovery Final V4.1Document50 pagesCCNA 2 Discovery Final V4.1Sandra100% (5)

- Curriculum Vitae Tubagus WahyudiDocument2 pagesCurriculum Vitae Tubagus WahyudiMuhammad Rizky AK0% (1)

- Technical Integrity ManagementDocument23 pagesTechnical Integrity ManagementYounes OULMANENo ratings yet

- OMSM Suggested Answers Dec 2021Document12 pagesOMSM Suggested Answers Dec 2021Babai MondalNo ratings yet

- Financial Management Principles and Applications Australia 8th Edition Titman Test BankDocument36 pagesFinancial Management Principles and Applications Australia 8th Edition Titman Test Bankrappelpotherueo100% (26)

- Divider Block - Operation and MaintenanceDocument51 pagesDivider Block - Operation and MaintenanceMahfuz50% (2)

- Elements of Letter of Recommendation For PHDDocument2 pagesElements of Letter of Recommendation For PHDSachin SrivastavaNo ratings yet

- Bhanu ResumeDocument4 pagesBhanu ResumeBhanu Chandar ChallaNo ratings yet

- Vel Tech, Soc - CseDocument4 pagesVel Tech, Soc - Csesravanth chilukuriNo ratings yet

- AVN ILS Category Checklist (Order 8400.13E, Appendix D)Document2 pagesAVN ILS Category Checklist (Order 8400.13E, Appendix D)AndréPereiraNo ratings yet

- Risk Assessment Techniques (IEC 31010:2019) : Session - 3Document9 pagesRisk Assessment Techniques (IEC 31010:2019) : Session - 3kanchana rameshNo ratings yet

- Analog Video 101 - National Instruments PDFDocument7 pagesAnalog Video 101 - National Instruments PDFjollygreengiant001No ratings yet

- Impacts of TourismDocument13 pagesImpacts of TourismAubrehhh MaNo ratings yet

- 689 Track HoldDocument35 pages689 Track HoldShiva KumarNo ratings yet

- Catalog Appleton N2led Series Emergency Luminaires en Us 185148Document7 pagesCatalog Appleton N2led Series Emergency Luminaires en Us 185148Devin Yhojan Viafara MancillaNo ratings yet

- Lec 03 Pseudo Code Flowchart CsDocument27 pagesLec 03 Pseudo Code Flowchart Csprincessoke141No ratings yet

- Abbreviations GSMDocument2 pagesAbbreviations GSMverma.bsnlNo ratings yet