Professional Documents

Culture Documents

Sanitary Appliance

Uploaded by

patrick kivutiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sanitary Appliance

Uploaded by

patrick kivutiCopyright:

Available Formats

SANITARY APPLIANCES

SANITARY FIXTURES

SPECIFIC OBJECTIVE

By the end of this topic the trainee should be able to:

List the various types and applications of sanitary appliances.

Describe the working principles of sanitary appliances.

List the materials and design features of sanitary appliances.

Install siphon and ball valve in WC cistern.

Fit taps and wastes in wash hand basins and baths.

SANITARY FIXTURES

One of the most important and interesting aspects of the plumber’s work is the installation of sanitary

appliances. This calls for a knowledge of many different fitments now available for this work; where

they should be used; and how they should be connected to their respective water supply and waste

pipes.

Sanitary appliances are divided into two main groups:

Waste appliances.

Soil appliances.

The most common types of sanitary appliances are listed below:

WASTE APPLIANCES

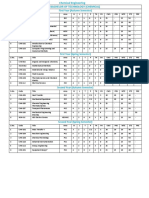

Table 1. Waste appliances and their use

Appliance Use

Bath Washing the body, for which reason they are frequently

Bidet referred to as ablution appliances.

Shower tray

Wash hand basin

Domestic sink Household purposes

Cleaners sink Floor washing in large buildings

Utensil sink Large kitchens, for example canteens and hotels

Vegetable sink

Drinking fountain Drinking water in schools, factories etc.

PREPARED BY PATRICK MACHARIA KIVUTI Page 1

SANITARY APPLIANCES

SOIL APPLIANCES

Table 2. Soil appliances and their use

Appliance Use

Urinal Gentlemen’s toilet, usually in large buildings and public

conveniences

Water Closet (WC) Ladies toilets and domestic toilets

Slop sink For use in hospitals

Bed-pan washer An item from the specialised range of equipment for

hospitals

Design and Construction of Sanitary Appliances

1. Durable (long lasting).

2. Impervious to water (it must not absorb water).

3. Resistant to corrosion (in order to make it long lasting and to be hygienic).

4. Simple in outline (so that there will be no crannies to hold dirt).

5. Smooth surfaced inside and out (for ease of cleaning and to be largely self-cleansing internally as

flushed in use).

6. With the inside so designed that the water will drain naturally to the outlet.

MATERIALS FOR SANITARY APPLIANCES

The materials from which sanitary appliances are manufactured are dependent upon the type of fitment

and the use of the building into which it is to be installed. In general terms the materials must be non-

corroding, non-absorbent and easily cleaned. In factories and schools, materials must also be capable

of withstanding rough treatment, but for domestic use this requirement can be discounted.

Metal

Baths, shower trays and flushing cisterns are commonly made out of cast iron, although this is being

superseded to a large extent by the use of plastics. The interior surfaces of cast iron baths and shower

trays are vitreous enamelled to provide a smooth, hard wearing surface that is corrosion resistant.

Articles manufactured from cast iron are very heavy and brittle, and great care must be exercised when

handling them.

Ceramic

Ceramic or Pottery ware has always been a popular material for such appliances as WCs, wash hand

basins, urinals, sinks and shower trays. The term ceramic means a substance made by firing clay and

includes various forms of pottery such as fireclay, stoneware and vitreous china. Fitments

manufactured from fireclay and stoneware would be porous, i.e. would absorb moisture, unless coated

PREPARED BY PATRICK MACHARIA KIVUTI Page 2

SANITARY APPLIANCES

with vitreous enamel. Appliances made from fireclay and stonewash are strong and heavy and this

makes them particularly useful in situations where hardwearing qualities are essential, i.e. factories and

schools. Belfast sinks, urinal slabs and stalls, shower trays and WCs are all made from these two

materials.

Vitreous china is a special type of earthenware which, as a result of high firing temperature, is made

impervious, i.e. will not absorb water. Its hard surface coating serves to aid cleaning and to improve its

appearance. The strength of vitreous china allows fitments to be manufactured with a very thin section

reducing their weight. Wash hand basin and WCs are the most common appliances made of vitreous

china.

Plastic

Acrylic plastic produces appliances that are very light in weight and cheap to manufacture. A gloss

finish can be obtained, but this must be carefully cleaned to avoid scratching. The plastic becomes soft

when heated, so the appliances must always be exposed to cold water before being subjected to hot

water, or mixing taps should be used. Baths must be provided with supports, which usually consists of

timbers on metal cradles. A variety of colours can be obtained.

Glass-reinforced polyester appliances are much stronger than those made from acrylic plastic, but

they are more expensive. Baths and shower trays are often made from this material, and should have a

good gel coat finish. Thin coats may be worn away by cleaning, which could expose the glass fibre.

Vitreous enamelled pressed steel is also used for the manufacture of baths and sink units. It is

cheaper material but does not have the long lasting qualities of cast iron. Manufacturers of porcelain

enamelled ware always attached a label to the appliance giving instruction on its care and methods of

cleaning. Always make sure that this is intact when the job is complete.

Stainless steel is also extensively used for a wide range of sanitary appliances including WCs, sink

units, urinal stalls and wash hand basins. Its popularity derives from the properties it possesses:

(a) It has a clean, pleasant appearance.

(b) It is non-corrosive.

(c) It is hard wearing.

(d) It has no vitreous enamelled surface to chip.

(e) It is easily cleaned.

PREPARED BY PATRICK MACHARIA KIVUTI Page 3

SANITARY APPLIANCES

Figure 1. Sanitary Appliances

Flushing Cisterns

The cistern is operated by depressing a lever which lifts the piston. This action forces or lifts a body of

water over the crown of the siphon and into the flush pipe. Siphonic action is then created which

empties the cistern.

For siphonic action to take place all siphons require a short leg and a long leg see Fig 1.

In a WC cistern the short leg of the siphon is located within the cistern, and the long leg is created by

the addition of a flush pipe to the outlet connection of the siphon see Fig 2. This pattern of cistern is the

most common sort and is known as the plunger or disc type cistern.

Figure 2. Flushing Cisterns

PREPARED BY PATRICK MACHARIA KIVUTI Page 4

SANITARY APPLIANCES

Figure 3. Crown

Figure 4. Flush Pipe

PREPARED BY PATRICK MACHARIA KIVUTI Page 5

SANITARY APPLIANCES

Figure 5. Flushing Cistern

The bell-type flushing cistern is rather noisy but may be used in factories and schools. The cistern is

operated by the chain being pulled down which also lifts the bell. When the chain is released the bell

falls thus displacing water under the bell down the stand pipe. Siphonic action is then created which

empties the cistern.

PREPARED BY PATRICK MACHARIA KIVUTI Page 6

SANITARY APPLIANCES

Figure 6. Bell Type Flushing Cistern

PREPARED BY PATRICK MACHARIA KIVUTI Page 7

SANITARY APPLIANCES

Figure 7. Bell Type

PREPARED BY PATRICK MACHARIA KIVUTI Page 8

SANITARY APPLIANCES

Figure 8. W.C. Flushing Cistern Maintenance

PREPARED BY PATRICK MACHARIA KIVUTI Page 9

SANITARY APPLIANCES

Wash Down PC Pans

The wash down WC pan is cheap, simple and efficient and rarely becomes blocked. It is used in all

types of buildings and is made from vitreous china, glazed fireclay or stonewash.

The contents of the pan are removed by the momentum of the water flush. A high-level flushing

cistern gives a good flush but is noisy. A low-level cistern gives a quieter flush, is neater and now

more popular.

The outlet of the pan may be horizontal, P, S left or right hand.

A plastic connector is a popular outlet joint and only requires pushing over the outlet and into the soil

pipe. The flush pipe joint is usually made by a rubber cone connector.

Figure 9. Wash Down WC Pan

PREPARED BY PATRICK MACHARIA KIVUTI Page 10

SANITARY APPLIANCES

Figure 10. Wash Down PC Pan

Figure 11. Connector Types

PREPARED BY PATRICK MACHARIA KIVUTI Page 11

SANITARY APPLIANCES

Figure 12. Close Coupled Washdown

PREPARED BY PATRICK MACHARIA KIVUTI Page 12

SANITARY APPLIANCES

Figure 13. Clear of Floor Washdown or Corbel

PREPARED BY PATRICK MACHARIA KIVUTI Page 13

SANITARY APPLIANCES

Figure 14. Flush Pipe

PREPARED BY PATRICK MACHARIA KIVUTI Page 14

SANITARY APPLIANCES

Siphonic Water Closets

With their silent and positive action, siphonic WCs are strongly recommended for fixing in houses,

flats, hotels, hospitals etc. They also have a larger water area and a deeper seal than ordinary wash-

down types. Siphonic WCs are, however, more expensive than the wash-down type and do not stand

up as well to rough usage.

A variety of siphonic WCs can be obtained but all types fall within the category of either single or

double traps.

Fig 1 shows a siphonic WC with two traps, and is known as the ‘ exhaust action’ type. Its action is as

follows:

The flushing cistern lever is pulled down, causing water to pass down the flush pipe.

Water passing the end of the air pipe at A draws some of the air from the space between the two

traps at B, and creates a reduction in air pressure (partial vacuum) at this point.

Immediately this partial vacuum has been created at B, the greater pressure of the atmosphere

103 kN/m² approximately, acting on the surface of the water in the pan, sets up siphonic action

and forces the water with its contents out of the pan.

This siphonic action is completed and the pan is emptied before the flush water enters the pan.

The water therefore simply washes the pan down and refills the first seal.

Figure 15. Siphonic Action

PREPARED BY PATRICK MACHARIA KIVUTI Page 15

SANITARY APPLIANCES

Figure 16. Siphonic Action

PREPARED BY PATRICK MACHARIA KIVUTI Page 16

SANITARY APPLIANCES

Figure 17. Siphonic Action

PREPARED BY PATRICK MACHARIA KIVUTI Page 17

SANITARY APPLIANCES

Figure 18. Double Trap Syphonic

Figure 19. Slop Hopper

PREPARED BY PATRICK MACHARIA KIVUTI Page 18

SANITARY APPLIANCES

Figure 20. Cleaners Sink

Figure 21. Figure 21 - Sink

PREPARED BY PATRICK MACHARIA KIVUTI Page 19

SANITARY APPLIANCES

Figure 22. Drainer Types

PREPARED BY PATRICK MACHARIA KIVUTI Page 20

SANITARY APPLIANCES

Figure 23. Sink

Figure 24. Urinal

PREPARED BY PATRICK MACHARIA KIVUTI Page 21

SANITARY APPLIANCES

Figure 25. Bowl Urinal

PREPARED BY PATRICK MACHARIA KIVUTI Page 22

SANITARY APPLIANCES

Figure 26. Urinal Types

PREPARED BY PATRICK MACHARIA KIVUTI Page 23

SANITARY APPLIANCES

Figure 27. Spray

Bidets

A bidet is a sanitary fitting used for washing the lower parts of the body. A secondary but nevertheless

important use of the bidet is as a footbath.

For identification purposes, bidets are usually classified in two distinct types which are as follows:

Submerged inlet.

Over-rim-supply.

Tap controls are conveniently placed to enable the user to adjust the flow rate and temperature of the

water.

With most submerged inlet bidets the rim seat may be warmed by an ascending spray which then fills

the bowl for washing.

Most water authorities have special requirements for bidets with submerged inlets.

Non-return valves should be fitted to both the hot and cold supplies.

Hot and cold pipes to the bidet should be taken at least two metres above the appliance before being

connected into the main supplies.

In some instances a separate cistern may be required.

The reason for these recommendations is to prevent back siphonage.

Bidets with over-rim supply are simpler to install and are supplied with water in the same manner as a

wash basin.

PREPARED BY PATRICK MACHARIA KIVUTI Page 24

SANITARY APPLIANCES

Figure 28. Bidets

Exercises.

1. With the aid of sketches, show how a bell type cistern works.

2. Sketch and describe the operation of a dual action cistern.

3. Sketch and describe a Washdown WC pan.

4. Sketch and describe two types of joint used to connect flush pipes to WC pans.

5. State the recommended depth of seal for a Washdown WC pan.

6. Sketch and describe the types of joint used to connect a WC pan to a PVC soil pipe.

7. With the aid of sketches, describe how a double trap siphonic action WC pan operates.

8. Describe how the pan and cistern of a close-coupled WC suite are connected.

9. Describe the advantages of the siphonic WC.

10. Draw a section through an automatic flushing cistern and explain its operation.

11. State the recommended fitting height for wash hand basins.

12. Using a sketch, describe the means by which a washing machine is connected to both hot and cold

supplies and connected to a single stack soil pipe system.

13. Using a sketch, describe how a bidet operates and make recommendations with regard to hot and

cold supplies and waste outlet.

14. Using a sketch, describe how a slop hopper works including soil outlet, cistern, hot and cold

supplies.

PREPARED BY PATRICK MACHARIA KIVUTI Page 25

You might also like

- Sanitary FixturesDocument21 pagesSanitary Fixturesanisha binthNo ratings yet

- Nixson 2Document21 pagesNixson 2Brian OmondiNo ratings yet

- EACQ 3277 Group 1-Soil and Waste AppliancesDocument16 pagesEACQ 3277 Group 1-Soil and Waste AppliancesEdward ChrisNo ratings yet

- Sanitary AppliancesDocument27 pagesSanitary Appliancesn_euda75% (8)

- Sanitary AppliancesDocument6 pagesSanitary AppliancesHood LumNo ratings yet

- Sanitary FixturesDocument165 pagesSanitary FixturesZahra BathoolNo ratings yet

- Topic 1sanitation System SlideDocument66 pagesTopic 1sanitation System Slidedhevashini narayananNo ratings yet

- CH 4. Sanitary Fixtures PDFDocument24 pagesCH 4. Sanitary Fixtures PDFashe zinabNo ratings yet

- Plumber: - Utility Consisting of The Pipes and Fixtures For The Distribution of Water or Gas inDocument7 pagesPlumber: - Utility Consisting of The Pipes and Fixtures For The Distribution of Water or Gas inaileen eustaquioNo ratings yet

- CH - 04 - Plumbing Fixtures and FittingsDocument10 pagesCH - 04 - Plumbing Fixtures and FittingskNo ratings yet

- Lamera, Alyanne Marianne L. - Research PaperDocument35 pagesLamera, Alyanne Marianne L. - Research PaperAlyanne LameraNo ratings yet

- Plumbing FixturesDocument32 pagesPlumbing FixturesCharles CresinoNo ratings yet

- Sanitary Appliances: Desirable Characteristics of Sanitary FittingsDocument4 pagesSanitary Appliances: Desirable Characteristics of Sanitary Fittingshoney4747No ratings yet

- bARC 454 Lecture NotesDocument5 pagesbARC 454 Lecture NotesOkafor VictorNo ratings yet

- Dishwashing LiquidDocument8 pagesDishwashing LiquidKervie ManuelNo ratings yet

- Annex 5toilet Care and Maintenance - 2015june13Document17 pagesAnnex 5toilet Care and Maintenance - 2015june13Sol Christian Cuenca SayreNo ratings yet

- TOPIC 1 Sanitation SystemDocument50 pagesTOPIC 1 Sanitation Systemروسيده بت محمد سعدNo ratings yet

- Vitra WCDocument160 pagesVitra WCcothacoNo ratings yet

- Filter Bakki ShowerDocument3 pagesFilter Bakki ShowerWaDikun0% (1)

- Sanitaryware: Ancient Time To Modern TimeDocument17 pagesSanitaryware: Ancient Time To Modern TimeparadisegoldNo ratings yet

- G026 Pour Flush Latrines On LineDocument12 pagesG026 Pour Flush Latrines On LineIzwar Hani Abd JalilNo ratings yet

- GROUP 1 Basic Principles of Sanitary Plumbing DesignDocument72 pagesGROUP 1 Basic Principles of Sanitary Plumbing DesignMa Linda MolinaNo ratings yet

- TOPIC 1 Sanitation SystemDocument50 pagesTOPIC 1 Sanitation SystemAmar AshrafNo ratings yet

- Cleanage Readymade Toilet Blocks (S) - Rev 01-05-2019 PDFDocument2 pagesCleanage Readymade Toilet Blocks (S) - Rev 01-05-2019 PDFarjun 11No ratings yet

- Cleanage Readymade Toilet Blocks PDFDocument2 pagesCleanage Readymade Toilet Blocks PDFshehanNo ratings yet

- Wolkite University College of Engineering and Technology Department of Mechanical EngineeringDocument13 pagesWolkite University College of Engineering and Technology Department of Mechanical EngineeringMikias Belayneh100% (1)

- JTL Book Above Groung Discharge SystemsDocument54 pagesJTL Book Above Groung Discharge SystemsbendeniNo ratings yet

- DWV, Are Used For Drainage, Waste and Vent. Commonly Used Are The Series 600 andDocument2 pagesDWV, Are Used For Drainage, Waste and Vent. Commonly Used Are The Series 600 andChuckMañoscaNo ratings yet

- G030 Septic Tank and Aqua Privy Design OnlineDocument20 pagesG030 Septic Tank and Aqua Privy Design OnlineshemksNo ratings yet

- I04mv RfyniDocument32 pagesI04mv RfyniSagar BollineniNo ratings yet

- Wa0002.Document8 pagesWa0002.irshadmirza753No ratings yet

- Lesson 3 Plumbing Fixtures Part 1Document19 pagesLesson 3 Plumbing Fixtures Part 1Junnaz BalacuitNo ratings yet

- School of Architecture, Building and Design Bachelor of Quantity Surveying (Honours)Document32 pagesSchool of Architecture, Building and Design Bachelor of Quantity Surveying (Honours)Tham CherryNo ratings yet

- L4-Sanitary Appliances 3Document40 pagesL4-Sanitary Appliances 3WAN NURULAIN ARIBAH BINTI WAN HASSANNo ratings yet

- Assignment#01 Engineering System Topic: Sanitary Fittings: Mam Komal MirzaDocument10 pagesAssignment#01 Engineering System Topic: Sanitary Fittings: Mam Komal MirzaFatima EjazNo ratings yet

- Written ReportDocument14 pagesWritten ReportHansel TayongNo ratings yet

- Plumbing Technology Materials: Prepared by Patrick Macharia KivutiDocument8 pagesPlumbing Technology Materials: Prepared by Patrick Macharia KivutiPatrick MachariaNo ratings yet

- 3 Plumbing Fixtures and ComponentsDocument12 pages3 Plumbing Fixtures and ComponentsDrew FrancisNo ratings yet

- Dishwasher Engineering ReportDocument27 pagesDishwasher Engineering ReporttiarnamNo ratings yet

- General Notes On Sanitary FittingsDocument41 pagesGeneral Notes On Sanitary Fittingsmaxie1024No ratings yet

- 151 Group SiapDocument8 pages151 Group Siap2022486166No ratings yet

- Masonry AND Concrete Works: "Plumbing System in Relation To Masonry" & "Plumbing Terms"Document7 pagesMasonry AND Concrete Works: "Plumbing System in Relation To Masonry" & "Plumbing Terms"mitch willyNo ratings yet

- Tank CleaningDocument12 pagesTank Cleaningmabrouk2013No ratings yet

- Clayton Nolte Shower Unit - Dynamic Structured WaterDocument4 pagesClayton Nolte Shower Unit - Dynamic Structured Watermagic12kennethNo ratings yet

- Practical Plumbing Engineering Design Vol 4 2004 PDFDocument288 pagesPractical Plumbing Engineering Design Vol 4 2004 PDFmimahmoudNo ratings yet

- All About Repairing Major Household Appliances Service ManualDocument228 pagesAll About Repairing Major Household Appliances Service ManualiliiexpugnansNo ratings yet

- Smart Showers Smart Toilets and Smart Sinks Should You Set Your Plumbing Onlinewrivc PDFDocument3 pagesSmart Showers Smart Toilets and Smart Sinks Should You Set Your Plumbing Onlinewrivc PDFDugganFranks4No ratings yet

- Written Report On Water ResourcesDocument6 pagesWritten Report On Water ResourcesDave Khyl Josol BosqueNo ratings yet

- Plumbing Fixtures LinesDocument3 pagesPlumbing Fixtures LinesMJ ArboledaNo ratings yet

- Sanitary Appliances Plumbing System: Dqs 184 - Building Services IDocument43 pagesSanitary Appliances Plumbing System: Dqs 184 - Building Services IanlynNo ratings yet

- Readymade Toilet Blocks and Ladies Urinals: Jeevan Bhar Ka Saath..Document2 pagesReadymade Toilet Blocks and Ladies Urinals: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Membrere, Estillero - BuildingUtilitiesDocument15 pagesMembrere, Estillero - BuildingUtilitiesjurilyn estilleroNo ratings yet

- Vitra Basin CatalogDocument152 pagesVitra Basin CatalogcothacoNo ratings yet

- Case Studies-Industrial BuildingsDocument13 pagesCase Studies-Industrial Buildingsgligamsn0% (1)

- Intro To ASCP PresentationDocument32 pagesIntro To ASCP PresentationSundar SeetharamNo ratings yet

- Research Update: How To Conduct Fresh Cut Flower Vase Life ExperimentsDocument2 pagesResearch Update: How To Conduct Fresh Cut Flower Vase Life ExperimentsAndrea NemenzoNo ratings yet

- Data Sheet: DEGALAN® LP 64/12Document2 pagesData Sheet: DEGALAN® LP 64/12Akhtar aliNo ratings yet

- AC Service Appointment and Maintenance FormDocument11 pagesAC Service Appointment and Maintenance FormRiad RahmanNo ratings yet

- Familyresourcepage MiddleschoolDocument2 pagesFamilyresourcepage Middleschoolapi-521845594No ratings yet

- Lecture 01 (Basics) ME141 PDFDocument18 pagesLecture 01 (Basics) ME141 PDFAlteaAlNo ratings yet

- 2015 Catalog 4400 ParkerDocument448 pages2015 Catalog 4400 ParkerJustin Duffy100% (1)

- AHA - Working On Slope RoofDocument2 pagesAHA - Working On Slope RoofTopsun EnergyNo ratings yet

- Athens RestaurantsDocument2 pagesAthens RestaurantsAthens GreeceNo ratings yet

- Internal Medicine Ethics JournalDocument4 pagesInternal Medicine Ethics Journalzellinda kuswantoNo ratings yet

- Area Chart Presentation Slides: Lorem Ipsum Dolor Sit Amet, Consectetur Adipiscing Elit. Aliquam Eu Lobortis ErosDocument14 pagesArea Chart Presentation Slides: Lorem Ipsum Dolor Sit Amet, Consectetur Adipiscing Elit. Aliquam Eu Lobortis ErosRahman IskandarNo ratings yet

- IIT Roorkee Programme Structure CHeDocument4 pagesIIT Roorkee Programme Structure CHeabcNo ratings yet

- Dissertation On Bronchial AsthmaDocument7 pagesDissertation On Bronchial AsthmaInstantPaperWriterSpringfield100% (1)

- Inventive IndianDocument168 pagesInventive Indianvijay7775303No ratings yet

- IIA Lunch and Learn - Risk Assessment - 2.4.13Document40 pagesIIA Lunch and Learn - Risk Assessment - 2.4.13WM4scribdNo ratings yet

- Case Study To Investigate The Adoption of Precision Agriculture in Nigeria Using Simple Analysis To Determine Variability On A Maize PlantationDocument14 pagesCase Study To Investigate The Adoption of Precision Agriculture in Nigeria Using Simple Analysis To Determine Variability On A Maize PlantationPremier PublishersNo ratings yet

- KYNAR (PVDF) Chemical Compatibility & Chemical Resistance ChartDocument11 pagesKYNAR (PVDF) Chemical Compatibility & Chemical Resistance ChartRAMESH SHETTYNo ratings yet

- Savio v. Peterson ComplaintDocument15 pagesSavio v. Peterson ComplaintChicago TribuneNo ratings yet

- Use of Alternative Energy Sources For The Initiation and Execution of Chemical Reactions and ProcessesDocument21 pagesUse of Alternative Energy Sources For The Initiation and Execution of Chemical Reactions and ProcessesNstm3No ratings yet

- De Minh Hoa Vao 10 To Hop Vinh Phuc 20202021-1-3Document3 pagesDe Minh Hoa Vao 10 To Hop Vinh Phuc 20202021-1-3Yennhi DoanNo ratings yet

- Total Physical ResponseDocument7 pagesTotal Physical ResponseDesak RossyanaNo ratings yet

- Describing People Greyscale KeyDocument3 pagesDescribing People Greyscale KeyNicoleta-Cristina SavaNo ratings yet

- Calc. Hid. ManguerasDocument8 pagesCalc. Hid. ManguerasJonahtan A. Navas G.No ratings yet

- 103 Servodyn Standalone Conectivity BoschDocument130 pages103 Servodyn Standalone Conectivity BoschOHW SERNo ratings yet

- 1 ReproductioninOrganismsDocument22 pages1 ReproductioninOrganismsPriNce KhatriNo ratings yet

- 6009Document5 pages6009Oktasari Dyah AnggrainiNo ratings yet

- UAE Defaulters ListDocument2 pagesUAE Defaulters Listshitijkumar100% (1)

- Leopold SDocument14 pagesLeopold STina TalmadgeNo ratings yet

- Form 5 Biology Notes C1 & C2Document18 pagesForm 5 Biology Notes C1 & C2m-7940668No ratings yet