Professional Documents

Culture Documents

Untitled

Untitled

Uploaded by

Maurício Duarte de Andrade0 ratings0% found this document useful (0 votes)

25 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views6 pagesUntitled

Untitled

Uploaded by

Maurício Duarte de AndradeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Into account!

‘Beekdes this ism copy land oniy for In-house purposes of

‘SMS Schioernann-Siemag AG. (acc 19 DIN reference sheet 3)

i

5

permission ot

tn case of changes this printout Is not tae

tandirg maybe reprogucea wimouk

1 No part

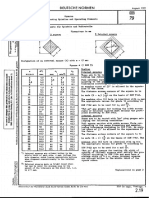

UDC 774.43:001.4

DEUTSCHE NORM

Engineering drawing practice

Dimensioning

Concepts and generat principles

Technische Zeichnungan; MaBeintraguna:

Begrfe, allgemeine Grundiagen

This standard supersedes April 1977 edition of

DIN 406 Part 1 and, together with Decernber 1992

‘edition of DIN 406 Parts 1 and 12. supersedes August 1981

edition of DIN 406 Part 2

See Explanatory notes for connection with International Standard {SO 129: 1986 published by the international Organization

Jor Standardization (ISO).

Contents

11 Scope and field of application ..

2 Concepts be

3. General principles...

31 Dimensioning elements

32. Symbols 7

33. Dimensioning systems 7

4 Orientation ot drawing and letter

35. Appiation |

1 Scope and fleld of application

This standard specifies concepts and general principtes

relating to dimensioning on ongingsring drawings. The spec

‘fications may be applied analogously to dimensioning on

other technical documents.

Further datais and practical examples are provided in other

parts of the DIN 406 series of standards,

2 Concepts

In the definitions given balow, an arrow (~) precedes terms

which aro themselves defined elsewhere in this clause,

2.1 Dimensioning from a common feature

Dimensioning trom a common feature is a method in which

fe number of featutes are dimensioned from a common faa-

ture (Le. where a number of cimensions of the same direc-

tion relate to a common origin).

‘The dimensions are based on the theoretically exact shape

of the commen feature,

dou me Geieanlngusge aia shoul 96 cans

2.2 Datum

Addatum is a dimension of a feature which rafers to another

aiven feature of the game object (datum feature).

2.3. Single dimensioning

In single dimensioning, the features are individually dimen-

sloned without reference to a common feature.

2.4 Finished dimension

{finished dimension is @ ~> dimension which refers to the

object as an end product.

NOTE: The representation of the object as an end

product may refer to the raw (ag. as formed), inter-

‘mediate oF finighad state of the ebject, or even toa

surface treatmont

‘ean Vary Gon

Stondarde referred to

Other relevant standards

Provious editions

Amendments

Explanatory notes

Atphabatical index...

25 Functional dimension

‘A functional dimension is a -> dimension serving to define

the shane, size or orientation of features, or the spaces

bbetwaen them, which are essential to the function of a part

‘oF group of parts.

2.6 Initial length

‘Tho inital length is the Jength of @ part prior to its being

bent

2.7 Auxiliary dimension

‘An auxilary dimansion is a~ dimension given for itormation

purposes anly and not exsential to the geometrical defini:

tion of a part It does not count as a dimansional specifics

tion for contractual purposes.

2.8 Leader line

‘Aleader line used to indicate - dimensions is a fine connect

ing the representation of an object and a dimensional value

‘and is generally drawn a6 a line extending obliquely out of

the representation.

2.9 Informative dimension

{An informative dimensions a-- dimension which is indicated

in tender, sales and advertising documentation and in other

‘technical documents. is generally nat specifically ident

fied as such, is not toleranced and only counts as a dimen-

sional specification for contractual purposes when this has

been expressly agroed between the contracting parties.

NOTE: I, in @ glvon document, informative dime

sions need to be distinguished from other diman-

sions, they may be identified ag such (9. by a

lower-case | in a circle being placed next to them),

Continued on pages 2 to 6

‘DIN 405 Part 10 Engl Price group 7

Seen Ne 107

Page 2 DIN 406 Part 10

2.10 Chain dimensioning

In chain dimensioning, single dimensions are indicated con-

secutively,

2.11 Dimensioning by coordinates

Dimencicning by coordinates is a form of > dimensioning

trom a common toature within a system of (cartesian oF

polar) coordin

2.42 Dimension

‘A dimension is 2 physical quantity defined by a numerical

value and a unit of measurement. The dimensions in this

standard are linaar dimensions, which are indicated in units

Of length, and angular dimensions, indicated in units of

angle,

2.13 Dimensioning by tables

In dimensioning by tables, the parts and/or features and/or

dimensions are identified by digits or letters, which are

entered in tables together with the corresponding +

dimensional valugs,

2.14 Projection tine

‘A projection line is a line drawn to connect the feature to be

dimensioned to the associated -» dimension line.

2.15 Dimension line

A dimansion line isa straight or curved fine running between

two edges, between an edge and a» projection line, ot

between two = projection lines. Where drawings and/or

dimensioning ara simplified, the dimension line may

terminate at oniy one of the toatures referred ta

246 Termination

A termination is a marker on a + dimension line that indicates

where the line ends,

217 Contre fine

A centre ine is a ine that defines the geometrical cantro of

faatureo in drawings,

2.18 Parallel dimensioning

Parallel dimensioning is a form of ~ dimensioning from a

‘common feature in-which the. features. are individually,

dimensioned by way of dimension lines drawn parallel or

‘concentric to each other,

2.49 Check dimension

‘A-check dimension is @ + dimension designated as requiring.

particular consideration when the scope or stringency of

Inspection ie specified.

2.20. Raw dimension

‘A raw dimension is a + dimension which refers to the inital

‘geometry of an object.

2.21 Line of symmetry

Aine of symmetry identities the plane of symmetry which

divides an object notional into two symmeirical halves,

2.22 Superimposed running dimensioning

‘Superimposed running dimensioning is 2 form of ~ dimension

ing from a common feature in which each feature is dimen

sioned trom a common origin with the dimensional values

‘being given in ascanding progression, The + dimension ines.

are generally placed as a superimposed series,

23. Repetition

For the purposes of this standard, ‘repetition’ is the raguiar

‘recurrence of features at equal intervals or angles which are

assigned to one or more common datum features (aleo ter

med ‘repetetive features). 7

2.26

‘Theoretically exact dimension

theoretically exact dimension is a ~ dimension used to ind-

cate the geometrical

‘ideal (thaorarically exact) orientation

or form of a dimensioned feature,

2.25

A on

intermediate

Pre-work dimension

‘work dimension is a» dimension which defines an

during the processing of a feature (ea,

the + dimension prior to grinding or coating).

2.26

Other concepts.

For detintions of ‘actual size’, nominal size’, ‘olerance’ and

it, ene ISO 286 Part 1

For defintions of

fatum,, ‘datum feature! and ‘datum sys

tem, see ISO 5459 and Tor the definition of origins, see

ISO/DIS 10 209 Part 2

For definitions relating to drawings, s

DIN 199 Part 1, and

for those associated with components, assombly units, etc,

DIN 189 Part 2.

3 General principles

4.1. Dimensioning elements

The elements used in dimensioning are:

,

dimension ines;

projection tines;

terminations:

‘dimensional values:

dimensional values with symbol for tolarance class;

dimensional values with limits of size;

units of measurement;

Une widths shall be

leader ines,

‘specitiod in DIN 15 Parts 1 and 2.

3.2 Symbols

324

Arrowhead

‘The arrowhead is a termination in the form of an isosceles

triangle

with an included angle of 19*and length of ten times

tha width of the dimension ling, or

with an included angle of 90° and a length of tour

times the width of the dimension ine

——

—_—

—

Arrowheads are placed at the ends of the dimension or

leader ines with their tins ending on the associated projec

tion tine or autling,

322

Oblique stroke

‘The ablique stroke isa termination running from bottom lett

10 top right at an angle of 45° to the lay ofthe drawing, with

‘length of 12 thnes the width of the dimension line, The

centre of the oblique stroke passes through the intorsectlon

Of dimension Kno, projection tine oF t

ture outing |),

fai

1) The specifications 2.14" and 215" in this drawing and the:

following drawings aro references to the corranponding

subelauses in clause 2

323 Dot

Tha dat is a dimension line termination which has a diame-

ter 5 times the width of the wider of the lines fo which it is

assigned. The centte of the dot shall be placed on the inter-

section of dimension line and projection line or feature out-

line.

14

324 Chole

3.2.41 Tho dot used as 2 dimension line termination may

‘also be drawn as a circle.

th

| 215,

3.242 Tho circle used to indicate the origin sa dimension

lina termination which is 8 times the wicth of the wider of

the two intersecting fines. The centre of the citcle shail be:

placed on the intersection of dimension tine and the line of

the datum feature

2.1%

32.43 A circle from the bottom of which a tangent Is

‘drawn horizontally, ending In an arrowhead, is @ graphical

symbol that is used instead of the writen inaication ‘inital

length’ and Is always placed bafora the dimensional value of

‘the inital Jongth, This circle has a diameter equal to ten

times tho ling width of the lettering. The length of the tine

‘with the arrowhead is equal to 15 times the diameter of the

circle (arrowhead: leg angle of 15°, length ten times the line

width of tne lettering).

32.44 The circle used to indicate the origin signifies,

‘when combined with a datum indication (ct. 60 5459), that

the specified datum is the origin of a dimensional system.

425 Triangle

32.5.1 The right-angled triangle is a graphical symbol

Which Is used instead of the written Indication ‘slope’, The

‘orientation of he tnangle is determined by the shage of the

part at the point where it slopas (cf, figure 88 in DIN 406

Part ft, December 1992 edition)

‘The triangle is alweys placed before the dimensional vaive

fof the slope and has a leg ratio of 1:2 (length: 16 times ine

width of fettering)

DIN406 Part 10. Page 3

3.25.2 For the graphical symbol used to indicate the fea-

tures ‘cone’ and ‘Yaper’ (height of triangle: 16 times tine

width of lettering: ratio of base to height: 1:2) (see figure 2

in ISO 3040),

9.25.3 See figure 17 in ISO 7083 tor graphical symbols

sed to indicate datums,

326 Framee

3.28.4 A frame consisting of two parallel lines set a dis-

tance twice the height of the lettering apart and connected

at eactr end by semicircles is used to identity check dimen:

sions. The frame may, where necessary, be civided into

fields by vertical lines.

ceeaeeee)

3.2.6.2 See figure 19 in ISO 7083 for the frame to be used

for theareticaly exact dimensions,

3.26.3 See figures 22 and 23 n ISO 7083 for the frame 10

be used for geometrical tolerances.

32.7 Undertining

‘AN underfining 1s a straight thin continuous line drawn

beneath the dimensional value. Unterining io used to ic

tify dimensionai values which differ in scale from the scale

appiying ta the other dimensions in a drawing. This symbol

ts not to be used in computer assisted drawings.

3.28 Round brackets)

Round brackets are used to indicate auxiliary dimensions or

supplementary indications, e.g. supplementary ingications

near the tite block,

22.8 Square brackets 2)

‘Square brackets are used to indicate raw and pro-work

imensions in drawings of assembly parts. They are also

used for dimensions on parts which must be preserved as

finished dimensions for the next highest stage of manufac-

ture (0.9. finished bush in welded assembly),

[1]

3.210 Curly brackets

Curly brackets are used to enclose groups of related indica-

0

3211 Square 2)

[A square Is @ graphical symbol which Is us

the dimensional valua of the side length

feature concernad is a square of that size.

Oo

together with

ate that the

1) The specifications 218” and "216' In this drawing and the

following drawings are reterences to the correspencing

subclauses in clause 2,

28) See DIN 6776 Part 1 for size

Page 4 DIN 408 Part 10

8.2.12. Circle with oblique stroke 2)

A circle with an oblique stroke is a graphical symbol used to

indicate a diameter.

3.2.13 Letter R2)

‘The dimensional values of cadi are identified by a capital R

boing placed in frant of them,

R

8.214 Letter 82)

‘The dimensional valuos of spherical features are additionally

identified by a capital 5 being placed in front of the diame-

ter symbol or of the capital R.

SR S¢

3.2.18 Letters Sw2)

‘The dimensional values of widthe across flats aro identified

by the capitals letters SW being placed in front of them,

SW

3.2.16 Sembclrcle/curve symbol

‘The dimensional values of curve lengths are identifiad by a

somi-circla (diameter: 14 times lIne width of lattaring) pre-

coding the dimensional value.

mm

Whare the drawing is prepared manually, a modified curve

symbol may be placed above the dimensional value of the

curve length,

3.2.17 Symmetry symbol

‘A symmetry symbol consists of two parallel thin continuous

linea which are placed at right angles to, and axially on, the

fends of a line of symmetry, their minimum length being

8mm

+

8.218 Other symbols

Other symbols (eq. those specified in DIN+302 or

DIN 6473) may also be used. Such symbols shall be axe-

cuted in accordance with the standardized rules of lattering

‘and drawing.

9.3 Dimensioning systems

The objects represented may be dimensioned and toler-

anced with reference to their function, their production, oF

to the criteria of inspection.

In a given drawing, more than one such system of dimen-

sioning may be used concurrently

8.8.1. Dimensioning for function

Dimensioning for function is characterized by the selection

indication and tolerancing of dimensions being undertaken

oxclusively on the basis of design criteria aimed at ensuring

that the parts of a product will combine smoothly so 96 10

permit the product to fultl its intended function, The

manufacturing and inspection conditions are not taken into

account,

3.32. Dimensioning for production

Dimensioning for production is characterized by the dimen:

sions directly requirad for production purposes being calcu

lated from the functional dimensions, indicated the draw:

ing and toleranced as a function of the functional dimen:

‘ions 80 as to meet manufacturing requirements,

Dimensicning for production fs a tunction of the particular

‘production mothod.

18.8 Dimensioning for Inspaction

Dimensioning for inspection is characterized by the dimen:

sions and dimensional tolerances being indicated In the

drawing to suit tho requirements of the intended inspection.

Dimensioning for inspection purposes is a function of the

particular inspaction procedure,

3.4 Orientation of drawing and lettering

3A1 The orientation of the drawing shall correspond to

the reading direction of the ttle block.

34.2 All dimensions, graphical symbols and written spect

fications shall proforably be so indicated that they can be

read in the viewing direction of the drawing from below and

from the right (main reading direction).

3.5 Application

3.5.1 Drawings shall generally contain dimensions which

refer to the object as itis cepresented,

3.52 All dimensional specifications which are necessary

for a clear and complete descriotion of an object shall be

indicated In the drawing

‘The drawing may refer to the raw state, an Intermediate

state of to the finighed state of an object and may also

include an information on surface treatment.

Features of an object shall only be dimensioned once in a

‘drawing or set of drawings. Dimensions which are specified

in associated documents (0g. standards, supplementary

‘drawings), shall not be repraated: they may. where approori

ate, be indicated as auxiliary dimensions

353 Dimensions shall be indicated in that part of the

representation in which the feature concerned is most

clearly recognizable.

‘Asa rule, lingar dimensions are indicated without unit sym-

bois, The unit symbol which is exclusively or predominantly

Used shall be specified in the tite block), Other unit symn-

bois shall bo specified inthe ttle block in parantheses; they

shall also be indicated folowing the dimensional values con-

corned,

2.5.4 In the case of dimensional valvas indicated in dect-

‘mai notation, a comma shall be used as the decimal

marker),

3.85 Soe DIN 406 Part 12 for the indication of tolerances.

38.6 Dimansion tines shall normally be drawn without a

break from termination to termination

When all dimensions are indioated in tha same direction of

reading, non-horizontal dimension lines may be interrupted

to insert the dimensional values.

If the arrowhead termination is placed outside the limits of

the dimension line, the dimension tine shall be extendad so

as 10 project to the required length beyond the arrowhead,

2) See IN G76 Part 1 for size

9) See DIN 671 Part

4) See OIN V 820 Part 2

DIN406 Part10 Page 5

In any given drawing, only one of tha following combinations Dimension lines of radi shall be aligned on the centre of the

‘of terminations is permitted: radius.

15" arrownead, doticircle, common ongin circles, or

— 90° arrowhead, oblique stake, origin (only for particular —&5.7_Dimension lines and non-related projection lines

fields of engineering, eg. In construction drawing practice). shall not cross.

Standards referred to

DIN 15 Part! Technical drawings; ines; basic principles

DIN 15 Pan2 Technical drawings: ines; general application

DIN 199 Part 1 Terminology associated with drawings and Item lists; drawings

DIN 199 Part 2 Terminology associated with drawings and iter ists; item ists

IN 406 Part 12 Engineering drawing practice; cimensioning; tolerancing of linear and angular dimensions

DIN V 820 Part 2 Standards work: presentation of standards

DIN 1902 General mathematical symbols and concopts

DIN 5473 ‘Symbols and concepts in sot thoory; sats, relations and functions

DIN 6771 Part 1 Title blocks for drawings, plans and lists,

DIN 6776 Part} Tachnical drawings; lettering: character

SO 286-1: 1988 ISO system of limits and fits: bases of tolerances, deviations and fits

180.3040: 1990 Technical drawings; dimensioning and tolorancing; conas

180 5480: 1981 Technical drawings; geometrical tolerances; datums and datumsystems for geometrical tolerancing

180 7063: 1983 Technical drawings; symbols for geometrical tolerancing; proportions and dimensions

1SO/D81 10209-2 Technical preduct documentation; concepts; concepts for projeation methods

Other relevant standards

ON 30 Drawings; simplified representations

DIN 406 Part4 Engineering drawing practice; dimensioning: dimensioning for machine programming

DIN 4895 Part 1 Orthogonal coordinate eystoms; gonaral concepts

DIN6771 Pert —Preprinted forms for technical documentation; drawings

DIN 6774 Part 1 Technical drawings; rules of execution: drawings suitable for reproduction

DIN 6774 Part 10. Technical drawings; rules of execution: computer-assisted drawings

1s0 1101 =1983 Technical drawings; geometrical tolerancing: tolerancing of form, orientation, location and run-out;

generalites, defintions, symbols, indications on drawings

180 1902: 1978 Technical drawings; method of Indicating surface texture on drawings

180 5488: 1979 Technical drawings; scales

ISO/DIS 1195-1 Technical drawings; indications for moulded parts; preforms

Previous editions

DIN 406 Part 1 to Part $: 1222; DIN 406 Part 4: 1222, 0597; DIN 406 Part 5: 11.24, 10.41; DIN 406 Part 6: 12.24, 01.26,

10.41; DIN 406: 09.49, 08:88; DIN 406 Part: 07.75; DIN 408 Part 2: 0668, 0480, OBBI; DINV.406 Part 1: 10.70;

DIN 406 Part 1: 04.77

‘Amendments:

The following amencments have been made to DIN 406 Part 1, April 1977 edition and DIN 406 Part 2, August 1881 eattion:

18) the organization of the content of the standard has bean revised;

b) concepts, features and systems of dimensioning have been specttied:

‘s) the definition of ‘auxiiary dimension’ has been revised (cf. Explanatory notes).

Explanatory notes

On the publication of 180 120 :1988, Technical drawings: dimensioning; ganeral principles. definitions, methods of execution

and special indications’, tha ragponsible committee of the Normenausschue Zeichnungswesen (Drawing Practice Standards

Committee) had to decide, on the basis ofa draft translation, in what form the rules specified In that standard were to be incor:

porated in German standards

‘Owing to the large number of text passages and fgures needing supplementary ehicidation (clarification or qualification) it was

decided to revise DIN 406 Parts 1 to 3 on the basis of 150 129 in such a way that the ravisad vorsions may servo as proposals

for the next revision of ISO 129, In tis respect. attention was also to be given to data (graphical and non-grephical) transfer in

numerically controlled systems (CA),

Page 6 DIN 406 Part 10

(On the assumption that the standards of the DIN 406 series should give specifications of general validity. Le. there should be na

distinction made in the standards between manual and machine drawing, the whole subject ofthe ‘indication of dimensions and

tolerances in engineering drawings’ will in future be organized as follows:

DIN 406 Part 10 Engineering drowing practice: dimensioning; concepts and general principles

DIN 406 Part 11 Engineering drawing practice; dimensioning; principles of application

DIN 406 Part 12 Engineering drawing practice: dimensioning; indication of tolerances for linear and angular dimensions

Greater clarity has been reached with respect to ‘euaiiary dimensions’ by omitting the term ‘auxiliary dimensions for construct

tion/preduction’ previously included in the Aptil 1977 edition of the standard. Auxiliary dimensions are, irrespective of their pur-

pose in the drawing, of no significance for the geometrical shape of a part or configuration and are accordingly not toleranced.

They serve only to provide (supplementary) information and do not apply to the manufacture or inspection of tha parts.

English-German index of terms defined in this standard

Auxiliary dimension

Hiltsmas, Infomationsmas

Centee tine Mittelinie

Chain dimensioning Kettenbemasung

Check dimension Prutmas

Datum Bezugsmas

Dimension Mas

Dimension tne MaBlinie

Dimensioning by coordinates Koordinatenbemagung

Dimensioning by tables Ma8eintragung mit Hilfe von Tabelien

Dimensioning from a common feature Bezugsbemasung

Finished dimension Fertigmas

Functional dimension Funktionsmaa

Initia length gestreckte Lange

Leader tine Hinweistinie

Line of symmetry Symmetrioinie

Parallel cimensioning ParallelbemaSung

Pre-work cimension Vorarbeitungsmab

Projection ine Mashilfstinio

Raw dimension Rohmaé.

Repetition Tellung

Single dimenstoning EinzelbemaBung

‘Superimposed running dimensions

Termination

‘Theoretical exact dimansion

International Patent Classification

oop

steigende BemaBung

Ma6iinionbegrenzung

theoretisch genaues MaB

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Dinen837 1Document23 pagesDinen837 1Maurício Duarte de AndradeNo ratings yet

- Dinen837 3Document20 pagesDinen837 3Maurício Duarte de AndradeNo ratings yet

- Dinen292 1Document25 pagesDinen292 1Maurício Duarte de AndradeNo ratings yet

- Dinen292 2Document47 pagesDinen292 2Maurício Duarte de AndradeNo ratings yet

- Diniso4783 2Document8 pagesDiniso4783 2Maurício Duarte de AndradeNo ratings yet

- DINEN1274Document18 pagesDINEN1274Maurício Duarte de AndradeNo ratings yet

- DIN34109Document14 pagesDIN34109Maurício Duarte de AndradeNo ratings yet

- Dinen485 4Document9 pagesDinen485 4Maurício Duarte de AndradeNo ratings yet

- E DIN39Document2 pagesE DIN39Maurício Duarte de AndradeNo ratings yet

- Din5480 14Document6 pagesDin5480 14Maurício Duarte de AndradeNo ratings yet

- E BSEN10131Document11 pagesE BSEN10131Maurício Duarte de AndradeNo ratings yet

- eBSEN10045 1Document12 pageseBSEN10045 1Maurício Duarte de AndradeNo ratings yet

- E DIN79Document2 pagesE DIN79Maurício Duarte de AndradeNo ratings yet

- eBSEN10002 1Document26 pageseBSEN10002 1Maurício Duarte de AndradeNo ratings yet

- E SN809Document1 pageE SN809Maurício Duarte de AndradeNo ratings yet

- Round Washers SN 808: July 2000Document1 pageRound Washers SN 808: July 2000Maurício Duarte de AndradeNo ratings yet

- SN901 1Document2 pagesSN901 1Maurício Duarte de AndradeNo ratings yet

- SN807Document2 pagesSN807Maurício Duarte de AndradeNo ratings yet

- SN900Document22 pagesSN900Maurício Duarte de AndradeNo ratings yet

- SN912Document2 pagesSN912Maurício Duarte de AndradeNo ratings yet

- SN806Document3 pagesSN806Maurício Duarte de AndradeNo ratings yet

- SN805Document4 pagesSN805Maurício Duarte de AndradeNo ratings yet

- eSN901 3Document1 pageeSN901 3Maurício Duarte de AndradeNo ratings yet

- SN901Document3 pagesSN901Maurício Duarte de AndradeNo ratings yet

- SN910Document2 pagesSN910Maurício Duarte de AndradeNo ratings yet

- SN922Document2 pagesSN922Maurício Duarte de AndradeNo ratings yet

- eSN901 7Document1 pageeSN901 7Maurício Duarte de AndradeNo ratings yet

- SN913Document2 pagesSN913Maurício Duarte de AndradeNo ratings yet

- SN911Document2 pagesSN911Maurício Duarte de AndradeNo ratings yet

- eSN470 1Document4 pageseSN470 1Maurício Duarte de AndradeNo ratings yet