Professional Documents

Culture Documents

Pre-Job Hazard Analysis

Uploaded by

Firas HamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pre-Job Hazard Analysis

Uploaded by

Firas HamanCopyright:

Available Formats

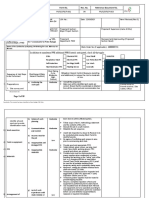

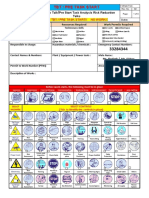

PRE-JOB HAZARD ANALYSIS

JHA No. Site Name New Analysis By:

Date: Site Location Revised Revised By:

Project No. Contractor Proj. Mgr. Approved By:

Job Description:

Hazards Hazards (body) Personal Protective Equipment General Requirements Environmental

Airborne Particulates Fall Potential Gloves/Types Relocate Flammable Materials Chemical and MSDS Sheet

Chemicals (Acids & Bases) Pinch Points Respirator/Type Post Warning Signs Spill Kit

Electrical Shock Electrical Shock Hearing Protection Barricades Permits

Falls Housekeeping Safety Glasses, Goggles, etc. Use Ventilation/Exhaust Procedure

Heat Stress Slip/Trip (Cords, Pipe, etc) Protective Clothing/Footwear Other Labels for Chemical Storage

Hot/Cold Surfaces Flying Particles Hardhat/head protection Special Operations Hazards (Environmental)

Noise Thermal Burns Electrical LockOut/TagOut (LOTO) Airborne Particulate (Fumes, Mists)

Operating Machinery Sharp Objects Fall Protection Confined Space Entry Other Heat Stress (Hot/Cold Surfaces)

Other Heavy Equipment Hazards Other Construction Activities Materials

Oxygen Deficiency Hygiene Training Hot Tap Adequate Lighting

Restricted Access/Egress Chemical Burns Confined Space Entry Procedures Crane Suspended Work Platform Noise

Rotating Equipment Water Skin/Eyes LockOut/TagOut (LOTO) Working on Energized Electrical Circuit Access/Egress

Hazard Flammable Respiratory Protection Scaffolding (Green, Yellow and Red Card) Radiation from Radiography

Other Inhalation Other Radiation from Other Source

Skin Contamination

Sequence of Job Potential Hazards Recommended Action, Procedure, and/or Equipment

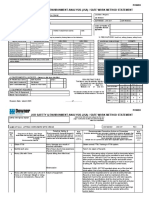

Job Preparation Miss coordination and miss Plan the work involving personnel responsible for preparation (removal of joint coupling,

Persiapan Pekerjaan communication electrical work, measurement of motor parameters)

kesalahan koordinasi dan Rencanakan kegiatan termasuk tanggung jawab tiap personnel untuk persiapan

(memasang jont coupling, pekerjaan elektrik,

kesalahan komunikasi

Ensure communication devices are adequate for the job coordination

Memastikan ketersediaan alat komunikasi mencukupi untuk pekerjaan yang akan

dilakukan

PTW Violation Job description details and location of work to be confirmed

Pelanggaran PTW Rincian uraian pekerjaan dan lokasi pekerjaan harus dikonfirmasi

Use multilock & tag for isolation carried out

Menggunakan kunci-kunci dan tag pada poin-poin isolasi

Pre-job Hazard Analysis Form Rev-0 Page 1 of 5

Sequence of Job Potential Hazards Recommended Action, Procedure, and/or Equipment

No risk kontrol Make sure job hazard analysis has been made and socialized to the worker and signed

Pastikan job hazard analysis sudah dibuat dan disosialisasikan kepekerja san sudah

ditandatangani

Unauthorized personnel entry Install Barricade in the system affected by the testing of the equipment

Orang yang tidak Memasang barikade pada system yang terpengaruh oleh pengetesan peralatan

berkepentingan memasuki area

testing

Predicted high vibration factor Ensure the motor are grouted as per requirement of manual book from vendor

Vibrasi tinggi yang dapat Memastikan motor sudah di grouting secara benar sesuai dengan manual book dari

dipersiapkan vendor

Motor not connected to the Ensure joint coupling from motor to coupler/ pump already assembled

pump Memastikan joint couple dari bagian motor ke coupler/ pompa sudah terlepas

Motor masih belum tersambung

dengan pompa

Motor unable to stop Ensure emergency push button already position tested

Motor tidak bisa di stop Memastikan Emergency Push Button sudah di tes posisi

Unmonitored Data Ensure equipment to measure motor parameter are ready (vibration, temperature, speed)

Data test tidak termonitor Mempersiapkan alat ukur vibrasi, temperature dan tachometer

Filling up the system line Unmonitored Leakage Ensure adequate personnel is ready for the system and got a proper communication tool

Pengisian air ke pipa sistem Kebocoran tidak termonitor Memastikan ketersediaan personel cukup untuk sistemnya dan semua membawa alat

komunikasi yang berfungsi dengan baik

Ensure every personnel is continuously monitoring in each position

Memastikan setiap personel memonitor secara kontinu pada posisi masing-masing

Fall during operation of venting Use proper scaffolding (already green tagged)

valve Menggunakan scaffolding yang sudah ber tag hijau (aman)

Jatuh ketika pengoperasian

venting

Use full body harness with double lanyard

Menggunakan full body harness dengan hook ganda

Equipment/ material fall Use watchmen to warn people below venting points, install barricade when necessary

Barang terjatuh Menggunakan watchmen untuk memperingatkan orang di bawah titik venting, memasang

barikade jika diperlukan

Pre-job Hazard Analysis Form Rev-0 Page 2 of 5

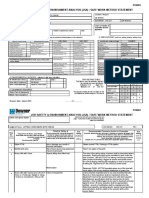

Sequence of Job Potential Hazards Recommended Action, Procedure, and/or Equipment

Water spray, slippage Use temporary hose from vent points to drain pit

Basah, terpeleset Menggunakan selang temporer dari titik venting ke tempat pembuangan air

Flushing dirty water from the system line when needed Leakage/ flood Operate drain points one by one, monitor each drain line, immediately close the drain

Membuang air kotor dari system ketika dibutuhkan Bocor/ banjir valve whe leakage is found

Mengoperasikan drain valve satu demi satu sambil memonitor kebocoran pada pipa drain

Monitor drain pit which filled by the drain line, close the valve when the drain pit is full

Memonitor drain pit yang diisi oleh drain yg dibuka valve nya, tutup valve jika drain pit

penuh

Ensure drain pump are ready and operating when needed

Memastikan pompa drain pit siap dan beroperasi ketika dibutuhkan

Starting the pump Uncontrollable Leakage Close unneeded isolation valves

Menyalakan pompa Kebocoran yang tidak terkontrol Menutup isolation valve yang tidak terpakai

Ensure no opening in the system (all gasket are installed, all bolt nuts are tightened, are

uninstalled instruments are plugged)

Memastikan tidak ada pipa yang terbuka pada system (semua gasket terpasang, semua

baut terpasang erat, dan instrument yang belum terpasang sudah di plug)

Electrical shock Use proper PPE

Sengatan listrik menggunakan PPE

Ensure insulation resistance test prior to motor solo run is good

Memastikan hasi tes insulation resistance pada motor yang akan di tes sudah sesuai

standard

Ensure earthing installation is proper

Memastikan pemasangan earthing pada motor sudah sesuai

Overpressure Fluid Ensure minimum flow line is full open

Tekanan berlebih Memastikan jalur minimum flow dalam keadaan terbuka

Pump Cavitation Ensure pump is primed

Kavitasi pompa Memastikan jalur fluida pada pompa terisi air

Ensure strainer at the system is not blocked

Memastikan saringan tidak buntu

Monitoring Pump and Motor Parameter Rotating equipment Maintain safe distance to the rotating parts of the equipment

Memonitor parameter pompa dan motor Peralatan yang berputar Menjaga jarak aman dari peralatan yang berputar

Electrical Induction Maintain safe distance to the motor winding area

Induksi elektrik Menjaga jarak aman dari winding motor yang beroperasi

Pre-job Hazard Analysis Form Rev-0 Page 3 of 5

Sequence of Job Potential Hazards Recommended Action, Procedure, and/or Equipment

Abnormal Vibration Continue monitoring vibration, stop the motor if necessary

Vibrasi yang tidak normal Terus memonitor vibrasi motor dan pompa, mematikan motor jika diperlukan

(tinggi)

Abnormal Bearing Temperature Ensure adequate lubricants are supplied to the bearings, add if neccessary, stop motor if

Bearing motor panas necessary

Memastikan pelumasan yang diberikan pada bearing motor dan pompa sudah cukup,

tambahkan bila diperlukan , jika masih naik matikan motor

Stumble/ Fall Ensure adequate illumination/ install additional lighting if neccessary

Tersandung / terjatuh Memastikan penerangan cukup/ memasang lampu tambahan jika dibutuhkan

Unrecorded Parameter Ensure record of the parameter are monitored thoroughly

Parameter tidak terdata Memastikan pencatatan parameter pompa dilakukan dengan benar

Stopping the pump Motor unable to stop Ensure emergency push button already position tested

Mematikan pompa Motor tidak bisa di stop Memastikan Emergency Push Button sudah di tes posisi

House keeping Foreign material left Ensure there is no tool, equipment, rags or other material left

Kebersihan tempat kerja Benda tertinggal Memastikan tidak ada peralatan ataupun material yang tertinggal

Pre-job Hazard Analysis Form Rev-0 Page 4 of 5

JHA Employee Signatures

JHA No. Site Name New Analysis By:

Date: Site Revised Revised By:

Project No. Contractor Proj. Mgr. Approved By:

Job Description:

Employee Name (Print) Employee Number Employee Signature

Pre-job Hazard Analysis Form Rev-0 Page 5 of 5

You might also like

- JSA For HVAC WorkDocument8 pagesJSA For HVAC Worksathakathulla100% (3)

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- Electrical Isolation PermitDocument2 pagesElectrical Isolation Permitsindarth raveendrakrishnan100% (9)

- Jsa For HydrotestDocument10 pagesJsa For HydrotestAnonymous CcGYhZb080% (5)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- Tata CRMDocument39 pagesTata CRMRoger Brown100% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSFrom EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSRating: 1 out of 5 stars1/5 (1)

- Pre-Job Hazard AnalysisDocument3 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- Jha 1Document3 pagesJha 1Firas HamanNo ratings yet

- Pre-Job Hazard AnalysisDocument4 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- TRA - Amine System Degreasing - October 14, 2018Document9 pagesTRA - Amine System Degreasing - October 14, 2018Ijaz HussainNo ratings yet

- TRA Strainer Cleaning 01Document7 pagesTRA Strainer Cleaning 01Ijaz Hussain0% (1)

- Job Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisDocument25 pagesJob Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisFaraz KhalidNo ratings yet

- JSA Pipping & InstrumentDocument6 pagesJSA Pipping & Instrumentkristina panjaitanNo ratings yet

- No TBT / Pre Task Start!! No Work!!Document4 pagesNo TBT / Pre Task Start!! No Work!!Muhammad Iqbal Niyazi100% (3)

- WirelessEstimatorJHA YESElevatedDocument5 pagesWirelessEstimatorJHA YESElevatedmohammed tofiqNo ratings yet

- JSA G17 Lift Container With Crane PDFDocument4 pagesJSA G17 Lift Container With Crane PDFsetiawanaji407100% (1)

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With Cranesetiawanaji407No ratings yet

- JSA G20 Scaffolding Erection DismantlingDocument4 pagesJSA G20 Scaffolding Erection DismantlingemmyNo ratings yet

- BBS Form - Rev 1Document2 pagesBBS Form - Rev 1Riccardo GastaldoNo ratings yet

- SH-F43 - PTW Format - R02Document2 pagesSH-F43 - PTW Format - R02vini100% (1)

- Job Safety & Environment Analysis (Jsa) : Activity or TaskDocument3 pagesJob Safety & Environment Analysis (Jsa) : Activity or TaskLusy Gusti EfendiNo ratings yet

- Job Hazard Analysis Worksheet Form HSEDocument2 pagesJob Hazard Analysis Worksheet Form HSEChaimaa EnnouhiNo ratings yet

- Topographical SurveyDocument5 pagesTopographical SurveyEbi StephenNo ratings yet

- Method Statement: Date: Project No: Date of Issue: RevisionDocument7 pagesMethod Statement: Date: Project No: Date of Issue: RevisionDawit SolomonNo ratings yet

- Job Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCDocument4 pagesJob Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCChukwuma Emmanuel Onwufuju0% (1)

- MS-As-FRM-0063 Job Hazard Analysis Worksheet FormDocument3 pagesMS-As-FRM-0063 Job Hazard Analysis Worksheet Formأم رهامNo ratings yet

- Safe Work Method Statement (York Street EC) 2023.06.23Document8 pagesSafe Work Method Statement (York Street EC) 2023.06.23manuel010478No ratings yet

- The Form Should Be Used in Accordance With The Job Hazard Analysis Standard MS-AS-STD-0064Document3 pagesThe Form Should Be Used in Accordance With The Job Hazard Analysis Standard MS-AS-STD-0064Mounir HammoutiNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- Rme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20Document1 pageRme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20nanthan06No ratings yet

- Work Permit Sample For Contractro TresDocument6 pagesWork Permit Sample For Contractro TresretheepNo ratings yet

- Pe - PTW FormDocument2 pagesPe - PTW FormDilip MenonNo ratings yet

- Review Safe Work Permit Hazard ChecklistDocument6 pagesReview Safe Work Permit Hazard ChecklistSuud SenanNo ratings yet

- Daily Plant InspectionDocument5 pagesDaily Plant InspectionSteve O'DonoghueNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- Minor Works MSRADocument2 pagesMinor Works MSRAananthu.uNo ratings yet

- JSA Meter SystemDocument3 pagesJSA Meter SystemKorinne ShabiraNo ratings yet

- JSA - Scissor - Lift 2023Document4 pagesJSA - Scissor - Lift 2023syed khaja misbhuddinNo ratings yet

- SWMS Crane 1711211774Document13 pagesSWMS Crane 1711211774Sarmad AbbasiNo ratings yet

- 5 - JSA - Radiography TestDocument5 pages5 - JSA - Radiography TestAijaz AhmedNo ratings yet

- 02 - Radiography Certificate (4022802 - v1)Document1 page02 - Radiography Certificate (4022802 - v1)Ali.N AlsaadyNo ratings yet

- Job Safety Analysis WitcoDocument2 pagesJob Safety Analysis WitcoOmega Chang'eNo ratings yet

- Job Safety Analysis FormatDocument2 pagesJob Safety Analysis FormatSpeed Tech தமிழ்No ratings yet

- Risk Assessment Work at Height ExpertiseDocument8 pagesRisk Assessment Work at Height ExpertiseyasirNo ratings yet

- Electrical (Islation) Permit-YELLOWDocument2 pagesElectrical (Islation) Permit-YELLOWAravind Babu Dasari50% (2)

- Intext Solutions RamsDocument7 pagesIntext Solutions Ramsjoshua achukaNo ratings yet

- Welding Method Statement (SWMS) PDFDocument6 pagesWelding Method Statement (SWMS) PDFallanidunNo ratings yet

- W Nit-466 4 2Document3 pagesW Nit-466 4 2A ReddyNo ratings yet

- BSH Safe Work Method StatementDocument9 pagesBSH Safe Work Method StatementHariprakash karuppannanNo ratings yet

- Work Permits Formats For WorkplaceDocument4 pagesWork Permits Formats For WorkplaceDnyaneshwar PatilNo ratings yet

- RoutineJobHazardAnalysis 000Document2 pagesRoutineJobHazardAnalysis 000sugiyanto100% (1)

- HSE Plan Ocon CommentsDocument4 pagesHSE Plan Ocon CommentsqaqqaqqNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- JSA For Lift Personnel in Scissor LiftDocument6 pagesJSA For Lift Personnel in Scissor Liftnawalmaftah23No ratings yet

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- Permit To WorkDocument1 pagePermit To WorkIshtiaq AhmadNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Guidelines For Research ProjectsDocument10 pagesGuidelines For Research Projectspriyanshu shrivastavaNo ratings yet

- Thermodynamics JAM 2021 1Document42 pagesThermodynamics JAM 2021 1krishna prasad ghanta100% (2)

- BUDGET OF WORK SY: 2021-2022: Subject: Tle 8 Grading Period: 3Document2 pagesBUDGET OF WORK SY: 2021-2022: Subject: Tle 8 Grading Period: 3michelle dayritNo ratings yet

- Đề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Document8 pagesĐề Trung Học Thực Hành Đại Học Sư Phạm 2020-2021Chi Vũ LinhNo ratings yet

- Class-5 Unit-5 (Prose) Shabale (Sabala)Document16 pagesClass-5 Unit-5 (Prose) Shabale (Sabala)GKHPS B HOSAHALLINo ratings yet

- Admission Notification 2024-2025Document12 pagesAdmission Notification 2024-2025jsbska88No ratings yet

- Ancient AstronomyDocument26 pagesAncient AstronomyRodel RamosNo ratings yet

- IHS Markit Seed Market Analysis and Data InfographicDocument1 pageIHS Markit Seed Market Analysis and Data Infographictripurari pandeyNo ratings yet

- SP Q4 Week 2 HandoutDocument10 pagesSP Q4 Week 2 HandoutLenard BelanoNo ratings yet

- I Learned Chapter 8-The Power of GuidanceDocument1 pageI Learned Chapter 8-The Power of Guidanceapi-295870335No ratings yet

- Design of Deep Supported Excavations: Comparison Between Numerical and Empirical MethodsDocument7 pagesDesign of Deep Supported Excavations: Comparison Between Numerical and Empirical MethodsNajihaNo ratings yet

- Unit 5Document3 pagesUnit 5api-665951284No ratings yet

- SM2 Polygon of ForcesDocument11 pagesSM2 Polygon of ForcesMel DNo ratings yet

- Accion Didactica 1st Grade NovemberDocument3 pagesAccion Didactica 1st Grade NovemberAntonio Abad GutiérrezNo ratings yet

- Department of Education: Region IIIDocument14 pagesDepartment of Education: Region IIICe JeyNo ratings yet

- Scaffold 2Document3 pagesScaffold 2Mahmoud Elsayed MohamedNo ratings yet

- Komatsu Wb93r 5 Shop ManualDocument20 pagesKomatsu Wb93r 5 Shop Manualsandra100% (32)

- StringDocument4 pagesStringAadyant BhadauriaNo ratings yet

- Rd6appspecDocument2 pagesRd6appspecravi00098No ratings yet

- A Summary of The Theories or Concepts About Child Development From Piaget, Vygotsky, Brunner, and Gardner-Zahra Warda Mufidah 183221217Document16 pagesA Summary of The Theories or Concepts About Child Development From Piaget, Vygotsky, Brunner, and Gardner-Zahra Warda Mufidah 183221217Fida100% (1)

- English 900 - 01Document147 pagesEnglish 900 - 01Hnin Hnin AungNo ratings yet

- Akshay Urja Full PDFDocument56 pagesAkshay Urja Full PDFNeelam Shrivastava100% (2)

- R.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickDocument1 pageR.M. M, J. C, S.L. I S.M. H R C. M P J. M G : Aier Horover Verson AND Ayes Odney Aier and Eter C OldrickPeter McGoldrickNo ratings yet

- Foundations For Low Loss GRIN Fiber CouplingDocument16 pagesFoundations For Low Loss GRIN Fiber CouplingpsylabsNo ratings yet

- DLL-All Subjects - Week 7 Day 1Document5 pagesDLL-All Subjects - Week 7 Day 1Windel Beth Quimat ZafraNo ratings yet

- 003 Users Manuel of Safir 2016 - MechanicalDocument74 pages003 Users Manuel of Safir 2016 - Mechanicalenrico_britaiNo ratings yet

- Cars MasonryDocument1 pageCars MasonryAbdullah MundasNo ratings yet

- h1 Styleclearboth Idcontentsection0the Only Guide To Commercial Fisheries Reviewh1jbfch PDFDocument14 pagesh1 Styleclearboth Idcontentsection0the Only Guide To Commercial Fisheries Reviewh1jbfch PDFgalleymark22No ratings yet

- LEPTOSPIRADocument31 pagesLEPTOSPIRADinar NastitiNo ratings yet