Professional Documents

Culture Documents

Safe Work Method Statement (York Street EC) 2023.06.23

Uploaded by

manuel010478Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safe Work Method Statement (York Street EC) 2023.06.23

Uploaded by

manuel010478Copyright:

Available Formats

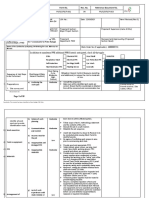

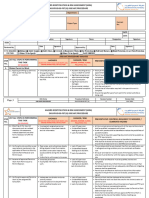

Safe Work Method Statement

(Record Approval)

Exhaust extension for existing standby AFRIWATT 365 PTY LTD

Nature of the work Principal Contractor Name

generator set

106 York Street, George, Eastern Cape NIL

Contractor, other than the

Principle Contractor,

Site / Building Name

carrying out the work (sub-

contractor)

Location (Indoor / OUTDOOR AREA Planned Start Date TBA Time 08h00

Outdoor Area, Building

Section, Floor, Room, TBA

Planned Finish Date Time

etc.)

Name of appointed Lindiwe Mqweba +27 67 703 4159 Number of 3

Mobile Phone Number

Supervisor on Site Persons

Name(s) of Emergency KEVIN DHAPI Office Telephone or Cell 011 864 2584 / 067 698 5418

Contact Person(s) MUTONDI SADIKI Phone Number 067 699 4139

Name(s) of the Client VONGANI CHIRINDI Office Telephone or Cell

Contact Person(s) Phone Number

SITE PREPARATION – 1 DAY

ACCESS, USE OF PLATFORM FOR EXHAUST EXTENSION

Description of the STEEL/ MECHANICAL WORKS

method to follow FITTING SLEEVE JOINT

(attach sketches /

FITTING CLAMP TO JOINT

drawings if possible)

FITTING SUPPORT BRACKET FOR EXTENSION

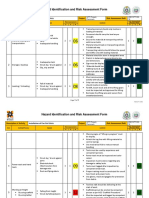

Risk Rating

Health and Safety Environmental Business time loss Matrix

Methodology

Catastrophic, Fatality, Loss of limb 80% of the environmental impact is irreversible 1 day or more 3 3 6 9

Severity Lost Time Injury (> 3 days) 60% of the environmental impact is irreversible Less than 1 day 2 2 4 6

First Aid Treatment / Near Miss The environmental impact is fully reversible 1 hour or less 1 1 2 3

Acceptable Risk Control High Risk (4-9) - Supervision, Safe Work Procedure(s), Permit to Work System, as well as the controls listed below 1 Unlikely 2 Likely 3 Certain

Level for Medium and Low Risk. Probability

Medium Risk (2-3) - Competent Workers, Site Risk Assessment and Risk Controls Training.

Low Risk (1) - Method Statement Awareness Training.

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 1 of 8

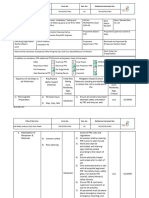

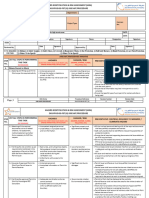

Safe Work Method Statement (Record Approval)

Sequence of events

Potential Hazards and Risks Appropriate Controls

Risk Rating (S x P)

Job Step / Task

Probability (P)

Sequence No.:

Severity (S)

Activity / Task

[Engineering, Administrative, Personal

Describe, in detail and as far as List the potential hazards and risks associated Protective Equipment / Wear (PPE / PPW) Responsible Person

reasonably possible, the steps with each step, which could cause injury or to Mitigate the Risk

required to perform the activity or and Training]

damage to property when the activity or task List the control measures required to eliminate or

task in the sequence in which it is is performed. (Indicate the worst-case

carried out. minimise the risk of injury or damage to property

scenario, in terms of Severity and Probability, associated with the hazards identified.

for each step).

1 Offloading material and equipment offsite

Occupational driving/ driving Poorly maintained or improperly Construction vehicles to be Project manager /

1 onsite handled vehicles can lead to 2 2 4 installed with reverse alarms, Supervisor

crushing injuries onsite and ensure they are functioning on all

collisions. vehicles.

Designate a spotter for direction

and assistance of driver when

driving vehicle onsite

Competent driver of vehicles,

ensure vehicle is fit for purpose

and in good working order – pre-

inspection of vehicles before use

Positioning of truck Unstable or Wet ground and Position the truck on level ground. Operator

2 Uneven surfaces 2 2 4 All the wheels of the truck to be Supervisor

Truck losing balance resulting in chocked and in contact with the

property damage and injuries. ground when the outriggers are set

(suspension not to be completely

unloaded).

Load test certificate for the crane

truck

Driver must have a valid certificate

for operating the crane.

The crane must be inspected prior

to start of work activities

3 Suspended load Equipment can fail unexpectedly, 3 3 9 The work area must be barricaded Operator

and operator errors can have off to avoid public interference. Supervisor

serious ramifications including No one must be under the

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 2 of 8

Safe Work Method Statement (Record Approval)

severe injuries/death suspended load during lifting

activities

Access control must be

implemented around the work area

4 Lifting the load Inclement Weather (high winds, 3 3 9 No work will take place if the wind Operator

lightning, Rainy)- Poor Vision / speed exceed 40km/h No Supervisor

Dust / Electrocution work to be carried out during

adverse weather conditions

Risks shall be assessed prior to

lifting and must be then approved

by Bidvest Project

manager/Engineers before any

work commences.

Manual Handling Slips, Trips and Falls due to poor Good housekeeping practices for a

5 housekeeping. safe place of work. Clear access Installer

2 2 4 routes and signage. Continuous

Manual Handling – carrying of removal of all waste. / Site Supervisor

material, equipment ladders, tools Hand tools are relatively lightweight

(tools to be carried in single

toolbox). Train employees in

Manual Handling techniques. Large

and awkward cable tray or ladder

rack to be handled/carried by two

workers.

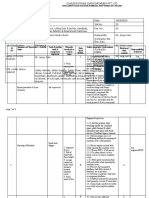

INSTALLATION OF EXTENSION PIPES

Drilling support bracket Existing services in the wall can Confirm no services at points to be

6 cause electrocution and other dug, client to issue written

property damages 3 2 6 notification, if services are Site Supervisor

identified in the area, an isolation

certificate must be issued

Awkward postures and repetitive 2 2 4 Implement manual handling SWP Site Supervisor

motions can lead to sprains, strains Conduct toolbox talks about

and other musculoskeletal disorders manual handling

Exposure to Dust, inhalation causing 3 2 6 Dust suppression – wet surface Site Supervisor

lung infections before digging, workers to wear

FFP2 type dust masks

Exposure to excessive weather 2 2 4 Allow short breaks and rotation of Site Supervisor

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 3 of 8

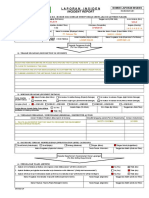

Safe Work Method Statement (Record Approval)

conditions causing hyperthermia/ task.

hypothermia - Dehydration and

dizziness

Faulty tools/ Equipment 3 2 6 Do not use defective tools Site Supervisor

Inspect hand tools before use

Do not modify hand tools

Train employees on the SWP for

hand tools

Portable hand drill must be

inspected before use

Noise-NIHL 2 2 4 Use ear protection when using Site Supervisor

portable drill

7 Portable electrical tools Electric shock 1.SWP, Monthly Portable Electric

Equipment Inspections

2.Use Personal Protective

Equipment

3.All defect tools must be reported

to the supervisor and removed from

site.

8 Paint work, painting exhaust Inhalation of fumes Rinse eyes with water if they come

extension Paint flung into eye

2 1 2 into contact with cement. Site Supervisor

Use soap and water to wash off dust

to avoid skin damage.

Wear full PPE; pants and long sleeve

jacket, apply hand protection –

crayfish gloves to avoid skin

irritation

Inserting clamps and backet Installer shall wear appropriate

9 to hold extension in place. Handling of sharp edges of steel PPE, leather gloves, goggles, ear

Manual handling 2 2 4 plugs Site Supervisor

Training in suitable lifting

techniques and assisted lifting, 2

employees to lift the palisade panel

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 4 of 8

Safe Work Method Statement (Record Approval)

and place where there are to be

installed

Using a ladder Working at height -Fall risk 3 3 9 Fall protection and rescue paln Site Supervisor

10 must be implemented.

Employees must be trained on

SWP for working at heights

Employees must hook up at

heights

Ladders must be inspected prior to

use

SWP for Ladder must be trained on

employees

Vehicles and Mobile Plant Truck mounted crane Equipment to be used Ladder, generator unit,

(Cherry Picker, Back Actor, etc., (Scaffold / Ladder, Compressor, Porta

List Registration Numbers) Pack, Welding Machine, etc.)

Cement, Palisade poles, concrete mix, Chemicals to be used (Paint, oil, Cement, coolant, engine oil, diesel

Materials to be used reinforcement steel, cable, Thinners, etc.)

Grinder, extension cables Hand Pick, Shovels, Pliers,

Electrical Tools to be used Hand Tools to be used

Safety Signage and Site safety board, No entry, danger – Incident Management ✘ First Aid Kit available on site and adequate

Barricading to be used lifting operations. (Mark the item with an “X” if applicable) ✘ Spillage Kit available on site and adequate

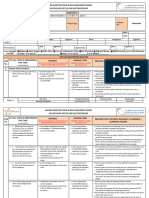

The following records to be submitted as part of the Safe Work Method Statement conditional Site/Team/

Vendor

approval process. Clearly mark “X” in the appropriate block to indicate the location where Portal

Vehicle N/A Specify

documents can be reviewed. SHE File

Certificates of Specialised Equipment e.g. Lifting Equipment / Devices, Slings, etc. ☐ ☒ ☒ ☐ Submit records to ensure

compliance with CR and DMR

18

Company / Supervisor / Technical Staff Competency Records ☐ ☒ ☒ ☐ Qualifications of the Electrical

(e.g. HVAC, Electrical, Fire and Access, Plumbing, Carpentry, Welding, etc.). competent person

Site Supervisor

Fall Protection Plan and Rescue Plan ☐ ☐ ☐ ☒

Legal Appointments (Site Supervisor, Risk Assessor, Fall Protection Planner, First Aider, Rigger, ☐ ☒ ☒ ☐ Supervisory person on site

etc.).

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 5 of 8

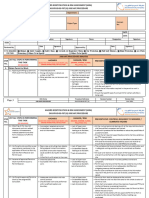

Safe Work Method Statement (Record Approval)

Material Safety Data Sheets for Hazardous Chemical Substances ☐ ☒ ☒ ☐ Diesel, Antifreeze, oil,

(Risk of exposure to the product, e.g. toxic fumes / poisonous / corrosive substances, etc.). sanitiser

Mandatory / Section 37.2 Agreement Signed ☒ ☒ ☐ ☐

Medical Certificates of Fitness (Working at Heights, Suspended Platforms, Cranes, Mobile ☒ ☒ ☐ ☐

Elevated Work Platforms).

Public Liability Insurance / Contractor’s All Risk Insurance ☒ ☐ ☐ ☐

Safe Work Procedures (Working at Heights, Suspended Platforms, Cranes, Mobile Elevated Work ☐ ☒ ☒ ☐ Related to the Project and

Platforms, Electrical and Mechanical Equipment). LOTO

Site Induction (Client / Bidvest Facilities Management / Safe Work Method Statement). ☐ ☒ ☒ ☐ Toolbox for the site

installation

Statutory Training Certificates, e.g. Scaffold Supervisor, Erector and Inspector, Mobile Elevated ☐ ☒ ☐ ☐ Basic Fire Training

Work Platform Operator, Rope Access and Fall Prevention Certificates, etc.). First Aider

Mobile Crane Operator

Valid Letter of Good Standing (Compensation for Occupational Injuries and Diseases Act 130 of ☒ ☒ ☐ ☐

1993)

Vehicles, Mobile Plant and Equipment Inspections as per the list above. ☐ ☒ ☐ ☐

Certificates of Specialised Equipment e.g. Lifting Equipment / Devices, Slings, etc. ☐ ☒ ☒ ☐ Submit records to ensure

compliance with CR and DMR

18

Company Authority Name (I confirm, to the best of my knowledge, that the information above is correct and I will ensure that the prescribed

Confirmation (Designated health, safety and environmental precautions are implemented before work commences on site.)

Contractor Representative) Name: Mutondi Sadiki Designation: 16.2 Signature: Date: 2023 / 06 / 23

For office use only

Hot Work Excavations Isolation (electrical, water, mechanical, live / pressurised

Permit to Work Required

Maximum depth: _______m equipment, fire alarm and gas suppression system)

Confined Space Lifting Operations: Working at Heights:

Applicable Not Applicable

Maximum lifting weight: ±_________kg Maximum Height: ±_________m from floor level

Compliance Representative Company Authority Name (I confirm, to the best of my knowledge, that the above information is correct and that the prescribed health,

verifies the content when a safety and environmental precautionary measures are appropriate for the risk exposure. In addition, the Permit Issuer may proceed to

Permit to Work is required, conditionally approve this Safe Work Method Statement)

Operational or live work is Name: Designation: Signature: Date:

performed, or on request for

confirmation by the Permit

Issuer.

Applicable Not Applicable

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 6 of 8

Safe Work Method Statement (Record Approval)

Bidvest Facilities Management Authority Name / Permit Issuer (I confirm, to the best of my knowledge, that the above information is

correct and that all prescribed health, safety and environmental precautions have been verified as indicated.

Conditional Approval

Conditional Approval to proceed with the work is subject to the following conditions being implemented by the Designated Contractor

Representative, prior to work commencement on site);

Herewith provide conditional Hand tools, electrical tools, ladders and equipment inspected and in good condition.

approval to proceed with the Personal protective equipment / wear (PPE / PPW) inspected and in good condition.

work, subject All appropriate controls / precautionary measures, related to the Risk Assessment above, implemented.

All employees have received awareness training on the content of this document.

Documentation in the site / team / vehicle Safety, Health and Environment (SHE) file reviewed prior to work commencement.

A Daily Site Risk Control Check (Task Risk Assessment) or Daily Safety Task Instruction (DSTI) conducted and risk controls

implemented.

All conditions of this Permit to Work implemented.

Other, specify:

Name: Designation: Signature: Date:

DESIGNATED CONTRACTOR REPRESENTATIVE TO COMPLETE THE FOLLOWING BEFORE WORK COMMENCEMENT ON SITE

Register and inspection of the condition of hand and electrical tools, ladders, equipment and personal protective equipment / wear (PPE / PPW)

List of critical tools, ladder(s) and Tool Identification Condition Employee Name List of PPE / PPW Condition

equipment Number (Good or Bad) (Good or Bad)

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 7 of 8

Safe Work Method Statement (Record Approval)

SAFE WORK METHOD STATEMENT BRIEFING

I, the undersigned, hereby confirm that I have read / discussed and understand the attached Method Statement and Risk Assessment, and that I will comply with the

specific requirements and control measures indicated. If work activities change or deviate from that originally envisaged, I will seek further advice and request an

amended Method Statement and Risk Assessment.

Name (Print) Signature Name (Print) Signature

WORK COMPLETION

Designated Contractor Representative (I hereby certify that the work specified in this Safe Work Method Statement has been completed.

In addition, I confirm that:

All persons under my supervision, together with all work materials and equipment have been withdrawn, and that the site has been left clean, tidy, safe and free

of any risks (including fire) for normal work to resume.

The completed Safe Work Method Statement and the attached Daily Site Risk Control Check (Task Risk Assessment) or DSTI will be submitted to the Bidvest

Facilities Management Facilities Manager or Technical Manager for record keeping.

Name: Designation: Signature: Date:

Bidvest Facilities Management Authority Name / Permit Issuer (I confirm, to the best of my knowledge, that the work has been completed, that equipment has

been tested, and that the area is safe and free of risk (including fire) for normal work to resume).

Name: Designation: Signature: Date:

Document No.: GOV0-4-503 Bidvest Facilities Company Restricted

SharePoint Ver.: 10.0 Management (Pty) Ltd Author: J Taylor

Date: 2022-10-24 Page 8 of 8

You might also like

- ABSA Bidvest FM Safe Work Method Statement Template - May 2023Document7 pagesABSA Bidvest FM Safe Work Method Statement Template - May 2023manuel010478No ratings yet

- Pre-Job Hazard AnalysisDocument5 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- Permit To Work Ref TemplateDocument2 pagesPermit To Work Ref Templatenatamas systemsNo ratings yet

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- HSE-PRO-03-INR 0.3 - Incident ReportDocument2 pagesHSE-PRO-03-INR 0.3 - Incident ReportSoufian BahmadNo ratings yet

- Work at Height PermitDocument2 pagesWork at Height PermitVenkadesh Periathambi67% (3)

- Jha 1Document3 pagesJha 1Firas HamanNo ratings yet

- Piling Works, Pile Head Cutting and Trimming at Pipe BridgeDocument28 pagesPiling Works, Pile Head Cutting and Trimming at Pipe BridgeAlif Shahril100% (1)

- JSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsDocument8 pagesJSP For SS 9013 No. JSP#04 Cutting and Bending of Steel Reinforcement BarsAbdul Rasheed Mangrio100% (1)

- JSA For Metering Panel Installation at SS 40 CO2 Recovery PlantDocument11 pagesJSA For Metering Panel Installation at SS 40 CO2 Recovery PlantHabib ur rahmanNo ratings yet

- SWP, OFFICE BUILDING - Copy With Pages RemovedDocument45 pagesSWP, OFFICE BUILDING - Copy With Pages Removedsambit sarat satpathyNo ratings yet

- PTW - AG&P Main (Weekly)Document10 pagesPTW - AG&P Main (Weekly)Caleb del MundoNo ratings yet

- Permit of WorkDocument24 pagesPermit of WorkSantanu SharmaNo ratings yet

- Cme Iraq CF Oi 5 1 Cold Work PermitDocument1 pageCme Iraq CF Oi 5 1 Cold Work Permitmurtadanajem1999No ratings yet

- One Punggol - General Work Permit FormDocument3 pagesOne Punggol - General Work Permit FormSelvamNo ratings yet

- Night and Holiday Work PermitDocument1 pageNight and Holiday Work PermitWaqas IslamNo ratings yet

- MASTER - Incident ReportDocument6 pagesMASTER - Incident ReportMiracle DavidNo ratings yet

- Taws Recieving SotreDocument5 pagesTaws Recieving SotresahilNo ratings yet

- Pre-Job Hazard AnalysisDocument3 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- HSE Daily ReportDocument1 pageHSE Daily Reportmohamed ElsayedNo ratings yet

- Daily Safety Report: Reported By, Acknowledged ByDocument1 pageDaily Safety Report: Reported By, Acknowledged ByAswar SaniNo ratings yet

- HSE Daily Report 258963Document1 pageHSE Daily Report 258963Mohammed Amer PashaNo ratings yet

- HSE Daily ReportDocument1 pageHSE Daily ReportYassineNo ratings yet

- JSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Document23 pagesJSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Shaikh Abu bakarNo ratings yet

- Pre-Job Hazard AnalysisDocument4 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- 52e40 PDF enDocument5 pages52e40 PDF enLynne Ivy IllagaNo ratings yet

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- Tele HandlerDocument30 pagesTele HandlerArturNo ratings yet

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedNo ratings yet

- JSP For SS No. 4 Commissioning of High Voltage EquipmentDocument21 pagesJSP For SS No. 4 Commissioning of High Voltage EquipmentmohammedtofiqahmedNo ratings yet

- JSA-578 Underground Duct CleaningDocument9 pagesJSA-578 Underground Duct CleaningHabib ur rahmanNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- Excavaten Work PermitDocument1 pageExcavaten Work Permitasem sawalmehNo ratings yet

- Mohamad FadliDocument6 pagesMohamad Fadlishamierrul shahliNo ratings yet

- CMEC-HSE-PR-15-F-009 Permit To Work Form - CCEED-MMC Tracker Installation Work BlanckDocument1 pageCMEC-HSE-PR-15-F-009 Permit To Work Form - CCEED-MMC Tracker Installation Work BlanckaNo ratings yet

- Confined Space Entry Plan: Plan Review Approval Team: # Position Name Badge Number SignatureDocument3 pagesConfined Space Entry Plan: Plan Review Approval Team: # Position Name Badge Number SignaturetusharDJNo ratings yet

- RAMS For Confined Space Activities in Underground Water TankDocument13 pagesRAMS For Confined Space Activities in Underground Water TankEm NiaxNo ratings yet

- DESCON HSE Report FormatDocument66 pagesDESCON HSE Report FormatMustafa Ricky Pramana Se100% (1)

- JSA For HVAC WorkDocument8 pagesJSA For HVAC Worksathakathulla100% (3)

- 334 - Manual Handling of GRP PipingDocument7 pages334 - Manual Handling of GRP Pipingcontrax8No ratings yet

- Tra ExcavationDocument7 pagesTra ExcavationBilal50% (2)

- RA For MPI TestDocument3 pagesRA For MPI TestLu Min Han100% (1)

- BBS Form - Rev 1Document2 pagesBBS Form - Rev 1Riccardo GastaldoNo ratings yet

- DOD-MST-EQ-025 (Rev-C) RE-COATING OF FLARE DERRICKDocument5 pagesDOD-MST-EQ-025 (Rev-C) RE-COATING OF FLARE DERRICKMohammedNo ratings yet

- Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)Document6 pagesSafe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)tamoor sarwarNo ratings yet

- JSP For SS No. 8 Installation of EOT CraneDocument28 pagesJSP For SS No. 8 Installation of EOT CraneJaafar LagayanNo ratings yet

- Tra 002Document6 pagesTra 002Bilal0% (1)

- JSA - Undergound MappingDocument2 pagesJSA - Undergound Mappingshamierrul shahliNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- PTW - AG&P Delivery and Laydown (Weekly)Document1 pagePTW - AG&P Delivery and Laydown (Weekly)Caleb del MundoNo ratings yet

- BSH Safe Work Method StatementDocument9 pagesBSH Safe Work Method StatementHariprakash karuppannanNo ratings yet

- JSP For SS No. 7 PACU InstallationDocument13 pagesJSP For SS No. 7 PACU InstallationJaafar LagayanNo ratings yet

- PCD-OSH-SF-35 PTW For Confine SpaceDocument2 pagesPCD-OSH-SF-35 PTW For Confine Spacerizal azizanNo ratings yet

- JSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaDocument11 pagesJSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- Drp001-Ouf-Inc-Gmd-Z-000-060-O2. C4Document16 pagesDrp001-Ouf-Inc-Gmd-Z-000-060-O2. C4rodman823No ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- Jsa Install Distribution PipeDocument8 pagesJsa Install Distribution PipeMuhammad YusufNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- HSE Annual Report 2011 PDFDocument10 pagesHSE Annual Report 2011 PDFHasanuddin HAMIDNo ratings yet

- 1,10-Phenanthroline (2007 v3.0)Document5 pages1,10-Phenanthroline (2007 v3.0)tpr314No ratings yet

- 2014 02 28 Item 2 AERB IBA Radiation Safety AspectsDocument27 pages2014 02 28 Item 2 AERB IBA Radiation Safety AspectsSUBHANo ratings yet

- Sample Question & AnswersDocument9 pagesSample Question & Answersabhi_mohit2005No ratings yet

- HEPS2011 Reiman Pietikainen Patient Safety Culture SurveyDocument4 pagesHEPS2011 Reiman Pietikainen Patient Safety Culture SurveyTeemu ReimanNo ratings yet

- Abb Substation Instr.Document8 pagesAbb Substation Instr.Ramesh RakhadeNo ratings yet

- SFS RS BHS FP 04Document46 pagesSFS RS BHS FP 04mohammad arshadNo ratings yet

- Personal Protective Equipment (PPE)Document52 pagesPersonal Protective Equipment (PPE)Yeyeri SantosNo ratings yet

- 1 PBDocument11 pages1 PBAkun M naibahoNo ratings yet

- OM Part A - Rev - 6Document812 pagesOM Part A - Rev - 6Abdou Touj100% (9)

- 4BS0801 001 en Applikationshandbuch MarineDocument52 pages4BS0801 001 en Applikationshandbuch MarineTraian SerbanNo ratings yet

- O - (TOC) - SOP - 017 - R0 - SOP For For Static Equipment InstallationDocument8 pagesO - (TOC) - SOP - 017 - R0 - SOP For For Static Equipment InstallationMDhana SekarNo ratings yet

- Epc in NutshellDocument83 pagesEpc in NutshellBilal A Barbhuiya100% (2)

- Wiring Diagram Manual Split System Air Conditioner R4A3, WCA3 4Document3 pagesWiring Diagram Manual Split System Air Conditioner R4A3, WCA3 4andyNo ratings yet

- Astm d4101 - IhsDocument1 pageAstm d4101 - IhsAndres Fitria FarrelNo ratings yet

- Operating Instructions: Vibrating Level Switch With Tube Extension For Granuled Bulk SolidsDocument36 pagesOperating Instructions: Vibrating Level Switch With Tube Extension For Granuled Bulk Solids..........................No ratings yet

- Permatex 52 HDSDocument10 pagesPermatex 52 HDSItzel L CalderónNo ratings yet

- Chlorpheniramine (Maleate)Document5 pagesChlorpheniramine (Maleate)Eka KusyantoNo ratings yet

- Delhi Factories Rule 1950 PDFDocument84 pagesDelhi Factories Rule 1950 PDFAkhilesh Kumar SinghNo ratings yet

- Disaster Management in Turkey: A Spatial ApproachDocument8 pagesDisaster Management in Turkey: A Spatial ApproachProf. dr Vladimir M. Cvetković, Fakultet bezbednosti, Univerzitet u BeograduNo ratings yet

- RA78 - Installation of Fan Coil UnitsDocument5 pagesRA78 - Installation of Fan Coil Unitsachusanachu100% (1)

- FAGOR Hardware ManualDocument384 pagesFAGOR Hardware Manual이태규No ratings yet

- Santos, Kim Franz F. HRST-32Document4 pagesSantos, Kim Franz F. HRST-32Kiem SantosNo ratings yet

- 62R-11 - Risk Assessment - Identification and Qualitative AnalysisDocument13 pages62R-11 - Risk Assessment - Identification and Qualitative AnalysisPratik ChouguleNo ratings yet

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (2)

- Principles of Personal Development in AdDocument6 pagesPrinciples of Personal Development in AdAnca ElenaNo ratings yet

- TWM50FBM User ManualDocument28 pagesTWM50FBM User ManualhamorcomNo ratings yet

- DRRR - Week 5-8Document48 pagesDRRR - Week 5-8Willy Albert BrazaNo ratings yet

- SITXFSA002 Assessment B Short Answer V1-0Document21 pagesSITXFSA002 Assessment B Short Answer V1-0Niomi Golrai52% (21)