Professional Documents

Culture Documents

JSP For SS No. 1 Battery Charging and Testing

Uploaded by

mohammedtofiqahmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSP For SS No. 1 Battery Charging and Testing

Uploaded by

mohammedtofiqahmedCopyright:

Available Formats

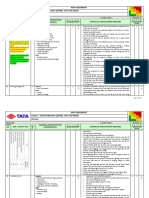

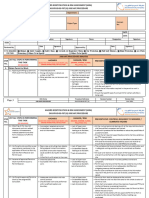

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

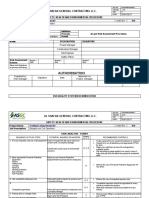

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

Operating Area: Department:

Project Name:

Contract

Contractor Name: Project Type:

No.:

JOB/TASK TYPE: Battery charging and testing DATE:

JOB SAFETY PROCEDURE

COMPILED BY: DATE:

N0:

Name Designation Signature Name Designation Signature

HIRA

TEAM

Date Signature Date Signature

Reviewed by: Approved by:

: : : :

P.P.E. REQUIRED ☐ Helmet, ☐ Safety Goggles, ☐ Safety Shoes, ☐ Coverall, ☐ Respiratory Musk, ☐ Ear Protection, ☐ Full body Harness, ☐ Hand Protection, ☐ Arc Flash Protection,

FOR TASK: ☐ Others To be Specify: __________________________, ☐ Others To be Specify: __________________________

JOB SAFE PROCEDURE ANALYSIS

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

1. Obtain Permit to Work

1.1. Applying and filling-up permit to Untrained personnel. Accident resulting serious Work permit receiver and issuer must be identified and with an

Work as per the required activity. Wrong information or details are injury or death to worker appointment letter.

written in the PTW. Significant property and Permit Issuer and Receiver must be qualified, trained and

Other activities may not be cover with appurtenances damage competent.

the PTW. Loss of production Work permit system shall be properly implemented as per the SEC

Significant cost due to 5 Star Safety standard and work permit procedure.

damages Ensure that all activities and the safety precautions are covered

Governmental violation with the work permit.

Environmental complaint Ensure that all information required in the permit to work is

complete.

Ensure that specific type of work permit for certain activities is

being used.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 1 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

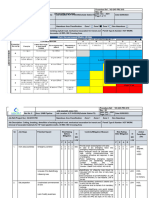

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

1.2. Attaching all the required Incompetent assigned personnel. Lack of Supervision All the involved personnel dealing with all the required documents

documents such as a related Unidentified or incomplete hazards Unidentified Hazards shall be qualified, competent and trained.

checklist, risk assessment, and risk information. leading to an Accident. A safe work practice shall be identified to reduce the possibilities of

method statement and other Lack of productivity accident/incident.

forms necessary to fulfill the Ensure that all required supporting documents shall be available as

request. per PTW requirements.

All the required related documents as identified to be attached in

PTW shall be reviewed and evaluated by issuer and receiver to

ensure that all hazard and risk is identified and complete.

1.3. Verifying the site condition as per Open areas, protruding sharp objects, Lack of Supervision The workplace shall be pre-checked, free from any obstruction and

requirements mentioned in the falling objects limited illuminations Unidentified Hazards in safe good working condition prior to a combined verification

application of Permit to Work by and other construction hazards may leading to an Accident. visit.

both the Permit Receiver and cause accidents during the Lack of productivity All Issuer and receiver must be aware of the hazard present in the

Permit Issuer. verification visit. area and must be familiar with the ingress and egress of the project

Unfamiliarity with access to the areas. site.

1.4. Issuance of approved Permit to Untrained personnel. Lack of Supervision Permit Issuer and Receiver must be qualified, trained and

Work from Permit Issuer to Incomplete information on Permit to Unidentified Hazards competent.

Permit Receiver. work. leading to an Accident. Permit Issuer shall ensure that the site was visited to ensure that

Lack of productivity workplace hazards and risk are adequately identified and mitigating

measure shall be established.

Permit Issuer and Receiver shall ensure that all the information

required in the permit to work are reviewed, completed and

signed.

1.5. Verifying the approved Permit to Inadequate coordination and area Lack of Supervision Permit to Work shall be displayed at the worksite

Work by the assigned SEC control protocol. Unidentified Hazards Permit Receiver shall not leave the area for the whole duration of

Consultant. Unauthorized work to be performed leading to an Accident. permit to work.

within a defined location and Lack of productivity Work shall not proceed without the presence of approved PTW and

boundary. the Permit Receiver overseeing the activity.

Permit Receiver shall account all workers under his Permit to Work

before the start of work.

Work shall not be started until duly approved Permit to Work is

available at the site and that Safety Toolbox meeting was

conducted.

Ensure all the information required in the permit to work shall be

OHS Forms Procedure Reference Revision Number Revision Date

Page |2 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

completed, signed and updated by the authorized personnel.

2. Mobilization of manpower, tools, equipment, and materials inside Battery Room

2.1. Perform physical inventory for all Unsecured tools, equipment & Materials, tools, and equipment to be used shall be checked by a

the tools, materials, equipment materials qualified, trained and competent person.

Accident results in physical

and manpower to be used. Untrained personnel Materials, tools, and equipment should be maintained in good

injuries.

working condition.

Property damage.

Closed supervision by the Engineer, Supervisor or Foreman must be

observed.

The use of appropriate equipment.

2.2. Lifting and loading of tools and Unsecured tools, equipment & Lifting accessories should be checked and inspected.

materials onto trailer bed either materials Vehicular accident. Equipment operator must be certified.

manually and/or mechanical Unstable load Accident resulting Injury to Equipment shall have a valid third-party inspection.

handling. Defective sling belt personnel. Daily equipment checklist should be conducted and completed by

Property damage of the certified operator.

adjacent structure or Materials should be secured properly.

appurtenances. Provision of certified flagman/banks man.

Close supervision is required.

2.3. Transporting/shifting of the load Over speeding Accident resulting injuries

from the laydown area to site Uneven surfaces to the operator or driver

activity (substation). Unsecured tools, equipment & once struck the structure Observe the speed limit in the area.

materials Significant property Mobilization of materials on normal weather condition.

Unsafe driving damage to adjacent The permanent lighting system should be working.

Adverse weather condition structure First aid kit should be available with adequate quantity of

Injuries to other personnel medicines.

involved to the activity Driver must have a valid SAG driving license.

Damage to property by the

equipment.

2.4. Unloading/carrying of loads going Unsecured tools, equipment & Equipment failure during Materials should be secured properly.

inside the substation. materials operation Only qualified and trained personnel on the job.

Unstable and uneven ground surface Accident resulting injury or Provision of certified flagman/banks man.

Fall or drop death to personnel Lifting accessories should be checked and inspected.

Sling failure Significant property Equipment operator must be certified.

damage Equipment shall have a valid third-party inspection.

Vehicular accident or Closed supervision by the Engineer, Supervisor or Foreman must be

OHS Forms Procedure Reference Revision Number Revision Date

Page |3 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

observed.

collision The use of appropriate equipment.

Provision of certified flagman/banks man.

3. Setting and preparation of battery room for desired temperature, ventilation, exhaust system

3.1. Selecting the appropriate and Accumulation of flammable Fire Incident. Provide hydrogen sensor and ensure it is operable.

adequate exhaust ventilation concentration of Hydrogen gas Lack of Oxygen The room should always keep clean and dry.

system that provides natural or Drowsiness Ensure to maintain required and sufficient room temperature,

mechanical dilution sufficient to lighting, ventilation, and exhaust system as per manufacturers

limit the accumulation of design.

hydrogen gas in air at the Warning and regulatory signage should be installed inside and

charging site to levels below the outside the battery room.

lower explosive limit of 4.1. Only non-sparking tools must be used inside the battery room.

Housekeeping like electrical cables, materials on the floor, the

material arrangement should be observed.

Only anti-static clothing is allowed inside the battery room.

Closed supervision by the Engineer, Supervisor or Foreman must be

observed.

3.2. Check and inspect equipment Equipment failure (alarm and sensor Poor housekeeping may Pre checks should be conducted (battery charger installation,

condition such as performance monitoring system is not working) cause injury of a person connections & torque requirement, alarm system, first aid box,

indicator instruments, such as Accumulation of hazardous/toxic gas due to slip trip and fall emergency eyewash, sensors, and monitoring system).

manometers on hood ducts, Damage to property Materials should be kept away from batteries cell surfaces.

should be installed so that the Fire and explosion, Indicators instruments must have a valid third-party inspection.

employer and employees can Accident resulting injury of First aid kit should be available with adequate quantity of

determine and record, if a person. medicines.

necessary, the performance rate Appropriate personal protective equipment should be observed.

of the system. Closed supervision by the Engineer, Supervisor or Foreman must be

observed.

3.3. Verify if it has been assembled Poor housekeeping of tools and Proper manual handling if Installation of equipment should follow as per manufacturers

correctly (e.g., fan rotation) and materials not observe could cause design.

according to agreed drawings Equipment failure injury to a person The adequate number of fire suppression equipment should be

and plans. Sharp edges if not installed in a strategic location.

identified and isolated Appropriate personal protective equipment should be observed.

causes skin laceration and Closed supervision by the Engineer, Supervisor or Foreman must be

cuts observed.

OHS Forms Procedure Reference Revision Number Revision Date

Page |4 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

Poor supervision by

engineer or foreman could

cause accidents.

4. Charging the battery

4.1. Before switching on the charger Incompetent worker Using an inappropriate Workers performing the battery charging shall be competent in

or controller, ensure that Poor supervision tool may cause short doing the job.

shipping vent plugs are removed, Inappropriate tools circuit, electric shock or Worker conducting the test and measurement shall wear PPE as

and flame arrestors are installed electrocution to a person required by the manufacturer with arc flash rated clothing.

and damage to property Only non-sparking tools must be used inside the battery room.

Inhalation of fumes causes Any source of naked flames and sparks should be prohibited,

dizziness, irritation of prevented inside the battery room.

throat, passage way,

chronic disease or fatality

Equipment failure will

result to fire and

explosion.

4.2. Using external constant voltage Overcharging Electrocution. Workers performing the battery charging shall be competent in

charger, charge at a constant Equipment failure Fire Incident. doing the job.

voltage of 2.40 VPC at 77°F, Asset loss. Regular document review and verification should be done.

corrected for temperature, for a SEC required full supervision by the Commissioning Engineer at all

minimum of 48hrs. Current times while activity is ongoing.

should be limited to 0.14C. Interval battery test and measurement shall be done as per the

manufacturer’s recommendation.

Check all wiring and connection of battery charger and make sure

all are intact and properly secured.

Special personal protective equipment must be observed like anti-

static clothing, rubber gloves, respiratory equipment, clear goggles

and etc.

Ensure no power interruption during the whole operation.

Supervising Engineer and Foreman shall ensure that workers

performing the job are competent and certified by the

manufacturer.

Ensure to maintain required and sufficient room temperature,

lighting, ventilation, and exhaust system as per manufacturers

OHS Forms Procedure Reference Revision Number Revision Date

Page |5 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

design.

Closed supervision by the commissioning engineer, supervisor or

foreman must be observed at all time while charging is ongoing.

4.3. End-of-charge is when all cell Incompetent worker Poor housekeeping may Workers involve shall be trained by the battery manufacturer or

voltages and electrolyte specific Equipment failure cause injury of a person vendor and certified to conduct charging and discharging.

gravities (corrected to 25°C) Accumulation of hazardous/toxic gas due to slip trip and fall Workers performing the battery charging shall be competent in

cease to rise for three Damage to property doing the job.

consecutive hourly readings. Fire and explosion, Regular document review and verification should be done.

Continue charging until the Accident resulting injury of Supervising Engineer and Foreman shall ensure that workers

specific gravity of electrolyte for a person. performing the job are competent and certified by the

all cells rise to nominal specific manufacturer.

gravity at maximum level. Add SEC required full supervision by the Commissioning Engineer at all

fluid if cells did not reach the times while activity is ongoing.

maximum level. Allow an All equipment should have an emergency stop button.

additional 6 hours of charge for First aid kit should be available with adequate quantity of

stirring of the electrolyte. medicines.

Limit the duration of stay of personnel inside the battery room.

Ensure fire suppression equipment is working and readily available

in a strategic location at all time.

Ensure to maintain required and sufficient room temperature,

lighting, ventilation, and exhaust system as per manufacturers

design.

Frequent rotation of workers.

Battery charging shall not be allowed without the presence and

supervision of commissioning engineer.

5. Battery testing

5.1. Perform visual inspection and Untrained personnel Using inappropriate tools Only certified and competent personnel will engage in the job.

looks for cracks, leaks, and could cause short circuit Check visually the physical appearance of the battery case for any

corrosion. and equipment failure signs of bulging, spillage before allowing anyone to touch or open.

Wearing inadequate PPE Close supervision by Engineer or Foreman should be observed.

may cause physical injuries

Mobilizing untrained

personnel could cause

accidents

OHS Forms Procedure Reference Revision Number Revision Date

Page |6 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

5.2. Verify that the battery has had a Untrained personnel Using inappropriate tools Only certified and competent personnel will engage in the job.

high-rate charge completed Inappropriate tools could cause short circuit Regular training should be given to personnel.

more than 1 day and less than 30 and equipment failure Test the battery as per the manufacturer’s recommendation.

days before the start of the test. Wearing inadequate PPE Close supervision by Engineer or Foreman should be observed.

may cause physical injuries

Mobilizing untrained

personnel could cause

accidents

5.3. Perform the capacity testing by Inappropriate tools Using inappropriate tools Only certified and competent personnel will engage in the job.

disconnect the charging source, Inadequate PPE could cause short circuit Test the battery as per the manufacturer’s recommendation.

connect the load to the battery, and equipment failure Observe the “use the right tool” rule.

start the timing, and continue to Wearing inadequate PPE Check for air concentration inside the battery room before allowing

maintain the selected discharge may cause physical injuries personnel to enter.

rate. Provide an adequate and safe standing platform to reach the

battery for specific gravity and another testing to be conducted.

Close supervision by Engineer or Foreman should be observed.

5.4. Read and record the float voltage Untrained personnel Mobilizing untrained Only certified and competent personnel will engage in the job.

of each cell just before and at Inappropriate tools personnel could cause Use approves and appropriate testing equipment.

the completion of the test. accidents Check for air concentration inside the battery room before allowing

Using inappropriate tools personnel to enter.

could cause short circuit Appropriate personal protective equipment should be observed

and equipment failure like coverall, hand gloves, eye protection, and etc.

Close supervision by Engineer or Foreman should be observed.

5.5. Read and record the Untrained personnel Using inappropriate tools Only certified and competent personnel will engage in the job.

temperature of the battery Inappropriate tools could cause short circuit Check for air concentration inside the battery room before allowing

electrolyte to determine an Poor supervision and equipment failure personnel to enter.

average temperature (every Wearing inadequate PPE Appropriate personal protective equipment should be observed

tenth cell is suggested). may cause physical like coverall, hand gloves, eye protection, and etc.

injuries. Close supervision by Engineer or Foreman should be observed.

Mobilizing untrained

personnel could cause

accidents

6. Mobilization, setting and preparation of load bank / disconnecting, demobilization of testing equipment load bank

6.1. Using the right battery charger is Inappropriate tools Proper manual handling if The only trained worker should do the job.

OHS Forms Procedure Reference Revision Number Revision Date

Page |7 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

the first step in protecting and Poor supervision / untrained not observe could cause Observe the “use the right tool” rule.

maintaining your expensive deep personnel injury to a person Observe proper posture and natural working position.

cycle battery bank. Sharp edges if not Appropriate personal protective equipment should be observed

identified and isolated like coverall, hand gloves, eye protection, and etc.

causes skin laceration and Closed supervision by the Engineer, Supervisor or Foreman must be

cuts observed.

Poor supervision by

engineer or foreman could

cause accidents

6.2. The battery charger should be Poor supervision / untrained Poor supervision by Follow the battery as per the manufacturer’s recommendation.

switched off or disconnected personnel engineer or foreman could Work should be done in a timely manner.

from its power supply before cause accidents Appropriate personal protective equipment should be observed

making a connection with like coverall, hand gloves, eye protection, and etc.

battery cables for battery Observe proper posture and natural working position.

charging. Closed supervision by the Engineer, Supervisor or Foreman must be

observed.

6.3. Check that the polarities of Poor supervision / untrained Proper manual handling if The only trained worker should do the job.

terminals of the battery and the personnel not observe could cause Work should be done in a timely manner.

battery charger are correct Inappropriate tools injury to a person Observe the “use the right tool” rule.

before connecting the two for Sharp edges if not Appropriate personal protective equipment should be observed

charging. identified and isolated like coverall, hand gloves, eye protection, and etc.

causes skin laceration and Closed supervision by the Engineer, Supervisor or Foreman must be

cuts. observed.

Poor supervision by

engineer or foreman could

cause accidents

6.4. Disconnect battery cables after Poor supervision / untrained Poor supervision by Only a trained worker should do the job.

battery charging. personnel engineer or foreman Appropriate personal protective equipment should be observed

could cause accidents. like coverall, hand gloves, eye protection, and etc.

Closed supervision by the Engineer, Supervisor or Foreman must be

observed.

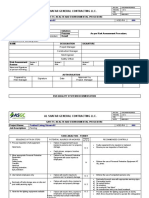

7. Housekeeping (clearing the work area)

7.1. Prior to housekeep, wearing Inadequate PPE Wearing an inadequate Install appropriate notices and signage.

personal protective PPE may cause skin Special personal protective equipment must be observed like

OHS Forms Procedure Reference Revision Number Revision Date

Page |8 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

equipment such as safety irritation coverall clothing, rubber gloves, respiratory equipment, clear

gloves and mask must be goggles and etc.

fulfilled by the personnel Close supervision by the Engineer, Supervisor or Foreman

involved. must observe.

7.2. Removal of tools, equipment, Presence of sharp edges Tools and materials if not Appropriate personal protective equipment should be observed

and other excesses/ unused Poor supervision / untrained properly arranged could like coverall, hand gloves, eye protection, and etc.

materials manually. personnel cause slip trip and fall Tools and other materials should be properly arranged/ removed

which results to injury of a inside the battery room if not in use.

person. First aid kit should be available with adequate quantity of

medicines.

A spill kit should be available in the area.

Close supervision by the Engineer, Supervisor or Foreman must

observe.

7.3. Disposing of waste to dedicated Tools and materials scattered on the Waste materials if not Proper disposal and segregation of waste / used materials.

waste bin/container. floor properly segregated and Provision of an appropriate waste container in the area.

disposed could cause Close supervision by the Engineer, Supervisor or Foreman must

environmental observe.

contamination

7.4. Sweeping and cleaning the area. Inadequate PPE Tools and materials if not Appropriate personal protective equipment should be observed

Presence of waste material properly arranged could like coverall, hand gloves, eye protection, and etc.

Inappropriate tools cause slip trip and fall Observe the “use the right tool” rule.

which results to injury of a Close supervision by the Engineer, Supervisor or Foreman must

person observe.

Wearing an inadequate

PPE may cause skin

irritation

Waste materials if not

properly segregated and

disposed could cause

environmental

contamination.

8. Closing of Permit to Work

OHS Forms Procedure Reference Revision Number Revision Date

Page |9 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

8.1. Returning of the Permit to Work

to Permit Issuer for closing.

8.2. Verifying the site condition as per Poor housekeeping Significant property and Permit Receiver shall ensure that housekeeping is done before,

requirements mentioned in the Undisposed waste materials appurtenances damage during and after the work.

closing of Permit to Work by Unaccounted workers Governmental violation All waste materials generated from the work shall be properly

both the Permit Issuer and Unsecured electrical equipment Environmental complaint disposed and shall not be left unattended at the worksite.

Permit Receiver. /energized equipment Loss of production Electrical equipment shall be properly secured, distribution board

Poor storage of chemical, flammable Accident resulting serious closed and padlocked

and combustible materials and etc. injury or death to worker All materials used at the site such as chemicals, flammable and

Unattended unsafe condition Significant cost due to combustible materials shall be stored at the designated storage at

Unfamiliarity with access to the areas damages. the end of each day

and the present construction hazard. Mobile equipment shall properly park on a designated equipment

laydown.

Ensure that all workers are accounted and there was no

incident/accident occurred which is not reported

All Issuer and receiver must be aware of the hazard present in the

area and must be familiar with the ingress and egress of the project

site.

8.3. Signing/clearing of the Permit to Inadequate communication Accident resulting serious Work permit issuer and receiver must be qualified, trained and

Work by the Permit Issuer upon Untrained personnel injury or death to worker competent.

verification of site condition and Proper communication should be observed.

satisfactorily comply with the

requirements mentioned.

8.4. Keeping and recording of the

completed and signed Permit to

Work by ensuring that the permit

to work register is duly

accomplished.

OHS Forms Procedure Reference Revision Number Revision Date

P a g e | 10 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

OHS Forms Procedure Reference Revision Number Revision Date

P a g e | 11 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

You might also like

- GIS Building Expansion and Reactor Installation HIRADocument8 pagesGIS Building Expansion and Reactor Installation HIRAAbdul Rasheed Mangrio100% (1)

- HSE-RA-052 Repairs of Concrete Imperfections - Rev 0Document11 pagesHSE-RA-052 Repairs of Concrete Imperfections - Rev 0عمروNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- Jsa-007 PaintingDocument14 pagesJsa-007 PaintingDamien Monize100% (1)

- Steel YardDocument6 pagesSteel YardAtiq ShaikhNo ratings yet

- 01 JSA - Material ShiftingDocument5 pages01 JSA - Material Shiftingsyed khaja misbhuddinNo ratings yet

- 2 ConectionDocument2 pages2 ConectionMohammed AdnanNo ratings yet

- Ceiling WorkDocument10 pagesCeiling WorkNisanth ThulasidasNo ratings yet

- Rare GusterDocument16 pagesRare Gusterreemy sarkNo ratings yet

- RAMS MAnual LiftingDocument12 pagesRAMS MAnual LiftingCarlos Immanuel100% (1)

- URC Insulation For Ducting (SWMS)Document9 pagesURC Insulation For Ducting (SWMS)syed khaja misbhuddinNo ratings yet

- Intelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2Document221 pagesIntelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2raymundwat11No ratings yet

- Managing mobile plant risksDocument2 pagesManaging mobile plant risksPravin GowardunNo ratings yet

- November December 2020 PDFDocument32 pagesNovember December 2020 PDFSamundeswaran SatiwasilanNo ratings yet

- SOP - Burisch 100Ltr Air CompressorDocument1 pageSOP - Burisch 100Ltr Air CompressorDaniel DerzaNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Document21 pagesOHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Jaafar LagayanNo ratings yet

- JHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10Document11 pagesJHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10M.k.BurhanNo ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- JSA - Baby Rollar and CompectorDocument5 pagesJSA - Baby Rollar and CompectorRaju100% (1)

- SWP Automotive Parts Washer - AS502Document2 pagesSWP Automotive Parts Washer - AS502Gowtham KishoreNo ratings yet

- OHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021Document7 pagesOHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021MuhammadAsimMuneerNo ratings yet

- Installation of Cable Trays and LaddersDocument13 pagesInstallation of Cable Trays and LaddersamalNo ratings yet

- Be Accountable For Your Safety at Work by Dr. Anuar SuunDocument27 pagesBe Accountable For Your Safety at Work by Dr. Anuar SuunakubestlahNo ratings yet

- Information Sheet: Crystalline Silica DustDocument2 pagesInformation Sheet: Crystalline Silica DustIoana UrsanNo ratings yet

- Expert Risk AssessmentDocument37 pagesExpert Risk Assessmentmohamed elhawaryNo ratings yet

- Hand Tools & Safety PracticesDocument4 pagesHand Tools & Safety PracticesRecel Ann RiveraNo ratings yet

- Risk assessment and register for electrical pole installationDocument8 pagesRisk assessment and register for electrical pole installationshaibaz chafekarNo ratings yet

- Risk Assessment - Steel Erection WorksDocument11 pagesRisk Assessment - Steel Erection Worksmahmoud nadaNo ratings yet

- 2 Hand and Power ToolsDocument34 pages2 Hand and Power ToolsEthyl Jean Gallarte100% (1)

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- Lawn Scarifier PDFDocument1 pageLawn Scarifier PDFcityofdarwingisNo ratings yet

- Night WorkDocument3 pagesNight Workkessery koivoguiNo ratings yet

- PPT: - Hse DepDocument9 pagesPPT: - Hse Depaimri_cochinNo ratings yet

- HSE-RA-044 Painting Rev 0Document14 pagesHSE-RA-044 Painting Rev 0عمروNo ratings yet

- Job Safety Analysis for Plumbing WorksDocument15 pagesJob Safety Analysis for Plumbing WorksLeo PascualNo ratings yet

- 4.1 Subcontractor Induction HandbookDocument37 pages4.1 Subcontractor Induction HandbookShamsul AffendiNo ratings yet

- Kumbirai Answer Madenyika UB10930SME17914: Safety EngineeringDocument11 pagesKumbirai Answer Madenyika UB10930SME17914: Safety EngineeringKumbirai Answer MadenyikaNo ratings yet

- Form E26-Inspection of Earthing Electrodes-SignDocument16 pagesForm E26-Inspection of Earthing Electrodes-SignFinanceAdmin FKSIENo ratings yet

- Assignment HiracsDocument29 pagesAssignment HiracsIntanNo ratings yet

- HSE-RA-013 Deshuttering - Rev 0.Document16 pagesHSE-RA-013 Deshuttering - Rev 0.عمروNo ratings yet

- Learning Objectives:: To Begin We Will Consider The OAC Model For Managing SafetyDocument13 pagesLearning Objectives:: To Begin We Will Consider The OAC Model For Managing SafetyRakesh KumarNo ratings yet

- Welding, Cutting and BrazingDocument66 pagesWelding, Cutting and BrazingSohail AnjumNo ratings yet

- Binder Spine Indexing SlipsDocument4 pagesBinder Spine Indexing Slipspundir_vineetNo ratings yet

- Concrete Work Formingand PouringDocument3 pagesConcrete Work Formingand PouringKimberly Juarez100% (1)

- JHA For BreakingDocument18 pagesJHA For BreakingRaheenNo ratings yet

- Individual Performance Commitment and Review Form (Ipcrf) : ObjectivesDocument16 pagesIndividual Performance Commitment and Review Form (Ipcrf) : ObjectivesMichael BandalesNo ratings yet

- HSE-RA-014 Using of Cutting Torch - Rev 0Document15 pagesHSE-RA-014 Using of Cutting Torch - Rev 0عمروNo ratings yet

- 3384 SWM Ergonomic Risk Factor Checklist1Document5 pages3384 SWM Ergonomic Risk Factor Checklist1Anonymous V2HS9gtFNo ratings yet

- Hazards and Risk Identification and ManagementDocument2 pagesHazards and Risk Identification and Managementsai ramNo ratings yet

- JHA For DrillingDocument10 pagesJHA For DrillingRaheenNo ratings yet

- Safe Usage of PPE Toolbox Talk Global EHS TBT 006Document4 pagesSafe Usage of PPE Toolbox Talk Global EHS TBT 006Global EHSNo ratings yet

- Overhead RAMS2Document5 pagesOverhead RAMS2Asad RazaNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- Sop Changing A Toner CartridgeDocument2 pagesSop Changing A Toner CartridgezaheerNo ratings yet

- Risk Assessment (INTERCOM)Document9 pagesRisk Assessment (INTERCOM)rocknNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- JSP For SS No. 4 Commissioning of High Voltage EquipmentDocument21 pagesJSP For SS No. 4 Commissioning of High Voltage EquipmentmohammedtofiqahmedNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- JSP For SS No. 5 Tower Crane InstallationDocument15 pagesJSP For SS No. 5 Tower Crane InstallationmohammedtofiqahmedNo ratings yet

- JSP For SS No. 3 Lifting of Heavy Equipment Using CraneDocument14 pagesJSP For SS No. 3 Lifting of Heavy Equipment Using CranemohammedtofiqahmedNo ratings yet

- TBT TopicsDocument30 pagesTBT TopicsmohammedtofiqahmedNo ratings yet

- Do's and Don't at WorkplaceDocument26 pagesDo's and Don't at WorkplacemohammedtofiqahmedNo ratings yet

- Oil Spill Response Plan Bo2 April 2018 RedactedDocument125 pagesOil Spill Response Plan Bo2 April 2018 RedactedHSE PULAI A100% (1)

- HSE Plan-1Document100 pagesHSE Plan-1mohammedtofiqahmedNo ratings yet

- Guide Specifications Symmetra 96 160kVADocument8 pagesGuide Specifications Symmetra 96 160kVAAugusto Francisco Diaz LaraNo ratings yet

- Datasheet BMV 712 Smart enDocument2 pagesDatasheet BMV 712 Smart entongaiNo ratings yet

- Accident Handling of Electrical Fire and China's Experience - 0602Document80 pagesAccident Handling of Electrical Fire and China's Experience - 0602Susi SusilowatiNo ratings yet

- SH5.0RT / SH6.0RT / SH8.0RT / SH10RT: User Manual 3-Phase Hybrid InverterDocument108 pagesSH5.0RT / SH6.0RT / SH8.0RT / SH10RT: User Manual 3-Phase Hybrid InverterQuang TuanNo ratings yet

- H-1004010002-01 3.2 Digital Radiography System Operation Manual - MobileSparklerDocument78 pagesH-1004010002-01 3.2 Digital Radiography System Operation Manual - MobileSparklerВладислав АлександровичNo ratings yet

- Chemistry 3Document7 pagesChemistry 3syed waseemNo ratings yet

- HS165 en ManualDocument22 pagesHS165 en ManualMatt DunnNo ratings yet

- Review: Carbonyl-Coordinating Polymers For High-Voltage Solid-State Lithium Batteries: Solid Polymer ElectrolytesDocument25 pagesReview: Carbonyl-Coordinating Polymers For High-Voltage Solid-State Lithium Batteries: Solid Polymer ElectrolytesA1234 AJEFNo ratings yet

- v580 v580c HMM enDocument114 pagesv580 v580c HMM enmoment of powerNo ratings yet

- Spectroquant Multy Operating Manual - 2014 - 08Document276 pagesSpectroquant Multy Operating Manual - 2014 - 08Sun lrNo ratings yet

- 3U-SE-G5.1 Pro - DeyeDocument4 pages3U-SE-G5.1 Pro - DeyeMtek Solar energyNo ratings yet

- Wind power hybrid system optimizationDocument3 pagesWind power hybrid system optimizationAhmetNo ratings yet

- Datasheet A HV 3U Battery BOS G V1.4Document4 pagesDatasheet A HV 3U Battery BOS G V1.4Alaa ENo ratings yet

- Section 4003 Electronic Instrument ClusterDocument30 pagesSection 4003 Electronic Instrument Clusterlungu mihaiNo ratings yet

- Manual: EnglishDocument84 pagesManual: Englishjameel babooramNo ratings yet

- Field Service Report Three Phase Ups: Products OfferingDocument4 pagesField Service Report Three Phase Ups: Products OfferingKarthick Rajan DNo ratings yet

- Report On Teamtronix India PVT LTDDocument64 pagesReport On Teamtronix India PVT LTDIn nuNo ratings yet

- Astm F-2490-05Document8 pagesAstm F-2490-05NAOMI AYELEN BECERRA MORALESNo ratings yet

- 10 to 200 kVA UPS specificationDocument17 pages10 to 200 kVA UPS specificationmulyonoNo ratings yet

- Galant CH 6 Chassis Electrical PDFDocument76 pagesGalant CH 6 Chassis Electrical PDFjustcheerfulNo ratings yet

- Caution: EG21 and EGS21 Series Electric Gage and Swichgage InstallationDocument2 pagesCaution: EG21 and EGS21 Series Electric Gage and Swichgage InstallationAndres CelyNo ratings yet

- Bharati Vidyapeeth Institute of Technology Question Bank: Unit Test-I (Shift:-I)Document14 pagesBharati Vidyapeeth Institute of Technology Question Bank: Unit Test-I (Shift:-I)Shr3yasNo ratings yet

- GUIDE T120H Fever Screening Thermal CamerasDocument4 pagesGUIDE T120H Fever Screening Thermal CamerasEVERNo ratings yet

- Manual CRT 6900 ENGDocument22 pagesManual CRT 6900 ENGstrijker13No ratings yet

- M1226e Peristaltic Pump Compact b19b PDFDocument12 pagesM1226e Peristaltic Pump Compact b19b PDFRenatoNo ratings yet

- Flex Li3 21 VAADocument1 pageFlex Li3 21 VAAAyman Al-YafeaiNo ratings yet

- NGenuity Criticare - 8100 CatálogoDocument2 pagesNGenuity Criticare - 8100 CatálogoClaudio Roberto da CostaNo ratings yet

- Manual Perkins 3012Document252 pagesManual Perkins 3012Alejandro Castagna100% (1)

- ROTORK IQTF Pub002-065-00 0318Document34 pagesROTORK IQTF Pub002-065-00 0318Arturo Treviño MedinaNo ratings yet

- 840d SL Internal CoolingDocument112 pages840d SL Internal Coolingopenid_6qpqEYklNo ratings yet