Professional Documents

Culture Documents

JSP For SS No. 3 Lifting of Heavy Equipment Using Crane

Uploaded by

mohammedtofiqahmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSP For SS No. 3 Lifting of Heavy Equipment Using Crane

Uploaded by

mohammedtofiqahmedCopyright:

Available Formats

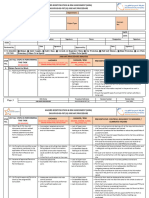

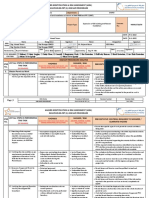

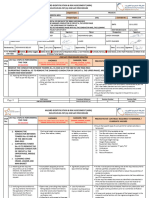

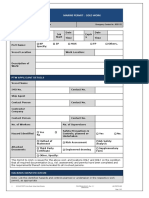

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

Operating Area: Department:

Project Name:

Contract

Contractor Name: Project Type:

No.:

JOB/TASK TYPE: Lifting of heavy equipment using crane DATE:

JOB SAFETY PROCEDURE

COMPILED BY: DATE:

N0:

Name Designation Signature Name Designation Signature

HIRA

TEAM

Date Signature Date Signature

Reviewed by: Approved by:

: : : :

P.P.E. REQUIRED ☐ Helmet, ☐ Safety Goggles, ☐ Safety Shoes, ☐ Coverall, ☐ Respiratory Musk, ☐ Ear Protection, ☐ Full body Harness, ☐ Hand Protection, ☐ Arc Flash Protection,

FOR TASK: ☐ Others To be Specify: __________________________, ☐ Others To be Specify: __________________________

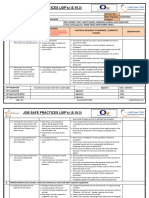

JOB SAFE PROCEDURE ANALYSIS

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

1. Obtain Permit to Work

1.1. Applying and filling-up permit to Untrained personnel. Accident resulting serious Work permit receiver and issuer must be identified and with an

Work as per the required activity. Wrong information or details are injury or death to worker appointment letter.

written in the PTW. Significant property and Permit Issuer and Receiver must be qualified, trained and

Other activities may not be cover with appurtenances damage competent.

the PTW. Loss of production Work permit system shall be properly implemented as per the SEC

Significant cost due to 5 Star Safety standard and work permit procedure.

damages Ensure that all activities and the safety precautions are covered

Governmental violation with the work permit.

Environmental complaint Ensure that all information required in the permit to work is

complete.

Ensure that specific type of work permit for certain activities is

being used.

OHS Forms Procedure Reference Revision Number Revision Date

Page | 1 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

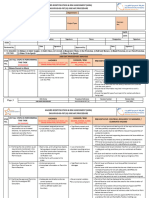

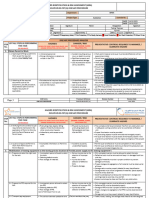

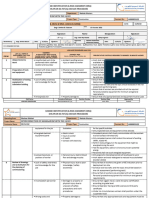

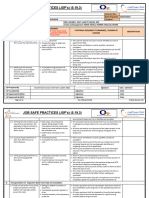

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

1.2. Attaching all the required Incompetent assigned personnel. Lack of Supervision All the involved personnel dealing with all the required documents

documents such as a related Unidentified or incomplete hazards Unidentified Hazards shall be qualified, competent and trained.

checklist, risk assessment, and risk information. leading to an Accident. A safe work practice shall be identified to reduce the possibilities of

method statement and other Lack of productivity accident/incident.

forms necessary to fulfill the Ensure that all required supporting documents shall be available as

request. per PTW requirements.

All the required related documents as identified to be attached in

PTW shall be reviewed and evaluated by issuer and receiver to

ensure that all hazard and risk is identified and complete.

1.3. Verifying the site condition as per Open areas, protruding sharp objects, Lack of Supervision The workplace shall be pre-checked, free from any obstruction and

requirements mentioned in the falling objects limited illuminations Unidentified Hazards in safe good working condition prior to a combined verification

application of Permit to Work by and other construction hazards may leading to an Accident. visit.

both the Permit Receiver and cause accidents during the verification Lack of productivity All Issuer and receiver must be aware of the hazard present in the

Permit Issuer. visit. area and must be familiar with the ingress and egress of the project

Unfamiliarity with access to the areas. site.

1.4. Issuance of approved Permit to Untrained personnel. Lack of Supervision Permit Issuer and Receiver must be qualified, trained and

Work from Permit Issuer to Incomplete information on Permit to Unidentified Hazards competent.

Permit Receiver. work. leading to an Accident. Permit Issuer shall ensure that the site was visited to ensure that

Lack of productivity workplace hazards and risk are adequately identified and

mitigating measure shall be established.

Permit Issuer and Receiver shall ensure that all the information

required in the permit to work are reviewed, completed and

signed.

1.5. Verifying the approved Permit to Inadequate coordination and area Lack of Supervision Permit to Work shall be displayed at the worksite

Work by the assigned SEC control protocol. Unidentified Hazards Permit Receiver shall not leave the area for the whole duration of

Consultant. Unauthorized work to be performed leading to an Accident. permit to work.

within a defined location and Lack of productivity Work shall not proceed without the presence of approved PTW and

boundary. the Permit Receiver overseeing the activity.

Permit Receiver shall account all workers under his Permit to Work

before the start of work.

Work shall not be started until duly approved Permit to Work is

available at the site and that Safety Toolbox meeting was

conducted.

Ensure all the information required in the permit to work shall be

OHS Forms Procedure Reference Revision Number Revision Date

Page |2 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

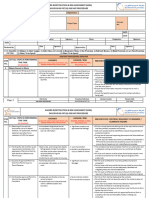

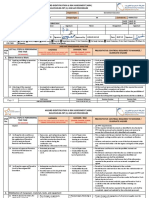

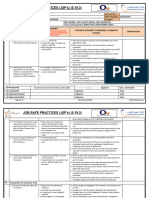

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

completed, signed and updated by the authorized personnel.

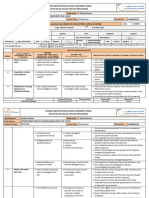

2. Site mobilization, selection, and preparation of tools, lifting gears and necessary accessories to start heavy equipment lifting, operator and driver

2.1 Crane to position and set up near Unfamiliar to the construction site. Slip and trip that can cause All workers/personnel and visitors must attend the required safety

the work area. Dilapidated equipment. sprain and strain induction before allowing to work on the site.

Damage or defective condition of the Getting injured from All workers/personnel and visitors must sign the attendance

equipment. protruding object. records and acceptance for a new employee on the job orientation.

Incompetent equipment operator or Struck-by, hit into or Provision of pedestrian access, signage, and building/structure

driver. injured by moving vehicle / identification.

Unauthorized entry of the equipment equipment. Awareness/training for all operator and driver.

to the site. Property damage, fatality Heavy equipment shall not be used if found any defects or damage

or injuries during the that might affect its safe operation.

operation of the Repair of heavy equipment shall not be done on the site. It must be

equipment. brought to the designated workshop and only certified mechanic

Fire due to leaking shall make repair of the equipment.

hydraulic oil system Ensure that there are no leaking hydraulic oil system or signs of

Accident resulting serious leaks and oil contamination.

injury to personnel Select and mobilize only good condition equipment.

Equipment certification and registration must be secured and

available.

Operator and driver must have certification and license

Implementation of Log-in and Log-out from the security post.

Equipment/vehicle insurance.

2.2 Trailer carrying large equipment Struck by moving equipment and Accident resulting injury to Trailer driver must have certification and SAG license

and materials to a position near vehicle. personnel Equipment certification and registration must be secured and

the crane. Area congestion. Vehicular accident available.

Trailer blind spot. Property damage to Establish equipment access and shall be free from any obstruction.

Incompetent equipment driver. equipment or materials Designate parking area.

Designate a location for unloading of materials.

Designate spotter and flagman to guide all equipment and

personnel movement.

2.3 Install barricade around the trailer Struck by moving equipment and Accident resulting injury to Barricade the working area around the trailer and crane to prevent

and working radius of the crane. vehicle. personnel unnecessary workers to enter the area

Area congestion. Vehicular accident Safety signage shall be posted to communicate the hazards and

Property damage to activity.

OHS Forms Procedure Reference Revision Number Revision Date

Page |3 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

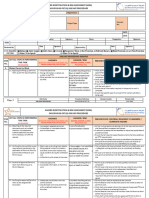

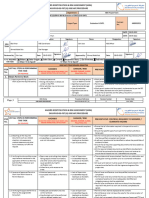

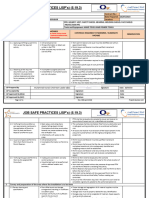

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

equipment or materials

2.4 Unbox and remove binder from Poor access and egress. Physical Injury from poor Use an appropriate ladder for the job.

the trailer and unbox the Inappropriate or defective tools. safety awareness Only competent person to conduct an inspection for the ladder

equipment. Physical injury from prior to use.

damaged/ handmade tools Defective tools ladder must not be used, marked and remove from

Muscular injuries (back service.

pain, strain, fractures) Fabricated or homemade ladder are prohibited.

Damaged PPE resulting Close supervision required/ respective foreman & supervisor shall

body injuries be present on site.

Physical injury from slip,

trips & fall

Eye injury due to poor

heavy

Heat Stress (stroke, cramps,

skin rashes etc.)

2.5 Install lifting gears on the Fall from the equipment during the Property damage, fatality Only competent riggers shall be assigned for rigging & lifting job.

equipment. installation of the slings and shackles or injuries during the Valid Third-party training is a must.

from equipment. operation of the When more 1.8 meters high, rigger must wear a full-body harness

Pinch/crushing points resulting in a equipment. with double shock-absorbing lanyards.

hand injury. Muscular injuries (back Prove proper access ladder to the equipment.

pain, strain, fractures). Ensure the ladder is free of obstruction.

Keep hands away from pinch & crush points.

Use leather gloves during the lifting activity.

2.6 Pre-lift the equipment to Equipment failure/ defective lifting Slip and trip that can cause Only trained competent riggers & certified operators shall be

determine the center of gravity. tools and tackles. sprain and strain assigned for rigging & lifting job with valid Third-party training.

Incorrect lifting procedures Getting injured from Crane operator with valid Saudi driving license and third-party

2.7 Lift the material on the desired Unorganized materials and access. protruding object. training.

drop off location. Incompetent personnel. Struck-by, hit into or Ensure lifting equipment, crane, is in safe operating conditions.

injured by moving vehicle / Crane load charts are available, all systems are functional and

equipment. Third-party certificates must be valid.

Property damage, fatality Safety inspection checklist shall be filled out prior to crane usage.

or injuries during the Conduct inspection lifting tools/tackles prior to use to ensure safe

operation of the operation.

equipment. Provide color coding on the inspected and safe tools.

OHS Forms Procedure Reference Revision Number Revision Date

Page |4 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

Fire due to leaking Presence of personnel below the load prohibited.

hydraulic oil system Any deficiency and defects must be reported to concerned

Accident resulting serious supervisors for their immediate action and the job will suspend

injury to personnel. until the problem was resolved.

Fall and topple of crane Used of fabricated or homemade tools are prohibited.

Preventive maintenance shall be strictly monitored and adhered as

per manufacturer's recommendation.

All lifting equipment and tools shall be provided with identification

and must be recorded.

Housekeeping shall be done before, during and after the job.

All material location and storage shall be barricaded and provided

with adequate signage.

2.8 Trailer to demobilize from the Struck by moving equipment and Accident resulting injury to Trailer driver must have certification and SAG license.

area. vehicle. personnel Equipment certification and registration must be secured and

Area congestion. Vehicular accident available.

Trailer blind spot. Property damage to Establish equipment access and shall be free from any obstruction.

Incompetent equipment driver. equipment or materials Designate spotter and flagman to guide the trailer and personnel

movement.

3. The positioning of crane and trailer in preparation for lifting activity

2.9 Crane enters the facility. Unfamiliar to the construction site. Slip and trip that can cause Supervisor/Foreman with the Crane/Trailer operator making a

Dilapidated equipment. sprain and strain walkthrough of the access and work area before entering the site.

Damage or defective condition of the Getting injured from All workers/personnel and visitors must attend the required safety

equipment. protruding object. induction before allowing to work on the site.

Incompetent equipment operator or Struck-by, hit into or All workers/personnel and visitors must sign the attendance

driver. injured by moving vehicle / records and acceptance for a new employee on the job orientation.

Unauthorized entry of the equipment equipment. Provision of pedestrian access, signage, and building/structure

to the site. Property damage, fatality identification.

or injuries during the Awareness/training for all operator and driver.

operation of the Heavy equipment shall not be used if found any defects or damage

equipment. that might affect its safe operation.

Fire due to leaking Repair of heavy equipment shall not be done on the site. It must be

hydraulic oil system brought to the designated workshop and only certified mechanic

Accident resulting serious shall make repair of the equipment.

injury to personnel Ensure that there are no leaking hydraulic oil system or signs of

OHS Forms Procedure Reference Revision Number Revision Date

Page |5 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

leaks and oil contamination.

Select and mobilize only good condition equipment

Equipment certification and registration must be secured and

available.

Operator and driver must have certification and license

Implementation of Log-in and Log-out from the security post.

Equipment/vehicle insurance.

2.10 Position the trailer in the front Struck by moving equipment and Slip and trip that can cause Trailer driver must have certification and SAG license.

of the crane. vehicle. sprain and strain Equipment certification and registration must be secured and

Area congestion. Getting injured from available.

Trailer blind spot. protruding object. Establish equipment access and shall be free from any obstruction.

Incompetent equipment driver. Struck-by, hit into or Designate parking area.

injured by moving vehicle / Supervisor/Foreman with the Crane/Trailer operator making a

equipment. walkthrough of the access and work area before entering the site.

Property damage, fatality Designate a location for unloading of materials.

or injuries during the Designate spotter and flagman to guide all equipment and

operation of the personnel movement.

equipment.

Fire due to leaking

hydraulic oil system

Accident resulting serious

injury to personnel

2.11 Position on the specific Poor/unsafe routing of Crane Struck-by, hit into or Informing the contractor about the arrival time of Crane to the

location where the material to be Unsafe parking of Crane. injured by moving vehicle / work site so that he may arrange in advance.

unloaded. equipment. The arrival of Crane to the site should be through proper and safe

route only.

Crane arriving the site should be parked at a specific location

where its boom can reach easily to the required location for

Operation.

2.12 Set up the crane by extending Soft ground /Uncompact fill. Fall and topple of crane Responsible Engineer and his Supervisor/ Foreman inspection of

its outrigger. Poor and unstable set-up of the crane. Accident resulting injury or exclusion zone/staging area for compaction and level of the

Inexperienced or untrained operator. death to personnel ground.

Site access limitation. Significant property Check first for soil stability on the crane pad

damage to crane and Ground or crane pad shall be compacted and stable enough to

OHS Forms Procedure Reference Revision Number Revision Date

Page |6 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

offices building carry the weight of the crane

Outrigger must be fully extended on a stable and flat even ground.

Outrigger spreader mat pad shall be 4 times the diameter of the

outrigger pad.

All tires of the crane must be elevated at least 3 inches from the

ground for the whole body to act as the counterweights.

2.13 Simulate boom swing in order Overhead/Nearby obstructions. Struck-by, hit into or Responsible Engineer and his Supervisor/ Foreman with the

to estimate the reach and height Struck into adjacent structures or injured by moving vehicle / certified crane operator and rigger to inspection the lifting radius

of the boom. worker. equipment. area is free from any overhead powerlines and other obstructions.

Property damage, fatality Only competent riggers & certified operators shall be assigned for

or injuries during the rigging & lifting job. Valid Third-party training is a must.

operation of the An operator with a valid Saudi driving license and third-party

equipment. training.

Crane load charts are available, all systems are functional and

Third-party certificates must be valid.

Safety crane inspection checklist shall be filled out prior to crane

usage.

Lifting must not be done during bad weather conditions or high

wind.

Any lifting cannot be done above 32km/h of wind.

Check wind Speed before lifting.

2.14 Install barricade around the Struck by moving equipment and Struck-by, hit into or Barricade the working area around the trailer and crane to prevent

working radius of the crane. vehicle. injured by moving vehicle / unnecessary workers to enter the area

Area congestion. equipment. Safety signage shall be posted to communicate the hazards and

Property damage, fatality activity.

or injuries during the

operation of the

equipment.

4. Lifting of Heavy Equipment using Crane

4.1 Crane to position and set-up near Unfamiliar to the construction site. Slip and trip that can cause All workers/personnel and visitors must attend the required safety

the work Dilapidated equipment sprain and strain induction before allowing to work on the site.

Damage or defective condition of the Getting injured from All workers/personnel and visitors must sign the attendance

equipment. protruding object. records and acceptance for a new employee on the job orientation.

Incompetent equipment operator or Struck-by, hit into or Provision of pedestrian access, signage, and building/structure

OHS Forms Procedure Reference Revision Number Revision Date

Page |7 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

driver. injured by moving vehicle / identification.

Unauthorized entry of the equipment equipment. Awareness/training for all operator and driver

to the site. Property damage, fatality Heavy equipment shall not be used if found any defects or damage

or injuries during the that might affect its safe operation.

operation of the Repair of heavy equipment shall not be done on the site. It must be

equipment. brought to the designated workshop and only certified mechanic

Fire due to leaking shall make repair of the equipment.

hydraulic oil system Ensure that there are no leaking hydraulic oil system or signs of

Accident resulting serious leaks and oil contamination.

injury to personnel Select and mobilize only good condition equipment.

Equipment certification and registration must be secured and

available.

Operator and driver must have certification and license

Implementation of Log-in and Log-out from the security post.

Equipment/vehicle insurance.

4.2 Trailer carrying large equipment Struck by moving equipment and Slip and trip that can cause Trailer driver must have certification and SAG license.

and materials to a position near vehicle. sprain and strain Equipment certification and registration must be secured and

the crane. Area congestion. Getting injured from available.

Trailer blind spot. protruding object. Establish equipment access and shall be free from any obstruction.

Incompetent equipment driver. Struck-by, hit into or Designate parking area.

injured by moving vehicle / Designate a location for unloading of materials.

equipment. Designate spotter and flagman to guide all equipment and

Property damage, fatality personnel movement.

or injuries during the

operation of the

equipment.

Fire due to leaking

hydraulic oil system

Accident resulting serious

injury to personnel

4.3 Install barricade around the trailer Struck by moving equipment and Accident resulting injury to Barricade the working area around the trailer and crane to prevent

and working radius of the crane. vehicle. personnel unnecessary workers to enter the area.

Area congestion. Vehicular accident All material location and storage shall be barricaded and provided

Property damage to with adequate signage.

OHS Forms Procedure Reference Revision Number Revision Date

Page |8 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

equipment or materials Safety signage shall be posted to communicate the hazards and

activity.

4.4 Unbox and remove binder from Poor access and egress. Struck-by, hit into or Use an appropriate ladder for the job.

the trailer and unbox the Inappropriate or defective tools. injured by moving vehicle / Only competent person to conduct an inspection for the ladder

equipment. equipment. prior to use.

Defective tools ladder must not be used, marked and remove from

service.

Fabricated or homemade ladder are prohibited.

Close supervision required/ respective foreman & supervisor shall

be present on site.

4.5 Install lifting gears on the Fall from the equipment during the Accident resulting injury to Only competent riggers shall be assigned for rigging & lifting job.

equipment. installation of the slings and shackles personnel Valid Third-party training is a must.

from equipment. Struck-by, hit into or When more 1.8 meters high, rigger must wear a full-body harness

Pinch/crushing points resulting in a injured by moving vehicle / with double shock-absorbing lanyards.

hand injury. equipment. Prove proper access ladder to the equipment.

All the tools and tackles to be used in the activity should be tested

by competent third-party personnel and visual inspection will be

done prior to using them.

Inspect lifting gears before use to ensure that it is free of any

damage, kink, crack, shear, change in diameter, bent, deformed or

sign of damage.

Check all lifting gears Safe Working Load to ensure the capability to

lift the load without breaking.

Damaged lifting gears or any sign of defects should not be used for

lifting.

Ensure the ladder is free of obstruction.

Keep hands away from pinch & crush points.

Use leather gloves during the lifting activity.

4.6 Pre-lift the equipment to Unstable set-up of crane or lifting Slip and trip that can cause Use third-party certified mobile crane and a certified operator,

determine the center of gravity. equipment. sprain and strain conduct pre lifting checks before starting lifting as per lifting plan.

Getting injured from Check first for soil stability on the crane pad.

protruding object. Ground or crane pad shall be compacted and stable enough to

Struck-by, hit into or carry the weight of the crane.

injured by moving vehicle / Outrigger must be fully extended on a stable and flat even ground.

OHS Forms Procedure Reference Revision Number Revision Date

Page |9 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

equipment. Outrigger spreader mat pad shall be 4 times the diameter of the

Property damage, fatality outrigger pad.

or injuries during the All tires of the crane must be elevated at least 3 inches from the

operation of the ground for the whole body to act as the counterweights.

equipment. Crane side lifting shall be discouraged.

Fire due to leaking Make sure to locate the center of gravity of the load before the

hydraulic oil system final lift.

Accident resulting serious Pre-lift shall be done to elevate the load for at least 6 inches from

injury to personnel. the ground in order to find and adjust the balance of the load.

Fall and topple of crane

4.7 Lift the material on the desired Equipment failure/ defective lifting Getting injured from Only trained competent riggers & certified operators shall be

drop off location. tools and tackles. protruding object. assigned for rigging & lifting job with valid Third-party training.

Incorrect lifting procedures. Struck-by, hit into or Crane operator with valid Saudi driving license and third-party

Unorganized materials and access injured by moving vehicle / training.

Incompetent personnel . equipment. Ensure lifting equipment, crane, is in safe operating conditions.

Personnel roaming under the Property damage, fatality Crane load charts are available, all systems are functional and

suspended load. or injuries during the Third-party certificates must be valid.

Inadequate capacity of lifting gears operation of the Safety inspection checklist shall be filled out prior to crane usage.

and accessories. equipment. Conduct inspection lifting tools/tackles prior to use to ensure safe

Overloading of crane or lifting tackles. operation.

Adverse weather Condition. Provide color coding on the inspected and safe tools.

Exposure to strong wind above 32 Presence of personnel below the load prohibited.

kph, sand storm, heavy rain. Any deficiency and defects must be reported to concerned

supervisors for their immediate action and the job will suspend

until the problem was resolved.

Crane safety feature to detect the proximity of other equipment

shall be tested, checked and in good condition.

Crane’s safety feature to stall once unsafe situation occurs must be

in good operating condition and shall not be bypassed

unnecessarily.

SWL of crane and lifting tools should not be exceeded.

The total lift weight shall not exceed 75% of crane chart capacity.

When an overload alarm is heard, lifting activity should be stopped

immediately.

Do not bypass overload alarm provided to the crane.

OHS Forms Procedure Reference Revision Number Revision Date

P a g e | 10 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

Preventive maintenance shall be strictly monitored and adhered as

per manufacturer's recommendation.

All lifting equipment and tools shall be provided with identification

and must be recorded.

No personnel will be allowed to work under a suspended load.

Nobody shall pass, walk or stay or cause anyone to be under the

suspended load

Conduct toolbox meeting and discuss with all the workers.

Do not operate a crane in high or gusty wind conditions that may

put the load or personnel at risk.

Always use the crane's load rating charts for guidance, these have

wind and weather factors built into them.

Monitor wind speed and stop lifting job if wind speed increases

more than 32 km/h.

4.8 Trailer to demobilize from the Struck by moving equipment and Slip and trip that can cause Trailer driver must have certification and SAG license.

area. vehicle. sprain and strain Equipment certification and registration must be secured and

Area congestion. Getting injured from available.

Trailer blind spot. protruding object. Establish equipment access and shall be free from any obstruction.

Incompetent equipment driver. Struck-by, hit into or Designate spotter and flagman to guide the trailer and personnel

injured by moving vehicle / movement.

equipment.

Property damage, fatality

or injuries during the

operation of the

equipment.

Fire due to leaking

hydraulic oil system

Accident resulting serious

injury to personnel

5. Housekeeping (clearing the work area)

5.1 Prior to housekeeping, wearing Inadequate PPE. ● Physical injury from slip & Install appropriate notices and signage.

personal protective equipment Special personal protective equipment must be observed like

such as safety gloves and mask trip coverall clothing, rubber gloves, respiratory equipment, clear

must be fulfilled by the personnel goggles and etc.

OHS Forms Procedure Reference Revision Number Revision Date

P a g e | 11 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

involved. Close supervision by the Engineer, Supervisor or Foreman must

observe.

5.2 Removal of tools, equipment, and Presence of protruding object and ● Muscular injuries (Back Appropriate personal protective equipment should be observed

other excess/unused materials sharp edges. like coverall, hand gloves, eye protection, and etc.

manually. Poor supervision / untrained pain, strain, fractures) Observe proper posture during manual lifting, pushing, pulling, etc.

personnel. ● pinch/crash points resulting Remove all unwanted/protruding materials/object at the site.

Improper manual handling. Close supervision by the Engineer, Supervisor or Foreman must

hand injuries.

observe.

5.3 Disposing of waste to dedicated Tools and materials scattered on the ● Hand injuries due to Proper disposal and segregation of waste / used materials.

waste bin/container. floor. Provision of an appropriate waste container in the area.

handling of sharp object & Close supervision by the Engineer, Supervisor or Foreman must

materials observe.

● Significant property and

appurtenances damage

● Governmental violation

● Environmental complaint

● Loss of production

● Accident resulting serious

injury or death to worker

● Significant cost due to

damages

5.4 Sweeping and cleaning the area. Inadequate PPE. ● Hand injuries due to Appropriate personal protective equipment should be observed

Presence of waste material. like coverall, hand gloves, eye protection, and etc.

handling of sharp object & Observe the “use the right tool” rule.

Inappropriate tools.

materials Close supervision by the Engineer, Supervisor or Foreman must

● Governmental violation observe.

OHS Forms Procedure Reference Revision Number Revision Date

P a g e | 12 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

● Environmental complaint

● Loss of production

6. Closing of Permit to Work

6.1 Returning of the Permit to Work

to Permit Issuer for closing.

6.2 Verifying the site condition as per Poor housekeeping. Significant property and Permit Receiver shall ensure that housekeeping is done before,

requirements mentioned in the Undisposed waste materials. appurtenances damage during and after the work.

closing of Permit to Work by both Unaccounted workers. Governmental violation All waste materials generated from the work shall be properly

the Permit Issuer and Permit Unsecured electrical equipment Environmental complaint disposed and shall not be left unattended at the worksite.

Receiver. /energized equipment. Loss of production Electrical equipment shall be properly secured, distribution board

Poor storage of chemical, flammable Accident resulting serious closed and padlocked.

and combustible materials and etc. injury or death to worker All materials used at the site such as chemicals, flammable and

Unattended unsafe condition. Significant cost due to combustible materials shall be stored at the designated storage at

Unfamiliarity with access to the areas damages. the end of each day.

and the present construction hazard. Mobile equipment shall properly park on a designated equipment

laydown.

Ensure that all workers are accounted and there was no

incident/accident occurred which is not reported.

All Issuer and receiver must be aware of the hazard present in the

area and must be familiar with the ingress and egress of the project

site.

6.3 Signing/clearing of the Permit to Inadequate communication. Accident resulting serious Work permit issuer and receiver must be qualified, trained and

Work by the Permit Issuer upon Untrained personnel. injury or death to worker competent.

verification of site condition and Proper communication should be observed.

satisfactorily comply with the

requirements mentioned.

6.4 Keeping and recording of the

completed and signed Permit to

Work by ensuring that the permit

to work register is duly

accomplished.

OHS Forms Procedure Reference Revision Number Revision Date

P a g e | 13 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

HAZARD IDENTIFICATION & RISK ASSESSMENT (HIRA)

OHS-PR-09-03-F07 (A) JOB SAFE PROCEDURE

LIST ALL STEPS IN PERFORMING HAZARDS DANGER / RISK

STEP PREVENTATIVE CONTROLS REQUIRED TO MINIMIZE /

THIS TASK IN EACH STEP, WHAT COULD CAUSE INJURY, LOSS, (INJURIES, DAMAGE, ILLNESS,

No. DAMAGE INTERRUPTION, OR POLLUTION? POLLUTION, ETC)

ELIMINATE HAZARD

(IN SEQUENCE)

OHS Forms Procedure Reference Revision Number Revision Date

P a g e | 14 JOB SAFE PROCEDURE OHS-PR-09-03-F07 (A) 0 MAY 2021

You might also like

- Task Risk Assessment For Sign Boards InstallationDocument19 pagesTask Risk Assessment For Sign Boards InstallationVenkadesh Periathambi100% (5)

- BSBDIV501 Student Assessment TasksDocument50 pagesBSBDIV501 Student Assessment TasksÇrox Rmg Punk100% (1)

- Formative Assessments WHS 401Document16 pagesFormative Assessments WHS 401Alan Luk100% (1)

- Risk Assessment For .TESTING AND COMMISSIONING OF STORM NETWORK-RCDocument9 pagesRisk Assessment For .TESTING AND COMMISSIONING OF STORM NETWORK-RCarun kurlan100% (1)

- JSP For SS No. 5 Tower Crane InstallationDocument15 pagesJSP For SS No. 5 Tower Crane InstallationmohammedtofiqahmedNo ratings yet

- JSP For SS No. 7 PACU InstallationDocument13 pagesJSP For SS No. 7 PACU InstallationJaafar LagayanNo ratings yet

- JSP For SS No. 8 Installation of EOT CraneDocument28 pagesJSP For SS No. 8 Installation of EOT CraneJaafar LagayanNo ratings yet

- JSP For SS No. 4 Commissioning of High Voltage EquipmentDocument21 pagesJSP For SS No. 4 Commissioning of High Voltage EquipmentmohammedtofiqahmedNo ratings yet

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- JSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsDocument10 pagesJSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsJaafar LagayanNo ratings yet

- JSP For OHTL No. 12 Jumper Installation WorksDocument13 pagesJSP For OHTL No. 12 Jumper Installation WorksJaafar LagayanNo ratings yet

- JSP For OHTL No. 15 Erection of Common Body StructureDocument14 pagesJSP For OHTL No. 15 Erection of Common Body StructureJaafar LagayanNo ratings yet

- JSP For OHTL No. 17 Underline Gantry Installation and ErectionDocument15 pagesJSP For OHTL No. 17 Underline Gantry Installation and ErectionJaafar LagayanNo ratings yet

- JSP For OHTL No. 16 Erection of Upper Body StructureDocument14 pagesJSP For OHTL No. 16 Erection of Upper Body StructureJaafar LagayanNo ratings yet

- JSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaDocument11 pagesJSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- JSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyDocument10 pagesJSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyJaafar LagayanNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- JSP For SS No. 9 Filling of Battery Fluid Inside Battery RoomDocument15 pagesJSP For SS No. 9 Filling of Battery Fluid Inside Battery RoomJaafar LagayanNo ratings yet

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- GIS Building Expansion and Reactor Installation HIRADocument8 pagesGIS Building Expansion and Reactor Installation HIRAAbdul Rasheed Mangrio100% (1)

- JSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerDocument11 pagesJSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerAbdul Rasheed MangrioNo ratings yet

- JSP For SS No. 2 GIS-GIB-Swithgear InstallationDocument19 pagesJSP For SS No. 2 GIS-GIB-Swithgear InstallationmohammedtofiqahmedNo ratings yet

- Job Safety SiteDocument11 pagesJob Safety SiteMohd Arfeen RezaNo ratings yet

- 8.JSP No.30 Hydro Testing of Gas Pipe LineDocument9 pages8.JSP No.30 Hydro Testing of Gas Pipe LineabbasNo ratings yet

- Ohs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingDocument16 pagesOhs-Pr-09-03-F07 (A) JSP No. 46 Cable PullingbilalgradioshNo ratings yet

- Page - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)Document10 pagesPage - 1: (In Sequence) (Injuries, Damage, Illness, Pollution, Etc)shafiezubier5No ratings yet

- Ohs-Pr-09-03-F07 (A) Job Safe ProcedureDocument1 pageOhs-Pr-09-03-F07 (A) Job Safe ProcedureShafie ZubierNo ratings yet

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- JSP For Communication Local TestDocument8 pagesJSP For Communication Local TestJaafar LagayanNo ratings yet

- JSP for Grounding grid InstallationDocument11 pagesJSP for Grounding grid InstallationAbdulsalam AneezeNo ratings yet

- JSP For SS No. 42 Line Stability Test (JD-RDS BB-1 PMD 110 KV)Document11 pagesJSP For SS No. 42 Line Stability Test (JD-RDS BB-1 PMD 110 KV)Mohd Arfeen RezaNo ratings yet

- Backfilling _ CompactionDocument11 pagesBackfilling _ CompactionFarooq MohammadNo ratings yet

- JSP for Installation of cable trayDocument11 pagesJSP for Installation of cable trayAbdulsalam AneezeNo ratings yet

- Marine Permit: Cold Work: Permit To Work Office No.: Refer To The Last PageDocument3 pagesMarine Permit: Cold Work: Permit To Work Office No.: Refer To The Last PagewaseemNo ratings yet

- JSP For SS No. 27 Excavation Work Using EquipmentDocument8 pagesJSP For SS No. 27 Excavation Work Using EquipmentMuhammad AtifNo ratings yet

- JSP for Installation of Battery BankDocument9 pagesJSP for Installation of Battery BankAbdulsalam AneezeNo ratings yet

- JSP for Installation of Capacitor BankDocument12 pagesJSP for Installation of Capacitor BankAbdulsalam AneezeNo ratings yet

- JVT W QS 000 033 B Digging or Excavation Permit FormDocument4 pagesJVT W QS 000 033 B Digging or Excavation Permit FormGilbert GillNo ratings yet

- JSP For Electrical Test (End To End Test)Document8 pagesJSP For Electrical Test (End To End Test)Jaafar LagayanNo ratings yet

- JSP For Open Loop Close Loop Test For Protection PanelDocument9 pagesJSP For Open Loop Close Loop Test For Protection PanelJaafar LagayanNo ratings yet

- SKN - 004 JRA Lift and Run Electrical CableDocument3 pagesSKN - 004 JRA Lift and Run Electrical Cable121212No ratings yet

- JSP for Installation of AC-DC PanelsDocument11 pagesJSP for Installation of AC-DC PanelsAbdulsalam AneezeNo ratings yet

- Jsa PrintDocument1 pageJsa PrintVENKATESH TekkaliNo ratings yet

- StudentStudymet581161 4Document4 pagesStudentStudymet581161 4CM VendhenNo ratings yet

- Work Permit System Inspection ChecklistDocument2 pagesWork Permit System Inspection ChecklistABDUL RISHAD KunduthodeNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (08) Concrete Poring and Removal of CasineDocument16 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (08) Concrete Poring and Removal of Casinemohammed tofiqNo ratings yet

- Contractor Evolution PlanDocument4 pagesContractor Evolution PlanCharantej TejaNo ratings yet

- Ptw-Kec - Final v3 - SparkDocument1 pagePtw-Kec - Final v3 - SparkXiang JintaoNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (03) Excavation Auger DrillingDocument17 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (03) Excavation Auger Drillingmohammed tofiqNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (15) Stringing Pulling Conductor and OPGW-JSPDocument18 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (15) Stringing Pulling Conductor and OPGW-JSPmohammed tofiqNo ratings yet

- HIRA & Risk Assessment for Template Setting JobDocument13 pagesHIRA & Risk Assessment for Template Setting Jobmohammed tofiqNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (02) Access Road and Structure PadDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (02) Access Road and Structure Padmohammed tofiqNo ratings yet

- App-16.2 - Risk Assessment For Traffic Signal SystemDocument13 pagesApp-16.2 - Risk Assessment For Traffic Signal Systemloveson709100% (2)

- PS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)Document27 pagesPS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)RABIE EL MAGHWRY ABDELKHALEK ELGHAMRY0% (1)

- Issuance of Citation Tickets For COB Violations DraftDocument7 pagesIssuance of Citation Tickets For COB Violations DraftArvin OmboyNo ratings yet

- HSE Job Safety Plan TemplateDocument1 pageHSE Job Safety Plan Templatejoenediath9345No ratings yet

- RA 16 (Anchor Bolt Installation)Document7 pagesRA 16 (Anchor Bolt Installation)abdulthahseen007No ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (11) Tower Gantry Erection WorkDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (11) Tower Gantry Erection Workmohammed tofiq100% (1)

- Risk Assessment & Method Statement: Insert Company Name/LogoDocument14 pagesRisk Assessment & Method Statement: Insert Company Name/Logoahmed khairyNo ratings yet

- RA 18 (Well Bore Using Excavator Mounted Earth Auger Drill) 2Document8 pagesRA 18 (Well Bore Using Excavator Mounted Earth Auger Drill) 2abdulthahseen007No ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- Do's and Don't at WorkplaceDocument26 pagesDo's and Don't at WorkplacemohammedtofiqahmedNo ratings yet

- TBT TopicsDocument30 pagesTBT TopicsmohammedtofiqahmedNo ratings yet

- HSE Plan-1Document100 pagesHSE Plan-1mohammedtofiqahmedNo ratings yet

- Oil Spill Response Plan Bo2 April 2018 RedactedDocument125 pagesOil Spill Response Plan Bo2 April 2018 RedactedHSE PULAI A100% (1)

- Cism Domain 2 Information Risk Management and ComplianceDocument80 pagesCism Domain 2 Information Risk Management and Compliancejustice friendsNo ratings yet

- Contractor HSE Capability Assessment and Scoring System - Supplement To Report 423 (2017 APR)Document44 pagesContractor HSE Capability Assessment and Scoring System - Supplement To Report 423 (2017 APR)Htoo Htoo KyawNo ratings yet

- Family Reunification Plan Version 2Document31 pagesFamily Reunification Plan Version 2gusyahri001No ratings yet

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Pmpa Tools To Assist Risk Based Thinking 042318 UpdatedDocument41 pagesPmpa Tools To Assist Risk Based Thinking 042318 UpdatedarylananylaNo ratings yet

- 1809NRS Assignment Description & Marking Rubric - 2021 FINALDocument5 pages1809NRS Assignment Description & Marking Rubric - 2021 FINALSiddiqa ZubairNo ratings yet

- Literature Review of Fire Risk Assessment Methodologies: G.V. Hadjisophocleous and Z. FuDocument18 pagesLiterature Review of Fire Risk Assessment Methodologies: G.V. Hadjisophocleous and Z. FuBADWOLFNo ratings yet

- Fire Risk Assessment FormDocument20 pagesFire Risk Assessment FormAhmed Ibrahim100% (1)

- VICS Construction Plant Management ProcedureDocument8 pagesVICS Construction Plant Management ProcedureEkum EdunghuNo ratings yet

- Risk Management and AssessmentDocument50 pagesRisk Management and Assessmentfaik395No ratings yet

- Guidance Note Fatigue Risk ManagementDocument64 pagesGuidance Note Fatigue Risk ManagementJepri SihombingNo ratings yet

- TMSA - Tanker Management - July 2006 PDFDocument34 pagesTMSA - Tanker Management - July 2006 PDFnmospan75% (4)

- HSENI - Individual Risk Assessment TemplateDocument18 pagesHSENI - Individual Risk Assessment TemplateSonukrishnaNo ratings yet

- Service Standard 09B Clinical Services - Surgical Related ServicesDocument30 pagesService Standard 09B Clinical Services - Surgical Related ServicesSuhaimeNo ratings yet

- PAS 55-Implementation ExcellenceDocument56 pagesPAS 55-Implementation ExcellenceSuresh Ramachandran100% (2)

- Annex 11Document5 pagesAnnex 11antonygamalpharmaNo ratings yet

- Ig2 Forms Electronic SubmissionDocument6 pagesIg2 Forms Electronic Submissionakhil100% (2)

- Ansi B11.0 - 2010Document85 pagesAnsi B11.0 - 2010Mohammed100% (1)

- Briefer On RA 10611Document1 pageBriefer On RA 10611Eugene UC100% (1)

- Introduction To Environmental GeologyDocument37 pagesIntroduction To Environmental GeologyShraddha ShaduNo ratings yet

- Lifting & Hoisting PracticesDocument40 pagesLifting & Hoisting PracticesInternational Certification100% (1)

- CHAP 15. Audit Sampling For Tests of Controls and Substantive Tests of TranDocument32 pagesCHAP 15. Audit Sampling For Tests of Controls and Substantive Tests of TranNoroNo ratings yet

- Audit Question BankDocument379 pagesAudit Question BankShikaki OPNo ratings yet

- Installation of Office Furniture Method StatementDocument2 pagesInstallation of Office Furniture Method StatementSonukrishnaNo ratings yet

- OHS-PR-02-22-01 HSE Conditions of Contract HSE PlanDocument45 pagesOHS-PR-02-22-01 HSE Conditions of Contract HSE PlanSn Ahsan100% (1)

- Risk Assessment & Safety Measures for Quarry DevelopmentDocument6 pagesRisk Assessment & Safety Measures for Quarry Developmentfahro2000No ratings yet

- 02d.2 Schedule A Part 3 Annex1Document289 pages02d.2 Schedule A Part 3 Annex1tsingistrasNo ratings yet