Professional Documents

Culture Documents

HSE-RA-013 Deshuttering - Rev 0.

Uploaded by

عمروCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-RA-013 Deshuttering - Rev 0.

Uploaded by

عمروCopyright:

Available Formats

DOC No DS/CA006P02/00022

PAGE No 1 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Index:

Form 1 Task Analysis Initiation

Form 2 Risk Assessment Process As per Risk Assessment Procedure.

Form 3 Written Safe Work Procedure Result

Compiled by the following team:

NAME DESIGNATION SIGNATURE

Project Manager

Construction Manager

Site Engineer

Safety Officer

Risk Assessment Review 1 Review 2 Review 3 Review 4

Review Date: Date : Date : Date:

Name and Signature

of person reviewing :

AUTHORISATION

Prepared by: Approved by

Signature Date Signature Date

HSE Manager Project Manager

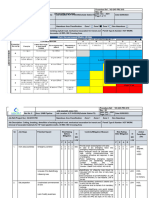

TASK ANALYSIS - FORM 1

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 2 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Impact

SEQUENCE OF TASK STEPS POTENTIAL INJURIES OR HAZARDS RECOMMENDED CONTROLS

H, S, E

1. Pre-use inspection and use of all equipment. Failure of equipment will cause injuries to Faulty equipment to be repaired/maintained or replaced.

persons and / or property damage. Guards to be on all Machinery and appropriate PPE to

be worn.

Engine ran machinery to have fire extinguishers

Fuel/oil leaks could cause environmental H, S, E

available locally.

concerns. Drip trays/heavy gauge plastic to be used in case of

leaks and spill kit to be within the project for accidental

spills.

2. Wear appropriate Personal Protective Failure to use Personal Protective

Equipment. Equipment will cause injuries to employees.

Gloves.

Safety boots. Enforce the use of Personal Protective Equipment AT

H

Overalls. ALL times

Hard hat.

Hearing protection.

Eye protection

3. Use trained employees only Failure may result in injuries to persons and Enforce the use of competent persons only throughout

H, S

property damage. the project.

4. Competent supervisor should be appointed for every

activity to monitor the workers.

Work task instruction should be provided for every

H, S activity.

Competent supervision Failure will cause injuries to employees and

or property damage

5. Use competent trained carpenters and Untrained carpenters will fail to remove Ensure availability of trained carpenters and supervisors

H, S

Supervisor formwork correctly and as per procedure and follow de-shuttering procedure completely.

6. Secure tools to carpenters with tie-lines Failure will cause falling tools resulting to H, S Enforce the use of tie-lines and life lines.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 3 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

injuries to employees

7. Barricade off De-shuttering Safe work area Allowing unauthorised entry in work area Ensure safe working area to be barricaded off and

enhancing the risk of injuries to employees H, S Signage “De-shuttering Area” erected from all possible

access ways.

8. All carpenters to make use of safety Failing to use harnesses can cause Enforce the use of safety harnesses

H, S

harnesses when exceeding 2.0 meters carpenters to fall

9. Never use parts of different ladders to gain Formwork collapsing causing injuries to Ensure the use of correct and sound formwork and

access to any level of formwork. persons and / or property damage. H, S access parts and planks.

10. Install access ladders to formwork as access Failing will allow persons to climb up against

points to de-shuttering points ledgers that can cause employees to slip H, S Enforce the installing of excess ladders.

and fall.

11. Removing formwork items as de-shuttering Fall of items on top of persons, damage to Enforce rules of passing down smaller items that can be

commences material and equipments. controlled and clearing area underneath if large items

have to be dropped.

H, S

Dropping of items from outer edges strictly prohibited

and must be secured via anchor lines before loosening

from surfaces.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 4 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

TASK ANALYSIS - FORM 1 (continued)

SEQUENCE OF TASK STEPS POTENTIAL INJURIES OR HAZARDS RECOMMENDED CONTROLS

12. Stacking of de-shuttered material Falls and slips and trips and housekeeping Every piece removed from shuttered area to be

and general safety of helpers removed and stacked immediately.

Nails to be removed before stacking and all items to be

H,S, E stacked individually according to size, allocation or

order.

Hand gloves, goggles and dust mask are compulsory

during this operation.

13. Lighting and ventilation of de-shuttering Trips and fall, dropping of material on top of Ensure proper lighting all around de-shuttering areas

areas others. and proper electrical cables management.

H, S

Forced ventilation to be provided in case of dusty and/

Suffocation or heat in closed de-shuttering areas.

14. Permit for de-shuttering Prevention of Injuries, damage Ensure de-shuttering permit is obtained from Safety

Dept and that all involved in process has had a toolbox

H,S

talk about the task at hand before work commences.

Supervisor to be present in the work area all the time

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 5 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

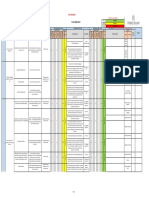

RISK ASSESSMENT – FORM 2

Risk Rating Calculation

Risk Rating = A + B + C + D.

A + B + C + D

Injury Severity Potential Damage / Loss Frequency or Likelihood Environmental Impact

0 No injury 0 No damage 0 Never happened before 0 No effect

1 Minor – (FAC) 1 Minor < 500 AED, No delay 1 Happened somewhere 1 Minor Effect - Short term < less 1 month

2 Major – (MTC) 2 Major > 500 AED, No delay 2 Happens occasionally 2 Major Effect - Long term > Greater 1 month

3 LTI 3 Major > 10 000 AED, one day delay 3 Happened before

4 Disabling Injuries 4 Serious > 100, 000 AED, >1 day delay 4 Happens regularly

Risk Rating Matrix

5 Fatality 5 Severe > 1, 000, 000 AED, Weeks delay. 5 Daily occurrence

Result Classification:

Risk Rating

Critical = 17►15 High = 14►11 Medium = 10►7 Low = 6►0 16

Immediate action. Action in 24 hours. Action in a week. ASAP. 14

12

10

Risk Reduction Hierarchy: 8

6

1. Engineering to reduce risk. 4

2. Replacement with lower risk. 2

0

3. Isolation of risk – Barricading or Guarding. 1

5

2 4

4. Reduction of exposure to risk. 3

4 3

5 Probability

5. PPE and Training Potential Impact 6

7 2 (C)

(A / B / D) 8

9 1

RISK ASSESSMENT – FORM 2 (continued)

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 6 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

1 Faulty hand tools Bruises, cuts. Gloves, trowels in good Supervisor Before &

condition. during

Mechanical guards not Entanglement, Skeletal Damage. the use

in place Guards in place and equipment of

H,S,E 13 regularly maintained. equipme 6

nt

Unwanted Fuel/Oil Contamination of the soil, atmospheric Care to be taken refuelling and

Spillages pollution, risk of fire. drip trays/heavy gauge plastic to

be in place as required.

2 Injury to project Potential Death, Major/Minor Skeletal Following PPE to be worn Supervisor Before &

employees damage, cuts and bruises to all parts of appropriately to the task – during

the body, asthma. Gloves. work

Safety boots.

H,S 10 5

Overalls.

Hard hat.

Hearing protection.

Eye protection

3 Un trained employees Poor quality of work, chance for Provided trained/competent PE/FM Always

H,S 7 5

accident /incident or property lost/damage worker and supervision

4 Poor Supervision Poor quality of work, chance for Ensure the availability of PE/FM Always

accident /incident or property lost/damage competent supervisor at work

place.

H,S 10 3

Work task instruction should be

provided to the workers prior to

the commencement of activity

5 Incompetent operatives Minor/Major injuries 10 Only trained carpenters to be Supervisor Always

Cuts and bruises on the body H, S used 3

Property damage.

6 Unsecured tools Falling materials leads minor/major H, S 10 Ensure the tools secured with Supervisor Always 2

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 7 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

injuries. tag-lines.

Potential Death, Major/Minor Skeletal

damage, cuts and bruises to all parts of

the body

7 Fail to barricade the work Falling materials Major/minor injuries, 12 Ensure the work area has been FM Before &

place potential death, property damage. barricaded and warning sign /Supervisor during

placed. work

H.S 4

Watchman should be posted in

necessary positions.

8 Not using Safety Falling of person from height 12 Full body safety harness must be PE/FM Before &

harnesses Potential Death, Major/Minor Skeletal worn where the working height Supervisor during

damage, cuts and bruises to all parts of exceeds 1.8 meters. work

the body H, S 4

Ensure the full body harness

anchor to a strong anchorage

point while working

9 Substandard materials Collapsing of the structure. 12 Ensure the use of correct and PE/FM Before &

Falling of person from height sound formwork and access Supervisor during

Potential Death, Major/Minor Skeletal H,S parts and planks. work 4

damage, cuts and bruises to all parts of

the body

10 Failure to install access Slipping and falling of employees 10 Ensure installation of steps FM Always

ladders Major Injuries H, S ladders to specifications Supervisor 3

Potential death

* RR = Risk Rating

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 8 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

11 Removing formwork Fall of materials on top of persons, 10 Enforce rules of passing down Supervisor At all

materials as de-shuttering damage to material and equipments. smaller items that can be times

commences. controlled and clearing area

underneath if large items have to

H, S be dropped. 3

Dropping of items from outer

edges strictly prohibited and must

be secured via anchor lines

before loosening from surfaces.

12 Failure to stack the Fall of materials H,S 12 PE/FM Always 3

materials Major Injuries Every piece removed from Supervisor,

Potential death shuttered area to be removed

Property damage and stacked immediately.

Nails to be removed before

stacking and all items to be

Muscular strains, Bruises and cuts stacked individually according to

Skeletal Damage. size, allocation or order.

Manual Handling Hand gloves, goggles and dust

mask are compulsory during this

operation.

Never throw the materials to the

below area.

Barricade the area from

unauthorized entry.

Maintain proper stacking of

materials.

Manual lifting procedure must be

applied, LITE to be consider at all

times.

never lifts manually heavy load

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 9 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

that exceed on the persons

capacity

Avoid protruding object on the

material

Avoid obstruction on passage

way.

Proper coordination when lifting

of heavy materials by multiple

operative.

13 Poor illumination and Injuries to the workers and property 12 Ensure provision of flood lights to PE/FM Through

ventilation at work place damage. ensure that the complete work Supervisor out the

area is covered not leaving any work

dark spots

Chronic occupational damage to H,S Forced ventilation to be provided 4

personnel’s respiratory systems. in case of dusty and/ or heat in

closed de-shuttering areas.

Evacuation procedure must be

discuss to the workers

14 Fail to adhere permit to Prevention of Injuries, damage 9 Ensure de-shuttering permit is PE/FM/ Before

work system obtained from Safety Dept and HSE Dept and

that all involved in process has Supervisor during

had a toolbox talk about the task work

H,S 3

at hand before work commences.

Supervisor to be present on the

area to adhere the safe work

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 10 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

procedure

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 11 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

WRITTEN SAFE WORK PROCEDURE

1. OBJECTIVE

1. To prevent injuries to employees and / or property damage incidents.

2. PROCEDURE

1. Do pre-use inspection of all equipment to be used and replace or repair faulty items.

2. Use trained competent employees only.

3. Use appropriate Personal Protective Equipment i.e.:

3.1. Hardhat.

3.2. Safety boots.

3.3. Hand gloves

3.4. Respiratory protection

3.5. Hearing protection

3.6. Overalls.

3.7. Eye protection.

Prior to work commencement

1. Must have PPE – safety footwear, gloves, hardhat, goggles, face musk, protective clothing etc.

2. Must have appropriate tools and equipment in good condition.

3. Must have weatherproof covers for materials and equipment, waste containers, warning tape.

4. Consider risks and hazards in work area. Refer any concerns to supervisor. Are relevant permits in place?

5. Check if it is necessary to secure area adjacent to work. Refer to supervisor if appropriate.

6. Arrange for transport of materials and equipment to site via supervisor.

7. Ensure materials and equipment are secure or removed when site unattended, eg overnight or during breaks.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 12 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Hazards

1. Manual handling of materials (Lifting and shifting of materials) LITE to be considered at all times.

2. Fall from height, while on erection

3. Slips and trips and fall( eg: Un stacked materials, uneven scaffold planks etc)

4. Falling materials (eg: Scaffold components, tools and equipments etc)

5. Collapse of scaffold( eg: insecure ties and bracing , substandard materials etc)

6. Hazards associated with equipment used for lifting of materials, eg. Cranes, forklift, etc.

7. Contact with sharp edges of materials.

8. Working at heights.

9. Adverse weather conditions. If any doubts refer to the supervisor.

10. Unsafe stacking of materials.

Harm

Potential Death, Minor/major cuts and contusions, loss of limbs, fractures, concussion to fatality, property damage

Persons in danger

1. Carpenters

2. Co-workers

3. Other workers/visitors in the vicinity

4. Public.

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 13 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

Control measures

No lone working

All formwork used on the site must comply with Dubai municipality regulations.

SAFE DE- SHUTTER WORK

MOST OF HAND AND FINGER ACCIDENTS HAPPENS ON SITE DURING DE-SHUTTERING. NO SAFETY MEASURES ARE TAKEN

AND THE WORK IS DONE IN BULK WITH MATERIAL SCATTERED EVERY WHERE AND THE SAFETY DEPARTMENT IS NOT

NOTIFIED WHEN THIS IS BEING DONE.

THE FOLLOWING WILL APPLY WITH IMMEDIATE EFFECT:

PERMIT TO WORK SYSTEM.

1. BEFORE DE-SHUTTERING COMMENCE, THE SAFETY DEPARTMENT MUST BE NOTIFIED AND A DE-SHUTTERING PERMIT

MUST BE OBTAINED.

2. THIS PERMIT IS VALID FOR ONE DAY ONLY.

3. THE SAFETY PERSONNEL WILL INSPECT THE AREA TO BE DE-SHUTTERED BEFORE ISSUEING THIS PERMIT.

4. NO PERMIT WILL BE ISSUED IF THE AREA IS NOT SAFE AND SECURED.

5. NO DE-SHUTTERING WILL BE ALLOWED WITHOUT A PERMIT.

RESPONSIBILITIES OF THE SAFETY DEPARTMENT:

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 14 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

THE SAFETY OFFICER SHOULD INSPECT THE AREA BEFORE ISSUEING THE PERMIT AND ENSURE THE FOLLOWING:

1. ENSURE AREA IS BARRICADED OFF.

2. ENSURE THAT WORKERS ARE EXPERIENCED IN DE-SHUTTERING.

3. CHECK THAT PREVIOUS SHIFT HAS STACKED MATERIAL PROPERLY AND THAT NO LOOSE MATERIAL IS LYING

AROUND IN THE AREA.

4. AREA SHOULD BE CLEAR OF MATERIAL LYING AROUND BEFORE NEW SHIFT STARTS TO DE-SHUTTER.

5. DE-SHUTTER AREA TO BE MARKED ON THE SITE PLAN.

6. FILE THE WORK PERMIT UP TO DATE AND CORRECTLY.

7. ENSURE CORRECT P.P.E. IS USED.

8. IN CASE OF DE-SHUTTERING ON EDGES, ENSURE LIFE LINES AND WARNING TAPE IS IN PLACE AND ENFORCE THE

USE OF SAFETY HARNESS.

9. SAFETY OFFICER TO BE PRESENT WHEN WORKING ON EDGE.

RESPONSIBILITIES OF SITE ENGINEER:

HE MUST ENSURE THAT:

1. VALID WORK PERMIT IS AVAILABLE.

2. SEPARATE TEAMS FOR DE-SHUTTERING, HOUSEKEEPING, AND MATERIAL STACKING WORKS.

3. ENSURE AVAILABILITY AND USE OF CORRECT P.P.E.

4. USE EXPERIENCED WORKERS FOR DE-SHUTTERING.

5. REPORT ALL ACCIDENTS AND NEAR MISSES TO SAFETY DEPARTMENT.

RESPONSIBILITIES OF THE FOREMAN:

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 15 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

THE FOREMAN MUST ENSURE THE FOLLOWING:

1. A COPY OF THE PERMIT IS IN HIS POSSESION.

2. EXPLAIN THE PROPER DE-SHUTTERING PROCEDURE TO THE WORKERS AND ENSURE THAT THEY UNDERSTAND AND

FOLLOW THE PROCEDURE.

3. REPORT ALL ACCIDENT AND NEAR MISSES TO SITE ENGINEER.

DE-SHUTTERING PROCEDURE:

1. BARRICADE THE AREA INTENDED TO BE DE-SHUTTERED.

2. ERECT PLATFORMS AT THE APPROPRIATE HEIGHT FOR THE CARPENTER TO REACH THE BEAMS EASILY.

3. LOOSEN THE BEAM, REMOVE AND LOWER BY HAND.

4. ONCE IT IS ON THE GROUND, IT SHOULD BE STACKED IMMEDIATELY AND NOT LEFT LYING ON THE GROUND. ENSURE

THE WORK AREA AROUND HIM IS CLEAR OF MATERIAL.

5. SCAFFOLDING MUST BE REMOVED PIECE BY PIECE AND STACKED IMMEDIATELY.

6. NOW REMOVE THE SHUTTERBOARD OR PLY ONE BY ONE MAKING SURE NO PERSON IS NEAR OR UNDER IT.

7. PERSONS REMOVING THE PLY SHOULD HAVE CLEAR ACCESS TO MOVE AWAY WITHOUT TRIPPING OVER MATERIAL.

8. WHEN AREA IS SAFE, THE BOARDS MUST BE STACKED PROPERLY.

9. NAILS MUST BE REMOVED FROM THE BOARDS BEFORE IT IS STACKED PROPERLY.

10. ALL WORKERS INVOLVED WILL WEAR PROPER P.P.E.

11. SAFETY HARNESS WILL BE WORN FOR THOSE DIRECTLY INVOLVED WITH DE-SHUTTERING AND ALSO WEAR GOGGLES

HSE/QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 16 of 16

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 013

Job Description: De-shuttering works

WHEN THEY REMOVE INFILL BEAMS AND BOARDS.

HSE/QUALITY SYSTEM DOCUMENTATION

You might also like

- Risk Assessment - Steel Erection WorksDocument11 pagesRisk Assessment - Steel Erection Worksmahmoud nadaNo ratings yet

- Safe Usage of PPE Toolbox Talk Global EHS TBT 006Document4 pagesSafe Usage of PPE Toolbox Talk Global EHS TBT 006Global EHSNo ratings yet

- Managing mobile plant risksDocument2 pagesManaging mobile plant risksPravin GowardunNo ratings yet

- PTCL Data Centre FinalDocument32 pagesPTCL Data Centre FinalZohaib Chachar100% (2)

- Canadian Aviation History and Career GuideDocument28 pagesCanadian Aviation History and Career GuideShreyas Pinge100% (1)

- HSE-RA-016 Waste Materials - Rev 0Document12 pagesHSE-RA-016 Waste Materials - Rev 0عمروNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- HSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0Document8 pagesHSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0عمروNo ratings yet

- HSE-RA-040 Marble Fixing Rev 0Document12 pagesHSE-RA-040 Marble Fixing Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-044 Painting Rev 0Document14 pagesHSE-RA-044 Painting Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- HSE-RA-052 Repairs of Concrete Imperfections - Rev 0Document11 pagesHSE-RA-052 Repairs of Concrete Imperfections - Rev 0عمروNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- HSE-RA-014 Using of Cutting Torch - Rev 0Document15 pagesHSE-RA-014 Using of Cutting Torch - Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-031 Back Filling of - Excavation - Rev 0Document9 pagesHSE-RA-031 Back Filling of - Excavation - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-061 Table and Bench Saw - Rev 0Document14 pagesHSE-RA-061 Table and Bench Saw - Rev 0عمروNo ratings yet

- 10 JSA - Cable Drums InstallationsDocument6 pages10 JSA - Cable Drums Installationssyed khaja misbhuddinNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Document21 pagesOHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Jaafar LagayanNo ratings yet

- 2 ConectionDocument2 pages2 ConectionMohammed AdnanNo ratings yet

- JSA - Baby Rollar and CompectorDocument5 pagesJSA - Baby Rollar and CompectorRaju100% (1)

- Ceiling WorkDocument10 pagesCeiling WorkNisanth ThulasidasNo ratings yet

- URC Insulation For Ducting (SWMS)Document9 pagesURC Insulation For Ducting (SWMS)syed khaja misbhuddinNo ratings yet

- OHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021Document7 pagesOHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021MuhammadAsimMuneerNo ratings yet

- Rare GusterDocument16 pagesRare Gusterreemy sarkNo ratings yet

- Intelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2Document221 pagesIntelliview - Baseline Safety Hazard Identification & Risk Assessment - RA001 - Rev 2raymundwat11No ratings yet

- 01 JSA - Material ShiftingDocument5 pages01 JSA - Material Shiftingsyed khaja misbhuddinNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- Assignment HiracsDocument29 pagesAssignment HiracsIntanNo ratings yet

- JSP For SS No. 1 Battery Charging and TestingDocument11 pagesJSP For SS No. 1 Battery Charging and TestingmohammedtofiqahmedNo ratings yet

- OHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaDocument10 pagesOHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaJaafar LagayanNo ratings yet

- RAMS MAnual LiftingDocument12 pagesRAMS MAnual LiftingCarlos Immanuel100% (1)

- Steel YardDocument6 pagesSteel YardAtiq ShaikhNo ratings yet

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- Jsa-007 PaintingDocument14 pagesJsa-007 PaintingDamien Monize100% (1)

- SOP - Burisch 100Ltr Air CompressorDocument1 pageSOP - Burisch 100Ltr Air CompressorDaniel DerzaNo ratings yet

- Night WorkDocument3 pagesNight Workkessery koivoguiNo ratings yet

- Expert Risk AssessmentDocument37 pagesExpert Risk Assessmentmohamed elhawaryNo ratings yet

- SWP Automotive Parts Washer - AS502Document2 pagesSWP Automotive Parts Washer - AS502Gowtham KishoreNo ratings yet

- JHA For BreakingDocument18 pagesJHA For BreakingRaheenNo ratings yet

- Work Permit 2.13Document14 pagesWork Permit 2.13Oliva Del Rosario Sagpao100% (1)

- Be Accountable For Your Safety at Work by Dr. Anuar SuunDocument27 pagesBe Accountable For Your Safety at Work by Dr. Anuar SuunakubestlahNo ratings yet

- Toolboxtalk2 Housekeeping PDFDocument2 pagesToolboxtalk2 Housekeeping PDFSajid HussainNo ratings yet

- Risk Assessment For Ceramic & Porcelain Tile WorksDocument6 pagesRisk Assessment For Ceramic & Porcelain Tile WorksFaizan TanveerNo ratings yet

- JHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10Document11 pagesJHA - 162 Cutting Breaking Demolition of Existing Asphalt Road Mechanical Excavation For Trench and Removal of Excavated Materials For 10M.k.BurhanNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- November December 2020 PDFDocument32 pagesNovember December 2020 PDFSamundeswaran SatiwasilanNo ratings yet

- Information Sheet: Crystalline Silica DustDocument2 pagesInformation Sheet: Crystalline Silica DustIoana UrsanNo ratings yet

- Job Safety Analysis for Plumbing WorksDocument15 pagesJob Safety Analysis for Plumbing WorksLeo PascualNo ratings yet

- Installation of Cable Trays and LaddersDocument13 pagesInstallation of Cable Trays and LaddersamalNo ratings yet

- Hand Tools & Safety PracticesDocument4 pagesHand Tools & Safety PracticesRecel Ann RiveraNo ratings yet

- Safety Inspection Course (With Workshop)Document86 pagesSafety Inspection Course (With Workshop)YeddaMIlaganNo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- HSE-RA-041 Water Proofing - Activities - Rev 0Document11 pagesHSE-RA-041 Water Proofing - Activities - Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-060 Using A Personnel Bucket - Rev 0Document11 pagesHSE-RA-060 Using A Personnel Bucket - Rev 0عمروNo ratings yet

- HSE-RA-018 Use of An Angle Grinder - Rev 0Document15 pagesHSE-RA-018 Use of An Angle Grinder - Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- RA - EIA HousekeepingDocument1 pageRA - EIA HousekeepingعمروNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- RISK-REGISTERDocument2 pagesRISK-REGISTERعمرو100% (1)

- RA - EIA ErgonomicsDocument2 pagesRA - EIA ErgonomicsعمروNo ratings yet

- RA - Concrete PouringDocument1 pageRA - Concrete PouringعمروNo ratings yet

- RA - Crane OperationDocument3 pagesRA - Crane OperationعمروNo ratings yet

- RA - EIA GeneratorDocument4 pagesRA - EIA GeneratorعمروNo ratings yet

- Erection, Testing, Commissioning, Trial OperationDocument131 pagesErection, Testing, Commissioning, Trial OperationTufan Maity100% (1)

- IBM POWER8 Systems Facts and FeaturesDocument18 pagesIBM POWER8 Systems Facts and FeaturesEdson Jeancarlo Rueda SocolaNo ratings yet

- Length of Source Code ExplainedDocument21 pagesLength of Source Code Explainedhi_baltazarNo ratings yet

- Cloud Computing Basics and Security BenefitsDocument13 pagesCloud Computing Basics and Security BenefitsJaskaranrehalNo ratings yet

- 236 Executive Board Meeting of NHADocument39 pages236 Executive Board Meeting of NHAHamid NaveedNo ratings yet

- Technical Investigation Report TSPDocument8 pagesTechnical Investigation Report TSPDeka TariganNo ratings yet

- DIP FaridabadDocument33 pagesDIP FaridabadShyam Nagina SharmaNo ratings yet

- Summmer Internship ReportDocument71 pagesSummmer Internship ReportjyotiNo ratings yet

- 01.sundram Fasteners LTDDocument60 pages01.sundram Fasteners LTDTapash Kumar PalNo ratings yet

- List of DMVsDocument3 pagesList of DMVsSrikanth KhghNo ratings yet

- Rotor Clip CatalogDocument172 pagesRotor Clip CatalogstanyeahNo ratings yet

- Marketing Strategy of PulsarDocument328 pagesMarketing Strategy of PulsarAlok Tiwari100% (1)

- Handling Unit Management Integration With Production PlanningDocument33 pagesHandling Unit Management Integration With Production PlanningpoojaNo ratings yet

- Cleaning of Analytical BalanceDocument2 pagesCleaning of Analytical BalanceFAYAZ HUSSAINNo ratings yet

- System Modeling and SimulationDocument2 pagesSystem Modeling and Simulationsalma sulthana. kNo ratings yet

- A320-214 - Yom 2014 (Sale)Document6 pagesA320-214 - Yom 2014 (Sale)Francisco SoFuentesNo ratings yet

- Drag Force ReportDocument8 pagesDrag Force ReportMateus RodriguesNo ratings yet

- Footing Schedule and Reinforcement DetailsDocument1 pageFooting Schedule and Reinforcement Detailsarif_rubinNo ratings yet

- FUSION - FS - Organizational Management - R - HR1 - 001 - V1.0-Position Details ReportDocument33 pagesFUSION - FS - Organizational Management - R - HR1 - 001 - V1.0-Position Details ReportkavitasreeNo ratings yet

- Conflict Situations Applying SLS 573 StandardsDocument34 pagesConflict Situations Applying SLS 573 StandardsCharith Dananjaya Kahingala73% (11)

- Noise CalculatorDocument9 pagesNoise CalculatorSivapriya SamyNo ratings yet

- MolexDocument39 pagesMolexMattH3No ratings yet

- Astm D1527Document8 pagesAstm D1527Hernando Andrés Ramírez GilNo ratings yet

- Bar CodeDocument13 pagesBar CodetruckturnerNo ratings yet

- IT Risk Assessment: City Auditor'S OfficeDocument14 pagesIT Risk Assessment: City Auditor'S OfficeOmerZiaNo ratings yet

- ANSI B4.1-1967 Preferredgggv Limits and Fits For Cylindrical Parts Engineering Tolerance EngineeringDocument1 pageANSI B4.1-1967 Preferredgggv Limits and Fits For Cylindrical Parts Engineering Tolerance EngineeringGym BuddyNo ratings yet

- AWS Welding Journal March 2013Document138 pagesAWS Welding Journal March 2013ferrero68No ratings yet

- Tufin Firewall Operations Management WPDocument9 pagesTufin Firewall Operations Management WPdubliner2929No ratings yet