Professional Documents

Culture Documents

HSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0

Uploaded by

عمروCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-RA-059 Mobile Elevating Work Platform Operation - Rev 0

Uploaded by

عمروCopyright:

Available Formats

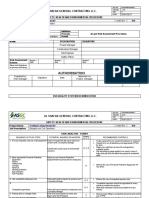

DOC No DS/CA006P02/00022

PAGE No 1 of 8

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 09/04/2016

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

Index:

Form 1 Task Analysis Initiation

Form 2 Risk Assessment Process As per Risk Assessment Procedure.

Form 3 Written Safe Work Procedure Result

Compiled by the following team:

NAME DESIGNATION SIGNATURE

Project Manager

Construction Manager

Site Engineer

Safety Officer

Risk Assessment Review 1 Review 2 Review 3 Review 4

Review Date: Date : Date : Date:

Name and Signature

of person reviewing :

AUTHORISATION

Prepared by: Approved by

Signature Date Signature Date

HSE Manager Project Manager

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 2 of 8

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 09/04/2016

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

TASK ANALYSIS - FORM 1

Impact

SEQUENCE OF TASK STEPS POTENTIAL INJURIES OR HAZARDS RECOMMENDED CONTROLS

H, S, E

1. Pre-use inspection and use of all Failure of equipment, will cause injuries to Faulty equipment to be repaired/maintained or replaced.

equipment. persons and / or property damage. Guards to be on all Machinery and appropriate PPE to be

Fuel/oil leaks could cause environmental worn.

concerns. H, S, E Engine ran machinery to have fire extinguishers available

locally.

Drip trays/heavy gauge plastic to be insitu in case of leaks

and spill kit to be within the project for accidental spills.

2. Wear appropriate Personal Protective Failure to use Personal Protective Equipment

Equipment. will cause injuries to employees.

Gloves.

Safety boots. Enforce the use of Personal Protective Equipment AT ALL

H

Overalls. times

Hard hat.

Hearing protection.

Eye protection

3. Use trained employees only Failure may result in injuries to persons and Enforce the use of competent persons only throughout the

H, S

property damage. project.

4. Manoeuvring of equipment Faulty of equipment result in injuries to person Manlift operator must hold the valid third party certificate.

and property damage. Oil leaks from the lifting Equipment to be inspected by approved third party and

equipment causing spillage / Environmental H,S,E checked by operator prior to use

damage. Passage way to be clear and not obstructed by people.

Reverse alarm and flagman required for manoeuvring onsite

5. Material Handling and Fixing while riding Failure may result in injuries to person and H,S, Permit to work procedure must be adopted.

on top of the equipment. property damage Use full body harness while on top of the manlift.

Materials should be properly placed inside the cage of

manlift.

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 3 of 8

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 09/04/2016

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

Do not keep more materials inside the cage.

Do not stand outside the rail of the cage

Barricade the underneath area avoid the people getting

closer to the equipment while operating.

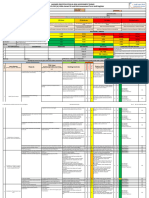

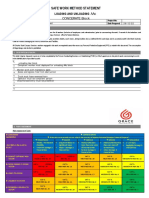

RISK ASSESSMENT – FORM 2

Risk Rating Calculation

A + B + C + D

Risk Rating Matrix

HSE QUALITY SYSTEM DOCUMENTATION

Risk Rating

16

14

8

6

4

2

0

DOC No DS/CA006P02/00022 5

1

2

3 PAGE No 4 of 8 4

AL SHAFAR GENERAL CONTRACTING LLC. 4

REV 5 0 3

6

7 2

DATE 809/04/2016

9 1

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

Injury Severity Potential Damage / Loss Frequency or Likelihood Environmental Impact

0 No injury 0 No damage 0 Never happened before 0 No effect

1 Minor – (FAC) 1 Minor < 500 AED, No delay 1 Happened somewhere 1 Minor Effect - Short term < less 1 month

2 Major – (MTC) 2 Major > 500 AED, No delay 2 Happens occasionally 2 Major Effect - Long term > greater 1 month

3 LTI 3 Major > 10 000 AED, one day delay 3 Happened before

4 Disabling Injuries 4 Serious > 100, 000 AED, >1 day delay 4 Happens regularly

5 Fatality 5 Severe > 1, 000, 000 AED, Weeks delay. 5 Daily occurrence

Risk Rating = A + B + C + D.

Result Classification:

Critical = 17►15 High = 14►11 Medium = 10►7 Low = 6►0

Immediate action. Action in 24 hours. Action in a week. ASAP.

Risk Reduction Hierarchy:

1. Engineering to reduce risk.

2. Replacement with lower risk.

3. Isolation of risk – Barricading or Guarding.

4. Reduction of exposure to risk.

5. PPE and Training

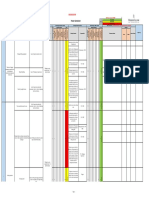

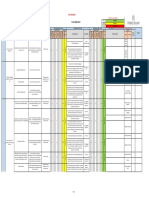

RISK ASSESSMENT – FORM 2 (continued)

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 5 of 8

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 09/04/2016

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

1 Faulty hand tools and Bruises, cuts. Gloves, trowels in good Supervisor Before &

equipment condition. during

Entanglement, Skeletal Damage. the use

Mechanical guards not Guards in place and equipment of

in place H,S,E 13 regularly maintained. equipme 6

nt

Contamination of the soil, atmospheric Care to be taken refuelling and

Unwanted Fuel/Oil pollution, risk of fire. drip trays/heavy gauge plastic to

Spillages be in place as required.

2 Injury to project Potential Death, Major/Minor Skeletal Following PPE to be worn Supervisor Before &

employees damage, cuts and bruises to all parts of appropriately to the task – during

the body, asthma. Gloves. work

Safety boots.

H,S 10 5

Overalls.

Hard hat.

Hearing protection.

Eye protection

3 Un trained employees Poor quality of work, chance for Provided trained/competent PE/FM Always

H,S 7 5

accident /incident or property lost/damage worker and supervision

4 Unsafe manoeuvring Road traffic incident involving pedestrians Operator must have the valid PE/ FM/ Always

of equipment and operatives third party certificate of Supervisor

competency.

Proper operating procedure must

be follow as per the manufacturer

recommendation.

Equipment to be inspected by

approved third party and checked

by operator prior to use

Speed limit to be imposed.

Ensure that the passage way is

clear and no people roaming.

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 6 of 8

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 09/04/2016

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

WRITTEN SAFE WORK PROCEDURE – FORM 3

1. OBJECTIVE

1. To prevent injuries to employees and / or property damage incidents.

2. PROCEDURE

1. Do pre-use inspection of all equipment to be used and replace or repair faulty items.

2. Use trained competent employees only.

3. Use appropriate Personal Protective Equipment i.e.:

3.1. Hardhat.

3.2. Safety boots.

3.3. Overalls.

3.4. Eye protection.

3.5. Face protection

Prior to work commencement

1. Must have PPE – safety footwear, gloves, hardhat, goggles, face musk, protective clothing etc.

2. Must have appropriate tools and equipment in good condition.

3. Must have weatherproof covers for materials and equipment, waste containers, warning tape.

4. Consider risks and hazards in work area. Refer any concerns to supervisor. Are relevant permits in place?

5. Check if it is necessary to secure area adjacent to work. Refer to supervisor if appropriate.

6. Arrange for transport of materials and equipment to site via supervisor.

7. Ensure materials and equipment are secure or removed when site unattended, eg overnight or during breaks.

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 7 of 8

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 09/04/2016

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

Hazards

1. Manual handling of materials and equipment – LITE to be considered at all times.

2. Slips and trips from untidy work area.

3. Falling from mobile elevating platform cage.

4. Collapse of existing structures and excavation.

5. Hazards associated with equipment.

6. Contact with sharp edges of materials.

7. Consideration of weather and ground conditions must be made. If in doubt refer to supervisor.

8. Environmental damage.

9. Fire and chemical hazard.

10. Working at heights.

Harm

Potential Death, Minor/major cuts and contusion, loss of limbs, fractures, damage to respiratory system, electric shock.

Persons in danger

1. Labour / Equipment operators.

2. Other workers/visitors in vicinity, eg. Passers - by in walkways etc.

Control measures

No lone working

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 8 of 8

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 09/04/2016

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 059

Job Description: Mobile Elevating Work Platform Operation

1. Appropriate PPE must be worn by all workers on site & special PPE should be provided for those who are directly involved in this

activity.

2. Site Induction and tool box talks should be given prior to start job.

3. Equipment to be used should be inspected and certified safe to use.

4. Employees shall be educated in keeping out of possible crush of the equipment turn into collide

5. Permit to work system should be followed by all supervisors and engineers.

6. Daily, weekly and monthly inspection to be done regularly any defect found must be reported immediately.

7. Physical barricade to installed and maintained with entry and exit points.

8. Only personnel involve in the operating and fixation activities are allowed inside the barricaded area. Enforce the use of competent

persons only.

9. All hand and power tools must be inspected before use

10. All hand and power tools must be safe for use

11. All type of power tools must be colour coded and tagged as safe for use also must be entered in register.

12. Permit to work system should be in place.

13. PPE should be worn by all operatives as per the job nature.

14. Maintain work area isolated with means of barricade and appropriate signage should be in place.

15. Remind personnel through toolbox talk to observe proper positioning when working

16. All the work should be done under the competent supervision.

HSE QUALITY SYSTEM DOCUMENTATION

You might also like

- Risk Assessment - Steel Erection WorksDocument11 pagesRisk Assessment - Steel Erection Worksmahmoud nadaNo ratings yet

- 3 MDRRMC SampleDocument57 pages3 MDRRMC SampleMakoy Salonga100% (2)

- Risk Rating CriteriaDocument3 pagesRisk Rating Criteriamalavpatel7100% (1)

- Bus and Coach Station Design GuideDocument35 pagesBus and Coach Station Design GuidemeshNo ratings yet

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- HSE-RA-016 Waste Materials - Rev 0Document12 pagesHSE-RA-016 Waste Materials - Rev 0عمروNo ratings yet

- HSE-RA-013 Deshuttering - Rev 0.Document16 pagesHSE-RA-013 Deshuttering - Rev 0.عمروNo ratings yet

- HSE-RA-040 Marble Fixing Rev 0Document12 pagesHSE-RA-040 Marble Fixing Rev 0عمروNo ratings yet

- HSE-RA-044 Painting Rev 0Document14 pagesHSE-RA-044 Painting Rev 0عمروNo ratings yet

- HSE-RA-014 Using of Cutting Torch - Rev 0Document15 pagesHSE-RA-014 Using of Cutting Torch - Rev 0عمروNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- HSE-RA-031 Back Filling of - Excavation - Rev 0Document9 pagesHSE-RA-031 Back Filling of - Excavation - Rev 0عمروNo ratings yet

- HSE-RA-030 Bulk Excavation With Excavator - Rev 0Document9 pagesHSE-RA-030 Bulk Excavation With Excavator - Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-061 Table and Bench Saw - Rev 0Document14 pagesHSE-RA-061 Table and Bench Saw - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- OHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaDocument10 pagesOHS-PR-09-03-F02 HIRA - 005 Access Road and Structure Pad Preparation For Plain AreaJaafar LagayanNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- Risk Assessment For Ceramic & Porcelain Tile WorksDocument6 pagesRisk Assessment For Ceramic & Porcelain Tile WorksFaizan TanveerNo ratings yet

- Lufkin ME: Audit ChecklistDocument18 pagesLufkin ME: Audit ChecklistmohammedNo ratings yet

- Assignment HiracsDocument29 pagesAssignment HiracsIntanNo ratings yet

- 01 WI HSE 001 - Risk Assessment BridgesDocument8 pages01 WI HSE 001 - Risk Assessment BridgesMisbah Ul Haq LabeedNo ratings yet

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Accident-Incident Report FormDocument3 pagesAccident-Incident Report Formmujahid_islam85No ratings yet

- Work Permit 2.13Document14 pagesWork Permit 2.13Oliva Del Rosario Sagpao100% (1)

- JSa For Glass FixingDocument17 pagesJSa For Glass FixingShekh BabulNo ratings yet

- 10 JSA - Cable Drums InstallationsDocument6 pages10 JSA - Cable Drums Installationssyed khaja misbhuddinNo ratings yet

- Ineco Hse Manual-SignedDocument27 pagesIneco Hse Manual-SignedTantely RazafimahatratraNo ratings yet

- Night WorkDocument3 pagesNight Workkessery koivoguiNo ratings yet

- RA Pump TemoraryDocument11 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- RA - 14 - For Waterproofing Membrane ApplicationDocument13 pagesRA - 14 - For Waterproofing Membrane ApplicationIbrahim EsmatNo ratings yet

- OHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Document21 pagesOHS-PR-09-03-F02 HIRA - 001 Mobilization and Preparation of Site Offices Rev. 2021Jaafar LagayanNo ratings yet

- JHA For BreakingDocument18 pagesJHA For BreakingRaheenNo ratings yet

- GIS Building Expansion and Reactor Installation HIRADocument8 pagesGIS Building Expansion and Reactor Installation HIRAAbdul Rasheed Mangrio100% (1)

- Sample of JHA - Roofing Top Installation Rev 2Document5 pagesSample of JHA - Roofing Top Installation Rev 2vajiravel407No ratings yet

- Hazards and Risk Identification and ManagementDocument2 pagesHazards and Risk Identification and Managementsai ramNo ratings yet

- Safety Inspection Course (With Workshop)Document86 pagesSafety Inspection Course (With Workshop)YeddaMIlaganNo ratings yet

- Risk Assessment - Concrete PouringDocument6 pagesRisk Assessment - Concrete Pouringabdullah ashrafNo ratings yet

- Risk Assessment - Hot WorkDocument6 pagesRisk Assessment - Hot Workabdullah ashrafNo ratings yet

- JSA - Baby Rollar and CompectorDocument5 pagesJSA - Baby Rollar and CompectorRaju100% (1)

- Rare GusterDocument16 pagesRare Gusterreemy sarkNo ratings yet

- OHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021Document7 pagesOHS-PR-09-03-F02 HIRA - 003 Temporary Perimeter Fencing Rev. 2021MuhammadAsimMuneerNo ratings yet

- RA For Fire A68Document11 pagesRA For Fire A68Sajid Shah100% (1)

- Ohs PR 09 19 f10 (A) Chain Block InspectionDocument2 pagesOhs PR 09 19 f10 (A) Chain Block InspectionShafie ZubierNo ratings yet

- RA - (LPG System)Document26 pagesRA - (LPG System)Md ShahinNo ratings yet

- 14.0 - Manual Handling and Ergonomics v3.1 English (Full Permission)Document10 pages14.0 - Manual Handling and Ergonomics v3.1 English (Full Permission)Amal JagadiNo ratings yet

- AHA-002, Geotechnical WorkDocument5 pagesAHA-002, Geotechnical WorkBuddhikaNo ratings yet

- Fire, Rev 0111Document85 pagesFire, Rev 0111Suraj AmbekarNo ratings yet

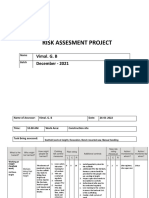

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Loading and unloading AAc blocksDocument18 pagesLoading and unloading AAc blocksAmit BhattNo ratings yet

- AHA-004, Earth Work Site PrepDocument6 pagesAHA-004, Earth Work Site PrepBuddhikaNo ratings yet

- Deep Excavation Risk AssessmentDocument12 pagesDeep Excavation Risk Assessmentdonfrancis639No ratings yet

- HSE-RA-041 Water Proofing - Activities - Rev 0Document11 pagesHSE-RA-041 Water Proofing - Activities - Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-060 Using A Personnel Bucket - Rev 0Document11 pagesHSE-RA-060 Using A Personnel Bucket - Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- RA - EIA HousekeepingDocument1 pageRA - EIA HousekeepingعمروNo ratings yet

- HSE-RA-018 Use of An Angle Grinder - Rev 0Document15 pagesHSE-RA-018 Use of An Angle Grinder - Rev 0عمروNo ratings yet

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- RA - EIA GeneratorDocument4 pagesRA - EIA GeneratorعمروNo ratings yet

- RA - EIA ErgonomicsDocument2 pagesRA - EIA ErgonomicsعمروNo ratings yet

- RISK-REGISTERDocument2 pagesRISK-REGISTERعمرو100% (1)

- RA - Concrete PouringDocument1 pageRA - Concrete PouringعمروNo ratings yet

- RA - Crane OperationDocument3 pagesRA - Crane OperationعمروNo ratings yet

- Risk Management in Industrial Companies: Conference PaperDocument6 pagesRisk Management in Industrial Companies: Conference Papermuhammad syahroniNo ratings yet

- Critical P&ID Reviews Using HAZOP/LOPA Methodology - Overkill or Underrated?Document16 pagesCritical P&ID Reviews Using HAZOP/LOPA Methodology - Overkill or Underrated?kirandevi1981No ratings yet

- Risk Assessment Process-1Document23 pagesRisk Assessment Process-1Mohd SalahuddinNo ratings yet

- 14 Miller)Document21 pages14 Miller)api-3733731No ratings yet

- Industries Du Pétrole Et Du Gaz Naturel - Estimation Des Coûts Globaux de Production Et de TraitementDocument64 pagesIndustries Du Pétrole Et Du Gaz Naturel - Estimation Des Coûts Globaux de Production Et de TraitementGeert Henk WijnantsNo ratings yet

- Wind Energy and Birds/Bats Workshop:: ProceedingsDocument132 pagesWind Energy and Birds/Bats Workshop:: Proceedingsmelita2No ratings yet

- How To Measure Your Waste: Making Waste Work: A ToolkitDocument27 pagesHow To Measure Your Waste: Making Waste Work: A ToolkitRushabh RoyNo ratings yet

- Risk Assessment Issue 1Document9 pagesRisk Assessment Issue 1api-90772375No ratings yet

- Implementation of Tie Forces For Progressive Collapse Resistance of A 12-Storey BuildingDocument10 pagesImplementation of Tie Forces For Progressive Collapse Resistance of A 12-Storey BuildingrahuljainNo ratings yet

- Mooring Incidents StatisticsDocument89 pagesMooring Incidents StatisticsАлександр Русских100% (3)

- Disaster ManagementDocument110 pagesDisaster ManagementAbdur Rashid KhanNo ratings yet

- What Is Electrical SafetyDocument3 pagesWhat Is Electrical Safety86000No ratings yet

- Brochure Isoiec 31010 Risk Assessment Techniques 1Document4 pagesBrochure Isoiec 31010 Risk Assessment Techniques 1Abd ZouhierNo ratings yet

- CISA Exam Prep Domain 1Document150 pagesCISA Exam Prep Domain 1james hillNo ratings yet

- DMA+Legal+Requirements UnlockedDocument20 pagesDMA+Legal+Requirements UnlockedAli ZafarNo ratings yet

- Practice Questions - Module 5Document8 pagesPractice Questions - Module 5Rosda DhangNo ratings yet

- CBC - Animation NC IIDocument52 pagesCBC - Animation NC IIMichael V. MagallanoNo ratings yet

- Astm E2026-07 PDFDocument17 pagesAstm E2026-07 PDFsimon100% (3)

- Motor Vehicle Mechanical Repair Workshop: Example Risk Assessment For ADocument5 pagesMotor Vehicle Mechanical Repair Workshop: Example Risk Assessment For AKimmy Lyons100% (1)

- Presentation - FAC - Risk Simulation Update 190620Document21 pagesPresentation - FAC - Risk Simulation Update 190620Dan RyanNo ratings yet

- Icao Doc 2618 PDFDocument20 pagesIcao Doc 2618 PDFPete Andre100% (1)

- Notes Pas 265Document4 pagesNotes Pas 265Files CompilationNo ratings yet

- ECA Computerised System Validation GAMP 5 Approach Live Online TrainingDocument6 pagesECA Computerised System Validation GAMP 5 Approach Live Online TrainingmezghichebiovitalNo ratings yet

- Long Blank FRA Template PDFDocument12 pagesLong Blank FRA Template PDFHani ThaherNo ratings yet

- BP Driving Standard PDFDocument42 pagesBP Driving Standard PDFWassim MansourNo ratings yet

- VCS - Tool For AFOLU Non-Permanence Risk Analysis and Buffer DeterminationDocument16 pagesVCS - Tool For AFOLU Non-Permanence Risk Analysis and Buffer DeterminationgruporeddperuNo ratings yet

- HAZOP Study Based On ANFIS Layer of Protection Analysis in Unit Kiln PT. Semen Indonesia Factory TubanDocument2 pagesHAZOP Study Based On ANFIS Layer of Protection Analysis in Unit Kiln PT. Semen Indonesia Factory TubanberlianaNo ratings yet