Professional Documents

Culture Documents

Linkbelt 90T LS 338s

Linkbelt 90T LS 338s

Uploaded by

Guruh Suprayitno0 ratings0% found this document useful (0 votes)

33 views11 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views11 pagesLinkbelt 90T LS 338s

Linkbelt 90T LS 338s

Uploaded by

Guruh SuprayitnoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

MC

o General Specifications

Link-Belt® 100-ton (90.70 metric ton)

Wire rope crawler crane/excavator

LS-338

a

General dimensions “General dimensions Feet [meters

Basic boom length, angle and tubular

(Overall width with:

{38 (0.81 m) track shoes

(Overall width for trangport = =

Tess side frames and catwalks: = =

axles In tine with upper wo | 33s

ce (ttm) tack shoes wath of cab legs catwalks wine | 338

winilom guna loronce Wath ot cab win cata both ses | Igo" | ar

‘arance undo: counterweight "A Tatowing of coumerwoight sive | der

anerweigt AB Taiswing of courterwesght “AS” wane | de

fer a earner ste ames, Overal neigh for enopert a | 40

Courier and coals unc machine use cramer side trames | 16° | 250

© [ewetcn et ctnr LLessirevong vopersteture oni so [an

GENERAL INFORMATION ONLY

eossra75 a1 Print in USA,

GENERAL INFORMATION ONLY

Machine working weights — approximate

Crawler mounting

clutch, turntabl 20' 0" (6.10 m) overall length

travel, swing bral

200" (6.10m) long crawler lower with removable side frames and 38° (0.97 m) | _Gounterweight “A” Counterwelght

wide track shoes plus the folowing: Pounds | kilograms | Pounds | kilograms

Ling crane — includes necessary drum laggings, main load holst wire rope:

done of the following booms:

Basie 5018.24 m) angle Boom s41o67 | 63 988 76 482

Basic 50° (15.24 m) tubular boom vaoisaz | 63750 | wes0e2 | 76204

‘Bragline — includes two dragline head sheaves, falrad. necessary drum

“aggings, Noist and Inhaul wire rope and one of tne Toliowing boams:

Maximum 80° (24.38 m) angie boom sarar2 | 64126 -

Maximum 80" (24.28 m) tubular boom soaer2 | 69446 = =

Clamshell — Includes two dragline head Sheaves, necessary drum laggings,

holding and closing wire ropes and one of the following booms:

Maximum 80" (24.38 m) angle boom wuosr2 | 63673 S

Maximum 80" (24-38 m) tubular boom xa0862 | 62988 = =

Weight deductions for transporting — approximate

Crawler mounting

20°0"(6.107m) overall length

Deduct for removal ofthe following Pounds | Hlegrame

Grawier side frames with = 7

38" (097 m) shows aeiso | 17900

4 (n920m) shoes gasio_| 17070

[Counterweight "a 3000 | 1130

QO feccnieweign ma S2s00_| daar

50" (16:24 rangle boom ‘3968 | 2707

50" (15.24 m) tuduar Boom 5162 | 235)

Basic revolving upperstruture iss counterweight 75.200 | 20.09

General specifications

Mounting — crawler

f wedgepacks per side frame. Four

[O] | Lower frame ‘optional hydraulic cylinders (two on Track carrier slide rails

‘each end of lower frame) provided to

assist in side frame assembly! =

All-welded, stress relieved, precision Gissassombly: drive chains temain ‘Tracks slide on rails; four rails on top of

‘machined; line bored for traction shaft. intact, each side frame.

Machined surtace provided for

{3} ae

‘Turntable bear

Ue " Cast stee!, heat treated, involute splined Heat treated, mounted on bronze

to shafts which are mounted on bronze bearings. Ten rollers per side frame.

bushings. One-piece track/chain drive

sprockets mounted on bronze bushings; ==)

‘Outer race with external ring (swing)

gear bolted to lower frame,

fone per side frame.

ese) | Tack idler wheels hinged track shoes joined by one-piece

Allwelded, stress relieved, precision {ull floating pins. 43 shoes per side

machined. Removable: positioned on Gast steel, heat treated; mounted on frame. Standard: 38" (0.97 m) wide.

‘ross axles by dowels and held in place Bronze bushings, One track idler whee! Optional: 44” (1.12 m) wide

with two patented, adjustable per side frame

Tracks

-ENERAL INFORMATION ONLY

FMC

Trackichain adjustment — Track drive inner traction shaft mounted on bronze

chains adjusted by shimming axles of bushings in precision bored lower frame.

Bain drive sprockets, Track adjusted Outer traction shaft engages spines in

with threaded adjusting bolts attached chain drive sprockets which are

to track idler (wheel) axles. mounted on bronze bushings in side

frames. Powered by bevel gear drive

7 enclosed in oil within lower frame.

G1 | independent travel

Travel speed — 0.875 m.p.h. (1.41 kmih).

Standard. Three-piece traction shat,

joined with involute splined couplings; Gradeability — 30% based on machine

equipped with “AB” counterweight, 50

‘and 44° (1.12 m) shoes.

mast and 50’ (15.24 m) tubular boom)

(15.24 m) tubular boom, boom live mast,

Steering — Power hydraulic. Travel’steer

jaw clutches hydraulically engaged,

spring released. Spring applied,

hydraulically released travellsteer/

digging/parking external contracting

band brakes simultaneously released by

interconnecting mechanical linkage,

Brakes automatically set when steel

levers are in neutral. Two 20" (0.51 m)

diameter by 4" (101.60 mm) wide brake

bbands; effective lining area 186 square

inches (1 200 cm?) per brake. Steer

brakes also serve as parkingidigging

brakes.

Ground contact area and ground bearing pressure (based on machine equipped with boom live

Track shoes. ‘Ground contact area ‘Ground bearing pressure

Counterweight Inches meters | Square inches emt Psi. KPa,

— 25,000 Ibs. 38 097 16,460 106 220 85 58.67

(17 340 kg) 44 112 19,060 122998 74 51.02

AB" — 52,500 bs. 38 037 76.460 706220, 702 70-40

(23.814 kg) “4 112 19,060 122098 89 61.37

Revolving upperstructure

Frame Turntable bearing

Allwwelded, stress relieved, precision _Inner race of bearing bolted to machined

machined; machinery side housings _ surface on under side of frame.

welded integral with frame.

[So] own

Full pressure lubrication, oil filter, oil

cooler, air cleaner, fuel filter, hour meter,

and hand throttle. Optional hand throttle

(lever type on swing control lever) and

foot throttle available. Manual control

shutdown for GM engine, electrical

shutdown for Cummins engine.

te 7 a 7g aa

oe = e 2 2

ore = = a

‘Quon TODOA 475 sing stage convrter

@iwin Disc tee stage converter

qj

406 gallon (401.21 L) capacity; equipped

with fuel sight level gauge, flame

arrester, and filler pipe cap with locking

eye for padlock.

Fuel tank

Power train

Transmission

FMC quadruple roller chain enclosed in

cchain case and running in oi.

=. |

“Full Function” design, two-directional

Power available to all operating shafts

shafts mounted on ant-friction bearings

in precision bored machinery side

housings. All load hoist, swing, and

boomhoist functions independent of one

another. Components such as gears,

Pinions, chain wheels, brake drums and

clutch spiders involute splined to shafts.

Drum geariclutch drum assemblies

led together and mounted on shafts

(oismtsttetion bearings. Machinecut

feeth on drum gears, pinions, spur

‘gears, and chain wheel

Machinery gear train

Principal operating

functions

a

ay | Control system

taste tat cama

Load hoisting

and lowering

Wire rope drum gear train (front and rear

main, and optional third, operating

drums) powered by chain transmission

from engine.

fy

Front and rear main operating drums —

‘Two-piece, removable, smooth or

grooved laggings bolted to adapter

which is splined to drum shaft. Extended

length shafts permit installation of

optional power load lowering clutches;

special length shaft required for, and

furnished with, optional planetary drive

Units for either or both drums.

— Lifting crane operation: 20° (0.61 m)

front and rear smooth drum laggings.

— Clamshell or magnet application: 20°

(0.51 m) front and rear grooved drum

laggings,

—Dragline application: 18" (0.46 m)

front and 20° (0.51 m) rear grooved drum

laggings,

Load hoist drums

Third operating drum - Optional; mounts

forward of front main operating drum.

Two-piece 13% (0.34 m) root diamater

‘smooth drum lagging bolted to brake

‘drum. Brake drum splined to shaft

Drum clutches

©

Speed-o-Matic® power hydraulic

‘two-shoe clutches; internal expanding,

lined shoes. Clutch spiders splined to

shafts; clutch drums bolted to drum spur

gears and mounted on shafts on

antiriction bearings.

Load hoist clutches — Speed-o-Matic®”

power hydraulic two-shoe clutches.

Front and rear main operating drums 30”

(0.76 m) diameter, 6Y%" (0.16 m) face

‘width; effective lining area 418 square

Inches (2 697 cm?). Optional third drum

20° (0.51 m) diameter, 5° (0.19 m) tace

width; effective lining area 218 square

inches (1 387 em?)

Load lowering clutches — Optional;

Speed-o-Matic® power hydraulic

‘two-shoe clutches. Front andlor rear

main operating drums 23" (0.58 m)

diameter, 6 (0.15 m) wide.

“ENERAL INFORMATION ONLY

Drum planetary drive units - Optional;

available for load hoist on either or both

{ront and rear main operating drums to

allow 70% increase of standard load

hoist line speed. Planetary units mount

‘on extended drum shafts between drum

spur gears and two-shoe clutch drums,

Two-shoe clutches control standard line

speeds. Planetary drive units controlled

by external contracting band brakes

through push button located on clutch

control levers.

Q.

‘Tworpiece, external contracting band:

brake drum involute spiined to shatt.

Mechanically foot pedal operated; foot

pedal equipped with latch to permit

locking brake in applied position.

Drum brakes

Front and rear main drums — Brakes 38°

(0.96 m) diameter, (0.13 m) face width;

effective lining area 547 sq, in.

(3.530 cm?)

Optional third drum — Brake 27°(0.69 m)

diameter, 4” (107.60 mm) face width,

effective lining area 256 sq. in

(1 652 cm?)

oft

Standard for front and rear main

operating drums. Two rotating dials

‘mounted on control stand: dials

actuated by flexible shaft drive from

front or rear main operating drum.

@

Spur gear

Drum rotation indicators

Swing system

driven; single bevel gears

(enclosed and running in oil) on

horizontal and vertical swing shatts.

‘Swing pinion, involute splined to vertical

swing shaft, meshes with external teeth

of swing gear

©

Speed-o-Matic® power hydraulic

two-shoe clutches. 30" (0.76 m)

diameter, 6%" (0.15 m) face width; lined

shoes.

Swing clutches

‘Swing brake — External contracting

band; spring applied, hydraulically

released by operator controlled lever.

Brake drum involute splined to vertical

‘swing shaft. Brake 18° (0.46 m) diameter,

4° (101.60 mm) face width; effective

lining area 181 sq. in. (1 039 om?)

LENERAL INFORMATION ONLY

FMC

‘Swing lock — Mechanically controlled

‘paw! engages external teeth of turntable

bearing swing (ring) gear,

Maximum swing speed — 3.20 p.m.

NS

Independent, spur gear driven. Precision

control boom hoisting and lowering

through power hydraulic two-shoe

clutches,

ja

Dual laggings splined to shaft. 1114"

(0.28 m) root diameter grooved.

Boom hoist!

lowering system

Boomhoist drum

Boomhoist drum

Tocking paw!

Operator controlled; mechanically

applied and released.

Boom hoist!

lowering clutches

Speed-o-Matic® power hydraulic

two-shoe clutches. One each for boom

hoisting and boom lowering: 20”

(0.51 m) diameter, 5° (0.13 m) face width.

Q

(One external contracting band brake:

spring applied, hydraulically released.

Brake drum involute splined to shaft,

Brake 26°(0.71 m) diameter, 4¥s"(0.12 m)

face width; effective lining area $21 sq,

in. (2071 cm

Boom hoist brake

Boomhoist limiting device — Provided to

restrict hoisting boom beyond

recomended minimum radius; located

‘on exterior right hand side of operator's

cab.

Electrical system

Battory, 12 volt, 226 ampere hour: either

‘one or two batteries depending on

‘engine. Optional: battery lighting

system, including two sealed beam

automotive type adjustable headlights

located on cab front roof, one interior

cab light and automotive type wiring,

Optional: additional 50 watt sealed beam

automotive type headlight mounted on

boom (three maximum quantity

recommended). Optional: Onan

independent light plant with single

cylinder, four cycle, air cooled diese!

engine with remote electrical starting,

3,000 watt, 120-volt, three-wire, single

hase, 60 cycles AG. including wiring in

conduit, three interior cab lights, trouble

lamp with cord, two 300 watt adjustable

flood lights on cab front root and

necessary cab extensions, Optional:

additional 300 watt floodlights available

for mounting on cab and Doom. Note:

Independent light plant cannot be

furnished in conjunction with magnet

generator package.

[é |

Optional. 27.5 kw magnet generator, belt

driven off engine power take-off shaft,

for use with 230-volt magnets rated at 81

to 115 operating amperes; rheostat,

controller, magnet lift control button on

rear drum lever, drop control button on

swing lever, and Rud-o-Matic #1848

combination taglinemagnet cable

take-up reel.

‘Magnet generator!

control package

Fullvision, equipped with safety glass

panels. Operator's door is hinged: front

window slides on ball bearing rollers.

Standard equipment includes dry

chemical fire extinguisher, machinery

guards. Optional: electric windshield

‘wiper, cab heater, defroster fan, Lexan

window panels, and sound reduction

material

i

Optional, 5° 6" (1.67 m) higher than

standard operator's cab. Catwalk is

required along operator's side.

aul

Equipped with warning horn, sliding

doors (two at rear, one at each rear side,

and one at right front side) for

machinery access, roof-top access

ladder, and skid-resistant finish on roof.

2

Operator's cab

Elevated operator's cab

Machinery cab

Cetwaiks

Optional for operator's side or both sides

of standard cab. Required for operator's

side of elevated cab. Channel and floor

plate construction with hand railings.

ral

Gantry

Fixed low, mounted to revolving

Upperstucture frame to support boom

stpenson sytem

ee

Gantry bail

Mounted to gantry headshatt. Contains

four 12° (0.30 m) root diameter sheaves

‘mounted on bronze bushings for 10:part

boomhoist wire rope reeving; six

sheaves for 14-part boomhoist wire rope

reeving with boom live mast.

On

Removable; held in position by "T"

bolts. Standard: "A" counterweight —

25,000 Ibs. (17 340 kg). Optional "AB

counterweight — 52,500 Ibs. (23 814 kg)

available for lifting crane service only;

three-piece allowing for reduction to

weight ‘A’. (Refer to counterweight

requirement instructions with lifting

‘capacity chart).

Counterweight

Counterweight removal device ~

Optional. Counterweight can be raised

‘or lowered with rope mechanism. Rope

drum splined to boomhoist drum shaft.

Counterweight is lowered with

oomhoist brake and raised with boom

hoist clutch.

Booms and jibs

Tubular boom

‘Two-piece basic boom 50° (15.24 m) long

with open throat top section; 60"

(1.52 m) wide, 54° (1.97 m) deep at

connections. Alloy steel round tubular

chords 336" (92.08 mm) outside diameter.

Base section — 25° (7.62 m) long:

boomfest 2%" (69.85 mm) wide on 54%"

(1.37 m) centers,

‘Boom extensions — Available in 10", 20',

30' and 40' (9.05, 6.10, 9.14 and 12.19 m)

lengths with appropriate length

Pendants

Boom connections — In-line pin

connections.

Boom top section — 28° (7.62 m) long.

Boom midpoint suspension pendants —

Required for tubular boom lengths

jing 150" (45.72 m).

“Two-piece basic jib 30° (9.14 m) long: 36”

(0.91 m) wide, 30° (0.76 m) deep at

connections. Alloy steel tubular chords

2" (57.15 mm) outside diameter.

Base section — 15° (4.57 m) tong:

mounted to boom headshatt hubs.

sb extensions — Available in 10°, 15°, 20°

‘and 30’ (2.05, 4.57, 6.10 and 9.14 m)

lengths; maximum jib length permitted

= 60' (18.29 m)

Jib connections — Incline pin

connections.

sib tip section — 18° (4.57 m) long:

‘single peak sheave 21° (0.53 m) root

diameter mounted on anti-riction

bearings.

eset

GaSb cer nme

‘Angle boom

‘Tworplece basic boom 50° (15.24 m) long

with open throat top section; 48"

(1.22 m) wide, 48" (1.22 m) deep at

‘connections. Alloy steel chord angles 4

x 4" x3" (101.60 x 101.60 x 9.59 mm).

Base section — 25° (7.62 m) long:

boomfeet 234” (77.85 mm) wide on 5444"

(0.86 m) centers.

Boom extensions — Bolted connections

available in §', 10°, 15", 20’ and 90" (1.52,

3.08, 4.57, 6.10 and 9.14 m) lengths with

appropriate length pendants. Pin

connections available in 10’, 20’ and 30°

(8.05, 6.10 and 9.14 m) lengths with

‘appropriate length pendants.

Boom connections — Bolted or pin

connected.

‘Boom top section — 25° (7.62 m) long

Oo

Ns

‘Two-piece basic jb 20° (6.10 m) long: 24”

(0.81 m) wide, 20" (0.51 m) deep at

‘connections. Alloy steel main chord

angles, 22" x 22" x 516" (63.50 x 63.50 x

7.95 mm),

‘Angle jib

Base section — 10" (3.05 m) long:

mounted to bracket welded on end

boom top section.

sib extensions — Available in 10° and 15°

(8.08 and 4.57 m) lengths; maximum jib

length permitted — 40° (12.19 m).

Jib connections — Bolted.

Jib tip section — 10" (3.05 m) long:

‘single peak sheave 1576" (4.57 m) root

diameter mounted on anti-trction

bearings.

Jib mast

10" (2.05 m) high, mounted on jib base

section. One deflector sheave mounted

(on antisriction bearings, mounted

within mast to guide jib load hoist line

Two equalizer sheaves mounted on top

lof mast — one for jib trontstay line, one

for jib backstay line,

Items applicable to both

tubular or angle booms

and jibs

Ce

Boom stops

Duat rail, retractable tubular typs

spring-loaded bumper ends.

‘Boom stop warning indicator — Mounts

‘on boom base section: visually warns

‘operator that boom is near minimum

radius and boom stops are approaching

seating condition. When boom stop

Gisengages, indicator is spring released

to original position.

a

Boomhoist bridle

‘Serves as connection between boom

Pendants and boomhoist reeving. Bridle

Contains five 12" (0.20 m) root diameter

sheaves, mounted on bronze bushings,

for ten-part boomhoist reeving for use

without boom live mast; seven sheaves

required for 14-part boomhoist reeving

for use with boom live mast.

Spreader bar — Arched to clear main

load hoist rope; installed at inner (lower)

fend of boom top section pendants.

Required on boom lengths exceeding

60" (18.29 m) without boom live mast,

and boom lengths exceeding 150’

(45.72 m) with boom live mast, with or

‘without jib. On boom lengths 60°

(19.28 m) through 140° (42.67 m)

spreader cannot be used with jib,

Boom live mast

Welded piate/tube construction. 30°

(8.14 m) long from center of head shaft

to mounting pin; mounts on front of

frame near boomfeet. Supports

boomhoist bridle and boom midpoint

‘suspension pendants. Required for both

tubular and angle boom lengths over 60°

(18.29 m) when using jib, and for all

boom lengths over 100! (30.48 m)

without jb. Mast may be used for

machine assemblyidisassembly, but itis

‘ot intended for general crane service

Note: Refer to Performance

Specifications for boom live mast lifting

capacities.

Auxiliary toad hoist sheaves — Two 6

(0.15 m) root diameter sheaves, mounted

‘on bronze bushings, grooved for %"

(19mm) diameter wire rope. For use of

boom live mast as a short boom.

Live mast stops — When using mast as

short boom, main boom stops must be

attached to cab for live mast backstops

to function properly. Live mast

backstops must be manually positioned.

Boompolnt machinery — Lifting crane

four 21” (0.53 m) root diameter head

‘sheaves for angle boom; five 21" (0.59 m)

root diameter head sheaves for tubular

boom: clamshell or dragline: two 26%"

(0.67 m) root diameter head sheaves. All

‘sheaves mounted on antifriction

bearings.

Boompoint sheave guards — Standard

for craneiclamshelldragline service.

Upper sheave guard: single tubular

{quard bolted to top side of boom head,

Lower sheave guards: tubular roller

‘guards mounted on anti-riction

earings; five for crane service, three for

clamsheli/dragline service,

GENERAL INFORMATION ONLY

FMC

Deflector rollers — Deflect main or third

drum hoist line off boom to avoid

chafing. Angle boom: one roller

standard on boom top section; one

additional required for boom lengths

100" (30.48 m) through 120" (36.58 m).

two additional required for boom lengths

beyond 120’ (36.58 m). Tubular boom:

two rollers standard on boom top

section; one additional required for

oom lengths 100" (90.48 m) through

210’ (96.58 m); two additional required

for boom lengths over 120° (36.58 m)

through 160° (48.77 m):; three additionat

required for boom lengths beyond 160)

(48.77 m).

Jib mast stops — Telescoping type:

pinned from jib mast to boom top

section and from mast to jib base

section.

Jib staylines — Back staylines attached

between top of jib mast and base of

‘boom top section on tubular boom. Back

staylines attached between top of jib

‘mast and peak of jib.

Boom carrying equipment — For

carrying boom in horizontal position

with live mast at approximate 15’

(4.57 m) overall clearance height from

ground. May be used with tubular booms

50’ through 120’ (15.24 through 36.28 m)

and with angle booms 60° through 110°

(18.24 through 93.53 m). Boom

‘suspension system uses two links at

each end at the 7 6" (2.29 m) pendant

Portion of basic pendants, The free ends

of the links are pinned together

shortening overall pendant length,

lowering live mast relative to the boom

Booms cannot be used to handle loads

with reduced mast height,

Auxiliary equipment

ee

Standard with either crane boom.

Pendulum type, mounted on boom base

section.

Fairlead

Optional. Full revolving type with barrel,

nd guide rollers mounted on

tion bearings.

Tagline

Optional. Spring wound drum type

‘mounted on crane boom. Rud-o-Matic®

models:

= 1248, double barrel with 20° (0.51 m)

reel for booms nat exceeding 80"

(24.38 m); for use with 1% to 4 cubie yard

(1.84 to 3.06 m') clamshell buckets

—1248, double barrel with 30° (0.76 m)

‘wel for booms not exceeding 100"

(0.48 m): tor use with 1% to 2 cubic yard

(1.34 to 1.58 m) clamshell buckets.

= 1848, tripe barrel with 30° (0.76 m)

reel for booms not exceeding 100"

(0.48 m); for use with 4 to 5 cubic yard

(8.06 to 3.82 m?) clamshell buckets.

GENERAL INFORMATION ONLY

We ee contanty inpong ou: pod and hele are he ght change cin and secatons

-7-

FMC

Link-Belt® LS-338 Performance Specifications

Boom live mast — lifting capacities when used as short boom ©

Boor ive meet adie Upper with or without courte mela

Feat aaa Pounds Tigran

Bo 306 “7300 Tava

2 30 000 aa

= ree aufo00 3608

2% B59 2000 naa

(C’Beam ive mast siops must we mproper worang sovaton and opeaive Uae | hve Wastes shor boom

Isinvengod or machine assomy gr dsaeeamBh only tanould not be aed for genaal etane series

{pent (22mm) damter hype Nw rope are equ red

(Ute mast must never be sperates a lee than 13/2960) ras

Wire rope and rope drum data

Main toad hoist wire rope length — for angle © and tubular ® open throat booms using 76

(22 mm) diameter wire rope

Fann] Boor longihe

ot | easzemy | so razem) | Taam | w asem) | so 7m) | wo noaA) |W psim) | Ws Gea

tne Feet Feet | meter | Fost | mete] Feet | meted | Feet | mete | root | maton | Fost | meters] Feet | melon

20 sw | azer [seo | serv [reo | sess | zoo | ena | 220 | erce | a} vais | amo | raze

1 zi | geor | 20 | 7935 | 20 | azo | Soo | S:4e | 350 | 0050 | Seo | roar | 300 | riser

20 bao | ese | 300 | orse| seo | roaza | aon | r2tge | dao | ioers | Yeo | taea0 | $20 | 13880

= asa | reeee | aco | 12192 | 40 | rarze | soo | t3zao | seo | teres | coo | tazae | 650 | tose

480

30

‘0 | s2e02 | 420 | taeao | te | tevee | coo | tezae | aso | dora | $20 | evece | 780 | 2arre

aso | rapas | S00 | 17009 | 20 | Iszce | 700 | Page | Tr | 25470 | exo | 25809 | O10 | dra?

seo | ioee | eso | tenor | a0 | Zveae | con | zazae | amo | dnaze | s00 | Zoee0 |s010 | Sro0o

gan | ozae | reo | 2iga5 | ero | Zues9 | G00 | Zrea2 | 900 | Jor7s |xo80 | 320.9 3.370 | a5662

Joo | 21335 | 660 | Zaaee | oo | rea f.ooo | aoeao |xsoo | Senza (i200 | gea76 |1200 | donee

bro | 22470 | ooo | 20022 | soe | 500.76 [S00 | aasze |1'2u0 | anne [rae | woeas j1ao0 | ase

ggewoe eon

ara Boom lengths

or Tao (WRET m) | 160 (45 7G m) [WO RTT m)® [170 (STEAD [Teo GARE MIO [iad GroT MO [RO KOsEATO

tne Feet meio | Feet [neler] Feet | mete | Feet | neler mete | Feet | meters] Feet | metere

7 aco [ gree | so | o7se | om | 10063 | 60 | voa79 i542 | 400 | r2ra2 | az | ra900

2 te | rse30| S10 | tases | Seo | Jered Haz | s00 | 1a2ee | bso | too02

8 00 10 | sasar | ee | 20726 | 720 | 2946 2145 | $00 | 2aee | mo | Zoe0s

‘ m0 20 | zaase | aso | Zao.00 | S00 | Sree 28086 (1000 | Soeeo [1.050 | S20ee

3 Fa So | de23r |x | Siag0 |.o80 | Sae%0 [1340 | Sura |i 00 | gosve | 1200 | Gass

é 18 tee | e090 | .s00 | Sea 7 [iano Secos (1350 | tease taao | deere [tate | seace

; 1200 2a0 | Soars aso | eso | aco | daar |1 20 tego | farae | tea | S208

4 sa fio | 43001 | 1330 | fee | 200 | faa7e [10 sco | s4oe« | seo | srsor

99 00 eae | 4ere0 | 1900 | Store |:00 | See [¥500

100) ed eo _| ssees | 7 | seoos [isco | c0n50

Dope tvoa! angle Boor lenge: 60. through 160 (1524 rough 48.72),

@ ofan teat taseler boom lengins $0 rough 200 (¥6 24 though 6936).

rosters Prntad in USA

LS-338 performance specifications

<@ENERAL INFORMATION ONL

Wire rope and rope drum data — (continued)

Jib load hoist rope lengths (whipline) — using %" (22 mm) diameter wire rope

mae Boom rahe

we | ot [sriseem [eo rezia) [Wem [Mem | wera) [ease [ne Gam [as Gea

tengo | tse [Feet meters] Feet | metore| Feat | melon

et [ motor | Feet | meters | Feat | motors | Feet | motors] Feet [ motere

nO eo | aa77 seas | 200 [ coos | 220 | 7a6 | 240 | 7915 | a0 | ro2s | 200 | ocae[ aco | over

wiom | > | as | ne e077 | 295 | sve | sas | S906 | Ses | sosz0 | Sos | siras | tis | s2ean| aus | san0r

= TH | Sa aoa] Bao | ero Hu | ITS | BO] ees | RS | as ae | B00 aa] 750

oisem | 2 | oes | oar e901 | 325 | see | 555 | 10920 | S00 | irae | aia | s2eas | 5 ais [yaere

7 2] aoe Brox] 2 | Fate 7% [aa asse | am | aes | ae 300 [raze

arem| 2 | tes | soae | soos | 355 | onze iris | a5 | 2649 | as sas | 275 sos [15392

are za | ered 7a95 | 260 | 728 eae] soo | rae | a | ora | a 360 | 7

stom | 2 _| 825 | sae a 20 | 395 | 11795, rasa | 4s 135 | 475 | secre | $05 Soe_[ reo

| ao ea | a Toa | 2a] 530 Brae | aa | ores [oo | 10aee | 280 750

wwzam | 2 | 455 | 0820 | 45 | siras | aie | veens | aus | rosea | ae | suse | soo | razee | 20 565

ao" | Yo— 7S | seo | vise | woo | 12192 | «2d | waa | ew [raet | wea Piao | aad Pre

ga0 | reser [a0 [aves | a= ee

es | 17221 { sop | tase | as ss | roves | bes | 20070 | M3 | aire | Jes

0 @ [1] ao | rater] e20 | vzace | 400 ‘60 | f00zi | aan [raeae | soo psa | S20

sz [2

Qaraie Boom ony

© tian angle Boom lange on whieh y> e2% be movntes is 160! 45.72 m). 180 through 190° 4877 trough 67.91 m) boom lengtns

bes _| 20070 | m3 | 2570 | ras | aro | 975

[tase | a2 | tose | 666

Drum wire rope capacities

Front or rear rum — 20 @ar my ‘Beonnarnt oun — hw (22m)

‘oat dametor smooth iag9ng Foot ameter smooth lagging

ane Te Erm wire rope TRE wie Pe Ye (18 nm} wir rope

‘ope [Rope periayer [Total wa rane Rope per ayer Tot Teal wie pe

‘ever [Feet Feet [meters | Feet Feet Feat [maton

us| ser |e 105, = | oer

as | rae | i 28 nm | pe

go | are | ib ar wa | S700

Sos | tare | tae to vs | 4

5 vai | dare | ise est ne | fan

e as | 2am | we e3 pa | as

: ns | Sao |_ is 58

é tas | Gore

Front orrear den = 207057 a7 eon arom (ahaa) — ae aaa)

‘grooved tagsing| rect diameter grooved Feat diameter vmooth lagging

Te (2) wie rope Teme wire Te (22mm) wire rope

ope par leyer Total wire ope Rope per layer [Total Tayer rere

ireiors | Feet | meters | Feet | motors | Feet | mete | Feet | mete | Feet] meter

aes [ime | see | o | zee | 95 | zom | a | reco | a | ooo

Bi | 2a | sear 338 | se | aoa | & | dees | sme | Stee

4220 | jan | sea | iz | asses | ae | seas | we | S200 | per | anes

a7ss | se | esr | ioe | Soa | us | sane

goo | mo | zea | sn | 4263 | seo | sees

siss | or | zo3s | i | “eas | de | Here

sroo | some | gers | tee | aoa | a | zrese

goss | uzre | sern_| vs | S273 | vorr__| aaaar

Mc

LS-338 performance specifications

| Ser

soon _| ee | me | as |e | os ee jin | 88 |S | 28 | 'e | ae

Thad arom — 8 tayo aloes

oot iegping using 22 mm) ametex wie rope ‘

reaeeUbe eed 2ENERAL INFORMATION ONL

singe unetoeg® [Frat yerrope | Second ayer rope [Tht eros

Poveds | wigan | tom [min | rom | minie[ tam | mini

sow ] 2260 | a0 | ore | ae | eras | a0 | voose

yoaw | 4 | 2 | re | Se | seer | de | tose

sow | See | ae | fas | on | fae | os | tre

soon | Soe | fe | om | fy | Bo

Oo:

s5pcable only to Curing N&S5.P235 angine package. lf regured Sin data for

pin pasuages avaabc from Sales Otten,

©Wax mum perms ond en singe part aflne. 22,700 Ibs (10237 kg) for "(22 mm)

iamterType"N wir ropa a aa0 ‘be (6719 4g) fr (2 mm Type we ope.

39100 tbe 19 427 Xp) tor Be mm amet ype "Nw spe

@ivsenina quipped wih sptonal high apeos planetary drum ere nis

ie re constant imsroung our proauels and herlore fener the night lo change designs and specifiemions

FMC Corporation Cable Crane and Excavator Division Cedar Rapids lowa 52406

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TF Roof Access PermitDocument1 pageTF Roof Access PermitGuruh SuprayitnoNo ratings yet

- TF - Use of Suspended ManbasketsDocument9 pagesTF - Use of Suspended ManbasketsGuruh SuprayitnoNo ratings yet

- Trailer Pre MobDocument1 pageTrailer Pre MobGuruh SuprayitnoNo ratings yet

- Excavating Fibrous MaterialsDocument7 pagesExcavating Fibrous MaterialsGuruh SuprayitnoNo ratings yet

- 0107 DART MIER ReportDocument2 pages0107 DART MIER ReportGuruh SuprayitnoNo ratings yet

- Hydraulic Crane Pre MobDocument1 pageHydraulic Crane Pre MobGuruh SuprayitnoNo ratings yet

- TF Scaffolding ProcedureDocument11 pagesTF Scaffolding ProcedureGuruh SuprayitnoNo ratings yet

- TF Respiratory Protection ProcedureDocument10 pagesTF Respiratory Protection ProcedureGuruh SuprayitnoNo ratings yet

- Vision Screening ProcessDocument1 pageVision Screening ProcessGuruh SuprayitnoNo ratings yet

- HazMat FormDocument1 pageHazMat FormGuruh SuprayitnoNo ratings yet

- HazMat Form Hyd Oil Shell TellusDocument1 pageHazMat Form Hyd Oil Shell TellusGuruh SuprayitnoNo ratings yet

- High Pressure Water Cleaning (HPWC) Procedure Typical HPWC Lancing ArrangementDocument1 pageHigh Pressure Water Cleaning (HPWC) Procedure Typical HPWC Lancing ArrangementGuruh SuprayitnoNo ratings yet

- 442 Forklift #CF18C-82775Document51 pages442 Forklift #CF18C-82775Guruh SuprayitnoNo ratings yet

- Respirator Inspection and Maintenance RecordDocument1 pageRespirator Inspection and Maintenance RecordGuruh SuprayitnoNo ratings yet

- JOB DESC Ade TopanDocument2 pagesJOB DESC Ade TopanGuruh SuprayitnoNo ratings yet

- HazMat Form Engine Oil & Hyd OilDocument2 pagesHazMat Form Engine Oil & Hyd OilGuruh SuprayitnoNo ratings yet

- Part & Consumable ReportDocument6 pagesPart & Consumable ReportGuruh SuprayitnoNo ratings yet

- JLG 800a 800aj PM 2011 1Document454 pagesJLG 800a 800aj PM 2011 1Guruh SuprayitnoNo ratings yet

- Linkbelt 90T LS 338bDocument8 pagesLinkbelt 90T LS 338bGuruh SuprayitnoNo ratings yet

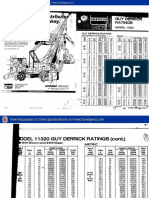

- American 11320 With MastDocument4 pagesAmerican 11320 With MastGuruh SuprayitnoNo ratings yet

- Service PERIODE JUL-AUG PT. FreeportDocument2 pagesService PERIODE JUL-AUG PT. FreeportGuruh SuprayitnoNo ratings yet

- Scope of Work MechanicDocument4 pagesScope of Work MechanicGuruh SuprayitnoNo ratings yet

- Scissorlift Skyjack8mSJ3226Document2 pagesScissorlift Skyjack8mSJ3226Guruh SuprayitnoNo ratings yet

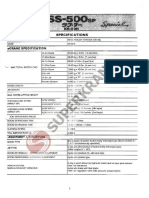

- Kato 50T SS500SP (50t)Document7 pagesKato 50T SS500SP (50t)Guruh SuprayitnoNo ratings yet