Professional Documents

Culture Documents

442 Forklift #CF18C-82775

442 Forklift #CF18C-82775

Uploaded by

Guruh Suprayitno0 ratings0% found this document useful (0 votes)

60 views51 pagesOriginal Title

442 FORKLIFT #CF18C-82775

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views51 pages442 Forklift #CF18C-82775

442 Forklift #CF18C-82775

Uploaded by

Guruh SuprayitnoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 51

SATOIL

CERTIFICATE OF THOROUGH EXAMINATION

‘This per caps wih Ling Ease gers Asin Toei eutornts

[uiza 4130 indonesia.

Dats Theagh earinaion [past Reeat [ome We

‘onie2a soueezs sooucssanves

EBS eG Tt Wa SS AC NW STR [>is ot promises a which the eraminaton was made

lp. Superirane ira Vara,

[nay Cain Cina N98, RT COS, Kel Sper Barat, Kee: Cin, tata Werkenop PT. Supatone

[Description and aniNCaT oT e SRUSRATT TSS

Forxit sae Wrng Los leraminatin

ne Leg ecarce ‘Sy Worang Lod

jos roa en)

Sena eer Crceers

esmcey este

Wwansacue wenn

2.510

| Proctor |

‘cute unt

Tetons

esto sne os nowdieas. opin nap tetaren crn en ce

“Tpe epee Se

aa Paar oe wee OATET Tt

[Was be eamntin corto

sts te tat examination ater instaoton or assonbtyat [Te Toa] cy] fem enmerwtetmenner =lol=la

new eo or cater?

[renin anne of12 mans? ves | & [no [T}

ne snort abo unten s YES ns he gent en pees ws] O] xo] 2

ae fs] [vo [] fn eriton ste o

|r tmcccurw decmtanscranstness? | ves |G | xo [

Saas aya Sasa ET a a US SSN Sa OT

cre ve HONE)

won

stm at ect ich itil dagen pons "Note Tea pret =o]

ste a a act wich aly ba cad Dane OS] aa

(Yes sec wen)

Pa ee oto BS TR TSH OS RT TE

PaaS a OT os SRST TOME

PiReport soauewuaniss

15 TH'S EQUPMENT FIT FOR PURPOSE yes| a [nolo

rs AEA) Wi

Jur er Lori, LEEA ODE, ABA, ASL

IPARIGAS ABAAK3U, foresee

Rane Geaicaions ed pasanmaling RS [Vane oe pam aaECaEG MPT

[ost ca by wih nt reg a

ar24

JL Taman Tekno Blok E3/No.10

BSD ~Tangerang 15314

(021) 7587-0022

F (021) 7587-0048

E info@satoilcom

www.satoil.com

SATOIL

PT. SATOIL

‘Taman Tekno Biok E3/No.10 BSD-Serpong 15314

Telp : 462 21 7587 0022, Fax: +6221 7587 0048

MAGNETIC PARTICLE EXAMINATION REPORT

Name & Address of equipment owner Customer: [acoor Naber:

Pr Superkrane Mira Utama so.oa/c/aaapuye3

ib Desaroton bate often Marz

Desciption of |: Foktte

Ecipment ob Location Workshop PT. Supertrane

Equipment Type: Ung Appliance lMPtProcedure No. : SAT-P.OPROSE

seria Number: cruace2775 Jcceptance Cetera AWSDLI/DLIM; AWS D141

Jou 12,5Ton Joust Requirement: ASTILE700.01

Material Type + carbon Stel Magnetization Techniques + YOKE

Welding Process + SMAW Euipment Serial Number

surface Preparation: ASWELDED, Wire Brushing, BaseMetal [Magnetization Currents: PERMANENT

Metal surface Temp: Ambience Temp. Examination Medium Wer visible

ight Meter wa Intenaty: Clear Daylight [Technique + Wet Continous Method

Black ight Meter: WA Intensity: WA naaterit Product Manufacture: Batch Not Sx:

iting Catbration 10\bsatainehegs Yoke maxctst _|teaner SKS Magnafux 160608 Jun23

Post Cleaning wipe lwite Contras cr? —-Magnalcx 190607 Jun23,

Stage Examination + Before oad test IMagneticParticle HF Magnaflex 210203 Feb-2d

[Application ‘Spraying

Field Meter Brand / strength: WA

eld indicator A

Residual Meter Brand wa

JDemagnetization Process: WA

; Ineation interpretation

no] partortsamination | Locaontoine umber | HHO] type otoetect | MEP PUTE | omar

Tapper ¥ oa YS Tone

Tet Lower ¥ os Ye ene

fight Upper ¥ NIA Yes None

Fight Lower ¥ mI Yes one

* Fork ‘Left Upper ¥ N/A ves ‘None

Tet Lower ¥ oa YS None

fio oer ¥ WA YS ene

Fight Lower Le NI YS None

Picture of eulpment: See Atachment

[Result of inspectio

Visually the structures are in good condition. During the MPI inspection no found indication in inspected area / Accepted

‘Name of person making this report

MT/PT Lev Il, LEA, OCE, AKQL, IPA MIGAS, IABA.AKSU,

SA

tL

Reviewed and.

raved By =

SAT-#-oPR.005-F (Rav.02)

SATOIL

PT. SATOIL,

Taman Tekno Blok E3/No.10 BSD-Serpong 15314

Telp : 462 21 7587 0022, Fax : +62 21 7587 0048

MAGNETIC PARTICLE EXAMINATION REPORT

Name & Address of equipment owner/Customer : [Report Number:

PT. Superkrane Mitra Utama $0.04/c/a42jin/23

[ob Description 7 ate of Test ‘o-Mar23

Description of Forklift,

Farad lob Location SAT-P-OPR-0S6

Equipment Type _: Lifting Appliance NPI Procedure No, (02/SAT/V¥/2010 Rev 01

Serial Number +: ¢F18C82775 Jacceptance Criteria ‘AWS D1.1/D1.1M; AWS 014.1

swe Ton Jouality Requirement: ASTME709-01

PHOTOGRAPH ATTACHMENT

Pm

|

Forklift

Name of person making this report ;

TOIL

Armand Zachary

TI PT Lev Il, LEEA, OCE, AKSL, IPA MIGAS, IABAAKSU,

ne By

Adi Latenrisau

Director

SAT-P-OPR-005-F2(FEV.2)

SATQIL

PT. SATOIL,

‘Taman Tekno Blok E3/No.10 BSD-Serpong 15314

‘Telp : +6221 7587 0022, Fax: +62 21 7587 0048

ws

MAGNETIC PARTICLE EXAMINATION REPORT

[Name & Address of equipment owner/Customer: Report Number:

PT Superkrane Mitra Utama ‘sooajcyaaz/uy/23

Hab Beseaton, Date of Text + Marz3

lovscription of Forklift

eaehsnans lob tocation Workshop PT. Superkrane

Equipment Type Lifting Appliance MPI Procedure No. ‘SAT-P-OPR-056

Serial Number = cF18C-82775 [Acceptance Criteria AWS DLI/DLAM; AWS 014.1

[sw £2,5Ton [Quality Requirement: ASTMET0S-01

Maternal Type Carbon Stead [Magnetization Techniques + YORE

Welding Process: SMAW Equipment Serial Number

Surface Preparation : AS-WELDED, Wire Brushing, Base Metal | Magnetization Currents PERMANENT

[Metal Surface Temp : Ambience Temp. [Examination Medium Wet Visible

ight Meter NA Intensity: clear Davieht Technique Wet Continous Method

Black ight Meter: WA Intensty: WA ate roduc Manufacture: Batch No: apie:

iting Calibration + 10Ubsatainch egeof Yoke maxcist [Cleaner SKCS Magna 180608 Jun23

Post Cleaning Wine white Contras WCP-2 —Magnafsx 190607 un

stage Examination + After Load Test Magnetic Particle 7HF ~——-Magnafx «210703. =Feb-2a

Lapptcation soraying

iets Meter Brand /Strength : NWA

ret indicator A

Residval Meter Brand NA

Demagnetization Process: N/A

: Indeation interpretation

ne] raorcuaminion | toetin/ein number | PHT peoteteer | SERN | pemars

Teton ¥ Wa Ye Tom

Tet Lower 7 Wx ve ene

Tight Upper v WA ve Tone

Tight Lower 7 WA 1S None

: Fork Teft Upper z WA ve Tone

Toft Lower 7 WA 1S None

ght Upper 7 WA 1S Tone

ant Lower 7 WR 1S. one

Picture of equipment: See Attachment

Result of Inspection :

Visually the structures are in good condition. During the MPI inspection no found indication in inspected area / Accepted

‘Name of person making this report

4

‘Armand Zachary.

MT/PT Lev ll, LEEA, OCE, AKSL, IPAMIGAS, IABA,AK3U.

SA

Reviewed and Approved By

"si Latensisau

Director

SAT-P-oPR005-F2 (Revd)

PT. SATOIL

‘Taman Tekno Blok E3INo. 10 BSD-Serpong 15314

‘Telp : #62 21 7587 0022, Fax: +6221 7587 0048

cone

MAGNETIC PARTICLE EXAMINATION REPORT

Name & Address of equipment owner/Customer: [Report Number :

PT. Superkrane mitra Utama so.o4/c/aazui/23

fab Beseristion 7 Date of Test = SMan23

Description of + Forklift,

gulooent: Lob Location ‘SAT-P-OPR-0S6

[Equipment Type _: Lifting Appliance ut Procedure No. = 02/SAT/VI/2010 Rev 01

Serial Number 1 CFLBC277S [Acceptance Criteria = AWSD11/D1.IM; AWSD14.1

swe , STon lcuaity Requirement = ASTME709-01

PHOTOGRAPH ATTACHMENT

Forklift

‘Name of person making this report

oe J

MT/ PT Lev Il, LEEA, OCE, AK3L, IPA MIGAS, IABA,AKSU.

‘SAT-P-OPR-005-72 (€V.2)

INSPECTION REPORT @ Interm

5 A ir 0 IL No.SO.04/R/442/N23 O Final

Ref: BS 1SO 5057:1993

Project: -

Name & Adress of enployer for whom the

| inspection : PT. Superk: litra Utama

Vendor (Equipment ‘Owner) : PT. § 7 ‘Superkrane Mitra

Teepection Requested by PT. Superkrane Mitra

Utama,

Equipment Description Type Equipment Model

Forklift NA FD25ND

Capacity Manufacture ‘Year BuiltlUsed

2.5 TON Mitsubishi 2019

‘SUPPLY / SUBJECT OF INSPECTION

ITEM / TAG NrJSerial No.

Docume Review, Physically Inspection

Destructive Te

Visual Inspection, Non CF18C-82775 tEa

and Proof Load Test

DOCUMENT OF REFERENCE: See continuation sheet for additional documents: LI Yes INO

Title Roferonce No. Rov. |___ Approved by Date

Cerificate of Thorough 7 ; 10 er

eo '$0,04/RU442/1U23 PT. Satoil phe

Mitsubishi Heavy

Cottiicate Of Origin (MFD-15-0081 : Industries Forkit | 90 Jul2019

(Dalian ) Co.,Ltd.

Emmission Gas Test 2023-03-AN-3993-N - ao

i Direkrokrat Jencral_ | 10 Feb

Centicate OF Migas | 107/S6-225/PA/DMTIZ020] - | grey oraeneal | IES

| 31 Aug

Certificate Sprak Arrestors a 7 Donaldson pon

Maintenance Record : 7 Superkrane 63 Now

‘Manual Book - Mitsubishi :

Reference Standard : BS ISO 5057:1983

Doc. No. SAT-P-OPR-005-F9.MA

SATOIL

SAT 0 IL INSPECTION REPORT @ Interm

No.SO.04/R/442/1/23. O Final

INSPECTIONS:

(09 March 2023, WS Superkrane

‘Stene of inspection: Inspection Activities:

«© Before manufacturing = Presnspection Mesting

f During manufacturing a Wines

8 Final © QC Inspection

Packing 5 Quality Audits

1 Factory Acceptance Test (FAT)

Type of inspection: 2 Site Acceptance Test (SAT)

5 Others

4 New ingpoction

5 Existing inspection bi a

21. CM 1 5, Mechanical Retating

Pactquip, Critical: 22. Piping 2 Process

= Rating 1 Rating 3 53. Prpoine [rT and Telecommunication

Rating 2 Rating 4 oa eal mothers, Fork it

© 5. Mechanical Static

‘Stamping:

Doc. to. SAT-P-OPR-005-F9.MA

gat oe

No.SO.04/R/442/1/23 O Final

SAT 0 IL INSPECTION REPORT @ Interm

l

Resuit of inspection: Satisfactory Unsatisfactory

(include NCR Number where required): NA

SSSR taved dag rote prod WA

© ListoFoutstanding NCR's : WA

Main Conclusions and Remarks: for details see continuation sheet)

‘Satisfactory

Nest vai scheduled: N/A

Description of the inspection carried out (Al the following fields should be filled out)

+ Attendees:

= Armand Zachary

Applicable Documents & Status Approval (List down the type of documents reviewed &

endorsed)

+ Cettificate of Thorough Examination

+ Cottiticate OF Origin

= Emmission Gas Test

= Certificate OF Migas

= Cerificate Sprak Arrestors

= Maintenance Record

= Manual Book

Manufacturing Progress Status (Complete. On-going, % completion)

= Completed

Dotalts of inspection activities carried out with respect to scope of work.

(Please describe the type of inspection carried out on the below space)

= Document Review

= Physically Inspection / Visual Inspection

= Non Destructive Test

= Proof Load Test

Result of inspection:

= Accepted

Inspection Finding:

- None

Date of issue: 10 march 2023

| lnspection center: WS. Superkrane

Distribution: EICLIENT [CO MANUFACTURER:

Doc. No. SAT-P-OPR-005-F9.MA

INSPECTION REPORT @ Interm

s A T 0 | L No.SO.04/R/442//23 {2 Final

annex

ocumenTs REE

0 erxcnoNTEn DOGTMERTS | ew RESULT

7 Certificate of Thorough Examination Yes Accepted

& Certificate Of Origin Yes Accepted

3 Emmission Gas Test Yes Accepted

4 | ete OF Niges Yes =

s Certificate Sprak Arrestors Yes Accepted

| [6] Maintenance Record’ Yes ‘Accepted

| 7 Manual Book Yes ‘Accepted

—

‘sua. misemcnon

poet

wo TNePECTION TEM 7 — —] werecnow nesuct

1 Inside Cabin Yes Accepted

3p ana Yer |

3 Tyre condition and reserve Yes Accepted

4 Engine and transmission group Yes Accepted

5 | Rotary and lamps function Yes [Accepted

Tangerang Selatan, 10 March 2023

SAT ZIL

{ Armand Zachary)

Doc. to. SAT-P-OPR-005-F9.MA

SATOQIL

INSPECTION REPORT

No.SO.04/R/442/1/23

@ Interm

O Final

Doc. No. SAT-P-OPR-005-F9.MA,

SATOIL| INSPECTION REPORT a Interm

|

No.SO.04/R/442/1/23

O Final

‘Photoghrapic details

™

SF:

Ss

View of Inside Cabin

View of Emergency Stop

View of Spark Arrestor

Doc. io. SAT-P-OPR-O05-F9.MA

SATOIUL

INSPECTION REPORT

No.SO.04/R/442/123.

@ Interm

O Final

Photoghrapic details

View of Machine And Battery

Doc. No. SAT-P-OPR-005-F9.MA

INSPECTION REPORT @ Interm

s AT 0 I L | No.SO.04/RI442/23 O Final

Photoghrapic details

Doc. No. SAT-P-OPR-O05-F9.MA

INSPECTION REPORT @ Interm

Ss AT 0 IL No.SO.04/R/442/23 O Final

| CERTIFICATE OF

| ORIGIN

sat Nt

Doc. No. SAT-P-OPR-005-F9.MA

MITSUBISHI HEAVY INDUSTRIES FORKLIFT(DALIAN) CO.LTO.

vom vgs sus a soe ss a

‘at acon 2018

Meo EF NO. ro 18-006

TO WHOM” MAY CONCERN

CERTIFICATE OF ORIGIN

Vie hereby certily Lua ful aweig guuds have Leen manutactured in China’ by

MITSUBISH! HEAVY INDUSTRIES FORKLIFT(OALIAN) GO.LTD.

DESCRIPTION

SUTEEN 16) UMTS OF MET EURIGH! FORME

Tove unais rotti ZSiWe GYC O LMD WS". ACR Wak 10.

‘oe Unt raven srPa0. SVK S¥e.3 LIBID Pee ACR PART FOO.

Five's) wars FOIOAT 2FPaD YR. 310 LIO7D FS:PS ACAIT PARTE TOOL

TWEE “Urs “bash agPa0 CyB/O Lose 8-Hs. Ad Haren. Tam

One an ORK TEND OVD IW PA ane ToOL

Two i ners roan PRG ENE HRD is 1g acer Pat TAM

One runt votant ue av8 Gye Bitov0 vs soar Paar TOO

‘OME "11 UR FORSN AFPQO C¥o/D'LIOPG Pong ACKIT PARTE, TOOL

eras rT we me

stan ssea9 Forow oF 86 so1as sas

te ett Fomouo CF so-s0150 Sas

Paty Fomut —€F 80 30151 ‘545 398203

Beast Fost Ss tow,

fe Metdarhgeaes osu Sissuaiat

1 stores Fost Bene

1 stn toes Foamt as Sens

1 igor 1987 Fost 45-398

ato? 1205 Fast Sass

fa sina rosso Bas ae

He stgartaa5 Fousno 545-3369

ean 9998 roe 45 3152

(ta a Fomud —Gers-aniis~ Sas aed

Io sn 418s Fomuo —cr'sc-aniie Sasa?

eee Foam Ge sonar ene

TsuR 9H wEAvY MOUSTES FORKLIFT BAAN 60.4

e900 weyrivaissmwos SaReLSTON ASH MEINEM

Sscu0tt sr weer 4 2 anweus

eanee-Se8 ouze-op. 39 Oizo

since 505 ‘nea

erect Se Guiza fc gs

esos, ‘iieas Sec-et/zsi-n

suber ses urea feccet eet

Seance sts, uee-o8.29 eas

zoe S65 Woo ri teas "

ott SS 908. 3r10 ante “

cee-SHS on-3iso Iutead seeeet/bsLan

cance Se8 ‘eto 99.49 Nea fin a

teovee-sre oploe-on 39 reas fein

subs Ses frioe ona sevad ees pst

TS OnE REO OO —— EET stvi30

oo ahve LOY S¥Sd OUOFT O1940 OCU UAGEOL LNA BNO

Nook HAV ID Set St 0:01 Q-O80 AC FelsE INEZOY HME NO

°C inva mow str sn gto Y QA Daa wee tne 2) Ott

“WoG1 BUNS. LOY Sa Se OL017 G’O19 Orde AVGROS LNT 3H

IGoL wiawe ing Se Se 90011 G/OAD OegSe CheTO= NT IHRM

Yoo Buta INOW Ses O01 G98 NAB ORasEL8GC0) Uns 3A

Noo: Einva uNOW. Sata WUBIN C°DAD MAP Dede nNEeA LIN I

ToeH Bi IHOY SA'SA BOLD 1-319 Oeasz MEY SIRN-7) Ot

{Het sensan se Su f0h aaa

Nouawos30

‘GL7°09 (Nyriva)LaT HOS SIRUSNONI AAVSH T4SIENSLIA,

quip Ww peunvaeytes s|q AMM KpONF FusnD oy win aw ANI ON

NIDIUO JO SLVOISILYIO

NasONCO AYH1 LOH OL

100-5 a OV.s38 aan

alo sige et

es gem eenes cas eeartoen

\yrrso 0ce0: | Wikiw CIACOTIATC HvTIWA_ 17H, § AOHISNVL ON

“G17°09 (NVTIVG)LTIOS S3IILSNONI AAWSH THSTANS.LIW

3355553

eo? enor SIRN 7 Out

20 So ta Nao

Nouanos30

‘SaRuLSNoMI AAYH IHSINSLIW

"vag ary spood Hun yay yer Ansa Aq

NUBONCO AWA 1 ACH OL

‘S.7e0 ayTvO:L THEO SSRASNOM MASH STENSLIA

vzeee-s¥5, ceeeo80 unezas

uibce-srs Meee 2 9

teooee-srs mute-38 23

beinee srs 25m 08.59

tsiaee Ss Grune 2

feiss are fate

Suisse fume 3

‘oote-sts ate-o8. 29

rene aes

fever sre aon.

tance fre ‘oe tao

water srs oso cima:

Stage srs soni OO

teeece sos feiae 30-2

5100-08 30"

ae

"eel hge Tao Se onsen

aa

x

S nottawos30

smuusnon anyon nisansin

zag anny spoom Bawa yo} ein AED Aq DN

{REZONCO AW I ROHN OL

sreezastiseeve sera nant

1 Ya8Y INMeOTINIC NYTI¥O 1778.5 NOTIBNVL 86.0%

HOS S3RLSNONI AAV3H IHSIBNS.LIN

INSPECTION REPORT @ Interm

s AT 0 IL No.SO.04/RI442/23 O Final

CERTIFICATE OF

MIGAS

SATQOIL

Doc. No. SAT-P-OPR-005-F9.MA

KEMENTERIAN ENERG! DAN SUMBER DAYA MINERAL

REPUBLIK INDONESIA

DIREKTORAT JENDERAL MINYAK DAN GAS BUMI

GEDUNG IBNU SUTOWO, JALAN H.R. RASUNA SAID KAV B - 5. JAKARTA 12910

KOTAK POS : 12961JKT 100.12 _TELEPON: 21) 5268010 (MUNTING) _FAKSIMMLE : (021) 5269114 e-mail:

BERITA ACARA INSPEKSI dan PEMERIKSAAN KESELAMATAN

Nomor : 107 / 56-225 / PA / DMT / 2020

Pada hari ini Senin, 10 Februari 2020 di Jakarta teish diaksanakan inspeksi dan pemeriksaan keselamatan pesawat angket

antara PT. Superkrane Mitra Utama Tbk., Perusahaan Inspeksi PT. Indo Yasa Prima, dan Inspektur Migas dengan hasil

sebagai berikut

1 DATAUMUM

Pemilik 2 PT. Superkrane Mitra Utama Tbk.

Item No 2 FLD25-2

Serial No 2 CFI8C- 82775

Model 2 FDQ5ND

Tipe Unt Forklift

‘Kapasiias 2 20Kg

‘Boban Kerja Aman (SWL) ‘2500 kg Pada Load Center 500 mm

Maksimal Tinggi Angkat 24000 mm

._ Pabrik Pembuat 2 Mitsubishi

Tahun Pembuatan 2019

Digunakan 2 m2

Pabrik Mesin Masubishi

Nomor Mesin SAS 336168

Putaran Mesin 35:3 KW 2250 p.m

Lokasi Digunakan 2 Area Papua

I PEMERIKSAAN VISUAL MENGACU PADA ASME B56.6 UNTUK FORKLIFT

Berdasarkan dari hasil pemerksaan tampak mata, Kondisi terhadap Forkift secara umum Kondisi balk dan dapat

beroperasi

Ill PEMERIKSAAN UJI TANPA RUSAK

Pemeriksaen uj tanpa rusak dengan metode maonetk partie! pada

1. Fork tidak diketeruan kondis retak

2. Sambungan antara Fork dan Arm tak diketemukan kondisiretak

3. Sambungan pin boom tidak diketemukan kondisi retake

KEMENTERIAN ENERGI DAN SUMBER DAYA MINERAL

REPUBLIK INDONESIA

DIREKTORAT JENDERAL MINYAK DAN GAS BUMI

GEDUNG IBNU SUTOWO, JALAN H.R. RASUNA SAID KAV B - 5. JAKARTA 12910

KOTAK POS : 1296/JKT 100.12_ TELEPON : (021) 5258910 (HUNTING) _FAKSIMILE : (021) 5269114 _ e-mail:

IV, UJI FUNGS! PENGOPERASIAN

1. Penguin fungsi pengangkatan dan penurunan Fork tanpa beban dalam kondis balk.

2. Pengujian fungsi pengangkatan dan penurunan Fork dengan beban dalam kondisi baik.

3. Pengujian fungsi sistem pengereman dalam kondisi bak.

4, Pengujian pada saat berjalan datam kondisi bak

5. Penguiian fungs safety device system berfungsi dengan bak.

6. Pengujan fungsi penyalaan lampu dalam kondisi balk.

V. UJI FUNGS! BEBAN

Pengujan Fungsi Beban mengacu pada ASME B56 6. Beban tidak melebihi rate load. Dan mengacu pada tabel beben

‘dari pabrik pemibuat.

Tigi rlean rm] Becton | 20d Cener [meen ig

= es +S ee

V. KESIMPULAN

‘Berdasarkan dari hasil pemeriksaan dan pengujian diates, kami menyimpulkan bahwa Forkift masih dalam kondisi dapat

diterima, aman untuk dioperasikan dengan beban kerja aman sesuai tabel pengujian diatas untuk dioperasikan dan

digunakan pada kegiatan usaha minyak dan gas bumi sesuai dengan masa berlaku sebagaimana tertera dalam Sertifikat

Inspeksi.

Jakarta, 10 Februari 2020

Diperksa dan dsertifikasi oleh,

PT. Indo Yasa Prima

Oe,

2

TYP certiricaTion a TECHNICAL SERVICES CERTIFICATION & TECHNICAL SERVICES:

100-014/LA-TYST/SUW205KT

+

aaa Tilt Range - Beban Kerja Aman (ke)

Ti

| Par | Times a Backward gaara Beban Uji (kg) | Alat Angkat | Alat Angkat

(Derajat) ‘Utama Banu

es 1000 610 300 7000 2500 =

500) 6-10 500 2500) 2500 :

Kesimpulan :

Berdasarkan hasil pengujian di atas, kami menyimpulkan bahwa peralatan tersebut aman dan layak untuk

digunakan pada kegiatan usaha minyak dan gas bumi.

Diterbitkan : Jakarta

Pada Tanggal : 12 Februari 2020

Berlaku Sampai Dengan: 12 Februari 2024

PT. Indo Yasa Prima

Inspector Direktur

Stefanus Edo Ediyanto

‘Address : Ruko Buana Gardenia A23 — A25, JI. KH. Hasyim Ashari, Pinang -Tangerang 15145, Banten, Indonesia

Phone : +62 21 7309609, Fax. : 462 21 7309610, E-mail: indoyosaprima@ymail.com : odmin@indoyasaprima.com

INSPECTION REPORT Zi Interm

s A T 0 | L No.SO.04/R/442/1/23 O Final

MANUAL BOOK

SATOIL

Doc. No. SAT-P-OPR-005-F9.MA

MITSUBI

FORKLIFT TRUCE

BISN crzsc-sso01.s0009 © FGEISN crstcoonsome

BASEN crss2001.s0000 = FGEABN crusnorss

CF2sc-75001-79999 FGEZOGN cre 30001-30000

BABZN cr4:72001-70000 © FGEZON crt70.2001.25050

G20CN crs<22001.20009 © FGE20ZN crs-200.200

CF17D-10001-19090 FGE25N cr170-70001.-79948

CF35-10001-19999 FGE25ZN cr35.70001.70000

CF170-80001-68999 FGE3ON cr12F-:0001-10999

FGE35N crisr-so001-2000

9) Nes tata: Resse, 0

tary Rice peg

SATOIL

INSPECTION REPORT @ Interm

No.SO.04/R/442/1/23 O Final

MAINTENANCE

RECORD

Doc. No. SAT-P-OPR-005-F9.MA

SATOIL

PT. SUPERKRANE MITRA UTAMA Tbk

HE) DI

surcncrane HEA LIFTING CONTRACTOR AND EQUIPTMENT RENT

Repaired By(mechane| Remar

[aru

a

ri

[ae [ears =

| Wish titer, wines | Y

ua ite Tis 1 [pa

a Tinaterephg ios Tieyse rem fos [eu| seaman

7 antiraiter ousllng tat aster oping tas mss [PUASLLONCEM | Lye] sucman

Heatal | ois i oon cr ae 1

oe a | ope eee

TOERO| rake | Foard oo T Taner

soyzozz | — raat —| Poo Borgia banark aPereN apd | Ban capa nan TOT [ae Baden erm

2 —Enge9

‘Wiehe ‘iter “inca |

ul rier ass

[sas |_| sons | var | Poo Seay Gree Tinea

3-1 593] co | infos | needa] Poacs [Booger ban unan Pernt poor? [Ban Fang kona TAO wos ra inva

SATQIL| .

INSPECTION REPORT

No.SO.04/R/442/1723

@ Interm

O Final

EMISSION GAS TEST

Doc. No. SAT-P-OPR-005-F9.MA

SATOIL

Certificate No: 2023-03-AN-3993-N

Date: 2023-03-03

Page 1 of 2

Report of Analysis

CUIENT : PT. Superkrane Mitra Utama Tbk.

: Jl. Cakung Cilincing Raya No.9, RT.11/RW.4,

ADDRESS ‘Semper Bar., Kec. Cilincing, Kota Jkt Utara, Daerah

Khusus Ibukota Jakarta 14130

SAMPLE TYPE el

SAMPLE DESCRIPTION emisi sumber bergerak

‘SAMPLE IDENTIFICATION 43-21-UE-384-N

‘SAMPLING DATE 2023-03-02

SAMPLING LOCATION ‘orklift 2,5 Ton (CF18C-82775 )

COORDINATE :0°0'0"S 0°0'0"E

DELIVERY DATE

RECEIVED DATE : 2023-03-03

SUBMITTED BY : Technician

ANALYSIS DATE : 2023-03-03 - 2023-03-02

YOUR REFERENCE : 968-QUO-AI-03-2023-N-REV01

Authorized By,

Eva Hasanah

Direktur Teknis

‘This Report of Analysis val ont or am. sample and issued by the Company complies with General Condon print overt! or avaliable on request.

Te acres or ty val Mons ara.cocer. Theatachnrs) aves anna part is Rap ot Ary. Wet

tho Company, his Report of Analysis nol permite to bo duplicated o extract by any means wahout writen permission fom tho

Certificate No: 2023-03-AN-3993-N

Date: 2023-03-03

Page 2 of 2

Report of Analysis

Tat REST FEST ESRTORY Una WETOOS SPECTRORTION

1 Opecty 50) % 12 0 ‘Suiee7r1822005

Notes:*) Accredited Parameters of KAN LP-720-IDN.

PERMENLH NO 05 TAHUN 2006 LAMPIRAN | KATEGORI M,N,O diesel, GVW = 3.5 ton = 2010

Authorized By,

Eva Hasanah

INSPECTION REPORT @ Interm

SAT 0 IL No.SO.04/R/442/11/23 0 Final

CERTIFICATE SPARK

ARRESTOR

SATO IL

Doc. No. SAT-P-OPR-005-F9.MA

41 Donaldson.

To Whom It May Concem

31 Aug 2007

Re: Spark Arrestor Qualification

Dear Customer,

This letter certifies that the below mentioned Spark Arrestors have been

qualified by the United States Department of Agriculture (Forestry) Equipment

Development Centre, San Dimas, California 91773, submitted by Donaldson

Company Inc...

MODEL POSITION

FCM04-5123-1 HORIZONTAL & VERTICAL

FCMO08-0024-1 HORIZONTAL & VERTICAL

FCM10-0016-1 HORIZONTAL & VERTICAL

FCMO06-0037-1 HORIZONTAL

FCM06-0038-1 HORIZONTAL & VERTICAL

FCM06-5030-1 HORIZONTAL

FCMO7-0068-1 HORIZONTAL & VERTICAL

FCMO07-0069-1 HORIZONTAL

FCMO09-0091-1 HORIZONTAL & VERTICAL

The spark arrestors have been tested in accordance with the “US Forest

Service Standard 5100-1 for Spark Arrestors” and have been qualified for

horizontal or vertical applications.

We trust this letter is sufficient and look forward to working with you.

Yours Truly,

=a

Leo D'cruz*

‘Technical Manager

Donaldson Filtration (Asia Pacific) Pte Ltd

@ Ponaldson

‘To Whom itMoy Concern

91 Aug 2007

Re: Spark Arestor Qualification

Dear Customer,

“Thi ater cenies hat he below mentonas Spark Arasiors have been

‘uolfedby he Unted Sites Department of Agiclture (Feast) Equipment

evelopment Core, San Dimas, Calfomia 91773, submited by Donaldson

Company nc.

MODEL, Position

FoMoas123-1 HORIZONTAL & VERTICAL

Fewos-0024-1 HORIZONTAL & VERTICAL

HORZONTAL 8.

Fewo7-0068-1

-FOWO7-0060-1

Fowos-009t-1

‘The spark arestrs have been tasted in accordance wih the "US

‘Service Standard 5100-1 fr Spark Arreslors and have been quelfied fr

hherlzontal oe vere appizaions.

‘We ist tis laters suffer and took forward to working with you.

Yours Truy.

Se

Leo Dene

Technica! Menager

Donaldson Filtration (Asia Paci) Pe Lis

SATOIL

FORKLIFT INSPECTION CHECKUST

[te Of apace March 3 =<

ena an Aaron a apa OORT a

pr. Suertrane Mitre Vas wodahop FSi

————a [asics a

—— = BCRT?S jrarsomnes : 2018

ho. " lees 2 P.Supetnne i vane

hyve ting Apa vers atte, + Say ah Ccing Wo 98 TOS/04. Kel Serr Saat

pt Fos ‘be Cincng nat tar 000 nos

Jcxmcty 223 Ton

pata ASME BS, 8 50.5057

[aoa

[ana Montacare

saa amber

SATOIL

smacomonne

wT»

an

Lifting Equipment Engineers Association

S

‘This is to certify that KD

Armand Zachary Sukanday)

passed,

icate

Part 4 Entra

of the << ‘examination

on

Galdctober 2016

o

wy»

on

Lifting Equipment Engineers Association

LEEA Academy Advanced Programing

‘This is to certify that XS

ve

Offshore Cont inced Programme

‘September 2017

—

Mile

(ue ner

Gul | Programme

Candidate Number: WTP3573,

Date of Birth: 24 August 1989

Ay

SAR NDT SERVICES (SNS)

Partner (OUTSIDE TRAINING SERVICES)

CERTIFICATE OF QUALIFICATION

Certificate No. SNS/MT/IN-22164

This is to certify that:

ARMAND ZACHARY SUKANDAR

PT. SATOIL

Has satisfactorily completed 24 hours training and examined ‘in according

With The American Society for Nondestractig Ne ing, Inc.,

Recommended Practice No.: SNT-TC- Edition

and he is qualified for if:

MAGNETIC PARTICLE regiing LEVEL II (Two)

Passing Grade (%)

General

Specific (A+B+0)/3= |- Individual>70

Practi 85 80,7 - Composite >80

:

|

}

|

\

Reference Code/S' : ASME, AWS and Other National Codes/Standards

Certificate Date: October 07,2022 Tangerang, October 07,2022

Expiration Date: October 06, 2027 eae tieaee

(OUTSIDE TRAINING SERVICES)

ee moat, ~~ SAR NDT SERVICES (SNS)

Partner

CERTIFICATE OF QUALIFICATION

Certificate No. SNS/PT/IN-22158

This is to certify that:

ARMAND ZACHARY SUKANDAR

PT. SATOIL

Has satisfactorily completed 24 hours training and media according

With The American Society for srs Totne inc,

Recommended Practice No.: SNT-T Edition

and he is qualified for the of:

LIQUID PENETRANT TESTING LEVEL II (Two)

EXA! IN RESULT

Type of Examination | Grade (36) | Composite Grade (%) | Passing Grade (%)

General Hoe

9

Specific (A+B+(C)/3= | - Individual>70

Practi¢ 85 84,3 - Composite >80

I

|

Reference Code/Si : ASME, AWS and Other National Codes/Standards

@ Certificate Date: October 07,2022 —_tangerang, October 07,2022

( Expiration Date: October 06, 2027 ‘Examiner:

KEMENTERIAN KETENAGAKERJAAN RI

KEPUTUSAN MENTER! KETENAGAKERJAAN REPUBLIK INDONESIA

NOMOR5/ 2¢2 /AS.02.01/ 1/2021

‘TENTANG

PENUNJUKAN AHLI KESELAMATAN DAN KESEHATAN KERJA BIDANG LISTRIK

ENTER! KETENAGAKERJAAN REPUBLIK INDONESIA

Menimbang : a. batwa untuk meningkatkan perindungan tenaga kerja den_membantu

pelaksanaan pengawasen ketenagakerjaan, khususnya dalam pelaksanaan

Norma K3 di tempat kerja, maka dipandang peru adanya tenaga Ani

Keselamatan dan Kesehatan Kerja yang memilki Keablian khusus di bidangnya;

. bahwa berdasarkan hasil penilaian syarat administrasi dan kemampuan teknis

keselamatan dan kesehatan kerja terhadap ARMAND ZACHARY SUKANDAR,

maka sesuai peraturan perundang-undangan peru. diberikan penunjukkan

‘sebagai tenaga Ahli Keselamatan dan Kesehatan Kerja Bidang Listrk;

‘bahwa untuk itu ditetapken dengan Keputusan Menteri

‘Undang-Undang No. 1 Tahun 197

Peraturan Menteri Tenaga Kerja R.1. Nomor Per. 4/MEN/1987;

Peraturan Menteri Tenaga Kerja RI. Nomor Per. 02/MEN/1092;

Peraturan Menteri Ketenagakerjaan R.l. Nomor 12 Thun 2015;

Keputusan Dirjen Pembinaan Pengawasan

Mengingat =

Memperhatikan : 1. Surat Permohonan dari Pimpinan PT. 16 Januari 2021 Perihal

Permohonan Perpanjangan tan dan Kesehatan Kerja

Bidang Listrik

2. Laporan kegiatan Anii Kesel a tan Kerja yang bersangkutan.

me y

KEPUTUSAN MENTERI KETEN. ERJAAN TENTANG PENUNJUKAN AHLI

KESELAMATAN DAN KESEHATAN KERJA

KESATU —_: Memberikan Perpanjan \unjukan Ahli Keselamatan dan Kesehatan Kerja

Bidang Listrik kepada;

Nama > ‘ARMAND ZACHARY SUKANDAR:

‘Tempat, Tanagé +: Saint Louis, USA, 24 Agustus 1993,

Perusahaan PT. SATOIL

Aiamai + Taman Tekno, Serpong, Banten

KEDUA + KapectNgploresin cee ORs KESATU ded Sagas maribants ceongswasl

norma K3 di tempat kerja, membantu pimpinan perusahaan melakukan

(Gentitkasi, pemerisaan, analisa dan meberikan persyaratan

Keputusan ini berlaku selama 3 (tiga) tahun terhitung sejak tanggal ditetapkan

‘dengan ketentuan apabila di kemudian hari terdapat kekeliruan dalam keputusan ini

akan diadakan perbaikan sebagaimana mestinya,

Menetepkan

KETIGA

Ditetapkan di Jakarta

Pada tanggal 29 Januari 2021

eae ain. MENTERI KETENAGAKERJAAN

REPUBLIK INDONESIA

DIREKTUR JENDERAL

PEMBINAAN PENGAWASAN KETENAGAKERJAAN

DAN KESELAMATAN DAN KESEHATAN KERJA

yondang

SNIP. 19840419 198903 2.001

KEWAJIBAN DAN WEWENANG

AHL! KESELAMATAN DAN KESEHATAN KERJA

BIDANG LISTRIK

Sesuai Peraturan Menteri Tenaga Kerja Nomor Per.02/Men/1992 jo

Peraturan Menteri Ketenagakerjaan RJ. No. 12 Tahun 2015

Keputusan Dirjen Pembinaan Pengawasan Ketenagakerjaan dan Keselamatan dan Kesehatan Kerja (K3)

No. Kep. 47/PPK&K3/VIN/2015,

Kanoanyue

Mec tempat sen dango ten peng

b. Meminta keterangan dan atau informasi mengenai pelaksanaan syarat-syarat K3 bidang

listrik pada tempat kerja sesuai dengan keputusan penunjukan ini,

‘¢. Memonitor, memeriksa, menguji, menganalisa, mengevaluasi, dan memberikan

peryaraan era pembiear KS bing tk pace tempat hae nese! eongun

hopin prion ow

d. Menyatakan keberatan atau menghentikan pelaksanaar n yang tidak memenuhi

Y

Kewajiban : 6

@ Membantu mengawasi pelaksanaan erundangan Keselamatan dan

Kesehatan Kerja di bidang listrik.

b. Memberikan laporan kepada

Ketenagakerjaan R.l. ¢.q. Dirjen Pembinaan

Pengawasan Ketenagakerja tembusan Kepala Dinas Ketenagakerjaan

‘setempat dan Direktur in Noma Keselamatan dan Kesehatan Kerja mengenai

hasil pelaksanaan 3 (tiga) bulan atau setiap saat setelah selesai melakukan

kegiatannya de

Penunjukan ri Ketenagakerjaan RI

©. Merahasiakan se¥jala Keterangan tentang rahasia perusahaanvinstensi yang didapat

bermubungan dengan jabatannya.

PERHATIAN:

Apabila melalaikan kewajiban dan kewenangan sebagaimana tersebut diatas maka

‘Surat Keputusan ini dapat dicabut.

01. 0003478

LSP MIGAS

BNSP Licenced

No: BNSP-LSP-0741D

SERTIFIKAT KOMPETENSI

(CERTIFICATE OF COMPETENCE

No. 71203 3117 5 0001069 2020 NS

een caer th

Armand Zacha opndar

No. Reg. IMG.07/ 2020

Telah bidang :

Is cor in the area of :

ie on ui reais

o Testing and Analysis

<>. Kualifikasi/Kompetensi :

with Qualifcation/Competency :

INSPEKTUR PESAWAT ANGKAT

CRANE INSPECTOR

Sertificat ini bertaku untuk : 3 (Tiga) Tahun

This certificate is valid for : 3 (Three) Years

Jakarta, 04 Juli 2020

LEMBAGA SERTIFIKASI PROFESI MINYAK DAN GAS (LSP MIGAS)

Professional Certification Body of Oil and Gas

SF Se

Dr-InM.Yudi M, Sholihin, MBA.M.Sc

Ketua LSP MIGAS ( President) eee

Daftar Unit Kompeten:

List of Unit (s) of Competency

ade Ua ma Tudul Unit Kompetensi

Gate of Competency Unit Tale of Competency Unit

‘Heakitan Veftan Dommen Pesonat Anghat

1 [__m212n3s.001.01 | peronn vermcation of Gane Document

‘elokukan Ideas Pesawat Angkat

.712035.002.01 | To pera laecaton of Gane

Menerapkan Keseiamatan Kera oi Temp Ca

1M-712035.003.01 | To agoly OHS inthe Work Pie

elakukan Pererksaan dan Vertis Siar

operon ispecon and Veraben of Stature

Telakukan Pemerksaen dan Verfias Kat Pemegarg Beban

M712035.005.01 | operon Inspection and Vetcatn of Hook

14.712035.004.01

To peratm inspection and verticaton of iting gear

(M.712035.007.01 CL raf Bae:

To perform Inspection and Veritcation of Rope Stee! 2 —-

Te pera Inapecton and Vartenton of Rog Part

‘akutan Pemerisaon dan Veritas Sisen

2

3

a

5

6 | mn |e ene

7

8

° To pero Ingen a Vartan Hey

n7amscona | Reba meron Vettes Boer an Ba oy

1¥.712035.008.01

10 | m712035.010.01

11 | .712038.011.01

12) mrizosso1201

13 | mz7i2035.013.01

14 | 71203501401

15 | M.712035.015.01

16 | ™.712035.016.01

17 | 712035.017.01

48 | m.712035.018.01

TUK 027

Jakarta, 04 Juli 2020

Lembaga Sertifikasi Profesi Minyak dan Gas (LSP MIGAS)

Professional Certification Body of Oil and Gas

Dr. Azwar Manaf, M.Met

Ketua Sertifikasi

(Certification Chairperson)

Sertifikat

Certificate

LEMBAGA PELATIHAN KERJA

KOPERASI PRIMA DAYA.MIGAS

(LPK KPDM) ° \

menyatakan babwa()

certify that:

ARMAND ZAC! / SUKANDAR

PT SATOIL OILFIELD SERVICE

telah sebagai:

1as QUALIFIED as:

INSPEK’ LAT BANTU ANGKAT

g jing Equipment Inspector

for having com iting Equipment Inspector Qualification Course conducted on?" - 12" of December 2020.

8 LEVEL 1

pada Bimbingan Teknis rama fat Bantu Angkat yang diselenggarakan tanggal 7 sampai dengan 12 Desember 2020.

i

>) Ketua LPK KPDM

Nomor Sertifkat 080/LPK/KPDM/1ABA/2021 Chairman of LPK KPDM

Certificate Number 3

‘Beclaku sejak 27 Januari 202%

Certificate effective date

Berlaku s/d 27 Januari 202

Volid une

Ir, Bayu Wahyudiono, MM.

eit ae era tp aon me PPO sean eae cc pos nh NAPA ea

Nomor Sertifikat

Certificate Number

MATERI BIMBINGAN TEKNIS KUALIFIKASI INSPEKTUR ALAT BANTU ANGKAT

LIFTING EQUIPMENT INSPECTOR QUALIFICATION COURSE SYLLABUS

+:080/LPK/KPDM/IABA/2021 Hasil : Baile (Good)

Result

INTRODUCTION OF ESDM LIFTING EQUIPMENT INSPECTION

SDM SAFETY REGULATION

‘ASME 830.1

ASME B:

ASME 830.9

‘ASME 830.10

ASME B30.16

ASME 830.20

ASME 830.21

ASME 230.26

BRITISH STANDARDS ~ BS EN 13155, BS EN 13157, BS EN 1341:

BRITISH STANDARDS - BS EN 13889, BS 1494, BS,

BRITISH STANDARDS - BS 4429, 8

en

102415

Kriteria Nill Hast! Kuallfikasi

Score Range of Qualification Result

BRITISH STANDARDS ~ BS EN 12079, BS EN 12305, BS EN. an

ak Sekeali (Excellent)

Balk (Good)

Cukup (Fair)

>90s/d 100

>805/d90

2708/4 80

‘Ambang Kelulusan (Passing Grado) = 70

180 3076

150 326

150 4309

Mv 2.7-4

(NDT KNOWLEDGE

(METRIC PRACTICE

JACKS, IN

SUNGS

Hoo)

\b CHAIN HOIST (CHAIN BLOCK)

in HOISTS

‘THE HOOK LIFTING DEVICES (LIFTING BEAM/SPREADER BEAM)

RIGGING HARDWARE

‘CARGO CARRYNG UNITS (cCU)

LIFTING EQUIPMENT APPLICATION

LIFTING EQUIPMENT LOAD TEST

xD

ILLERS, AIR CASTERS, AND HYDRULIC GANTRIES

KOORDINATOR INSTRUKTUR

Instructor Coordinator

TRI PURWANTO

LEMBAGA PELATIHAN KERJA

KOPERASI PRIMA DAYA MIGAS

(LPK KPDM)

SERTIFIKAT

Certificate

INSPEKTUR PESAWAT ANGKAT ESDM (Energi Bi Sumber Daya Mineral)

ESOM Crane Inspector

Level 1650

Diberikan

Give

ARMAND RY SUKANDAR

ATOIL

Sebagal Peserta Bimbingan Teknis Kualifikasi vane if Pesawat Angkat (Refreshing) yang diselenggarakan oleh LPK Koperasi Prima

Daya Miges di Jakarta pada tanggal 23 s.d 26 Juni 202 predikat LULUS dan hasil BAIK.

as participant of Online Crane Inspector Technic

AGHEINOAA

‘wanon aM

NOUSSESNI WWD IWSISAHS

INGISAS WOR DTA ANY

BNYuO OUVANNa GNY ONAVEGAH

BNVEO SIEOWN

NOUVINOY ALBaVS

“BURLOMALS GNVEIvaSe BNVES

‘BNO WO S01LOvad 33VS

ROMLDBSSNI 08 aNVHO

1881, avo) NYE,

NOWOSASNI SOU ONIANS

{1831 SALOMUISEO ONY GOUd TWRIBLVH

NOUSSISNI LON

souDvea ORL

AQ \30 ALS

sya

NOUVOIsLLMBO GNV NOULO3ESNI BNVO NOUONGOMINT

SMOTION SV SaINVINNS BUY ONINIWEL SLOArans

SMOTIO4 SY SanuvMMNE Ju¥ ONINIVaL SLograNs

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TF - Use of Suspended ManbasketsDocument9 pagesTF - Use of Suspended ManbasketsGuruh SuprayitnoNo ratings yet

- TF Roof Access PermitDocument1 pageTF Roof Access PermitGuruh SuprayitnoNo ratings yet

- Vision Screening ProcessDocument1 pageVision Screening ProcessGuruh SuprayitnoNo ratings yet

- TF Scaffolding ProcedureDocument11 pagesTF Scaffolding ProcedureGuruh SuprayitnoNo ratings yet

- 0107 DART MIER ReportDocument2 pages0107 DART MIER ReportGuruh SuprayitnoNo ratings yet

- Excavating Fibrous MaterialsDocument7 pagesExcavating Fibrous MaterialsGuruh SuprayitnoNo ratings yet

- Trailer Pre MobDocument1 pageTrailer Pre MobGuruh SuprayitnoNo ratings yet

- HazMat FormDocument1 pageHazMat FormGuruh SuprayitnoNo ratings yet

- Respirator Inspection and Maintenance RecordDocument1 pageRespirator Inspection and Maintenance RecordGuruh SuprayitnoNo ratings yet

- Hydraulic Crane Pre MobDocument1 pageHydraulic Crane Pre MobGuruh SuprayitnoNo ratings yet

- High Pressure Water Cleaning (HPWC) Procedure Typical HPWC Lancing ArrangementDocument1 pageHigh Pressure Water Cleaning (HPWC) Procedure Typical HPWC Lancing ArrangementGuruh SuprayitnoNo ratings yet

- JLG 800a 800aj PM 2011 1Document454 pagesJLG 800a 800aj PM 2011 1Guruh SuprayitnoNo ratings yet

- JOB DESC Ade TopanDocument2 pagesJOB DESC Ade TopanGuruh SuprayitnoNo ratings yet

- HazMat Form Hyd Oil Shell TellusDocument1 pageHazMat Form Hyd Oil Shell TellusGuruh SuprayitnoNo ratings yet

- TF Respiratory Protection ProcedureDocument10 pagesTF Respiratory Protection ProcedureGuruh SuprayitnoNo ratings yet

- HazMat Form Engine Oil & Hyd OilDocument2 pagesHazMat Form Engine Oil & Hyd OilGuruh SuprayitnoNo ratings yet

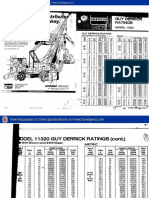

- American 11320 With MastDocument4 pagesAmerican 11320 With MastGuruh SuprayitnoNo ratings yet

- Scope of Work MechanicDocument4 pagesScope of Work MechanicGuruh SuprayitnoNo ratings yet

- Linkbelt 90T LS 338sDocument11 pagesLinkbelt 90T LS 338sGuruh SuprayitnoNo ratings yet

- Linkbelt 90T LS 338bDocument8 pagesLinkbelt 90T LS 338bGuruh SuprayitnoNo ratings yet

- Service PERIODE JUL-AUG PT. FreeportDocument2 pagesService PERIODE JUL-AUG PT. FreeportGuruh SuprayitnoNo ratings yet

- Part & Consumable ReportDocument6 pagesPart & Consumable ReportGuruh SuprayitnoNo ratings yet

- Scissorlift Skyjack8mSJ3226Document2 pagesScissorlift Skyjack8mSJ3226Guruh SuprayitnoNo ratings yet

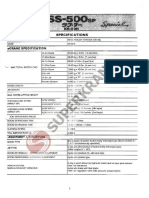

- Kato 50T SS500SP (50t)Document7 pagesKato 50T SS500SP (50t)Guruh SuprayitnoNo ratings yet