Professional Documents

Culture Documents

Jsa Check

Uploaded by

Md Danish RazaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa Check

Uploaded by

Md Danish RazaCopyright:

Available Formats

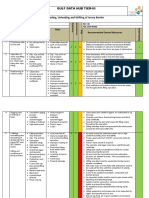

GEA PROCESS ENGINEERING

Project Name - ESP erection & commissioning(birla copper dahej) Document No:- HIL/JSA/EHS-01

Activity- Fabrication & erection of assembly bed

Rev-0

JOB SAFETY ANALYSIS

Location of Work : Smelter -1 ,ESP

JSA No- 01

Sr. Sub Activities / Tasks Hazards Impact in case of exposure Risk Control measures (There can be multiple control measure for one hazard) Responsibility

No.

1 Work start-up preparation & Un authorized work Physical Injury Must be followed HIL permit system site engineer and

obtaining work permit Invalid permit Supervisor must insure that all work activities are carried out by competent Supervisor

Lack of competency person

Poor communication Property damage Conduct tool box talk meeting

Hast or shortcuts stuck worker in case of Review the method

Don’t aware with plant emergency emergency Responsible person will conduct inspection

Consider all potential hazards: weather, wet or slippery conditions, overhead

hazards, proximity to trails and/or visitor traffic patterns/volume, slope, loose

footing, elevation, fatigue, hazardous insects or plants, etc.

awarness regarding HIL emergency procedure

2 shifting of materilas from storage Toppling or Falling of material Physical Injury Only competent and approved operator shall be deployed for equipment Rigger and Site

area to esp area by hydra & trailor Mechanical failure of lifting tools and operations. engineer and

tackles Equipment to be tested and certified by competent person before deployment. Supervisor

Property damage No overloading allowed.

Improper lifting pinch point Follow procedures.

Procedure Training and assistance of Banks man / Rigger

using of defective equipment ( Tools and Must be followed HILPermit

Tackles ) approved lifting plan must for crane / hydra lifting

Over loading. All equipment must be third party certified.

traffic accident Operators should be certified and valid license holder Equipment to be

inspected daily and all defects reported

3 Grinding cutting & welding of Radiation can damage Must be followed HIL hot work procedure fire watch and Site

structure platform Burns eyes and skin Use specified shielding devices and other PPE engineer/

Fire hazard Explosion may occur of correct specifications Supervisor/site hse

Explosion May cause fire Cylinder Move out any leaking cylinder

Tripping may burst Keep trolley for transportation of cylinders and chain them

Leaking gas cylinder or hoses Welders cataract Use flash back arresters

Rotating equipment sparks Burn Injury Use double stage regulatores

Damage / burst grinding wheel Lung ailments Purge regulators immediately and then turn off.

Electrocution Dermatitis Never use grease or oil on oxygen line connections and copper fittings on

Dust Hit injury / crush injury acetylene lines

Flying object eye injury Electric ShockFire / Work area should be barricated and sigage posted.

Welding radiates invisible ultraviolet Explosion Asphyxiation only trained and competent person only allowed

and infrared rays use dust mask

Improper placement of oxygen and use job specific ppe's

acetylene cylinders

Leakage / cuts in hoses

Opening – up of cylinders

Radiation harmful to naked eyes

Splinters / slag

Toxic fumes

4 Housekeeping and material Personal injury Incident / Injury Site Supervisor

removal after job complete Slip and trip Property Damage.

Dust exposure Must be used dust mask

ergonomic Followed material handling technique

Proper communication

Housekeeping awareness program to all employee

Approved By-

Prepared & Analysis by :- Danish (HSE),s.mujmdar(site incharge),

P.chinnamaharaja(site eng)

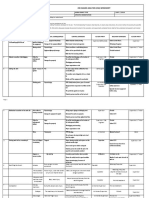

GEA PROCESS ENGINEERING

Project Name - ESP erection & commissioning(birla coper dahej) Document No:- HIL/JSA/EHS-09

Activity- fitup & assembely of 1st & 4th field

Rev-0

JOB SAFETY ANALYSIS

Location of Work : Smelter -1 ,ESP JSA No- 03

Sr. Sub Activities / Tasks Hazards Impact in case of exposure Risk Control measures (There can be multiple control measure for one Responsibility

No. hazard)

1 Work start-up Un authorized work Physical Injury Must be followed HIL permit system site engineer and Supervisor

preparation & Invalid permit Supervisor must insure that all work activities are carried out by site hse person

obtaining work permit Lack of competency competent person

Poor communication Property damage Conduct tool box talk meeting

Hast or shortcuts worker stucjk in emergency Review the method

plant emergency Responsible person will conduct inspection

Consider all potential hazards: weather, wet or slippery conditions,

overhead hazards, proximity to trails and/or visitor traffic

patterns/volume, slope, loose footing, elevation, fatigue, hazardous insects

or plants, etc.

proper communication

2 shifting & lifting of Toppling or Falling of material Physical Injury Only competent and approved operator shall be deployed for equipment Rigger teamand Site engineer and

casing panel by 80T Mechanical failure of lifting tools operations. Supervisor

mobile crane/farrana and tackles Equipment to be tested and certified by competent person before

Property damage deployment. hse person

pinch point No overloading allowed.

Improper lifting Procedure fatal Follow procedures.

using of Training and assistance of Banks man / Rigger

defective equipment ( Tools and Must be followed HILPermit

Tackles ) approved lifting plan must for crane / hydra lifting

Over loading. All equipment must be third party certified.

traffic accident Operators should be certified and valid license holder Equipment to be

Overloading due to load oscillation inspected daily and all defects reported

Collision with structure & lifting plan shall be prepare before work start

pipelines

3 Erection of scaffold for Collapsing of Scaffolding Personal Injury, followed HIL Procedure for Scaffold site engineer and Supervisor

casing panel Fall of person Fatal accident Competent scaffolding team scaffold team

assemble/work at hight Slip & trip Material damage Scaffolding Training hse person

Unauthorized modification in Property damages Scaffolding Inspection Check list before work start

scaffolding Electrocution Cordoning / barricade of Area

Erection of non standard Proper tying & handling of loose scaffolding materials

Scaffolding Use of good condition & sufficient Scaffolding materials

Gap between two scaffolding Weekly re-inspection of certified scaffold

planks maintain good housekeeping

Fall of Loose scaffolding / other Use of standard and certified full body safety harness with 100% tie off

loose Materials Proper Supervision shall be ensured

Un trained worker Suitabale & Sufficient Access at even low height provided wherever

Non inspected scaffold possible.

Improper communication

Scaffold nearby live electrical cable

Slip from ladder

4 Grinding ,cutting & Burns Radiation can damage eyes Must be followed HIL hot work procedure fire watch and Site engineer/

welding of structure Fire hazard and skin Use specified shielding devices Supervisor/site hse

platform Explosion Explosion may occur and other PPE of correct specifications

Tripping May cause fire Cylinder may Move out any leaking cylinder

Leaking gas cylinder or hoses burst Keep trolley for transportation of cylinders and chain them

Rotating equipment sparks Welders cataract Use flash back arresters

Damage / burst grinding wheel Burn Injury Use double stage regulatores

Electrocution Lung ailments Purge regulators immediately and then turn off.

Dust Dermatitis Never use grease or oil on oxygen line connections and copper fittings on

Flying object eye injury Hit injury / crush injury acetylene lines

Welding radiates invisible Electric ShockFire / Work area should be barricated and sigage posted.

ultraviolet and infrared rays Explosion Asphyxiation only trained and competent person only allowed

Improper placement of oxygen and use dust mask

acetylene cylinders use job specific ppe's

Leakage / cuts in hoses

Opening – up of cylinders

Radiation harmful to naked eyes

Splinters / slag

Toxic fumes

5 Housekeeping and Personal injury Incident / Injury Site Supervisor

material removal after Slip and trip Property Damage.

job complete Dust exposure Must be used dust mask

ergonomic Followed material handling technique

Proper communication

Housekeeping awareness program to all employee

Approved By-

Prepared & Analysis by :- Danish (HSE),s.mujmdar(site

incharge), P.chinnamaharaja(site eng)

You might also like

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- HARADH AND HAWIYAH FIELD GAS COMPRESSION PROJECT SAFETY ANALYSISDocument8 pagesHARADH AND HAWIYAH FIELD GAS COMPRESSION PROJECT SAFETY ANALYSISsathakathulla100% (3)

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- Erection JsaDocument52 pagesErection JsaMd Danish Raza100% (2)

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Ho'oponopono ! - The Power of ForgivenessDocument6 pagesHo'oponopono ! - The Power of ForgivenessParainNo ratings yet

- Job Safety Analysis Sheet: Operation Concrete Batching PlantDocument2 pagesJob Safety Analysis Sheet: Operation Concrete Batching Plantzabiulla100% (7)

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- RAMS-Loading, Unloading and Shifting of MaterialDocument5 pagesRAMS-Loading, Unloading and Shifting of MaterialEm Niax50% (2)

- Generic TPL JsaDocument83 pagesGeneric TPL JsaSanjay Kumar GhadaiNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- Concept MapDocument1 pageConcept MapKeith20% (5)

- Job Safety Analysis for Cement Silo ConstructionDocument7 pagesJob Safety Analysis for Cement Silo ConstructionArgi Bramantara100% (1)

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- RAM - Pile CroppingDocument14 pagesRAM - Pile CroppingDaniel Cryer0% (1)

- Cargo Security Awareness - Etextbook - 2nd - Ed - 2016 - TCGP-79Document185 pagesCargo Security Awareness - Etextbook - 2nd - Ed - 2016 - TCGP-79kien Duy Phan80% (5)

- JSA - Field Instruments InstallationDocument4 pagesJSA - Field Instruments InstallationSagar PadhiyarNo ratings yet

- HIRAC TemplateDocument45 pagesHIRAC TemplateMadelo, Allysa Mae, M.No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- HIRA Cage Ladder InstallationDocument9 pagesHIRA Cage Ladder InstallationR. Ayyanuperumal AyyanuperumalNo ratings yet

- Questions Scope PDFDocument10 pagesQuestions Scope PDFabdou madjidNo ratings yet

- Biotensegrity and Myofascial Chains A Global Approach To An Integrated Kinetic ChainDocument8 pagesBiotensegrity and Myofascial Chains A Global Approach To An Integrated Kinetic ChainMohamed ElMeligieNo ratings yet

- Method Statement For Access Road & Platform Construction in Hill Area (HSE)Document5 pagesMethod Statement For Access Road & Platform Construction in Hill Area (HSE)Rajesh100% (1)

- JHA HondaDocument2 pagesJHA HondaJaycee QuinNo ratings yet

- Work Method Statement PDFDocument8 pagesWork Method Statement PDFUsiwo Abed Soteria Otowa100% (2)

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RNo ratings yet

- Final Job Safety Analysis Pre AssemblyDocument2 pagesFinal Job Safety Analysis Pre AssemblyMd Danish RazaNo ratings yet

- GEA PROCESS ENGINEERING ESP ERECTION & COMMISSIONING JSADocument1 pageGEA PROCESS ENGINEERING ESP ERECTION & COMMISSIONING JSAMd Danish RazaNo ratings yet

- deSSEMBLY JSADocument2 pagesdeSSEMBLY JSAAbhi SandiNo ratings yet

- DismantlingDocument5 pagesDismantlingAbhi SandiNo ratings yet

- Jsa CheckDocument2 pagesJsa CheckAbhi SandiNo ratings yet

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- Job Safety Analysis for Fabrication WorkDocument4 pagesJob Safety Analysis for Fabrication WorkAbhi SandiNo ratings yet

- JHA WORKSHEET FOR LIFTING MATERIALS BY CRANEDocument4 pagesJHA WORKSHEET FOR LIFTING MATERIALS BY CRANE王志伟No ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- 015 - Heating Skid ConnectivityDocument4 pages015 - Heating Skid ConnectivitySiddhant choudharyNo ratings yet

- Jsa for Drilling WellDocument5 pagesJsa for Drilling WellAnna JisabaNo ratings yet

- Job Hazard Analysis for Fire Protection System RehabilitationDocument1 pageJob Hazard Analysis for Fire Protection System RehabilitationJane RoNo ratings yet

- Hazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012Document1 pageHazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012somashekhar. ncclNo ratings yet

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- Adr Jsa 1711 002Document7 pagesAdr Jsa 1711 002Dada KhalandarNo ratings yet

- Switch Board Erection Safety MeasuresDocument4 pagesSwitch Board Erection Safety MeasuresvasudevanmNo ratings yet

- Cooling Tower BiomateDocument8 pagesCooling Tower BiomateJavid AaqibNo ratings yet

- CMPL and MVPL Vent-Line Connectivity JHADocument4 pagesCMPL and MVPL Vent-Line Connectivity JHASiddhant choudharyNo ratings yet

- Red Tile Placing JSADocument5 pagesRed Tile Placing JSAShahid BhattiNo ratings yet

- Maintain Safety During Vehicle Entry and Material HandlingDocument51 pagesMaintain Safety During Vehicle Entry and Material HandlingJonathan BajelaNo ratings yet

- HEI JHA Leakage RectificationDocument7 pagesHEI JHA Leakage RectificationJavid AaqibNo ratings yet

- 06 Scaffold Erection and Dismantling (JHA-JSA)Document4 pages06 Scaffold Erection and Dismantling (JHA-JSA)AmanNo ratings yet

- AR08-16 Laying HDPE Pipes Risk AssessmentDocument5 pagesAR08-16 Laying HDPE Pipes Risk AssessmentAmrou Ben RjebNo ratings yet

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Document5 pagesOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibNo ratings yet

- Complex GenericSWMS FacadeDocument4 pagesComplex GenericSWMS FacadeAastha AluminaNo ratings yet

- JOB SAFETY ANALYSIS RISK ASSESSMENTDocument12 pagesJOB SAFETY ANALYSIS RISK ASSESSMENTMarhendraNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- 1 SurveyDocument5 pages1 Survey王志伟0% (1)

- Job Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001Document2 pagesJob Hazard Analysis (Jha) Worksheet SPOC-433-CPF-JSA-ELEC-001asteway gonfaNo ratings yet

- JSA SampleDocument19 pagesJSA SampleskmohdmusthafaNo ratings yet

- JSA For CWL - SRU R1, JSA No. 18Document5 pagesJSA For CWL - SRU R1, JSA No. 18Nikunja mohantyNo ratings yet

- Hydro Test PipesDocument3 pagesHydro Test PipesVikram Kumar MvsNo ratings yet

- Writing Part 2 - An Essay: (120-180 Words)Document7 pagesWriting Part 2 - An Essay: (120-180 Words)María Daniela BroccardoNo ratings yet

- Installation, Operation and Maintenance Instructions For 9957W Automatic Balancing ValveDocument2 pagesInstallation, Operation and Maintenance Instructions For 9957W Automatic Balancing ValveManuel Molina CamposNo ratings yet

- 14 Ways To Acquire KnowledgeDocument4 pages14 Ways To Acquire KnowledgeRenato MiguelNo ratings yet

- K Park 24 TH Edition ChangesDocument8 pagesK Park 24 TH Edition ChangesAnkit ChoudharyNo ratings yet

- Excerpts From The Way of The Samurai (Shīdo) : Primary Source Document With Questions (DBQS)Document2 pagesExcerpts From The Way of The Samurai (Shīdo) : Primary Source Document With Questions (DBQS)Valeria MontalvaNo ratings yet

- 1st Summative Test in Tle SmawDocument2 pages1st Summative Test in Tle Smawjenky agnoteNo ratings yet

- Saberry ® - Cosmeceutical Applications of SaberryDocument2 pagesSaberry ® - Cosmeceutical Applications of SaberryGopalaKrishnan SivaramanNo ratings yet

- Set 1Document24 pagesSet 1TutorTutorNo ratings yet

- PB ManualDocument23 pagesPB ManualwilyNo ratings yet

- CaracterizacióndeSalpicadurasSMAW Molleda 2007Document5 pagesCaracterizacióndeSalpicadurasSMAW Molleda 2007Tamara Maria Ortiz MendezNo ratings yet

- Enquiries: 1. Enquiry From A Retailer To A Foreign ManufacturerDocument7 pagesEnquiries: 1. Enquiry From A Retailer To A Foreign ManufacturerNhi Hoàng Lê NguyễnNo ratings yet

- Power Over Ethernet - Wikipedia, The Free EncyclopediaDocument7 pagesPower Over Ethernet - Wikipedia, The Free EncyclopediaManitNo ratings yet

- Course 1 ProjectDocument6 pagesCourse 1 ProjectDhruvNo ratings yet

- 7306 31980 1 PBDocument10 pages7306 31980 1 PBRaihan Aditiya JuniorNo ratings yet

- 2 Corinthians: Workbook OnDocument18 pages2 Corinthians: Workbook OnJhon Ray OtañesNo ratings yet

- Oromia State UniversityDocument65 pagesOromia State UniversityEYOB AHMEDNo ratings yet

- The University of QueenslandDocument2 pagesThe University of Queenslandimmanuel nauk elokpereNo ratings yet

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- Second Travel of Rizal: Week 8 Unit 3Document22 pagesSecond Travel of Rizal: Week 8 Unit 3John Russell GasangNo ratings yet

- The Right Help at The Right Time: MatterDocument24 pagesThe Right Help at The Right Time: MattermariustudoracheNo ratings yet

- EMAG W01 RodHeatingDocument16 pagesEMAG W01 RodHeatingMiguel Ángel ArizaNo ratings yet

- Timbering Week 5Document22 pagesTimbering Week 5FikaduKitessa0% (1)

- 1Document5 pages1qweqweNo ratings yet

- GARAM ModelDocument40 pagesGARAM ModelprasunmathurNo ratings yet

- Of Our TimesDocument84 pagesOf Our TimesThe Journal of Music100% (1)