Professional Documents

Culture Documents

AddPak Chemical Injector Technical Data

Uploaded by

eka pramudia santosoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AddPak Chemical Injector Technical Data

Uploaded by

eka pramudia santosoCopyright:

Available Formats

Technical Data

Brodie AddPak

Additive Injection Block

General Installation

Brodie’s AddPak Chemical Injector offers a wide variety The Injector’s slim footprint allows for easy installation

of service options. Due to its complete stainless steel with minimal space requirements. The AddPak Chemical

construction and elastomer selection, it is suitable for Injector easily incorporates into numerous applications

use in numerous chemical and industrial applications. from PLC to TAS Systems used as a slave injector.

The Injector is machined from a solid piece of stainless

Oval Gear Meter

steel bar stock which minimizes external leak points,

and also incorporates an inlet machined basket strainer The Injector’s oval gear meter design allows for wide

and an outlet check valve. chemical use in additives and marker applications. Due to

product design, the oval gears are able to achieve a highly

accurate measurement in single c/c units.

Mechanical

Available in 1-6 Pack Configuration

304 Stainless Steel Machined Block

Inlet & Outlet Isolation Valves

Calibration Port Valved with Dust Cap

Elastomers Wetted: Teflon or Teflon Encapsulated Material

Optional Elastomer Material: Kalrez or Chemrez Seals per Request

Flow Range .05 - 3 GPM

Oval Gear Meter K Factor ~4600 PPG

Process Connections 3/8” FNPT

Max WP 400 PSI

Electrical

ASCO Explosion Proof Solenoid

120VAC 60HZ Standard, Other Voltage Available per Request

Oval Gear Meter Sensor 5 - 30 VDC, Supply Hall-Effect or Reed Switch

Open Collector High Speed

Suitable for Hazardous Area

FM Approvals for use in Class I, DIV I Areas

All Electrical Conduit Connections 1/2’’ FNPT

Technical Data AddPak R07 Page 1/4

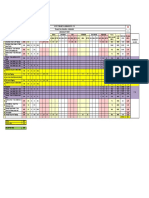

Model Code

CODE BAB Brodie AddPak Additive Injection Block

BAB

CODE 9 Revision

A

CODE M Mounting

0 Unmounted, Standard

1 BAB Mounted on Panel

2 BAB Mounted on Panel

3 BAB Mounted on Panel

4 BAB Mounted on Panel

5 BAB Mounted on Panel

6 BAB Mounted on Panel

CODE T Thermal Relief

0 None, Standard A

1 Thermal Relief (per block) 151070M (QTY 10)

Z Thermal Relief (for multiple blocks) 154704-024M

CODE G Gear Material

1 PPS (Ryton) 5000 PPG, Standard A

SS. STL. ~5000 PPG (price added per

2 151070M (QTY 10)

block)

SS. STL. ~5000 PPG (for multiple

Z 154704-024M

blocks)

CODE V Solenoid Voltage

1 120/60 VAC, 110/50 VAC

2 240/60 VAC, 220/50 VAC

CODE A Approvals

1 FM

CODE Injection Point Kits

AB1200 Standard Injection Kit

AB1300 Red Dye Injection Kit

AB1500 Calibration Test Kit

Technical Data AddPak R07 Page 2/4

Dimensional Drawings

in. [mm]

10.00

254

1.16 MTG HOLE

8.16 MTG HOLE

207

2.50 MTG HOLE

64

29

MTG HOLE

2.27

58

3.75

95

3.93

100

.47

12

2.62

67

1.36

35

INLET

3/8"-18 NPT OUTLET

3/8"-18 NPT

.92

23

1.48

38

3.93

100

Technical Data AddPak R07 Page 3/4

Technical Configuration

CAP

SOLENOID

PULSE NEEDLE

SENSOR VALVE

QUICK

DISCONNECT

INLET

3/8" NPT

NEEDLE

VALVE

OUTLET

3/8" NPT

INJECTOR BLOCK

CAP

For Optional Accessories Listed Below, Please Contact Factory:

Standard & Dye Injection Point Kits

Calibration Kits

Injector Thermal Relief Kits

Special Elasomers

Special Approvals

Brodie International

P.O. Box 450 (30459-0450)

19267 Highway 301 North

Statesboro, GA 30461

USA

Phone: +1 (912) 489-0200

Fax: +1 (912) 489-0294

Technical Data AddPak R07 Page 4/4

You might also like

- Analysis On TwitterDocument26 pagesAnalysis On Twitteryummy90100% (7)

- A320 - ATA 24 Electrical Power Line & Base MaintenanceDocument108 pagesA320 - ATA 24 Electrical Power Line & Base MaintenanceStifler Ho67% (9)

- Final Drawing DY152 DY153 - SperreDocument50 pagesFinal Drawing DY152 DY153 - SperreSimonaMauna50% (2)

- Additional Parts Book EGS Series - 678 - Receipt On Sept 2014 PDFDocument49 pagesAdditional Parts Book EGS Series - 678 - Receipt On Sept 2014 PDFFandi Achmad Akbar100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- SM FLOWSIC100 Flare en V2-1 2016-06Document298 pagesSM FLOWSIC100 Flare en V2-1 2016-06eka pramudia santosoNo ratings yet

- RBR Ball ValveDocument16 pagesRBR Ball Valveeka pramudia santosoNo ratings yet

- 1.1 Overview of The Modbus ProtocolDocument9 pages1.1 Overview of The Modbus Protocoleka pramudia santoso100% (1)

- TVT Product ListDocument20 pagesTVT Product ListRajesh HchNo ratings yet

- Comment Footprint Libref Description Quantity Total Qty Unit Price Total PriceDocument3 pagesComment Footprint Libref Description Quantity Total Qty Unit Price Total Pricegautamkr15No ratings yet

- Mast Raising Telescopic CylindersDocument5 pagesMast Raising Telescopic CylindersAyman AkrabNo ratings yet

- IL205AT/206AT/207AT/208AT: Vishay SemiconductorsDocument8 pagesIL205AT/206AT/207AT/208AT: Vishay SemiconductorsAhmed EmiraNo ratings yet

- ILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsDocument8 pagesILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsRohit SainiNo ratings yet

- AQUI-InfoPLC TX-TEP-0001 MP Interpretacion de Planos ElectricosDocument4 pagesAQUI-InfoPLC TX-TEP-0001 MP Interpretacion de Planos Electricosmarco antoniomegreteNo ratings yet

- F-SeriesSW Details & COSDocument3 pagesF-SeriesSW Details & COSjosehernandez51179No ratings yet

- Draft Spect No. TI-SPC-PSI-LVCBIN-0121Document51 pagesDraft Spect No. TI-SPC-PSI-LVCBIN-0121lovely jiNo ratings yet

- Vibration Eliminators SpecsDocument3 pagesVibration Eliminators SpecsShaik IrshadNo ratings yet

- High Density A.C. Input Phototransistor Optically Coupled IsolatorsDocument3 pagesHigh Density A.C. Input Phototransistor Optically Coupled Isolatorsabo.omar.elmasry.900No ratings yet

- Second Pump-R1 DesignDocument1 pageSecond Pump-R1 DesignIzaaz AhamedNo ratings yet

- EPE6119GDocument1 pageEPE6119Gmmdabase8617No ratings yet

- Lv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Document32 pagesLv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Chaturbhai Hadiyal0% (1)

- In Duc TorsDocument11 pagesIn Duc TorsAwe'r XoshnawNo ratings yet

- Residential Fan ManualDocument6 pagesResidential Fan ManualKSBNo ratings yet

- QTM5 VAN TỐC ĐỘDocument2 pagesQTM5 VAN TỐC ĐỘVăn Công LêNo ratings yet

- Bc63kb8a Dy152 - 153 Vendor Drawing n001 Air Compressors SperreDocument60 pagesBc63kb8a Dy152 - 153 Vendor Drawing n001 Air Compressors SperreSimonaMauna33% (3)

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN SOFTWARESNo ratings yet

- High - Low Limiter: R User'S ManualDocument35 pagesHigh - Low Limiter: R User'S ManualMijail David Felix NarvaezNo ratings yet

- V (V) I (Ma) V (V) at +25°C I (Ua) at +25°C: Surface Mount Schottky Barrier DiodeDocument5 pagesV (V) I (Ma) V (V) at +25°C I (Ua) at +25°C: Surface Mount Schottky Barrier DiodetusharNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- MTD4 (4870)Document2 pagesMTD4 (4870)Muthu KumarNo ratings yet

- RotaryDocument10 pagesRotaryVEERAMANINo ratings yet

- S. No Cable Tag No From To Power Cable Description Item Item Motor Rating KW No. of Runs No. of CoreDocument35 pagesS. No Cable Tag No From To Power Cable Description Item Item Motor Rating KW No. of Runs No. of CorejjspenceNo ratings yet

- 1B. Vendor Offer KOSO-CV - Code2Document7 pages1B. Vendor Offer KOSO-CV - Code2vivekanandakuwaitNo ratings yet

- BH-D6 BH-D10 BH-DN: Rated Short-Circuit Capacity (Ka)Document2 pagesBH-D6 BH-D10 BH-DN: Rated Short-Circuit Capacity (Ka)JV BalisiNo ratings yet

- Texas Instruments Pth12060waz DC DC Power Supply Through HoleDocument29 pagesTexas Instruments Pth12060waz DC DC Power Supply Through Holeednardo CunhaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- HydropompeDocument4 pagesHydropompeReggie TopsNo ratings yet

- E90-803-001-001-01 - X 500-2 Brushless - 24v DCDocument20 pagesE90-803-001-001-01 - X 500-2 Brushless - 24v DCAlexNo ratings yet

- Piping and Valves Specification SheetDocument1 pagePiping and Valves Specification SheetDmitriy RybakovNo ratings yet

- 120210lub - El350 Sae 40Document1 page120210lub - El350 Sae 40JorgeLuisRodriguezAguilarNo ratings yet

- Time Delay Sensitivity Housing Cable Entry: Production 712906Document2 pagesTime Delay Sensitivity Housing Cable Entry: Production 712906Arjun BharambeNo ratings yet

- 2SB624Document2 pages2SB624asam youssefNo ratings yet

- 3LEV02-Series 6 28 20Document7 pages3LEV02-Series 6 28 20Hernan RamirezNo ratings yet

- Miniature Circuit BreakersDocument24 pagesMiniature Circuit BreakersAhmed SherifNo ratings yet

- 22 08 09 Nord 18556010Document5 pages22 08 09 Nord 18556010Sebastián Felipe Argüello LópezNo ratings yet

- T.D.A 04H0SK1RDocument1 pageT.D.A 04H0SK1Rmichael luqueNo ratings yet

- P0420 Pulse Datasheet 8366683Document2 pagesP0420 Pulse Datasheet 8366683Moazzam KhalilNo ratings yet

- A82-00-0109 Datasheets USDocument3 pagesA82-00-0109 Datasheets UScarrei JohnNo ratings yet

- Ducted Split: LG Air ConditionersDocument100 pagesDucted Split: LG Air Conditionersjose antonioNo ratings yet

- Bohler S EMK 6Document1 pageBohler S EMK 6Enaam AtaallahNo ratings yet

- Wilson Cables - FR.Document12 pagesWilson Cables - FR.ថុន មករាNo ratings yet

- PTR90 777814Document5 pagesPTR90 777814Sgly ZemogNo ratings yet

- s30 SMetallic Data SheetDocument5 pagess30 SMetallic Data Sheetluis miguel velarde manriqueNo ratings yet

- 8067 FBDocument20 pages8067 FBrauolNo ratings yet

- CCL 1Document1 pageCCL 1prabu cNo ratings yet

- Low forward voltage Schottky rectifierDocument5 pagesLow forward voltage Schottky rectifiermedea2010No ratings yet

- MECHATROLINK-III Communications Reference Type SERVOPACK SpecificationsDocument14 pagesMECHATROLINK-III Communications Reference Type SERVOPACK SpecificationsMateus CorrêaNo ratings yet

- Weblink For Calculation: Pressure Drop Calculation R 1.0Document1 pageWeblink For Calculation: Pressure Drop Calculation R 1.0Sumit WaghmareNo ratings yet

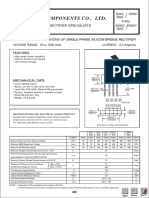

- DC Components Co., LTD.: Rectifier SpecialistsDocument2 pagesDC Components Co., LTD.: Rectifier Specialistszawmintun1No ratings yet

- DC Components Co., Ltd. Rs503Document3 pagesDC Components Co., Ltd. Rs503viernes06No ratings yet

- SDT S 105LMRDocument2 pagesSDT S 105LMReaherreramNo ratings yet

- LTM 8067Document20 pagesLTM 8067Sivasankar PoovaragavanNo ratings yet

- Cambridge Audio Azur 640c Service ManualDocument34 pagesCambridge Audio Azur 640c Service ManualMartin Szathmári100% (1)

- 314823114847pricebid JharbandhDocument94 pages314823114847pricebid Jharbandhpiyush kumarNo ratings yet

- Vishay Siliconix: Product SummaryDocument5 pagesVishay Siliconix: Product SummarySantiago SerranoNo ratings yet

- 40LX Ceiling Concealed CCAC InstallationDocument17 pages40LX Ceiling Concealed CCAC Installationjeferson binayNo ratings yet

- 1 - Product DescriptionDocument39 pages1 - Product Descriptioneka pramudia santosoNo ratings yet

- Supplement SM FLOWSIC100 Flare V2-1 en 2014-05Document5 pagesSupplement SM FLOWSIC100 Flare V2-1 en 2014-05eka pramudia santosoNo ratings yet

- TD OPTIMASS3000 en 4000651201 R07Document28 pagesTD OPTIMASS3000 en 4000651201 R07eka pramudia santosoNo ratings yet

- E 49990 CMI FLOWSIC100 Flare enDocument9 pagesE 49990 CMI FLOWSIC100 Flare eneka pramudia santosoNo ratings yet

- 2012 17 Different Requirements and Methods For Calibrating Gas and Liquid Ultrasonic Flow Custody Transfer Meters Kegel CEESIDocument13 pages2012 17 Different Requirements and Methods For Calibrating Gas and Liquid Ultrasonic Flow Custody Transfer Meters Kegel CEESIeka pramudia santosoNo ratings yet

- TD OPTIMASS2000 en 101122 4000228104 R04Document28 pagesTD OPTIMASS2000 en 101122 4000228104 R04eka pramudia santosoNo ratings yet

- Case Study BR 8 Inch R03 1Document4 pagesCase Study BR 8 Inch R03 1eka pramudia santosoNo ratings yet

- PD Meter BiRotor Plus Datasheet Low TempDocument6 pagesPD Meter BiRotor Plus Datasheet Low Tempeka pramudia santosoNo ratings yet

- Brodie Meters Chew Thru Paraffin: Case Study: Measurement of Crude Oil Containing ParaffinDocument2 pagesBrodie Meters Chew Thru Paraffin: Case Study: Measurement of Crude Oil Containing Paraffineka pramudia santosoNo ratings yet

- Non-Ferrous Birotor Plus (Models Ab270, Ab280, Ab290) : Technical DataDocument4 pagesNon-Ferrous Birotor Plus (Models Ab270, Ab280, Ab290) : Technical Dataeka pramudia santosoNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- ER100 Flow Monitor Certificates BinderDocument20 pagesER100 Flow Monitor Certificates Bindereka pramudia santosoNo ratings yet

- Brochure BiRotor Plus For Crude Oil R03Document4 pagesBrochure BiRotor Plus For Crude Oil R03eka pramudia santosoNo ratings yet

- PTZ-BOX FCD Download ModbusmapDocument8 pagesPTZ-BOX FCD Download Modbusmapeka pramudia santosoNo ratings yet

- Igtm - CT Igtm - Im Gas Turbine Meter: Installation, Operation and Maintenance Manual (IOM)Document48 pagesIgtm - CT Igtm - Im Gas Turbine Meter: Installation, Operation and Maintenance Manual (IOM)eka pramudia santosoNo ratings yet

- Brodie AddPak Pump Systems Technical DataDocument4 pagesBrodie AddPak Pump Systems Technical Dataeka pramudia santosoNo ratings yet

- PTZ FCDV3 CommunicationDocument9 pagesPTZ FCDV3 Communicationeka pramudia santosoNo ratings yet

- Flanged Ball Trunnion ValvesDocument24 pagesFlanged Ball Trunnion ValvesMahdi DalyNo ratings yet

- Atex 2 PDFDocument2 pagesAtex 2 PDFzainahmedscribdNo ratings yet

- Wonderware System Platform 2017 1 Day Workshop: Presented by GigihDocument46 pagesWonderware System Platform 2017 1 Day Workshop: Presented by Gigiheka pramudia santosoNo ratings yet

- Disk Shelf ds14hwg2 User GuideDocument128 pagesDisk Shelf ds14hwg2 User GuideJegan JeyarajNo ratings yet

- CWCT Curtain Wall Installation HandbookDocument34 pagesCWCT Curtain Wall Installation HandbookmoudshahineNo ratings yet

- Lesson 1 Cultural BackgroundDocument5 pagesLesson 1 Cultural BackgroundAngel Angeleri-priftis.No ratings yet

- Bk3500 BrochureDocument6 pagesBk3500 Brochurewillyg2k5No ratings yet

- PPTDocument37 pagesPPTEr Debasis Mishra0% (1)

- Bentone bg450 2Document32 pagesBentone bg450 2jvargasNo ratings yet

- Reflex QPADocument5 pagesReflex QPAmetal2567No ratings yet

- Death of Crypto King Nikolai Mushegian Fuels Conspiracy TheoriesDocument15 pagesDeath of Crypto King Nikolai Mushegian Fuels Conspiracy Theorieshans hansenNo ratings yet

- X RayDocument3 pagesX RayjacksonNo ratings yet

- Ali Campbell Complete PA Spec 2011 V8Document7 pagesAli Campbell Complete PA Spec 2011 V8Duke Smith-Holley0% (1)

- Information Technology Resume Sample - Windsor OliveDocument2 pagesInformation Technology Resume Sample - Windsor OliveEdcel CardonaNo ratings yet

- Viking: Product ManualDocument26 pagesViking: Product ManualCristian RobiconNo ratings yet

- Hilberseimer's Theories on Urban Planning and DecentralizationDocument2 pagesHilberseimer's Theories on Urban Planning and DecentralizationSwati ThakurNo ratings yet

- Python Financial Modelling PDFDocument54 pagesPython Financial Modelling PDFAmit KumarNo ratings yet

- RibbonDocument33 pagesRibbonjavluqNo ratings yet

- Design and Development of Treadmill To Generate Electricity by Using Mechanical EnergyDocument5 pagesDesign and Development of Treadmill To Generate Electricity by Using Mechanical EnergyAnonymous kw8Yrp0R5rNo ratings yet

- Autofrettage in Pressure VesselsDocument28 pagesAutofrettage in Pressure Vesselssran1986No ratings yet

- Exploded View & Parts List for Wind-Free Global 4wayDocument2 pagesExploded View & Parts List for Wind-Free Global 4wayRichard CarvajalNo ratings yet

- FKUv 1660 Premium - LiebherrDocument3 pagesFKUv 1660 Premium - Liebherraleks baltNo ratings yet

- Aeroscout Scout B1-100 BrochureDocument4 pagesAeroscout Scout B1-100 BrochureSebastian RentschNo ratings yet

- Axial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationDocument10 pagesAxial Turbine Stages Design 1D 2D 3D Simulation Experiment OptimizationAditya SawantNo ratings yet

- Manpower ListDocument1 pageManpower ListrijulNo ratings yet

- The Innovators DNADocument5 pagesThe Innovators DNAzia.ulhaq100% (2)

- 13.n-p-n TransistorDocument4 pages13.n-p-n TransistorkirtiNo ratings yet

- Workshop IDocument6 pagesWorkshop IValentina GonzálezNo ratings yet

- AudiDocument42 pagesAudiPokret Socijalista TemerinNo ratings yet