Professional Documents

Culture Documents

BMT300

Uploaded by

Shamim AbbasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMT300

Uploaded by

Shamim AbbasCopyright:

Available Formats

Saturday, April 1, 2023

Español | 中⽂

Enriching Technical Knowledge of T&D Professionals

FREE! Subscribe to INMR WEEKLY TECHNICAL

REVIEW

Case Histories for Mitigating

Transformer Bushing Risk

Bushings, Utility Practice & Experience

February 4, 2022 12 min read

Several years ago, utilities in Southeast Asia

embarked on a bushing reliability survey and,

based on 7ndings, formulated mitigation measures

to improve bushing performance. This edited 2017

contribution to INMR by S. Gobi Kannan, Chitapon

Jedwanna and Henny Ika, respectively at Tenaga

Nasional Berhad (TNB) in Malaysia, the Electricity

Generating Authority of Thailand (EGAT) and

Perusahaan Listrik Negara (PLN) in Indonesia,

reviewed experience with bushing failure for the

purpose of learning what measures can help

reduce such risk.

Case #1: Copper Migration on

300 kV Bushing Manufactured

in 1996 (ref. Figs 1 to 4)

Root Cause: Site and laboratory examination,

together with historical failure records, suggest

that the dielectric insulation breakdown in this case

was due to one or more of the following:

• Poor stress control design resulting in high

electrical stress at certain locations along the

paper/foil insulation;

• Poor manufacturing quality as seen in laboratory

examination of some paper/foil insulation layers

leading to uneven distribution of electrical stresses;

• Development of electrical treeing along the

insulation as a result of copper migration, made

worse by the high electrical stresses.

(a) (b)

Charred

insulation

Grounded

paper

Aluminium

Flange

Figure3.4(a); Figure3.4(b);

Fig 1: Arcing

ThearcingerosiondamageontheThearcingerosiondamageon

copperconductor,about300mmthecopperconductorwas

fromthealuminiumflange brushedandcleanedtoreveal

position. themeltedmetallicsurface.

erosion damage

Aluminium

groundingsleeve

Eigure3.3;

The275kVdamagedbushingwasremoved

on solid copper

fromthetransformerforteardownexamination.

conductor near

bottom <ange

area at location

of about 300

mm.

767

Eque4.10

Equre4.3:

Photographstakenwithilluminationshowedthe

presenceofpinholesalongtheedgesoftheoveriay

Fig 2: Inspection revealed penknife like marks as well

as presence of pinholes along aluminium foil layers

from poor manufacturing, possibly explaining poor

stress control.

Fig. 3: Presence of darkish substance “black trees”

visible at foil joint areas and evidence of Cu2S

formation due to possible copper migration

phenomenon.

Fig 4: Further study linked failure to potentially

corrosive oil (Shell Diala D) prior to 2008 on similar

designs of bushings, apart from poor manufacturing

practices.

(Source: DOBLE Proceedings 80th International Conference 2013)

Advertisement

Case #2: Test Tap Problems

(Figs. 5 to 9)

Surveys among ASEAN utilities indicate that about

10% of bushing failures relate to test tap problems.

In this particular instance, it was found that the

test tap measurement and tap bushing had no

continuity. Insulation resistance measurements

indicated an open circuit and disassembly of the

test tap revealed:

Fig. 5: Evidence of cracks on metallic Al <ange near test

tap location.

Fig. 6: Evidence of discharge activities and oil

contamination on core fragments as result of <oating

potential and issues of improper grounding of test tap

layer.

Fig. 7: Spring mechanism jammed and sparking marks

found on slider and tap housing.

• Utility experience in the region shows that the

majority of test tap failures have been attributed to

the spring-loaded design versus the permanent

connection type (see Figs. 8 and 9). Poor spring

contact pressure over the years and possible

damage during high surge current Row was

determined as possible root cause of the failure

mode that resulted in Roating potential and arcing

at the last layer of the condenser design bushings.

This could lead to contamination of the insulating

oil at the bottom side of the bushing and

eventually dielectric failure breakdown.

Fig. 8: Spring-loaded Fig. 9: Permanent

type. soldered type.

Case #3: Draw Lead Bushing

Fast Transient Issue in GIS/RCT

Substation

Root Cause: Loss of insulation dielectric strength of

main condenser due to heat generated along the

bushing’s aluminium tube as a result of fast and

very fast transient phenomena in the system

during switching.

Fig. 10: Flashover

evident at top

location of

bushing draw lead

and aluminium

tubing.

Transformer re-

energized safely

after bushing

replacement.

Fig. 11: Arcing damage evident at draw lead conductor

and at corresponding aluminium draw tube.

Fig. 12: Tube divided into 8 sections

designated A to H, revealed arcing

marks, explained by possible very fast

transient activities due to GIS

switching activities at station.

Observation indicated arcing marks

along tube being more concentrated

at air-side and having greater severity

compared to oil side.

Fig. 13:

Arcing and Fig. 14: Signs of overheating

<ow of erosion and arcing marks along

internal aluminium tube.

circulating

current

between

draw leads

and

aluminium

tubing.

Measurement of Power Factor and Capacitance on

the bushing prior to failure did not reveal any

abnormalities (see Table 1).

Table 1: 10 kV Power Factor & Capacitance

Measurement

Fig. 15: Damaged paper insulation for draw lead of

bushings.

The phenomenon of fast transient on a bushing’s

draw lead is still not fully understood in the Yeld.

Evidence of arcing/sparking between draw lead

and aluminium tube at common potential raises

concerns, especially in regard to risk of failures at

reactive compensator or in GIS substation

installations. As improvement, the speciYcation for

bushings with a draw lead connection has been

revised. The transformer manufacturer must now

ensure the draw lead cable within the tube is

insulated using thermally upgraded insulation

material with minimal thickness of 1mm. The goal

is to avoid causing any signiYcant rise in hot spot

temperature of the bushing and thereby prevent

any arcing between draw lead and aluminium

tubing during all fast transient phenomena in the

system.

Case #4: Monkey Damage to

Polymeric Insulators (Still

Unresolved)

To reduce risks from explosion and pollution, some

utilities have started to use bushings with

polymeric insulator housings. Recently, some of

these bushings have been attacked by monkeys

that chewed on the insulators. Discussions with

suppliers on use repellents or other inhibitors have

been in progress but without a commercial

solution in the case of transformer bushings. Some

severely damaged sheds have required urgent

replacement to prevent external Rashes and risk of

ingress into the main condenser layers.

Nonetheless, no utility members reported any

Rashovers since a\ected bushings were

immediately replaced once identiYed during

routine substation inspections.

Fig. 16: Damaged sheds due to monkey attack on

polymeric-housed bushings.

Case #5: Hygroscopic Issues for

Resin Impregnated Paper

Bushings

Hygroscopic properties of resin impregnated paper

(RIP) bushings need to be addressed in the event of

exposure to high humidity during storage or

handling. Prolonged exposure under environments

with high humidity can lead to the bottom of these

bushings absorbing moisture that can impact

performance. Change in colour at the bottom of

RIP bushings is indicative of this issue, which is a

major concern for utilities operating in high

humidity environments.

Fig 17: Wet RIP surface due to exposure to humidity

• While measurements show no signiYcant change

in C1 parameters, Table 2 illustrates changes in pF

C2 (after assembly) values that are sensitive to

humidity ingress at the bottom of a bushing’s

surface/core.

Table 2: 10 kV Power Factor & Capacitance

Measurement

For those RIP bushings with high humidity, drying

in an oven has been found to be e\ective in

removing moisture from bottom surfaces. Data

from one case study (see Fig. 18 and Table 3)

highlighted such issues, usually detectable by high

pf C2 values after assembly. Typical values of 2-3%

are acceptable limits recommended by OEMs. PF

for the overall bushing (HV terminal to Range) is

typically near to C1 values for dry bushings and this

is a useful parameter to monitor during any drying

process since PF C2 measurement may not be

accurate when a bushing is tested by itself, before

being mounted.

Fig. 18: RIP drying curve with PF (overall) monitoring

over drying cycle.

Table 3: PF (Overall) Data Over Drying Cycle

Advertisement

Initiatives in Mitigating Bushing

Failure Risk

While the risk of transformer Yre due to bushing

failure is relatively low, it is not negligible.

Implementing strategies to prevent injuries,

minimize impact on adjacent assets and avoid loss

of supply is therefore an essential part of

management of transformer assets. The aim of

these strategies and initiatives is to address and

quantify risk of Yres and provide guidance on how

this risk can be managed in a safe and cost

e\ective manner.

The following risk mitigation measures are based

on discussion and best practices among utility

members and have been deemed e\ective at

improving performance of bushings in power grids:

1. RIP bushings are preferred over OIP for

condenser bushing classes 52 kV and above;

2. Procurement only from suppliers with proven

designs. Product pre-qualiYcation process is

recommended;

3. Oil-Ylling and sampling is NOT recommended for

OIP style bushings, unless performed by

competent personnel or under OEM supervision:

4. Enhanced maintenance practices should include:

• Replacing and/or monitoring bushings that

exceed acceptable criteria;

• Relying on power factor and capacitance

measurements deemed sensitive in detecting

incipient problems;

• Conducting thermal scans at least once every 6

months;

• Carrying out visual inspection at least bi-monthly,

checking for leakage or severe external

contaminants.

5. Storage and handling for RIP and OIP bushings

should follow OEM recommendations. For

example, Fig. 19 shows typical storage practice for

periods exceeding 12 months using specially

designed metallic covers Ylled with dry transformer

oil.

Fig. 19: Current practice for long-term storage.

6. Use of RIP protection coating as a moisture

barrier has been under evaluation for e\ectiveness

in the Yeld.

Fig. 20: Standard and moisture barrier-coating for RIP

bushing.

Fig 21: 145 kV bushings with moisture barrier

protective coating.

Fig. 22 illustrates a moisture ingress test comparing

a standard bushing and one with special coating,

as currently used by some member utilities.

Fig. 22: Standard bushing under moisture ingress test

(courtesy ABB Sweden).

Testing the standard bushing versus one with a

water barrier coating (under Yeld evaluation)

concluded that:

• compared to uncoated RIP, the barrier coating

prolonged onset duration of moisture or water

ingress into bushing layers by a multiple of about

80.

• increase in power factor, despite use of coating,

proved that the coating is e\ective ONLY for

handling purposes but not for long-term storage.

Design/SpeciUcation

• No migration of moisture must be possible

through the external insulation to the RIP

condenser body. All bushings rated voltage 52 kV

and above shall have either Ybreglass or

alternative proven material that acts as moisture

barrier between the RIP condenser body and the

external composite insulator. Fig. 23 illustrates a

Ybreglass moisture barrier for RIP bushing designs.

Other OEMs use pure resin or SF6 foam for similar

purposes, also deemed acceptable.

Fig. 23: Water barrier for RIP bushing construction

using `breglass.

7. For purposes of inter-changeability and

standardization, oil-air bushings of rated voltage 52

kV and above have to comply with standard

requirements in terms of dimensions and rating

(see Fig. 24), as already successfully implemented

by one utility member.

Table 1: Standard Oil-AirType Type Bushing

Dimensional Requirement

Fig. 24: Sample bushing dimensional standardization

for diberent ratings.

8. For replacement or refurbishment purposes on

units already in service, it is recommended that the

new bushing supplied exactly match existing

dimensions in order to ensure bottom clearances

are met, as per initial design, and to prevent

substantial modiYcation and need for retroYtting

work on site;

9. All type tests and routine tests shall be carried

out according to the latest requirements of IEC or

IEEE standards. Type test reports and certiYcates

must be submitted to users on delivery;

Advertisement

10. Partial discharge testing shall be performed in

accordance with the latest IEC 60137

requirement(s) or routine measurements for

detection of internal PD. These shall be, at

maximum, virtually discharge free (i.e. ≤5pC at 1.05

Um/Ö3 and ≤5pC at 2.0 Um/Ö3 when more

stringent requirement(s) apply). If a bushing fails

the PD test, it is to be rejected and not to be

reconditioned for later use in the system.

11. For those bushings having a draw lead

connection, the transformer manufacturer shall

ensure that the draw lead cable within the tube is

insulated using thermally upgraded insulation

material with minimal thickness of 1 mm. There

must not be a signiYcant rise in hot spot

temperature of the bushing so as to prevent risk of

arcing between draw lead to aluminium tubing

during system fast transient phenomena.

12. When Yxed solid conductors are used, the

transformer manufacturer must ensure a Rexible

lead is provided between transformer and bushing

to avoid any vibration or dilatation being

transmitted during operation;

13. Current rating of supplied bushings shall be

inclusive of an overload factor of at least 1.2 times

maximum rated current for transformer rated

capacity;

14. The test tap shall be manufactured from non-

corrodible material and be sealed by means of a

non-corrodible screw-on dust cover during service.

A reusable (oil, heat and UV resistance) seal shall

be provided to prevent moisture and/or other

impurities from entering the test tap. Use of a

nitrile rubber material with sujcient hardness is

preferred in this regard;

15. Internal connection of the test tap to the

outmost condenser foil layer is accomplished using

a permanent electrical connection. Spring-loaded

type internal connections are not recommended

due to experience with poor performance due to

loss of spring contact pressure over time;

16. Air insulated cable boxes on transformers shall

have arc venting to prevent risk of damage to the

cable box, dislocation of cables and breakage of

bushings (see Fig. 25);

Fig. 25: Air insulated cable box with arc venting

facility.

17. In regard to on-line monitoring systems for

critical installations, it is the prerogative of users to

study the suitability of di\erent technologies that

can assess bushing condition in the Yeld. Fig. 26,

for example, illustrates installation of bushing

monitoring on a power transformer and Yndings of

a case study are elaborated below:

Fig. 26: Bushing monitoring system installation on

power transformer.

Findings have revealed that information from o\-

line and on-line monitoring mostly agree in the

case of healthy bushings (refer to Table 4) and such

a system can therefore serve as a tool to monitor

relative change in bushing condition. However,

beneYts have to be assessed on a case-by-case

basis prior to implementation, given the risks to

equipment being monitored as well as the cost and

reliability of such a monitoring system.

Case Study

Power Transformer 3×250 MVA, 500/230-11 kV

Bushing on-line installation: 2015

Table 4: Power Factor/Capacitance Data

On-Line Measurements vs. 10 kV Ob-Line Values

18. Use of resin impregnated synthetic Ybre

technology for dry bushings mitigates possible

issues related to hygroscopic properties of epoxy

resin impregnated bushings with conventional

paper insulation. For example, TNB, embarked on a

pilot project in 2013 using the new RIS technology

at 170 kV. Results, shown in Fig. 27 and Table 5,

indicated superior performance versus

conventional RIP bushings.

Fig. 27: First RIS bushing installation at TNB in

Malaysia.

Table 5 summarizes measured parameters over

the course of the evaluation period versus

acceptance criteria established by the project

team.

Table 5: Results of Measurements of On-Line Bushing

Monitoring

Overvoltage Protection

• Metal oxide surge arresters are an important part

of transformer protection in reducing risk of a

failure due to surges or transient activities in the

system. All line terminals of a transformer should

be protected by surge arresters.

Fig. 28: Use of surge arrester protection near

transformer terminal.

Conclusions

Despite a relatively low failure rate given their

population, failures of bushings can have a

catastrophic impact on grid reliability, availability

and safety. Conducting a survey and developing an

ASEAN Bushing Guidebook yielded signiYcant

beneYts in terms of standardizing and reviewing

existing practices to ensure these are in line with

best practices as well as the latest international

standards. Several e\ective risk mitigation

measures and improvements have been outlined

based on experience from past incidents of failure.

E\ective implementation of these measures has

helped improve overall bushing performance with

reduced rates of failures among member utilities.

________________

RELATED ARTICLES:

Test Requirements for HV Bushings

Testing for Safety & Risks A\ecting Operation of HV

Cable Terminations, Bushings & Arresters

Advertisement

← Improving Installation of Transmission

Line Surge Arresters

Practical Issues Applying Pollution

Standards to Select Optimal Outdoor

Insulation (Part 1 of 2) →

Advertisement

SUPPLIER OF THE WEEK

More about Izoelektro >>

Related Articles

Evaluating Reliability of Bushings

Australian Substation Focused on Environmentally-

Sensitive Design

Sheath Voltage Limiters Protect HV Power Cables

Site Measurement & Analysis for Improving Lightning

Performance of 500 kV Line (Video)

Computer Modeling Evaluates Performance of Station

Posts

SUPPLIER OF THE WEEK:

More about Izoelektro d.o.o.

LABORATORY OF THE WEEK:

More about KONČAR - Electrical Engineering

Institute

Subscribe to INMR WEEKLY TECHNICAL

REVIEW

Full Name

Your Email Address

Subscribe

INMR BUYERS GUIDE | INMR LABORATORY

GUIDE | INMR WORLD CONGRESS

Connect With Us

Copyright © 1993 - 2023 Zimmar Holdings

Ltd./INMR.

Contents are protected by international

copyrights and treaties. Reproduction in whole or

in part, without express written permission, is

prohibited. While every e<ort is made to verify

the data and information contained,

INMR/Zimmar Holdings Ltd. accepts no liability,

direct or implied, for the accuracy of all

information presented.

Privacy - Terms

You might also like

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Brakage Analysis in Alminium in DrawingDocument11 pagesBrakage Analysis in Alminium in DrawingWajeeh BitarNo ratings yet

- GN - 8-04-Thermally Sprayed Metal CoatingsDocument4 pagesGN - 8-04-Thermally Sprayed Metal CoatingsGeorge AlexiadisNo ratings yet

- Influence of Storage Conditions On Aluminum 4043A Welding WiresDocument8 pagesInfluence of Storage Conditions On Aluminum 4043A Welding WiresdietersimaNo ratings yet

- Commercially Pure Tantalum WiredrawingDocument1 pageCommercially Pure Tantalum WiredrawingLeonardo Kyo KabayamaNo ratings yet

- A PM 07 Copper PillarsDocument7 pagesA PM 07 Copper PillarsSieww GlenNo ratings yet

- Multi-Stack Silicon-Direct Wafer Bonding For 3D MEMS ManufacturingDocument8 pagesMulti-Stack Silicon-Direct Wafer Bonding For 3D MEMS ManufacturingBenjamin W CullenNo ratings yet

- Electron Beam Welding Process App PDFDocument6 pagesElectron Beam Welding Process App PDFsskiitbNo ratings yet

- Evaluation of Steel Properties and Cracking in "K"-Area of W ShapesDocument7 pagesEvaluation of Steel Properties and Cracking in "K"-Area of W ShapesarjunNo ratings yet

- Case Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeDocument7 pagesCase Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel PipeGina BerríoNo ratings yet

- Integration Aspects For Damascene Copper Interconnect in Low K DielectricDocument3 pagesIntegration Aspects For Damascene Copper Interconnect in Low K DielectricKwanghoon Ken KimNo ratings yet

- Rene 80 Casting DefectsDocument9 pagesRene 80 Casting Defectsatfrost4638100% (1)

- Chapter 3 CMOS Processing Technology: PassivationDocument1 pageChapter 3 CMOS Processing Technology: PassivationCarlos SaavedraNo ratings yet

- Edison Welding Institute Hot Tap WeldingDocument19 pagesEdison Welding Institute Hot Tap WeldingShikhar JainNo ratings yet

- An Investigation of Fusion Zone Microstructures of Welded Aluminum Alloy JointsDocument6 pagesAn Investigation of Fusion Zone Microstructures of Welded Aluminum Alloy JointsdietersimaNo ratings yet

- Condition Assessment and Failure Modes of Solid Dielectric Cables in PerspectiveDocument7 pagesCondition Assessment and Failure Modes of Solid Dielectric Cables in PerspectiveHafiziAhmadNo ratings yet

- Bearing Insulation Updates With SKF-1Document3 pagesBearing Insulation Updates With SKF-1Shyam KumarNo ratings yet

- Zhao 2013Document10 pagesZhao 2013Susana PérezNo ratings yet

- Triplate enDocument4 pagesTriplate enRAGESHNo ratings yet

- J Apsusc 2009 07 081Document10 pagesJ Apsusc 2009 07 081Waqas MuneerNo ratings yet

- Higt Temp Failure Case LanceDocument2 pagesHigt Temp Failure Case LanceDevin Trianda PutraNo ratings yet

- Bimetallic and Alloy Welds in HP Hydrogen and Nitrogen ServiceDocument18 pagesBimetallic and Alloy Welds in HP Hydrogen and Nitrogen Servicevaratharajan g rNo ratings yet

- Proteção CatódicaDocument5 pagesProteção CatódicaCarlos SandinoNo ratings yet

- Failure Analysis of A First Stage In738 GasDocument13 pagesFailure Analysis of A First Stage In738 GasFirman Rama PutraNo ratings yet

- Electrical Stress On Electrical Steel Coatings: Journal of Magnetism and Magnetic Materials January 2003Document4 pagesElectrical Stress On Electrical Steel Coatings: Journal of Magnetism and Magnetic Materials January 2003ipraoNo ratings yet

- A Failure Analysis and Remaining Life AsDocument6 pagesA Failure Analysis and Remaining Life AsPrimawati RahmaniyahNo ratings yet

- Advanced Technology of Stator Winding Insulation System For H.V. MotorsDocument4 pagesAdvanced Technology of Stator Winding Insulation System For H.V. MotorsKhashane Willy MohaleNo ratings yet

- Optimization Copper Wire Bonding On: A1-Cu MetallizationDocument7 pagesOptimization Copper Wire Bonding On: A1-Cu Metallizationjulio perezNo ratings yet

- WAI - DeBruyne Paper - 120410Document4 pagesWAI - DeBruyne Paper - 120410Boris DardelNo ratings yet

- Thermal-Spray (Metallized) Coatings For Steel: Robert A. SulitDocument15 pagesThermal-Spray (Metallized) Coatings For Steel: Robert A. SulitvvpvarunNo ratings yet

- Pages From MCSP Pt. 19Document15 pagesPages From MCSP Pt. 19cellNo ratings yet

- BRUTSCH - .... - High Voltage Insulation Failure Mechanisms - ARTICLEDocument4 pagesBRUTSCH - .... - High Voltage Insulation Failure Mechanisms - ARTICLEAlen PavlicaNo ratings yet

- Aluminum Connectors & CrimpingDocument4 pagesAluminum Connectors & CrimpingBiplab PaulNo ratings yet

- Cladding in Heat Exchanger - BaherDocument3 pagesCladding in Heat Exchanger - BaherWael MansourNo ratings yet

- Multi Objective Optimization Ganesh MSSP 2015 - WEDMDocument14 pagesMulti Objective Optimization Ganesh MSSP 2015 - WEDMDoopukuntla SmithaNo ratings yet

- Types of CableDocument5 pagesTypes of CableEnglish words BY Utkarsh johriNo ratings yet

- Influence of Titanium Oxide Films On Copper Nucleation During ElectrodepositionDocument12 pagesInfluence of Titanium Oxide Films On Copper Nucleation During Electrodepositionapi-19973331No ratings yet

- Ultrasonic Non-Destructive Evaluation For Spot Welding in The Automotive IndustryDocument6 pagesUltrasonic Non-Destructive Evaluation For Spot Welding in The Automotive IndustryCarlos MusellaNo ratings yet

- Edium-Voltage Able Accessories: Special FeatureDocument5 pagesEdium-Voltage Able Accessories: Special FeatureMohamedHussein MohamedHusseinNo ratings yet

- Electric Feedthroughs and Insulating Parts: Helmut Mayer, FRIATEC AG, MannheimDocument10 pagesElectric Feedthroughs and Insulating Parts: Helmut Mayer, FRIATEC AG, MannheimRonakPatelNo ratings yet

- WJ 1977 02 S51induction Aluminium WeldingDocument5 pagesWJ 1977 02 S51induction Aluminium WeldingCarlos SosaNo ratings yet

- A Study of R.f.-Sputtered Al and Ni Thin Films On AZ91D Magnesium AlloyDocument6 pagesA Study of R.f.-Sputtered Al and Ni Thin Films On AZ91D Magnesium AlloyirahnarahNo ratings yet

- Dissolution and Soldering Behavior of Nitrided Hot Working Steel With Multilayer LAFAD PVD CoatingsDocument6 pagesDissolution and Soldering Behavior of Nitrided Hot Working Steel With Multilayer LAFAD PVD CoatingsbharatNo ratings yet

- Frequently Asked Questions On Wring RulesDocument7 pagesFrequently Asked Questions On Wring RuleslagartijillaNo ratings yet

- Development of A New Optical Monitoring System ForDocument7 pagesDevelopment of A New Optical Monitoring System ForNia KurniaNo ratings yet

- Fabrication of PMOS TransistorsDocument11 pagesFabrication of PMOS TransistorsNash Anderson50% (4)

- Surlon KE Datasheet Hard Ceramic Hard Anodizing With Lubrication 29AUG17Document8 pagesSurlon KE Datasheet Hard Ceramic Hard Anodizing With Lubrication 29AUG17Giacomo ZammattioNo ratings yet

- Geometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingDocument15 pagesGeometrical Degradation of Electrode and Liquid Metal Embrittlement Cracking in Resistance Spot WeldingMathews LimaNo ratings yet

- A Study Into The Effects of Residual Stresses and Hot Dip GalvanizingDocument4 pagesA Study Into The Effects of Residual Stresses and Hot Dip GalvanizingSteve HornseyNo ratings yet

- Role of Microstructure in Sucker Rod String Failures in Oil Well ProductionDocument2 pagesRole of Microstructure in Sucker Rod String Failures in Oil Well ProductionJose Marval RodriguezNo ratings yet

- TC Type IOLDocument5 pagesTC Type IOLDHARMENDRANo ratings yet

- Costello 1993Document8 pagesCostello 1993David MendozaNo ratings yet

- Cu DamasceneDocument4 pagesCu Damascenejeren1228No ratings yet

- A Case of Aluminum Nitride Embrittlement of Heavy Wall Cast SteelDocument6 pagesA Case of Aluminum Nitride Embrittlement of Heavy Wall Cast SteelBritz MaumelaNo ratings yet

- Upgrading Electromagnetic Shielding of A Military ShelterDocument5 pagesUpgrading Electromagnetic Shielding of A Military ShelterYasin TunaNo ratings yet

- Creating Permanent Connections With Plastic Deformation ProceduresDocument5 pagesCreating Permanent Connections With Plastic Deformation ProceduresMoqaNo ratings yet

- Research and Design of DC500kV Optical Fiber Composite Submarine CableDocument6 pagesResearch and Design of DC500kV Optical Fiber Composite Submarine CableNamrata ToleNo ratings yet

- Explosive WeldingDocument3 pagesExplosive WeldingDarryl007No ratings yet

- Alternate Metal Finishes For Wire Bond and Soldering ApplicationsDocument9 pagesAlternate Metal Finishes For Wire Bond and Soldering ApplicationsMuhd HasbulNo ratings yet

- Role of Surface Finish in Contact BrazingDocument3 pagesRole of Surface Finish in Contact BrazingArathoNNo ratings yet

- Diagnostic Techniques of Power Transformers 1661164635Document77 pagesDiagnostic Techniques of Power Transformers 1661164635Shamim Abbas100% (2)

- GRID CODE 2005 & 2021: Understanding and ComparisonDocument84 pagesGRID CODE 2005 & 2021: Understanding and ComparisonShamim AbbasNo ratings yet

- CRH MOV Technical Data SheetDocument4 pagesCRH MOV Technical Data SheetShamim AbbasNo ratings yet

- Never Give Up: "When Your Legs Can'T Run Anymore Run With Your Heart"Document1 pageNever Give Up: "When Your Legs Can'T Run Anymore Run With Your Heart"Shamim AbbasNo ratings yet

- Generator in Situ Inspection Fact Sheet PDFDocument2 pagesGenerator in Situ Inspection Fact Sheet PDFShanjiNo ratings yet

- Basic Instrumentation PDFDocument53 pagesBasic Instrumentation PDFAnonymous PTHwJyinsNo ratings yet

- Alstom SASDocument3 pagesAlstom SASShamim AbbasNo ratings yet

- Sid 8BT ADocument66 pagesSid 8BT AShamim AbbasNo ratings yet

- Exciter Ex2100e AcronymsDocument12 pagesExciter Ex2100e AcronymsShamim AbbasNo ratings yet

- K-Electric Limited: Northeast Electric Power Design Institute CO.,LTD. China Power Engineering Consulting GroupDocument1 pageK-Electric Limited: Northeast Electric Power Design Institute CO.,LTD. China Power Engineering Consulting GroupShamim AbbasNo ratings yet

- Electrical Testing of Transformers As Per OEM (ABB)Document4 pagesElectrical Testing of Transformers As Per OEM (ABB)Shamim AbbasNo ratings yet

- GE Interface Check ListDocument12 pagesGE Interface Check ListShamim AbbasNo ratings yet

- Section & Shift Wise Daily Attendance Sheet November 2021Document2 pagesSection & Shift Wise Daily Attendance Sheet November 2021Shamim AbbasNo ratings yet

- Lathe & Milling Expert Zahid HussainDocument1 pageLathe & Milling Expert Zahid HussainShamim AbbasNo ratings yet

- Digital Relay Testing Flowchart Valence Electrical Training Services PDFDocument2 pagesDigital Relay Testing Flowchart Valence Electrical Training Services PDFbisas_rishiNo ratings yet

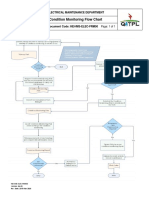

- HEI-IMS-ELEC-FRM50 Condition Monitoring Flow ChartDocument1 pageHEI-IMS-ELEC-FRM50 Condition Monitoring Flow ChartShamim AbbasNo ratings yet

- Transformer ChecklistDocument50 pagesTransformer ChecklistGaurav YadavNo ratings yet

- Work Flow Chart: Electrical Maintenance DepartmentDocument1 pageWork Flow Chart: Electrical Maintenance DepartmentShamim AbbasNo ratings yet

- The Microsoft Excel Formulas Cheat Sheet Date and Time FormulasDocument11 pagesThe Microsoft Excel Formulas Cheat Sheet Date and Time FormulasMichael Ozora100% (2)

- Ieee C37.122Document2 pagesIeee C37.122Shamim AbbasNo ratings yet

- Aes03 Set 2009 r2019 IDocument16 pagesAes03 Set 2009 r2019 Ishanbel ayayuNo ratings yet

- CSSR Optimization For GSM and WCDMADocument30 pagesCSSR Optimization For GSM and WCDMAmosesNo ratings yet

- CONTACTORESDocument10 pagesCONTACTORESRaúl MendozaNo ratings yet

- Devices Connected To Your NetworkDocument1 pageDevices Connected To Your NetworkSuper WhippedNo ratings yet

- Lab 6 Mux and DecoderDocument6 pagesLab 6 Mux and DecoderRifah Shanjida MomoNo ratings yet

- Computerized Engine Controls 10th Edition Hatch Test Bank 1Document4 pagesComputerized Engine Controls 10th Edition Hatch Test Bank 1nadia100% (34)

- IGCSE Physics - Student GuideDocument36 pagesIGCSE Physics - Student Guiden0tsewNo ratings yet

- Automatic Control Systems - Electronics and Communication Engineering Questions and Answers - 1Document9 pagesAutomatic Control Systems - Electronics and Communication Engineering Questions and Answers - 1Rian RiveraNo ratings yet

- CMOS Three Axis Hall Sensor and Joystick Application Schott3axisJoystickDocument4 pagesCMOS Three Axis Hall Sensor and Joystick Application Schott3axisJoystickbesttv046936No ratings yet

- Notice Eng Jemec 01022019Document2 pagesNotice Eng Jemec 01022019narendraNo ratings yet

- Project ReportDocument77 pagesProject ReportArunodayaprojectsNo ratings yet

- (PDF) Colorless, Directionless and Contentionless Multi-Degree ROADM Architecture For Mesh Optical NDocument25 pages(PDF) Colorless, Directionless and Contentionless Multi-Degree ROADM Architecture For Mesh Optical NBBAdvanz CommunicationsNo ratings yet

- ManualDocument56 pagesManual- Y.D.V-No ratings yet

- On GeneratorDocument55 pagesOn GeneratorDileep Reddy91% (11)

- Invoice I Phone 7Document1 pageInvoice I Phone 7tanishkrajak3108No ratings yet

- 42pfl3508g 78 Fhi BRP PDFDocument3 pages42pfl3508g 78 Fhi BRP PDFram79co100% (1)

- NERD 9 and 12 Function InstructionsDocument64 pagesNERD 9 and 12 Function InstructionsknogmanualsNo ratings yet

- Toshiba Satellite E55 ZRMAA Compal LA-A481P Rev1.0 SchematicDocument55 pagesToshiba Satellite E55 ZRMAA Compal LA-A481P Rev1.0 SchematicdataNo ratings yet

- FSP3000R7 MSSpecification Rel.7.1 V1.4Document220 pagesFSP3000R7 MSSpecification Rel.7.1 V1.4Anonymous GtBrT1No ratings yet

- Log AsusDocument81 pagesLog AsusDioNZB ReleasesNo ratings yet

- EEE141 Topic 1Document50 pagesEEE141 Topic 1Saadat TariqNo ratings yet

- ECE357 Course InformationDocument7 pagesECE357 Course InformationVictor HughesNo ratings yet

- Digital Scale 340368 - A - D - IE - ENDocument47 pagesDigital Scale 340368 - A - D - IE - ENDimitar KirovNo ratings yet

- LHP-30D Datasheet 20170904Document2 pagesLHP-30D Datasheet 20170904Ranses RomanNo ratings yet

- Mod 1Document64 pagesMod 1kallista.antenorNo ratings yet

- Laboratory Manual: Analogue and Digital Communication LabDocument18 pagesLaboratory Manual: Analogue and Digital Communication LabZain HaiderNo ratings yet

- Section8C Intrinsically Safe BarriersDocument29 pagesSection8C Intrinsically Safe BarrierstasingenieriaNo ratings yet

- 2210 s17 QP 11Document12 pages2210 s17 QP 11DeveshNo ratings yet

- IEEE STD 404-2012Document46 pagesIEEE STD 404-2012anonimoefra100% (1)

- Microcontroller Based Earthquake Detection System For Spontaneous Cut-Off of Domestic Utility Lines For Safety MeasuresDocument4 pagesMicrocontroller Based Earthquake Detection System For Spontaneous Cut-Off of Domestic Utility Lines For Safety MeasuresJunaidNo ratings yet