Professional Documents

Culture Documents

Module 3

Uploaded by

Bella LacsinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 3

Uploaded by

Bella LacsinaCopyright:

Available Formats

PAMPANGA STATE AGRICULTURAL UNIVERSITY

Department of Agricultural Business Economics & Entrepreneurship

Module 3 TRANSPORTATION AND ASSIGNMENT PROBLEMS

Transportation problem is concerned with selecting routes in product distribution network

among manufacturing firms/plants and distribution warehouses or among regional distribution

warehouses and local distribution outlets. The assignment problem, on the other hand, involves

assigning employees to tasks, salespersons to territories, contract to bidders, or jobs to plants.

In applying transportation method and the assignment method, management is searching for a

distribution route or an assignment which will optimize some objective; this can be the

minimization of total transportation cost, the maximization of profit, or the minimization of total

time involved.

Example

Let us consider the case the case of the Bass Gravel Company, which has received a

contract to supply gravel for three new road projects located in the towns of Greenville,

Fountain, and Ayden. Construction engineers have estimated the amounts of gravel which will

be needed at three road construction projects:

Weekly

requirements,

Project Location truckloads

A Greenville 72

B Fountain 102

C Ayden 41

Total 215

The Bass Gravel Company has three gravel plants located in the towns of Kinston,

Wilson, and Bethel. The gravel required for the construction projects can be supplied by these

three plants. Bass’s chief dispatcher has calculated the amounts of gravel which can be

supplied by each plant:

Weekly

requirements,

Plant Location truckloads

W Kinston 56

X Wilson 82

Y Bethel 77

Total 215

At this point, we see that the total amount available is exactly equal to the total amount

required. When total supply is equal to total demand, a balanced condition is said to exist.

Although the balanced case is very unlikely in actual practice, it will enable us to focus on the

basic ideas underlying the transportation method. The unbalanced case, where supply and

demand are unequal.

The company has computed the delivery costs from each plant to each project site. As in

the linear programming problems discussed, we assume that the variables in the problem must

be linearly related. In this case, total delivery costs between each plant and project site vary

directly with the number of truckloads of gravel distributed.

Management 181 Quantitative Business Analysis by: Prof. Leslie V. Torres

PAMPANGA STATE AGRICULTURAL UNIVERSITY

Department of Agricultural Business Economics & Entrepreneurship

Cost per truckload

From To project A To project B To project C

Plant W $4 $8 $8

Plant X 16 24 16

Plant Y 8 16 24

Linear Programming Formulation

I. Step 1: Set up the transportation tableau

Step 2: Develop an initial solution

Step 3: Test the solution for the improvement

Steps in evaluating any unused square

a. Choose the unused square to be evaluated.

b. Trace a closed path (measuring horizontally and vertically)

c. Assign + and – sign alternately.

d. Determine the net change in costs.

e. Repeat the above steps.

Step 4: Develop the improved solution, select the largest negative improvement index.

II. The MODI method may be summarized by the following steps.

a. For the solution, compute the R & K values using the formula R i + Kj = Cij (the

cost at the stone ij) Ri is always set equal to zero)

b. Calculate the improvement indices for all unused squares using Cij (cost of

unused square) - Ri - Kj = improvement index.

c. Select the unused square with the largest negative index.

d. Trace the closed path for the unused square having the largest negative index.

e. Develop an improved solution using the same procedure as the outlined in the

stepping stone method.

f. Repeat steps 1 to 5 until the optimal solution has been found.

The Transportation Method

Step 1: Set up the transportation tableau

From To Project A Project B Project C Plant Capacity

Plant W 56

Plant X 82

Plant Y 77

Project requirements 72 102 41 215 215

Step 2: Develop an initial solution

a. Starting at the upper-left hand corner (northwest corner rule) of the tableau, the supply

available at each row must be exhausted before moving down to the next row, and the

Management 181 Quantitative Business Analysis by: Prof. Leslie V. Torres

PAMPANGA STATE AGRICULTURAL UNIVERSITY

Department of Agricultural Business Economics & Entrepreneurship

rim requirements of any column must be exhausted before moving to the right next

column.

b. Check to see that all rim requirements have been satisfied.

The Initial Solution

From To Project A Project B Project C Plant Capacity

WA 4 WB 8 WC 8

Plant W 56 56

XA 16 XB 24 XC 16

Plant X 16 66 82

YA 8 YB 16 YC 24

Plant Y 36 41 77

Project requirements 72 102 41

215 215

Source–destination Quantity Unit Total

X = WA WB

Combination shipped Cost Cost

56 - +

WA 56 $4 224 XA + XB –

XA 16 16 256 16 66

XB 66 24 1,584

YB 36 16 576

YC 41 24 984

Total transportation Cost 3,624

Step 3: Test the solution for improvement.

Improvement index for square WB = WB – WA + XA – XB

= 8 – 4 + 16 – 24 = -4

` This means that for every truckload shipped form Plant W to project B, transportation

cost would be reduced by $4.

For YA = YA – XA + XB - YB

= 8 – 16 + 24 - 16

=0

For WC = WC – WA + XA - XB + YB –YC

= 8 – 4 + 16 – 24 + 16 – 24

= -12

For XC = XC – XB + YB –YC

= 16 – 24 + 16 – 24

= -16

Management 181 Quantitative Business Analysis by: Prof. Leslie V. Torres

PAMPANGA STATE AGRICULTURAL UNIVERSITY

Department of Agricultural Business Economics & Entrepreneurship

Step 4: Development the improved solution

To select among the unused squares, chose the most negative improvement index,

wherein it is 16. Determine the smallest stone in a negative position in the closed path.

XB XC Note: The stepping-stone method was used to

66-41=25 0+41=41 eliminate each unused square. If any

YB YC improvement index is negative, the best solution

36+41=77 41-41=0 has not yet attained.

Second calculation

From To Project A Project B Project C Plant Capacity

WA 4 WB 8 WC 8

Plant W 56 56

XA 16 XB 24 XC 16

Plant X 16 25 41 82

YA 8 YB 16 YC 24

Plant Y 77 77

Project requirements 72 102 41 215 215

Shipping Quantity Unit Total

X =

Assignments shipped Cost Cost

WA 56 $4 224

XA 16 16 256

XB 25 24 600

XC 41 16 656

YB 77 16 1232

Total transportation Cost 2,968

Unused Computation of

square Improvement index

WB 8 – 4 + 16 – 24 = -4

WC 8 – 4 + 16 -16 = 4

YA 8 – 16 + 24 – 16 = 0

YC 24 – 16 + 24 -16 = 16

WA WB

56-25 = 31 0+25 = 25

XA XB

16+25 = 41 25-25 = 0

Management 181 Quantitative Business Analysis by: Prof. Leslie V. Torres

PAMPANGA STATE AGRICULTURAL UNIVERSITY

Department of Agricultural Business Economics & Entrepreneurship

Third the solution

From To Project A Project B Project C Plant Capacity

WA 4 WB 8 WC 8

Plant W 31 25 56

XA 16 XB 24 XC 16

Plant X 41 41 82

YA 8 YB 16 YC 24

Plant Y 77 77

Project requirements 72 102 41 215 215

Shipping Quantity Unit Total

X =

Assignments shipped Cost Cost

WA 31 $4 124

WB 25 8 200

XA 41 16 656

XC 41 16 656

YB 77 16 1,232

Total transportation Cost 2,868

Unused Computation of

square Improvement index

WC 8 – 4 + 16 – 16 = 4

YB 24 – 8 + 4 -16 = 4

YA 8 – 4 + 8 – 16 = -4

YC 24 - 16 +8 – 4 + 16 -16 = 12

WA WB

31-31 = 0 25+31=56

XA XB

41

YA YB

0+31=31 77-31=46

Management 181 Quantitative Business Analysis by: Prof. Leslie V. Torres

PAMPANGA STATE AGRICULTURAL UNIVERSITY

Department of Agricultural Business Economics & Entrepreneurship

Optimal Solution

From To Project A Project B Project C Plant Capacity

WA 4 WB 8 WC 8

Plant W 56 56

XA 16 XB 24 XC 16

Plant X 41 41 82

YA 8 YB 16 YC 24

Plant Y 31 46 77

Project requirements 72 102 41 215 215

Unused Computation of

square Improvement index

WA 4 – 8 + 16 – 8 = 4

WC 8 – 16 + 16 – 8 + 16 – 8 = 8

XB 24 – 16 + 8 – 16 = 0

YC 24 – 16 + 16 – 8 = 16

Shipping Quantity Unit Total

Assignments shipped

X

Cost

= Cost

WB 56 8 448

XA 41 16 656

XC 41 16 656

YA 31 8 248

YB 46 16 736

Total transportation Cost 2,744

Management 181 Quantitative Business Analysis by: Prof. Leslie V. Torres

PAMPANGA STATE AGRICULTURAL UNIVERSITY

Department of Agricultural Business Economics & Entrepreneurship

Exercise 3

Solve

Sid Lane hauls oranges between Florida groves and citrus packing plants. His schedule

this week calls for 520 boxes with locations and costs as follows:

Grove Available per Packing plant Requirement per

week week

A 170 W 130

B 250 X 200

C 100 Y 190

Cost Information

From To plant W To plant X To plant Y

Grove A Php 12 Php 8 Php 5

Grove B 11 15 10

Grove C 2 7 6

Use Stepping-stone method to find the lowest transportation cost.

Management 181 Quantitative Business Analysis by: Prof. Leslie V. Torres

You might also like

- Site Control of Materials: Handling, Storage and ProtectionFrom EverandSite Control of Materials: Handling, Storage and ProtectionNo ratings yet

- Optimize Transportation CostsDocument19 pagesOptimize Transportation CostsJhon Lester SahagunNo ratings yet

- Seatwork Sample CaseDocument4 pagesSeatwork Sample CaseSione mae lastimosoNo ratings yet

- Optimal Cement DistributionDocument4 pagesOptimal Cement DistributionSoumendra Roy100% (2)

- Quantitative Techniques - Assignment 1 QuestionsDocument6 pagesQuantitative Techniques - Assignment 1 Questionsmy VinayNo ratings yet

- Bass Gravel Company Receives Contract to Supply Three Road ProjectsDocument1 pageBass Gravel Company Receives Contract to Supply Three Road ProjectsAilendeLuna0% (1)

- Transportation problem solutions and optimal schedulingDocument4 pagesTransportation problem solutions and optimal schedulingharryNo ratings yet

- Transportation Problem UnbalancedDocument21 pagesTransportation Problem UnbalancedPriyadarshini TripathiNo ratings yet

- Linear Programming Transportation MODELDocument3 pagesLinear Programming Transportation MODELMarvin Marquez PosadasNo ratings yet

- Transportation ProblemDocument21 pagesTransportation ProblemUTTAM KOIRALANo ratings yet

- Practice Problems For Mid Term TestDocument11 pagesPractice Problems For Mid Term TestAkshada VinchurkarNo ratings yet

- 73 220 Lecture11Document40 pages73 220 Lecture11api-26315128No ratings yet

- LP Balanced Transportation V2Document28 pagesLP Balanced Transportation V2Shaina SantosNo ratings yet

- The Special Purpose Algorithms of Linear Programming: By: Engr. Marizen B. ContrerasDocument64 pagesThe Special Purpose Algorithms of Linear Programming: By: Engr. Marizen B. ContrerasAdriel John100% (1)

- Special Cases of LPP: Chapter 6, Part A: Distribution and Network ModelsDocument39 pagesSpecial Cases of LPP: Chapter 6, Part A: Distribution and Network ModelsdsdfsdfsNo ratings yet

- Project Report For Quantitative Techniques For Business DecisionsDocument14 pagesProject Report For Quantitative Techniques For Business DecisionsMonu GuptaNo ratings yet

- Plant DesignDocument34 pagesPlant Designapi-3695407No ratings yet

- Chapter 2 - Locating Facilities - FULLDocument55 pagesChapter 2 - Locating Facilities - FULLTrần Thanh TrúcNo ratings yet

- Location AnalysisDocument7 pagesLocation AnalysisAhmed ElyazidNo ratings yet

- Chapter 2 - Locating FacilitiesDocument51 pagesChapter 2 - Locating FacilitiesTrần KhangNo ratings yet

- Transportation ModelsDocument19 pagesTransportation ModelsAbdi NegassaNo ratings yet

- Special PurposeDocument100 pagesSpecial PurposeSheena Pretesto100% (2)

- Minimizing Total Costs in a Multi-Stage Supply Chain Using a Transshipment ModelDocument9 pagesMinimizing Total Costs in a Multi-Stage Supply Chain Using a Transshipment ModelCésar Vázquez ArzateNo ratings yet

- Assignment 2 - EEE 475DDocument1 pageAssignment 2 - EEE 475DAbdul AlimNo ratings yet

- SCD-HW1-Full Name-Student IDDocument4 pagesSCD-HW1-Full Name-Student IDVân Huỳnh Ngọc ThảoNo ratings yet

- .206J/16.77J/ESD.215J Airline Schedule Planning: Cynthia Barnhart Spring 2003Document38 pages.206J/16.77J/ESD.215J Airline Schedule Planning: Cynthia Barnhart Spring 2003myself8888No ratings yet

- Transportation Problem PDFDocument14 pagesTransportation Problem PDFVIVEK KUMARNo ratings yet

- Location Planning & Analysis: OutlineDocument21 pagesLocation Planning & Analysis: OutlineWinter NaiNo ratings yet

- Home Assignment On Operations ResearchDocument4 pagesHome Assignment On Operations ResearchSubir ChakrabartyNo ratings yet

- Cam Lab - Production TonnageDocument5 pagesCam Lab - Production TonnageLASER LIONNo ratings yet

- Transportation problem solverDocument11 pagesTransportation problem solverRohan NagarNo ratings yet

- Oil Distribution Model: Unit Shipping CostsDocument3 pagesOil Distribution Model: Unit Shipping CostsHendra JayantoNo ratings yet

- Acme Alarms smoke detector production and subcontracting problemDocument4 pagesAcme Alarms smoke detector production and subcontracting problemSaif Tiushae100% (1)

- Chapter Three. Transportation.: ObjectiveDocument17 pagesChapter Three. Transportation.: ObjectiveMARION KERUBONo ratings yet

- Transportation ProblemDocument30 pagesTransportation ProblemYash JunejaNo ratings yet

- Or Individual Assignment For Queens MBA FINALDocument7 pagesOr Individual Assignment For Queens MBA FINALAster GebreNo ratings yet

- Solve The Following Problems Using: (A) MATLAB Built-In Functions (B) Graphically 1. Solve The Following Linear ProgramDocument4 pagesSolve The Following Problems Using: (A) MATLAB Built-In Functions (B) Graphically 1. Solve The Following Linear ProgramMortada OthmanNo ratings yet

- Application of improved multistage vehicle routing problemDocument4 pagesApplication of improved multistage vehicle routing problemDwi Agustin Nuriani SNo ratings yet

- Transportation Model Solution MethodsDocument6 pagesTransportation Model Solution MethodsRozana FerreiraNo ratings yet

- Chapter 3Document15 pagesChapter 3Eshetu HailuNo ratings yet

- 2A. Facility LocationDocument15 pages2A. Facility LocationNeeraj DaniNo ratings yet

- Operations Management Recitation 2 SummaryDocument3 pagesOperations Management Recitation 2 SummaryiNo ratings yet

- SJI Design of Steel Deck FINAL 062018 Handout 1Document74 pagesSJI Design of Steel Deck FINAL 062018 Handout 1pkdscdubaiNo ratings yet

- Distribution and Network ModelsDocument8 pagesDistribution and Network ModelsElaine EscobanezNo ratings yet

- Chapter 8 HeraguDocument103 pagesChapter 8 Heragusugar lollyNo ratings yet

- Maximum backfill layer thicknessDocument129 pagesMaximum backfill layer thicknessManoj EkNo ratings yet

- 1 BFT - V - Pom - QPDocument6 pages1 BFT - V - Pom - QPSalil SheikhNo ratings yet

- Breakeven and Payback Analysis PDFDocument19 pagesBreakeven and Payback Analysis PDFrahmi silviaNo ratings yet

- Status of R.W. Beck Study Findings 3.17.09 Black and White VersionDocument51 pagesStatus of R.W. Beck Study Findings 3.17.09 Black and White VersionAbhishekkalaNo ratings yet

- Logistique Et Distribution: The Facility Location ProblemDocument43 pagesLogistique Et Distribution: The Facility Location ProblemgillesNo ratings yet

- QAMD AssignmentDocument4 pagesQAMD AssignmentEmuyeNo ratings yet

- TransportationDocument10 pagesTransportationVikram MulikNo ratings yet

- Transportation ProblemDocument41 pagesTransportation ProblemAyalew TayeNo ratings yet

- Location Decision - Teaching NoteDocument20 pagesLocation Decision - Teaching NotedylanwangwwwNo ratings yet

- Transportation ModelDocument20 pagesTransportation Modelopathirage4321No ratings yet

- Selected Topics of VLSI Design: Part 2: AddersDocument46 pagesSelected Topics of VLSI Design: Part 2: AddersMuhammad Zeeshan QureshiNo ratings yet

- Quantitative Techniques Construction AssignmentsDocument6 pagesQuantitative Techniques Construction Assignmentsavdesh7777No ratings yet

- Solved Examples - Max Min LinearDocument12 pagesSolved Examples - Max Min LinearAzmol bdNo ratings yet

- Assignment # 02Document6 pagesAssignment # 02abdul ghaffarNo ratings yet

- Diffusion Mass TransferDocument18 pagesDiffusion Mass TransferbhuniakanishkaNo ratings yet

- Fire Fighting Robot Using ArduinoDocument18 pagesFire Fighting Robot Using ArduinoSadhana PalleNo ratings yet

- Safety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleDocument8 pagesSafety Solenoid Valve Nominal Width RP 1/2 - RP 2 SV SV-D Sv-DleAgustantoNo ratings yet

- KCA-201 Online PUE Theory of Automata & Formal Languages MCA 2nd SemDocument13 pagesKCA-201 Online PUE Theory of Automata & Formal Languages MCA 2nd SemakttripathiNo ratings yet

- Gen Math11 - Q1 - Mod1 - Functions - v2Document28 pagesGen Math11 - Q1 - Mod1 - Functions - v2Anonymous 6gthRen100% (1)

- Stoichiometry and Gravimetric Analysis of Strontium CarbonateDocument4 pagesStoichiometry and Gravimetric Analysis of Strontium CarbonateIbelise MederosNo ratings yet

- Benefits of Using FlowchartsDocument14 pagesBenefits of Using FlowchartsDave FlautaNo ratings yet

- MiniProject Assignment 3Document3 pagesMiniProject Assignment 3Asadullah ChoudharyNo ratings yet

- HabilitationDocument186 pagesHabilitationAland MediaNo ratings yet

- Color Doppler Imaging Codes:: ND RDDocument46 pagesColor Doppler Imaging Codes:: ND RDGervin Brian EspinoNo ratings yet

- Adaptive Control Introduction Overview ApplicationsDocument185 pagesAdaptive Control Introduction Overview ApplicationsTu DuongNo ratings yet

- Geo technical engineering fundamentalsDocument44 pagesGeo technical engineering fundamentalsSri Gaja Govind Babu100% (1)

- CDB 4323 Assignment 1Document2 pagesCDB 4323 Assignment 1Muhammad AnwarNo ratings yet

- Samsung CAC Duct S Brochure 20140729 0Document16 pagesSamsung CAC Duct S Brochure 20140729 0Callany AnycallNo ratings yet

- Strand7 - Buckling Analysis - Linear Vs NonlinearDocument5 pagesStrand7 - Buckling Analysis - Linear Vs Nonlinearaktc100% (1)

- RP963 Climatemaster Residential Tranquility Water To Water TCW Series Geothermal Heating and Cooling Systems Product CatalogDocument20 pagesRP963 Climatemaster Residential Tranquility Water To Water TCW Series Geothermal Heating and Cooling Systems Product CatalogZulfah NurkholisNo ratings yet

- D EquipmentDocument44 pagesD Equipmentosvald97No ratings yet

- How To Draw Manga - Vegeta (Dragon Ball Z)Document7 pagesHow To Draw Manga - Vegeta (Dragon Ball Z)Constantino Paucar Vega100% (1)

- David Lomas - Notes On Dali and LeonardoDocument39 pagesDavid Lomas - Notes On Dali and LeonardodorutNo ratings yet

- Vingcard ManualDocument202 pagesVingcard ManualPenta Guard50% (10)

- Accounting exam covers receivables, payablesDocument3 pagesAccounting exam covers receivables, payableseXpadaNo ratings yet

- 1999 Biology Paper I Marking SchemeDocument5 pages1999 Biology Paper I Marking Schemetramysss100% (1)

- GCE O Level Practice PaperDocument12 pagesGCE O Level Practice Paperjina910% (1)

- ALC887Document82 pagesALC887EmmanuelchatoNo ratings yet

- Electric and water requirements for concrete batch plantDocument8 pagesElectric and water requirements for concrete batch plantWael WaelNo ratings yet

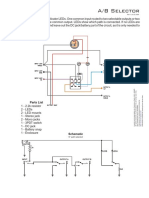

- A/B Selector: Parts ListDocument1 pageA/B Selector: Parts ListGiannis zmNo ratings yet

- JBM Report (20331) MEDocument30 pagesJBM Report (20331) MEKshitijKumarNo ratings yet

- UsersguideDocument87 pagesUsersguideJanet OtienoNo ratings yet

- The Cosmic Frequency of Universal ConscienceDocument23 pagesThe Cosmic Frequency of Universal ConscienceCamilo Carreño TorresNo ratings yet

- MOS-Construction of 132kv OHTL From Ad Darb To Looping PointDocument27 pagesMOS-Construction of 132kv OHTL From Ad Darb To Looping PointEngr Muhammad Azam ThaheemNo ratings yet