Professional Documents

Culture Documents

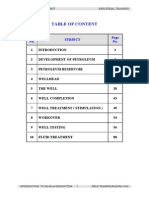

Study On Porous Concrete With Course Aggregate and Fine Aggregate Mix Proportions IJERTV6IS050326

Uploaded by

Mohan kumar R.kOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study On Porous Concrete With Course Aggregate and Fine Aggregate Mix Proportions IJERTV6IS050326

Uploaded by

Mohan kumar R.kCopyright:

Available Formats

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 05, May - 2017

Study on Porous Concrete with Course Aggregate

and Fine Aggregate Mix Proportions

Abrar Ahmed Khan1, Sayed Sarfaraz2, Avinash Patel K L4,

(4)

Syed Bilal Mansoori3, Assistant Professor,

(1),(2),(3)

Students Civil Engineering Department.

Civil Engineering Department, STJ Institute of Technology, Ranebennur

STJ Institute of Technology,

Ranebennur.

Poornima K B5, Dinesh S Magnur6

(6)

(5)

Assistant Professor, Assistant Professor,

Civil Engineering Head of Department, Civil Engineering,

Dept. STJ Institute of Technology, STJ Institute of Technology, Ranebennur.

Ranebennur.

Abstract - Porous concrete also known as gap graded concrete Hence porous concrete may be considered as a sustainable choice

is a special type of concrete obtained by the mixture of Portland in civil engineering.

cement, uniform coarse aggregate with or without fine Porous Concrete is a special type of concrete with a high porosity

aggregate and water. Porous concrete has an interconnected used for concrete flatwork applications that allows water from

pore structure that allows freely the passage of water to flow precipitation & other sources to pass directly through, thereby

through. reducing the runoff from a site & allowing groundwater recharge.

The use of Porous Concrete will reduce the need for large Porous concrete is a mixture of Portland cement, uniform

detention ponds, skimmers, pumps, drainage pipes and other coarse aggregate, building demolition waste & water in suitable

storm water management systems, expensive irrigation systems proportion.

can be downsized or even eliminated. Porous Concrete is a Carefully controlled amounts of water and cementations

durable material; parking areas properly designed and materials are used to create a paste that forms a thick coating around

constructed will last 20-40 years with little or no maintenance. aggregate particles without flowing off during mixing and placing.

Using just enough paste to coat the particles maintains a system of

Key words : Porous concrete, pervious concrete, gap graded interconnected voids.

concrete, Drain concrete, thirsty concrete, water absorption.

I. INTRODUCTION

1. Introduction

Porous concrete is a concrete with continuous voids which are

intentionally incorporated into the concrete. It belongs to a

completely different category from conventional concrete and

hence its physical characteristics differ greatly from those of

normal concrete.

This porous concrete mixture has little to no sand which

Fig (1). Porous concrete

creates an open-cell structure that allows rain water to filter right

through to the underlying soil.

Porous concrete is one of the leading materials used by 1.1 Background History of Porous Concrete

the concrete industry as GREEN industry practices for providing Porous concrete was first used in 1800 s in Europe as pavement

pollution control, storm water management and sustainable design. surfacing and load bearing wall. The initial use of porous concrete

Porous concrete can be used in numerous civil engineering and was in the United Kingdom in 1852 with the construction of two

architectural application. It has been called as the green residential houses and a sea groyne. Cost efficiency seems to have

construction material for pavement because it has been recognized been the primary reason for its earliest usage due to the limited

by the LEED (Leader shipping Energy and Environmental Design). amount of cement used. It was not until 1923 when porous concrete

The increased interest in porous concrete is due to those re surfaced as a viable construction material. This time it was

benefits in storm water management sustainable development. limited to the construction of 2-story homes in areas such as

Impervious nature of bituminous and concrete used for Scotland, Liverpool, London and Manchester.

the construction of pavements, walkways, open car parks Use of porous concrete in Europe increased steadily, especially in

contributes to the increased water runoff to the drainage system, the World War II era. Since porous concrete use less cement than

over-burdening the infrastructure and causing excessive flooding in conventional concrete and cement was scare at that time. It seemed

built-up areas. With the changing climatic conditions and that porous concrete was the best material for that period. Porous

increasing urbanisation had resulted in flooding in major cities concrete continued to gain popularity and its use spread to areas

around the world. Porous concrete is an engineered concrete to have such as Venezuela, West Africa, Australia, Russia and the Middle

very high permeability to allow the rain water to drain rapidly. East (Wanielista et al. 2007). After World War II, porous concrete

became wide spread for applications such as cast-in-place load-

IJERTV6IS050326 www.ijert.org 531

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 05, May - 2017

bearing walls of single and multi-storey houses and, in some e) The reduced runoff eliminates the problems of

instances in high-rise buildings, prefabricated panels, and stem- downstream flooding caused by traditional impervious

cured blocks (Ghafoori et al. 1995). Also applications include walls concrete surfaces.

for two story houses, load-bearing walls for high-rise buildings (up

f) The use of porous concrete as an edge drain or porous

to 10 stories) and infill panels for high-rise buildings (Tennis et al.

hard shoulders has been undertaken extensively in

2004).

India is facing a typical problem of ground water Table falling at a France. Excessive uplift pressures produced in concrete

faster rate due to reduced recharge of rain water into subsoil and pavements lead to the development of methods to rapidly

unplanned water withdrawal for agriculture and industry. It would drain water from the pavement base.

be beneficial for India to exploit the potential of porous concrete. g) Porous concrete in European countries is used for cast-

in-place load bearing walls in houses, multi-storey and

high-rise buildings as prefabricated panels and steam

1.2 Need Of Porous Concrete

cured blocks.

In rural areas larger amount of rainwater ends up falling on

impervious surfaces such as Parking lots, driveways, sidewalks, h) Because water is allowed to percolate into the ground,

and streets rather than soaking into the soil. This creates an nearby vegetation is watered &reduces irrigation needs,

imbalance in the natural ecosystem and leads to a host of problems groundwater is recharged & storm water runoff is

including erosion, floods, ground water level depletion and reduced.

pollution of rivers, as rainwater rushing across pavement surfaces i) Pervious Concrete as a Road pavement Low-volume

picks up everything from oil and grease spills to de-icing salts and pavements Sidewalks and pathways Residential roads

chemical fertilizers. and driveways Parking lots Noise barriers Slope

A simple solution to avoid these problems is to stop constructing stabilization Hydraulic structures Swimming pool decks

impervious surfaces that Block natural water infiltration into the Tennis courts.

soil. Rather than building them with conventional concrete, we

should be switching to Porous Concrete or Porous Pavement, a

material that offers the inherent durability and low life-cycle costs II. SCOPE AND OBJECTIVES

of a typical concrete pavement while retaining storm water runoff 2. Scope

and replenishing local watershed systems. Instead of preventing a) It is the evident that the fines of different grades and

infiltration of water into the soil, porous pavement assists the normal aggregates which are not used in preparations of

process by capturing rainwater in a network of voids and allowing concrete.

it to percolate into the underlying soil. b) It is yielded good permeability results but suffered in

satisfactory compressive strength and the split tensile

1.3 Advantages values.

a) Reduction in storm water infrastructure (Piping, Catch- c) In these study to know that effect of river aggregates and

Basins, Ponds, Curbing, etc.) the mix proportions to be obtain higher strength, higher

b) Suitable for cold-climate applications, maintains permeability and properties of concrete.

recharge capacity when frozen

c) No standing water or black ice development during

winter weather conditions 2.1 Objectives of the Study

d) Maintains traction while wet a) The main objective of study includes to carry out the various

e) Reduced surface temperatures, minimizes the Urban test on porous concrete.

Heat Island Effect b) To study the different properties in the permeability and

f) Extended pavement life due to well drained base and compressive strength.

reduced freeze-thaw c) To be consider permeability as the design parameter in

g) Less lighting needed due to highly reflective pavement designing pavements.

surface

h) Prevents water and polluted water from entering into III. MATERIALS AND METHODOLOGY

stream.

3.1 Materials

1.4 Applications In the study of porous concrete the following materials have to be

a) Porous concrete has had numerous useful non-pavement selected

applications including buildings, tennis courts, drains & 1 Cement

drain tiles, floors in greenhouses, slope stabilization

,swimming pools decks, zoo areas etc.

2 Normal aggregate

b) The majority of porous concrete applications are parking 3 Fine aggregate

lots, sidewalks, pathways, parks, shoulders, drains, noise 4 Water

barriers, friction course for highway pavements,

permeable based under a normal concrete pavement and 3.2 Methodology

low volume roads. The methodology consisting of collecting the specified

c) Water and Power resources services in America coarse and fine aggregate grouping them according to different

successfully tested the use of drains and drain tiles standard size like 12 mm passing size of coarse aggregates.

constructed from porous concrete beneath hydraulic Similarly fine aggregate like (4.75-1.18) mm and mixing them in a

structures. standard proportions as that of M20 grade concrete of 1:3:0.3 with

d) The use of porous concrete in parking lots helped in w/c of 0.3 and specimens were casted of by following standard

controlling water runoff in situations where flash procedure and properties have been evaluated for the analysis.

flooding frequently occurs.

IJERTV6IS050326 www.ijert.org 532

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 05, May - 2017

1V. EXPERIMENTAL PROGRAMME. Table 2. showing compressive strength of porous concrete for 3,

7, 14 and 28 days curing

4.1 Tests Carried Out On Porous Concrete Are

COMPRESSIVE STRENGTH AVERAGE

1. Density S1 S2 S3 COMPRESSIVE

2. Compression test DAYS STRENGTH

(Kg/m3 )

3. Split tensile test

4. Permeability Test 3 DAYS 6.9 7.32 7.28 7.16

7 DAYS 17.1 17.16 17.31 17.19

1. Density

The density of porous concrete depends on the properties and

14 DAYS 22.1 23.4 23.1 22.87

proportions of the materials used, and on the compaction

procedures used in placement. In-place densities in the order of

1600 kg/m³ to 2000 kg/m³ are common, which is in the upper range 28 DAYS 25.73 25.9 26.19 25.94

of lightweight concretes. Typically, between 15% and 25% voids

are achieved in the hardened concrete, and flow rates for water

through porous concrete are typically around 0.34 cm/s, although

they can be much higher. Both the low mortar content and high COMPRESSIVE STRENGTH OF CUBES

porosity also reduce strength compared to conventional concrete

mixtures. 30 25.94

25 22.87

STRENGTH

Density = in kg/m3 17.19

20

Where, M = Mass of concrete in kg.

15

V = Volume of concrete in m3. 10 7.16

5

Table 1. showing density of porous concrete

0

AGGREGAT F.A w/c DENSITY (Kg/m3 ) AVER

DAYS

E SIZE ratio S1 S2 S3 S4 AGE

SIZE (mm) DENSI DAY 3 DAY 7 DAY 14 DAY 28

PASSING TY

(Kg/m3 Fig (4.1) compressive strength of cubes

)

12 mm 4.75- 0.3 2003 2023 2009 2029 2016 3. Split tensile strength

1.18 The comparison of the 3, 7, 14, and 28 days cylinder strength

results represents that.

12 mm® - 0.3 1748 1763 1822 1807 1785 The fig (4.2) represents the split tensile value of cylinder is

gradually increases with respect to the period of curing.

The splitting tensile strength of concrete cylinder is calculated

Note: ® refers for conventional porous concrete without fine using formula ,

aggregates.

2𝑃

Splitting tensile strength = tsp=

2. Compression Test 𝜋𝐿

The comparison of the 3, 7, 14, and 28 days cube strength results

Where, P = Failure load in N.

represents that.

D = Diameter of the cylinder in mm.

The compressive strength of cubes is directly proportional to the

L = Length of the cylinder in mm.

period of curing as shown in fig (4.1)

IJERTV6IS050326 www.ijert.org 533

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 05, May - 2017

Table 3. showing splitting tensile strength of porous concrete for 3, 7, 14 V. CONCLUSIONS

and 28 days curing

a) The use of pervious concrete has increased significantly in the

DAYS S1 S2 S3 AVERAGE last several years, perhaps largely because it is considered an

SPLIT TENSILE environmentally friendly, sustainable product.

VALUE b) The use of pervious concrete provides a number of benefits,

3 DAYS 1.2 1.1 1.2 1.166 most notably in the effective management of storm water

runoff.

7 DAYS 1.5 1.5 1.4 1.46 c) Other significant benefits include reducing contaminants in

waterways, recharging groundwater supplies, reducing heat

14 DAYS 1.7 1.6 1.6 1.63

island effects, and reducing pavement–tire noise emissions.

28 DAYS 1.9 1.8 2 1.9

d) Still, there are a number of areas that need additional

developmental work to improve or enhance the capabilities of

pervious concrete pavements.

e) One area is the continued monitoring of the performance of

SPLIT TENSILE STRENGTH pervious concrete so that long-term performance trends can be

1.9 documented.

2 1.63 f) This will also help in evaluating the suitability of pervious

1.46 concrete for other applications, such as overlays.

STRENGTH

1.5 1.166 g) conventional concrete are not generally applicable to pervious

1 concrete.

0.5

REFERENCES

0

DAYS [1] Harshavarthana M Balaji.et.al (2015), “Design of eco

friendly pervious concrete”, volume 6, issue 2 (ijciet),

DAY 3 DAY 7 DAY 14 DAY 28 february (2015), pp. 22-29.

[2] Darshan S. Shah.et.al (2013),“Pervious Concrete: New

Fig (4.2) split tensile strength of cylinder. Era For Rural Road Pavement”, Volume 4 Issue 8

(IJEET), August 2013

[3] MADE A M.et.al (2013), “Development of High

4. Permeability test Quality Pervious Concrete Specifications for Maryland

The rate of flow under laminar flow condition through a unit cross Conditions” Project number SP009B4F,Final report,

sectional area of porous medium under unit hydraulic gradient is February 2013

known as co-efficient of permeability. It is calculated using the [4] Kevern, J.et.al (2006), “Pervious Concrete

following formulae Construction: Methods and Quality Control” Kevern et

k= (Q x L)/ (T x H x A) cm/s al, submitted to NRMCA Concrete Technology Forum:

Where, Focus on Pervious Concrete, May 24-25, 2006,

k = co-efficient of permeability Nashville, TN

Q = total quantity of flow in a time interval, T [5] Shivam Gupta (2010), “Design of Porous Pavements”

L = length of specimen, cm Term paper - CE682: Infrastructure and Transportation

T = time taken by the known amount of flow, sec Planning Indian Institute of Technology, Kanpur, march

H = difference in the water levels of the overhead and 6, 2010

bottom tank, mm [6] Dania M. Abdel-Aziz.et.al (2015), “Using Pervious

A = total cross sectional area of the sample, cm2 Concrete for Managing Storm Water Run-off in Urban

Neighborhoods”

[7] Husain N Hamdulay.et.al (2015), “Effect of Aggregate

Table 4. showing calculation of co efficient of permeability of Porous Grading and Cementitious By-product on Performance

Concrete of Pervious Concrete”

[8] Patil. V. R. et.al () “Use Of Pervious Concrete In

SAMPLE LENGT DIA AREA DISCHAR HEAD TIM CO-EFFICIENT Construction Of Pavement For Improving Their

H (cm) (cm2) GE H E OF

(cm) Q (mm) (sec) PERMEABILIT Performance”

(ml) Y [1] Uma Maguesvari. M. et.al (2014),“study of pervious

(X 10-3cm/sec)

concrete with various cement content”

1 30 15 176.51 3800 270 18 132 [2] KetanBrijesh Jibhenkar.et.al (2015), “Experimental

Investigation of Pervious Concrete using Titanium

2 30 15 176.51 3800 270 16 149 Dioxide.

3 30 15 176.51 3800 270 17 140

IJERTV6IS050326 www.ijert.org 534

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Flow in 3D Packed Bed Reactors COMSOLDocument10 pagesFlow in 3D Packed Bed Reactors COMSOLBenedictEkowPrahNo ratings yet

- A Study On Water AbsorbingDocument2 pagesA Study On Water AbsorbingInternational Journal of Innovative Science and Research Technology100% (1)

- Engineering: Pervious ConcreteDocument6 pagesEngineering: Pervious ConcreteDusmanta Kumar BeheraNo ratings yet

- Experimental Investigation of Porous Concrete For Concrete PavementDocument5 pagesExperimental Investigation of Porous Concrete For Concrete PavementFaizan AnsariNo ratings yet

- Porous PavementDocument5 pagesPorous PavementInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pervious Concrete: New Era For Rural Road PavementDocument5 pagesPervious Concrete: New Era For Rural Road PavementseventhsensegroupNo ratings yet

- Evolution Properties of Paver Blocks Using Waste Foundry Sand in ConcreteDocument8 pagesEvolution Properties of Paver Blocks Using Waste Foundry Sand in ConcreteEditor IJTSRDNo ratings yet

- ProcessDocument13 pagesProcessDuy Khanh HuynhNo ratings yet

- Study On Pozzolanas Effect On Fiber Reinforced ConcreteDocument6 pagesStudy On Pozzolanas Effect On Fiber Reinforced ConcreteIJIRSTNo ratings yet

- IJCRT2005165Document7 pagesIJCRT2005165Jhe Hann BurcaNo ratings yet

- Applications of Pervious Concrete in Road PavementsDocument15 pagesApplications of Pervious Concrete in Road PavementsIJRASETPublicationsNo ratings yet

- Improvement in Properties of Porous Concrete Using FiberDocument5 pagesImprovement in Properties of Porous Concrete Using FiberPawan Patidar0% (1)

- Structural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday KumarDocument4 pagesStructural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday Kumarivanhendriprasetyo 127No ratings yet

- A Study On Influence of Ldpe On Properties of Bitumen Pavement Under Submergence Condition IJERTV8IS060459Document6 pagesA Study On Influence of Ldpe On Properties of Bitumen Pavement Under Submergence Condition IJERTV8IS060459SyedBaqirNo ratings yet

- 93DSS JRP JJBIJETTIJETT V4I8P141Volume4Issue8 August2013Document6 pages93DSS JRP JJBIJETTIJETT V4I8P141Volume4Issue8 August2013Arham SheikhNo ratings yet

- Irjet V5i5381 PDFDocument4 pagesIrjet V5i5381 PDFAjay Kumar GantiNo ratings yet

- Major ProjectDocument18 pagesMajor ProjectAwesomeNo ratings yet

- An Experimental Investigation of The Effect of Pervious Concrete by Various Shape and Sizes of AggregateDocument10 pagesAn Experimental Investigation of The Effect of Pervious Concrete by Various Shape and Sizes of AggregateIJRASETPublicationsNo ratings yet

- 2007-Mechanical and Civil Engineering-PatilDocument3 pages2007-Mechanical and Civil Engineering-PatilSaul Lopez MejiaNo ratings yet

- Iarjset-Agni-Pankh 19 PDFDocument5 pagesIarjset-Agni-Pankh 19 PDFvipulnaidu18No ratings yet

- Construction of Water Absorbing Roads With Porous AsphaltDocument4 pagesConstruction of Water Absorbing Roads With Porous AsphaltBharath SrinivasreddyNo ratings yet

- Water Absorbing Pavements by Using Porous Concrete: A Project ReportDocument17 pagesWater Absorbing Pavements by Using Porous Concrete: A Project ReportSɪᴅᴅʜᴀɴᴛ Sᴀɢᴀʀ100% (1)

- Research On Permeable Pavement A Case Study of Sitapura Institutional Area Jaipur IJERTCONV4IS23074Document3 pagesResearch On Permeable Pavement A Case Study of Sitapura Institutional Area Jaipur IJERTCONV4IS23074MEGHA ANKALKOTINo ratings yet

- Compressive Strength of Fly Ash Based Cement Concrete: Syed Afzal BashaDocument16 pagesCompressive Strength of Fly Ash Based Cement Concrete: Syed Afzal BashaArul RajNo ratings yet

- IJSET V8 Issue1 181Document10 pagesIJSET V8 Issue1 181prajwal ursNo ratings yet

- Performance Assessment of Pervious Concrete Road On Strength and Permeability by Using Silica FumeDocument18 pagesPerformance Assessment of Pervious Concrete Road On Strength and Permeability by Using Silica FumeIJRASETPublicationsNo ratings yet

- 201509IOSRJMCEDocument12 pages201509IOSRJMCESreeja SadanandanNo ratings yet

- Pavan Savale Capstone 6I MY PROJECT (1) - OrganizedDocument28 pagesPavan Savale Capstone 6I MY PROJECT (1) - OrganizedSE-50 Yogesh KedarNo ratings yet

- Ijirstv4i2038 PDFDocument6 pagesIjirstv4i2038 PDFIJIRSTNo ratings yet

- Utilization of Demolished Building Waste in Paving Block With Coir Fibre Ijariie5493 PDFDocument9 pagesUtilization of Demolished Building Waste in Paving Block With Coir Fibre Ijariie5493 PDFShivanand Kuldeep SuyalNo ratings yet

- Thesis CPPDocument40 pagesThesis CPPParth KshirsagarNo ratings yet

- Compressive Behavior of Rice Straw-Reinforced Concrete For Rigid PavementsDocument8 pagesCompressive Behavior of Rice Straw-Reinforced Concrete For Rigid PavementsAngelica CabreraNo ratings yet

- Zheng 2020 IOP Conf. Ser. Mater. Sci. Eng. 782 042026Document8 pagesZheng 2020 IOP Conf. Ser. Mater. Sci. Eng. 782 042026Shehap SamirNo ratings yet

- Water Abserbation Concrete RoadDocument11 pagesWater Abserbation Concrete RoadsethyankitaraniNo ratings yet

- Some Aspects On Pervious Concrete: R. Selvaraj, M. AmirthavarshiniDocument5 pagesSome Aspects On Pervious Concrete: R. Selvaraj, M. AmirthavarshinierpublicationNo ratings yet

- Construction of Paving Blocks by Using Plastic WasteDocument8 pagesConstruction of Paving Blocks by Using Plastic WasteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review On Concrete TechnologyDocument6 pagesReview On Concrete TechnologyVikshita ShahNo ratings yet

- Case Studies in Construction Materials: Mohamed A. Safan, Zeinab A. Etman, Alaa KonswaDocument12 pagesCase Studies in Construction Materials: Mohamed A. Safan, Zeinab A. Etman, Alaa Konswadiana cristina arias aldanaNo ratings yet

- Construction of Water Absorbing Pavements by UsingDocument3 pagesConstruction of Water Absorbing Pavements by UsingAmmulu 123No ratings yet

- Production of Plastic BricksDocument8 pagesProduction of Plastic Bricksgalolo9334No ratings yet

- A Review of The Use of Recycled Materials in Rigid Pavements - BAKASH SOWMITH RAKESH RAHUL (2013)Document6 pagesA Review of The Use of Recycled Materials in Rigid Pavements - BAKASH SOWMITH RAKESH RAHUL (2013)Cleber de Souza CunhaNo ratings yet

- Experimental Investigation On Maximum Strength of Pervious Concrete Using Different Size of AggregatesDocument3 pagesExperimental Investigation On Maximum Strength of Pervious Concrete Using Different Size of AggregatesNatarajan SaravananNo ratings yet

- Concoction of Eco Crumb Shell Paver Blocks IJERTCONV7IS02014Document7 pagesConcoction of Eco Crumb Shell Paver Blocks IJERTCONV7IS02014GUGANATHAN ANo ratings yet

- The Use of Geosynthetics in Road Construction (Case Study - Geotextile)Document48 pagesThe Use of Geosynthetics in Road Construction (Case Study - Geotextile)Suresh DevarajanNo ratings yet

- V3i12 Ijertv3is120448Document7 pagesV3i12 Ijertv3is120448mcsomashekaraNo ratings yet

- Civil Engineering MaterialsDocument3 pagesCivil Engineering MaterialsJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Experimental Investigation of Concrete Using Coconut Shell As A Coarse Aggregate Replacement IJERTV6IS040769Document6 pagesExperimental Investigation of Concrete Using Coconut Shell As A Coarse Aggregate Replacement IJERTV6IS040769Chinni KranthiNo ratings yet

- A Project Report Water Absorbing Pavements by Using Porous ConcreteDocument17 pagesA Project Report Water Absorbing Pavements by Using Porous ConcreteAbhinandan PatilNo ratings yet

- A Study On The Suitability of Solid Waste Materials in Pavement Construction A ReviewDocument13 pagesA Study On The Suitability of Solid Waste Materials in Pavement Construction A Reviewaakash singhNo ratings yet

- UntitledDocument20 pagesUntitledbinnu SurlaNo ratings yet

- Evaluation of Polyurethane Resin Injection For Concrete Leak RepairDocument13 pagesEvaluation of Polyurethane Resin Injection For Concrete Leak RepairmarianaNo ratings yet

- Study On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementDocument13 pagesStudy On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementIJRASETPublicationsNo ratings yet

- Laboratory Experimental Studies On Previews Concrete PavementsDocument12 pagesLaboratory Experimental Studies On Previews Concrete PavementsIJRASETPublicationsNo ratings yet

- 3-24032017 Bottom Ash As Partial Sand Replacement in Concrete - A Review - Docx WordDocument17 pages3-24032017 Bottom Ash As Partial Sand Replacement in Concrete - A Review - Docx WordMd AwesshadabNo ratings yet

- Porous ConcreteDocument23 pagesPorous ConcreteSunanda Desai Ramteerth100% (1)

- Use of Polyethylene Terephthalate in Concrete - A Brief ReviewDocument5 pagesUse of Polyethylene Terephthalate in Concrete - A Brief ReviewPauloDyerNo ratings yet

- Utilization of Basaltic Quarry Dust As A Partial Replacement of Cement For Hollow Concrete Block ProductionDocument13 pagesUtilization of Basaltic Quarry Dust As A Partial Replacement of Cement For Hollow Concrete Block Productionnajathahamed880No ratings yet

- Effect of Partial Replacement of Cement by Fly Ash With Using Nylon Fiber in Concrete Paver Block IJERTV3IS10854Document5 pagesEffect of Partial Replacement of Cement by Fly Ash With Using Nylon Fiber in Concrete Paver Block IJERTV3IS10854GUGANATHAN ANo ratings yet

- Utilization of Egg Shell Powder (ESP) and M-Sand For Sustainable ConstructionDocument5 pagesUtilization of Egg Shell Powder (ESP) and M-Sand For Sustainable ConstructionArun anandNo ratings yet

- Experimental Study On Green ConcreteDocument5 pagesExperimental Study On Green ConcreteMaria HanyNo ratings yet

- Details of Processing Fees Made Through Neft / Upi PaymentDocument1 pageDetails of Processing Fees Made Through Neft / Upi PaymentMohan kumar R.kNo ratings yet

- IJSRDV7I40588Document4 pagesIJSRDV7I40588Mohan kumar R.kNo ratings yet

- Irjet V8i1240Document7 pagesIrjet V8i1240Mohan kumar R.kNo ratings yet

- Granite Powder Porous ConcreteDocument4 pagesGranite Powder Porous ConcreteMohan kumar R.kNo ratings yet

- Front Pages-InternshipDocument5 pagesFront Pages-InternshipMohan kumar R.kNo ratings yet

- Front Pages-Technical SeminarDocument4 pagesFront Pages-Technical SeminarMohan kumar R.kNo ratings yet

- Performance and Manufacturing of Pervious ConcreteDocument11 pagesPerformance and Manufacturing of Pervious ConcreteMohan kumar R.kNo ratings yet

- PerviouspaperDocument4 pagesPerviouspaperMohan kumar R.kNo ratings yet

- Materials 15 09066Document14 pagesMaterials 15 09066Mohan kumar R.kNo ratings yet

- IJERT An Experimental Study On PerviousDocument4 pagesIJERT An Experimental Study On PerviousMohan kumar R.kNo ratings yet

- IJSRDV7I40588Document4 pagesIJSRDV7I40588Mohan kumar R.kNo ratings yet

- Fin Irjmets1651657088Document4 pagesFin Irjmets1651657088Mohan kumar R.kNo ratings yet

- UbootpdfpaperDocument5 pagesUbootpdfpaperGauri PatekarNo ratings yet

- Utilization of Porous Concrete in Ground Water Recharge: Deepika K P, Zaiba FathimaDocument3 pagesUtilization of Porous Concrete in Ground Water Recharge: Deepika K P, Zaiba FathimaMohan kumar R.kNo ratings yet

- IJCRT22A6070Document3 pagesIJCRT22A6070Mohan kumar R.kNo ratings yet

- (IJETA-V7I6P2) :athira Anil, Vidya JoseDocument4 pages(IJETA-V7I6P2) :athira Anil, Vidya JoseIJETA - EighthSenseGroupNo ratings yet

- Fin Irjmets1651657088Document4 pagesFin Irjmets1651657088Mohan kumar R.kNo ratings yet

- A Review Paper On "U-Boot Beton: The Concrete Saver": Shoeb Khan Taslim Khan (B.E. Student)Document2 pagesA Review Paper On "U-Boot Beton: The Concrete Saver": Shoeb Khan Taslim Khan (B.E. Student)jay chitrodaNo ratings yet

- Hydrologic Principles and AnalysisDocument153 pagesHydrologic Principles and AnalysisLurima FariaNo ratings yet

- Soil and Water Conservation EngineeringDocument266 pagesSoil and Water Conservation EngineeringUnodosNo ratings yet

- 24 A - Review - On - The - Effect - of - Soil - Compaction - and - ItsDocument23 pages24 A - Review - On - The - Effect - of - Soil - Compaction - and - ItsLiv CBNo ratings yet

- 1 Elctric-PropDocument23 pages1 Elctric-PropHoracio HernandezNo ratings yet

- Acceptance Criteria-Asme Section 5Document18 pagesAcceptance Criteria-Asme Section 5HAKAN67% (3)

- 12 Ch12 Foundation GroutingDocument11 pages12 Ch12 Foundation GroutingAlexandru OlaruNo ratings yet

- Derivation of The Material Balance EquationDocument39 pagesDerivation of The Material Balance EquationMaria JosefaNo ratings yet

- Experiment 2 Sand Segregation TestDocument3 pagesExperiment 2 Sand Segregation TestZul HaswalNo ratings yet

- 06 - Membrane Separation ProcessesDocument141 pages06 - Membrane Separation ProcessesNagwa Mansy100% (1)

- A Workflow For Fully Consistent Water Saturation Initialization Without Capillary Pressure ScalingDocument7 pagesA Workflow For Fully Consistent Water Saturation Initialization Without Capillary Pressure ScalingAiwarikiaarNo ratings yet

- A Comparison Between Slurry and Earth Pressure Balanced SheildsDocument6 pagesA Comparison Between Slurry and Earth Pressure Balanced SheildsAnthony FuNo ratings yet

- Introduction To Oil and Gas Production PDFDocument105 pagesIntroduction To Oil and Gas Production PDFSufian R Ellabbad100% (1)

- Properties of Triaxial Porcelain BodiesDocument10 pagesProperties of Triaxial Porcelain Bodiesa.hameedNo ratings yet

- Artigo - He Et Al. (2007) - Self-Healing Capability Concreto - Computer Simulation Study of Unhydrated Cement StructureDocument7 pagesArtigo - He Et Al. (2007) - Self-Healing Capability Concreto - Computer Simulation Study of Unhydrated Cement StructureAdilson GonçalvesNo ratings yet

- Trisakti 2013 Teknik Reservoir LanjutDocument130 pagesTrisakti 2013 Teknik Reservoir LanjutKetut Suwadiaya P Adnyana100% (1)

- 3D - On The Influence of Face Pressure, Grouting Pressure and TBM Design in Soft Ground TunnellingDocument12 pages3D - On The Influence of Face Pressure, Grouting Pressure and TBM Design in Soft Ground TunnellingTai TienNo ratings yet

- Fracturing Technologies To Enhance Remediation GWRTAC 2002Document58 pagesFracturing Technologies To Enhance Remediation GWRTAC 2002RenatoNo ratings yet

- Sintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)Document13 pagesSintering Mechanisms of Porcelain Stoneware Tiles: Castell6N (Spain)volkanNo ratings yet

- Static Liquid Holdup in Packed Beds of Spherical ParticlesDocument4 pagesStatic Liquid Holdup in Packed Beds of Spherical ParticlesaegosmithNo ratings yet

- Agro 3611 Practical ManualDocument48 pagesAgro 3611 Practical Manual025Chetan baviskarNo ratings yet

- Weight-Volume Relationships: MohammadDocument33 pagesWeight-Volume Relationships: MohammadAadolf ElÿasNo ratings yet

- Structural LandformsDocument267 pagesStructural LandformsgeoecologistNo ratings yet

- Chemical Engineering and Processing: Process IntensificationDocument10 pagesChemical Engineering and Processing: Process IntensificationSofiaCarizDiazNo ratings yet

- Pore Pressure and Overburden PressureDocument35 pagesPore Pressure and Overburden PressureAreeshaNo ratings yet

- Fyp Reading MaterialDocument14 pagesFyp Reading MaterialRamaneish SivaNo ratings yet

- 416-Article Text-1078-1-10-20190130Document6 pages416-Article Text-1078-1-10-20190130yin hoe ongNo ratings yet

- High Entropy Alloy CoCrFeMnNi Produced by Powder MetallurgyDocument15 pagesHigh Entropy Alloy CoCrFeMnNi Produced by Powder MetallurgyKarthi SiddhNo ratings yet

- Statistical Modeling of Water Vapor Transport Through Woven FabricsDocument9 pagesStatistical Modeling of Water Vapor Transport Through Woven FabricsAjdina Batalović KrdžalićNo ratings yet

- Precompression Design PDFDocument38 pagesPrecompression Design PDFPatricio DinamarcaNo ratings yet