Professional Documents

Culture Documents

AppNote AAS 0009 en novAA800 Sewage Sludge

Uploaded by

mariholzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AppNote AAS 0009 en novAA800 Sewage Sludge

Uploaded by

mariholzCopyright:

Available Formats

Application Note · novAA 800

Determination of Toxic and Eco-toxic Elements

in Sewage Sludge

Introduction

A global boom of industrialization and an increasing demand for advanced

materials and products is leading to environmental release of harmful and even

toxic compounds in many regions of the world.

Toxic metals, such as cadmium, lead or chromium as well as high concentrations

of other potentially harmful elements, e.g. nickel or copper, often pass into eco

systems through sewage sludge from industrial sites, as well as from weathering

Challenge or wearing of pipes, reactors and other industrial facilities. Hence, a close

monitoring of sewage sludge is the key to meeting statutory limits, and to allow

Determination of Cd, Pb, Ni, Cu,

targeted intervention in case of potential hazards.

Mn, Zn and Cr in sewage sludge.

This application note describes a straight-forward and robust flame AAS method

for routine analysis of cadmium, lead, nickel, copper, manganese, zinc, and

Solution chromium in sewage sludge for industrial QC labs with moderate sample loads.

Reliable routine analysis using

flame AAS on the novAA 800 F.

2 Determination of Toxic and Eco-toxic Elements in Sewage Sludge

Materials and Methods

Samples and Reagents

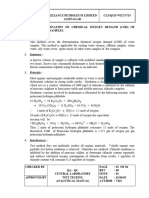

■ Reference materials for sewage sludge, BCR 143R, and BCR 146R

Two reference materials for sewage sludge with known analyte concentrations were analyzed for method validation.

Sample Preparation

The sample was prepared according to ISO 15587-1 using the microwave system TOPwave (vessel type PM60).

Approximately 0.5 g of the reference sample was digested in 6 mL aqua regia as digestion agent, transferred to a graduated

flask and filled up to 50 mL with deionized water. If the extraction of potential fumes during the aqua regia digestion cannot

be ensured, ISO 15587-2 using nitric acid as digestion agent can be applied as well. Alternatively, the sample can be digested

in a beaker on a hot plate. However, silicones or certain organic compounds of the sewage sludge may not be completely

digested in this case.

Calibration

A standard calibration was applied and standards were prepared manually using 1 % HCl and 0.1 % CsCl/LaCl3. Alternatively,

the standards can be prepared by the autosampler from a stock solution using the automated dilution function.

Table 1: Concentration of calibration standards

Standard Concentration [mg/L]

Cd Pb Ni Cu Zn Mn Cr

Cal. 0 0 0 0 0 0 0 0

Cal. Std. 1 0.1 1 0.25 0.5 0.1 0.2 0.5

Cal. Std. 2 0.2 3 0.5 1 0.2 0.5 1

Cal. Std. 3 0.4 6 1 1.5 0.4 1 2

Cal. Std. 4 0.6 9 1.5 2 0.5 1.5 3

Calibration Curves

non-linear rational non-linear rational non-linear rational non-linear rational

R2 = 0.9999 R2 = 0.9997 R2 = 0.9995 R2 = 0.9991

LOQ = 0.003 mg/L LOQ = 0.024 mg/L LOQ = 0.094 mg/L LOQ = 0.012 mg/L

non-linear rational non-linear rational non-linear rational

R2 = 0.9999 R2 = 0.9992 R2 = 0.9999

LOQ = 0.003 mg/L LOQ = 0.115 mg/L LOQ = 0.102 mg/L

Determination of Toxic and Eco-toxic Elements in Sewage Sludge 3

Instrumentation

The measurements were performed using a novAA 800 F for flame AAS, equipped with injection switch SFS 6.0 and an

autosampler with automatic dilution function. The analysis was carried out using a 100 mm burner head for air/acetylene

flame and a 50 mm burner head for air/nitrous oxide flame.

The use of an automatic burner head cleaner, the Scraper, allows automated removal of deposits from the burner slit at

regular intervals when using the nitrous oxide flame.

Instrument Settings and Method Parameters

Table 2: Instrument settings and method parameters

Element Wavelength Slit Lamp current Burner with Burner height Flame type Fuel gas flow

[nm] [nm] [mA] [mm] [mm] [L/h]

Cd 228.8 1.2 2 100 9 C2H2/air 40

Pb 283.3 1.2 4 100 7 C2H2/air 50

Ni 232.0 0.2 5 100 7 C2H2/air 50

Cu 324.7 1.2 5 100 6 C2H2/air 45

Zn 213.9 0.8 2 100 5 C2H2/air 50

Mn 279.5 0.2 5 100 9 C2H2/air 55

Cr 357.9 0.8 4 50 5 C2H2/N2O* 210

* Cr as a refractory metal requires higher atomization temperatures, hence a C 2H2/N2O gas mixture and a 50 mm burner head may benefit the Cr analysis

Results and Discussion

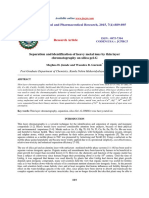

The analysis results (Table 3) for the two certified reference materials of industrial sewage sludge, BCR 143R and BCR 146R,

show very good agreement of 94-103% with the certified values. All elements could be quantified by external calibration

with aqueous standards in diluted or undiluted samples.

Table 3: Measurement results

Sample Element Dilution factor Measured RSD Certified Revovery rate

concentration [%] concentration [%]

[mg/kg] [mg/kg]

Sewage sludge Cd 3 71.8 0.6 72.0 100

BCR 143 R

Pb 2 174 3.7 174 100

Ni 3 290 3.4 296 98

Cu 2 125.7 0.6 128 96

Zn 50 1061 2.5 1063 100

Mn 15 848 0.6 858 99

Cr 4 419 1.2 426 98

4 Determination of Toxic and Eco-toxic Elements in Sewage Sludge

Sample Element Dilution factor Measured RSD Certified Revovery rate

concentration [%] concentration [%]

[mg/kg] [mg/kg]

Sewage sludge Cd 2 18.7 0.8 18.4 102

BCR 146 R

Pb 2 554 2.0 583 95

Ni 1 64.9 2.8 65 100

Cu 10 817 0.8 831 98

Zn 200 2975 1.9 3040 98

Mn 10 299 2.1 298 100

Cr 2 179 1.9 174 103

Conclusion

The novAA 800 F allows fast, simple and highly precise determination of cadmium, lead, nickel, copper, zinc, manganese,

and chromium in pre-digested sewage sludge samples. Very good agreement of the results with the values of two certified

reference materials (95-103%) as well as low standard deviations prove validity of the analysis procedure including the

microwave-assisted digestions and therewith the high method robustness in high matrix samples.

The SFS 6.0 injection switch with continuous rinsing function and segmented sample injection ensures reduced carryover

in case of high salt and matrix content while the automatic cleaning of the burner head using the Scraper provides stable

analysis conditions for highly reproducible results. Using the autosampler with integrated dilution function enables a high

sample throughput even for high matrix samples.

This document is true and correct at the time of publication; the information within is subject to change. Other documents may supersede this document, including technical modifications and

corrections.

Headquarters Version: 2.0 I Author: AnJu

Analytik Jena AG Phone +49 36 41 77 70 info@analytik-jena.com en · 09/2020

Konrad-Zuse-Strasse 1 Fax +49 36 41 77 9279 www.analytik-jena.com © Analytik Jena AG | Pictures ©: Pixabay/falco

07745 Jena · Germany Printout and further use permitted with reference to the source.

You might also like

- Design of Anaerobic Wastewater Treatment Processes - 5th EditionDocument24 pagesDesign of Anaerobic Wastewater Treatment Processes - 5th EditionTheeva RajNo ratings yet

- Role of Chemistry in Power PlantDocument42 pagesRole of Chemistry in Power Plantsevero97100% (1)

- Feed Water and Boiler Water of Steam GeneratorsDocument2 pagesFeed Water and Boiler Water of Steam GeneratorsIvicaT0% (2)

- B564 Plfy402430879val PDFDocument11 pagesB564 Plfy402430879val PDFCarlosIkeda100% (1)

- AppNote AAS novAA 800 0008 en Industrial EffluentsDocument4 pagesAppNote AAS novAA 800 0008 en Industrial EffluentsAlberto HernándezNo ratings yet

- AppNote AAS 0017 en contrAA Wastewater Sewage SlugdeDocument7 pagesAppNote AAS 0017 en contrAA Wastewater Sewage SlugdeAlberto HernándezNo ratings yet

- Shell Boiler Water Treated Reference StandardDocument4 pagesShell Boiler Water Treated Reference StandardOA AooNo ratings yet

- TEST BKC4543 Sem 1 20192020Document5 pagesTEST BKC4543 Sem 1 20192020mustaf mohamedNo ratings yet

- Biodeisel Using FuelProDocument4 pagesBiodeisel Using FuelProSylab InstrumentsNo ratings yet

- Classification: Outdoor (ISO 9223-9226) and Indoor (ISO 11844) ClassificationDocument29 pagesClassification: Outdoor (ISO 9223-9226) and Indoor (ISO 11844) ClassificationJoao CarlosNo ratings yet

- Bhu 202080Document8 pagesBhu 202080anilkumarak9532No ratings yet

- 6 Tech Spec AMOC Final V2Document26 pages6 Tech Spec AMOC Final V2bvdbNo ratings yet

- Test Method: Subject: ApprovedDocument4 pagesTest Method: Subject: ApprovedLucky KhanNo ratings yet

- Analysis of Oils Using Icp-Oes With Radial Plasma Observation English VersionDocument8 pagesAnalysis of Oils Using Icp-Oes With Radial Plasma Observation English VersionThais Roberta CamposNo ratings yet

- National RegulationDocument7 pagesNational RegulationNguyễn Nhật SangNo ratings yet

- EPA 29 MethodDocument36 pagesEPA 29 MethodGonzalo RosadoNo ratings yet

- Aa098-Cd, CR, Cu, Ni, PB EN SOLUCIONES SALINAS POR AASDocument6 pagesAa098-Cd, CR, Cu, Ni, PB EN SOLUCIONES SALINAS POR AASFranklin VrNo ratings yet

- Characterization of Domestic and Industrial WastewatersDocument53 pagesCharacterization of Domestic and Industrial WastewatersRicardo Vargas LaverdeNo ratings yet

- 8.12 Sodium CarbonateDocument7 pages8.12 Sodium CarbonateDheeraj DheeruNo ratings yet

- Weinrich 2021 Model ParametersDocument8 pagesWeinrich 2021 Model ParametersKentner Chavez CorreaNo ratings yet

- Astm C1529Document2 pagesAstm C1529SilviaMonica100% (1)

- Appendix 4: Permeability of Polychlorotrifluoroethylene (PCTFE)Document3 pagesAppendix 4: Permeability of Polychlorotrifluoroethylene (PCTFE)jonasNo ratings yet

- GB 15892-2009Document25 pagesGB 15892-2009dewi wulansariNo ratings yet

- Ju 001 06 0918 0000 04 Re 0002 - 1Document8 pagesJu 001 06 0918 0000 04 Re 0002 - 1aach17No ratings yet

- Trace Impurity Analysis of Hydrogen Fuel in Fuel Cell Vehicle-Related Fields. Application Note (Shimadzu)Document2 pagesTrace Impurity Analysis of Hydrogen Fuel in Fuel Cell Vehicle-Related Fields. Application Note (Shimadzu)Maikel Perez NavarroNo ratings yet

- c06s02 PDFDocument6 pagesc06s02 PDFDewiRSNo ratings yet

- AppNote AAS 0016 en ZEEnit Toxics Surface Drinking WaterDocument6 pagesAppNote AAS 0016 en ZEEnit Toxics Surface Drinking WaterAlberto HernándezNo ratings yet

- Method - 200-2 - Rev - 2-8 - 1994 Elementos RecuperablesDocument13 pagesMethod - 200-2 - Rev - 2-8 - 1994 Elementos RecuperablesPablo MéndezNo ratings yet

- Br28.Electronics and Electroplating ApplicationsDocument100 pagesBr28.Electronics and Electroplating ApplicationsanacrisstNo ratings yet

- Oil and Gas RefineryDocument22 pagesOil and Gas Refineryjay velNo ratings yet

- Conductance Data For Commonly Used Chemicals DataDocument36 pagesConductance Data For Commonly Used Chemicals DataAnshul TomarNo ratings yet

- Environmental Engg. 3160611 - Lab ManualDocument64 pagesEnvironmental Engg. 3160611 - Lab ManualShreyas PatelNo ratings yet

- LICENTADocument85 pagesLICENTAIoana JONo ratings yet

- Elsevier Science Publishers B.V., Amsterdam - Printed in The NetherlandsDocument6 pagesElsevier Science Publishers B.V., Amsterdam - Printed in The NetherlandsRENATO JAIR COSTA MINGANo ratings yet

- CN DISPONIBLE D6888 - 4082mthdDocument13 pagesCN DISPONIBLE D6888 - 4082mthdwcenttiNo ratings yet

- Aquatech China Shenhua Xinjiang CTX Project ProfileDocument5 pagesAquatech China Shenhua Xinjiang CTX Project ProfilecscPPDONo ratings yet

- Liq Handbook 51-6009 Conductance Data For Commonly Used Chemicals 199408Document36 pagesLiq Handbook 51-6009 Conductance Data For Commonly Used Chemicals 199408Dipmalya BasakNo ratings yet

- Method For Testing Trace Heavy Metal Concentration in Industrial Wastewater by GF AADocument6 pagesMethod For Testing Trace Heavy Metal Concentration in Industrial Wastewater by GF AADaniel Camilo CarreñoNo ratings yet

- CCPC Summary by Iea CCCDocument23 pagesCCPC Summary by Iea CCCProcess EngineerNo ratings yet

- Display Article For FreeDocument2 pagesDisplay Article For FreencaothachNo ratings yet

- B-AD-035 Metal Dispersion Rate Investigation For Cu Supported Catalyst by N2o Pulse Measurement enDocument3 pagesB-AD-035 Metal Dispersion Rate Investigation For Cu Supported Catalyst by N2o Pulse Measurement ennattaphong.boonsrisodNo ratings yet

- Whitepaper: Overcoming Challenges of Sulfur Analysis in Natural Gas and Gaseous FuelsDocument8 pagesWhitepaper: Overcoming Challenges of Sulfur Analysis in Natural Gas and Gaseous FuelsSiti Fajar karinaNo ratings yet

- Iso 9227 PDFDocument13 pagesIso 9227 PDFMario AguillonNo ratings yet

- Cod 3715Document4 pagesCod 3715shaukat786.No ratings yet

- Design Criteria 1 PDFDocument17 pagesDesign Criteria 1 PDFAnonymous ahdhFMaNo ratings yet

- Supplementary Materials (Applied Catalysis B: Environmental)Document33 pagesSupplementary Materials (Applied Catalysis B: Environmental)anhchangcodon88No ratings yet

- Molecules: Regioselective Monobromination of Phenols With KBR and Znal-Bro - Layered Double HydroxidesDocument9 pagesMolecules: Regioselective Monobromination of Phenols With KBR and Znal-Bro - Layered Double HydroxidesDidier tovarNo ratings yet

- Steam Purity of 500 MWDocument1 pageSteam Purity of 500 MWLipika Ghosh BiswasNo ratings yet

- 0 Electrode Materials: 2.1 LeadDocument17 pages0 Electrode Materials: 2.1 LeadpurushothamkrNo ratings yet

- Nitrogenous Oxygen DemandDocument21 pagesNitrogenous Oxygen DemandBharat MahajanNo ratings yet

- PipelinegasDocument17 pagesPipelinegasGhochapon MongkhonsiriNo ratings yet

- Aspen Plus Pipeline Gas From Coal ModelDocument17 pagesAspen Plus Pipeline Gas From Coal Modelzubair1951No ratings yet

- Corrosion Inhibition Performance of Copper Carbonate in MEADocument5 pagesCorrosion Inhibition Performance of Copper Carbonate in MEAdow2008No ratings yet

- 2 SO2-Air Cyanide OxydationDocument8 pages2 SO2-Air Cyanide OxydationbazanvlNo ratings yet

- Sewage Sludge: Characteristics and Recovery Options: L. Bonfiglioli, A. Bianchini, M. Pellegrini, C. SaccaniDocument21 pagesSewage Sludge: Characteristics and Recovery Options: L. Bonfiglioli, A. Bianchini, M. Pellegrini, C. SaccaniDana MateiNo ratings yet

- Niton XRF Precious MetalsDocument21 pagesNiton XRF Precious MetalsAmar100% (1)

- Steel Shot Grit MSDS Sheet - WabbrasiveDocument2 pagesSteel Shot Grit MSDS Sheet - WabbrasivelukmanNo ratings yet

- Handbook of Quality Integrated Circuit ManufacturingFrom EverandHandbook of Quality Integrated Circuit ManufacturingRating: 5 out of 5 stars5/5 (1)

- Cutting-Edge Technology for Carbon Capture, Utilization, and StorageFrom EverandCutting-Edge Technology for Carbon Capture, Utilization, and StorageKarine Ballerat-BusserollesNo ratings yet

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Introduction To Chrome PlatingDocument7 pagesIntroduction To Chrome PlatingWerner SchrammelNo ratings yet

- MOC - Ullmann'sDocument48 pagesMOC - Ullmann'sacer_asdNo ratings yet

- AISI Steel GradesDocument1 pageAISI Steel GradessanoopvkNo ratings yet

- Chemistry 1718 V2 EoS1 Past PaperDocument12 pagesChemistry 1718 V2 EoS1 Past PaperjcyNo ratings yet

- DSMTS-0008.5 Fe-High CR WireDocument4 pagesDSMTS-0008.5 Fe-High CR Wirepepito perexNo ratings yet

- 2011 C2 H2 Chemistry Paper 3Document15 pages2011 C2 H2 Chemistry Paper 3samuelthngNo ratings yet

- Astm B633-19Document3 pagesAstm B633-19Cj Elamparo100% (1)

- MP 2 9900 03 Aug 07Document10 pagesMP 2 9900 03 Aug 07Abhishek MishraNo ratings yet

- Catalytic Activity of Transition ElementsDocument47 pagesCatalytic Activity of Transition ElementsNeen Naaz100% (1)

- FINAL SMAW-12-Quarter-3-module 4 PDFDocument20 pagesFINAL SMAW-12-Quarter-3-module 4 PDFRandy Sacatani100% (1)

- Afm E308-16 Afm E308h-16Document13 pagesAfm E308-16 Afm E308h-16Julio Cesar Lazcano PintoNo ratings yet

- Naming Chemical Compounds Worksheet: © 2004 Cavalcade Publishing, All Rights ReservedDocument5 pagesNaming Chemical Compounds Worksheet: © 2004 Cavalcade Publishing, All Rights Reservedpao manaligodNo ratings yet

- DD Cen TS 14495-2003Document14 pagesDD Cen TS 14495-2003mossamorrisNo ratings yet

- Material Alloy KHR35CLDocument2 pagesMaterial Alloy KHR35CLIebe Seventynine50% (2)

- Chapter 13 Transition Elements ExerciseDocument6 pagesChapter 13 Transition Elements Exerciseisqma100% (1)

- Asme B31.3 - Coef C-6Document3 pagesAsme B31.3 - Coef C-6joaquin torrano veraNo ratings yet

- US EPA Test Methods IndexDocument85 pagesUS EPA Test Methods IndexNajma Hosein100% (1)

- Chemical ToxicologyDocument59 pagesChemical ToxicologyMonika Rana100% (1)

- 79 Chromium Plated Brass Angle ValveDocument2 pages79 Chromium Plated Brass Angle ValveArun UdayabhanuNo ratings yet

- WEEK 3 lESSON 1Document2 pagesWEEK 3 lESSON 1tiktokeristNo ratings yet

- Transition and Inner Transition Metal Chemistry: CML 524Document57 pagesTransition and Inner Transition Metal Chemistry: CML 524Rahul MalikNo ratings yet

- 09162014114959monograph Chromite PDFDocument162 pages09162014114959monograph Chromite PDFTamirat WorkuNo ratings yet

- Material Identification NumbersDocument2 pagesMaterial Identification Numbersrajatapc12007No ratings yet

- Catalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908Document188 pagesCatalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908iMiklaeNo ratings yet

- Separation and Identification of Heavy Metal Ions by Thin Layer Chromatography On Silica GelgDocument7 pagesSeparation and Identification of Heavy Metal Ions by Thin Layer Chromatography On Silica GelgDebraj Dhar PurkayasthaNo ratings yet

- RLM02Document6 pagesRLM02Muaz100% (1)

- Thyssen Cel 70 Se en 0Document6 pagesThyssen Cel 70 Se en 0antoncanuckNo ratings yet

- Ebook Gas Detection Tube and Sampling Handbook PDFDocument69 pagesEbook Gas Detection Tube and Sampling Handbook PDFhopkhtnNo ratings yet