Professional Documents

Culture Documents

Pera Hot Air Welder

Uploaded by

MohamedSaidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pera Hot Air Welder

Uploaded by

MohamedSaidCopyright:

Available Formats

HOT AIR WELDER

Scope

This document is to be completed for staff and student use of machinery,

plant and equipment as a part of a school curriculum activity or program.

Refer to the ITD Guidelines for further staff advice on the risk management

process for practical ITD curriculum activities in schools.

Plant/Equipment Description:

Teachers/Leaders:

Room Locations:

Assessment Date: Review Date:

N.B. This assessment can remain active for up to 5 years. However, an annual monitoring and review process

should be undertaken and recorded – refer to the last page of this document.

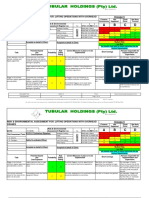

Below are the details of the manufacturing or production processes attributed to this item of equipment categorised

by their assessed inherent risk levels (refer to the Equipment/Process Risk Matrix). The actions required for

approval for each level of inherent risk are mandatory.

Inherent Risk Level Details of Processes Action Required/Approval

When heating and shaping and welding plastic

materials at moderate temperatures.

When used for softening specific adhesives. Document controls in planning

documents and/or complete this

Plant Risk Assessment.

Medium When used with welding attachments that

restrict or concentrate the hot air stream.

Consider obtaining parental

When the hot air welding gun is used within a permission.

typical school workshop environment and all

operations are under teacher supervision.

Reviewed July 2018 V3.

Uncontrolled when printed Organisational Safety and Wellbeing

Page 1 of 7

Minimum standards

Minimum qualifications and experience

Listed below are the general “minimum” recommendations for the management of this Plant/Equipment.

Indicate the minimum management controls.

Registered teachers with experience, ability and competency in the safe use of this plant/equipment

(indicate one or more of the following):

Specific knowledge of the safe and correct use of this plant/equipment

Experience (i.e. previous involvement and familiarity) in the safe use of this plant/equipment

Demonstrated expertise, ability and competency with this plant/equipment

Documented qualifications relating to the use of this plant/equipment (e.g. in a staff profile)

OR

An adult staff member or leader, other than a registered teacher, with:

Expertise in the safe and correct use of this plant/equipment

Documented qualifications that demonstrate experience, ability and competency in the safe use

of this plant/equipment.

Will any ITD staff require initial and/or ongoing training for the safe use of this plant/equipment?

If yes, give details:

Will students be operating this plant/equipment?

If yes, state how student use of this plant/equipment will be managed (e.g. Workshop Safety Induction)

Give details:

Further information if required:

Minimum control requirements

Supporting documentation available in the school on this plant/equipment includes:

Operators Manual

Safe Operating Procedures (SOP)

Equipment Maintenance Records (EMR)

A process for recording student safety induction e.g. Student induction register

A process for recording staff training and experience, e.g. ITD Staff induction register

All guards are in place and in good working order for this plant/equipment

Safe Working Zones are defined for this plant/equipment (e.g. yellow lines and/or appropriate signage)

Suitable personal protective equipment (PPE) is available to be used by all operators

This plant/equipment complies with relevant safety standards

Further information if required:

Reviewed July 2018 V3.

Uncontrolled when printed Organisational Safety and Wellbeing

Page 2 of 7

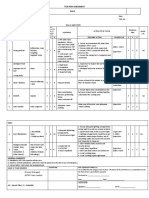

Hazards and control measures

Listed below are indicative hazards/risks and suggested control measures. These are by no means exhaustive

lists. Add details of any other hazards/risks or additional controls you intend to implement.

Indicate the control measures adopted. Detail their implementation and any additional controls required.

Details of how this will

Hazards/Risks Hierarchy of Recommended Yes No be implemented

Control Measures

(and any additional controls)

Exposure to Rotating 1. Where possible, potentially hazardous

or Moving Parts: portable power tools, including hot air

guns, are substituted or replaced with less

Entanglement and hazardous alternatives.

Entrapment 2. All necessary guards and safety devices

Could hair, clothing, ties, are in place protecting workers from all hot

jewellery or other materials surfaces or moving parts.

become entangled with

moving parts of plant or 3. Staff and student training is provided to

materials in motion? minimise exposure to these hazards and

risks.

Striking

4. Safe operating procedures (SOPs) are

Could anyone be struck by available and clearly displayed.

moving objects such as the

work piece being ejected, or 5. Warning notices are posted: e.g. “Read the

by the unexpected or SOP or Users Manual Before Operating

uncontrolled movement of the This Machine”.

plant or work piece?

6. “Safe Working Zones” are clearly defined

for workspaces where the hot air welding

gun is to be used.

7. Operators are required to remove all

jewellery, tuck in loose clothing and tie

back long hair.

8. All approved personal protective

equipment (PPE) is used where required.

Slips, Trips, Falls 1. Slip resistant flooring is encouraged.

and Abrasions: Regular checks are made for unsafe wear

and damage. Inspections are made for any

Can anyone using the plant or power leads, etc.

in the vicinity of the plant, slip,

trip or fall due to the working 2. Procedures are in place for the disposal of

environment or other factors? all waste materials around all work spaces

e.g. Poor housekeeping, dust where hot air welding activities are to be

on floors, slippery or uneven performed.

work surfaces, power cables 3. Staff training is provided to minimise

across work areas causing

exposure to these hazards.

injuries and abrasions?

Reviewed July 2018 V3.

Uncontrolled when printed Organisational Safety and Wellbeing

Page 3 of 7

Details of how this will

Hazards/Risks Hierarchy of Recommended Yes No be implemented

Control Measures

(and any additional controls)

Environmental: 1. Hot air welding guns are maintained to test

the thermostatic regulator controls and

Noise possible toxic vapour emissions.

Is it likely that the normal 2. All portable power tool maintenance is

operation of this plant will

documented.

produce excessive noise

levels? 3. Exposure to noisy ITD workshop

environments is monitored and evaluated

Dust, Fumes and regularly for all workers.

Vapours

Is it likely there will be airborne 4. Staff and student training is provided to

dust particles, toxic fumes or minimise exposure to these hazards.

volatile vapours produced and

therefore be present in the 5. All ducted fume and vapour extraction

workspace? systems are fully maintained, cleaned and

emptied, connected and operational.

Lighting

6. Good lighting is provided to all workspaces

Is there insufficient lighting to and this is maintained on a regular basis.

operate this plant in a safe Fluorescent tubes are checked and

manner? Is there a possible replaced as required.

strobe lighting effect caused

by faulty fluorescent tubes in 7. All approved personal protective

the workspace? equipment (PPE) is used where required.

Electrical: 1. Visual checks are made of all hot air

welding guns, their electrical switches,

Can the operator be injured by plugs and power leads, etc.

electrical shock due to 2. Electrical safety inspections, testing and

working near or contacting

tagging, etc. are completed regularly as

with damaged or poorly per guidelines.

maintained live electrical

conductors such as power 3. All portable power tools are only to be used

outlets, extension leads, where there is a RCD safety trip switch

safety switches, starters and connected?

isolators or casual water on

4. Warning “Danger” tags (or similar) are

the floor near plant and

affixed to all portable power tools under

machinery?

repair or maintenance preventing workers

from using them.

5. Electrical maintenance on all portable

power tools is documented.

Reviewed July 2018 V3.

Uncontrolled when printed Organisational Safety and Wellbeing

Page 4 of 7

Details of how this will

Hazards/Risks Hierarchy of Recommended Yes No be implemented

Control Measures

(and any additional controls)

Exposure: 1. Hot air welding guns are regularly

inspected and maintained to help minimise

the risk of exposure to the very hot metal

Heat, Burns and surfaces generated at the nozzle and the

Scalds extremely hot expelled air.

Could the plant operator be

exposed to heating elements, 2. All portable power tools maintenance is

exposed flame, flashback, documented.

molten metals or hot fluids 3. Any potentially hazardous waste materials

likely to cause scalding or or toxic vapours resulting from this hot air

burning? Humid and hot work welding process are monitored and

environments are often managed.

uncomfortable resulting in

stress and low productivity. 4. Staff and student training is provided to

minimise exposure to these hazards.

Hazardous

Substances 5. “Safe Working Zones” are clearly defined in

all workspaces where the hot air welding

Is it likely that the plant

gun is to be used.

operator or others nearby in

the workspace could be 6. All approved personal protective

exposed to hazardous or toxic equipment (PPE) is used where required.

chemicals such as oils,

greases, coolants, volatile

vapours, fumes or airborne

toxic particulates?

Ergonomics and 1. Where possible, practical work benches

Manual Handling: are planned and adjusted to a comfortable

work height thus minimising any unsafe or

excessively strenuous manual tasks.

Can the plant be safely

operated, in a suitable 2. Sufficient workspace is provided in all

location, providing clear and practical classrooms to help ensure

unobstructed access? unobstructed, safe operation.

Poorly designed work stations 3. Floors are regularly cleaned and free of

often necessitate teachers

excessive wood dust, waste materials and

and students performing other extraneous objects.

manual tasks involving heavy

lifting and lowering, pushing, 4. Staff training is provided with regard to

pulling or carrying, etc. Such manual handling techniques and

tasks then contribute to a procedures to minimise exposure to these

range of musculoskeletal hazards.

sprains and strains for

workers.

Explosion and Fire: 1. Fire extinguishers of the correct type are

readily available in all workspaces and

As a consequence of using positioned near exit doorways.

this particular item of plant 2. Staff training is provided regarding

and equipment, could anyone

procedures for the correct and appropriate

be injured by the release of use of fire safety equipment.

stored energy triggered by

volatile, explosive substances 3. Exits from buildings and other work areas

such as stored gasses, are defined and access to them kept clear

vapours or liquids? of obstructions.

4. Safety signage is posted clearly denoting

the location of all fire safety items and

emergency exits.

Reviewed July 2018 V3.

Uncontrolled when printed Organisational Safety and Wellbeing

Page 5 of 7

Additional Control Measures

Other Hazards/Risks These would relate to the specific student needs, locations and conditions in which you are

conducting your activity.

Approval

Submitted by: Date:

Approved as submitted.

Approved with the following condition(s):

Not Approved for the following reason(s):

By: Designation:

Signed: Date:

ITD staff members involved in the use of this risk assessment and the associated plant and equipment:

Signature: ……………………………….. Date:

Signature: ……………………………….. Date:

Signature: ……………………………….. Date:

Signature: ……………………………….. Date:

Signature: ……………………………….. Date:

Signature: ……………………………….. Date:

Signature: ……………………………….. Date:

Signature: ……………………………….. Date:

Reviewed July 2018 V3.

Uncontrolled when printed Organisational Safety and Wellbeing

Page 6 of 7

Monitoring and Review

This Plant and Equipment Risk Assessment is to be monitored and reviewed annually for a further four (4) years.

Review 1: Yes No

Are allocated risk levels and “Actions required” unchanged over the past 12 months?

Are Minimum Standards and Recommended Control Measures unchanged over 12 months?

ITD staffing details at this school have remained unchanged over the past 12 months?

If the responses are “NO” for any question, record current details here, and list all staff changes (with signatures)

Reviewed by: Designation:

Signed: Review Date :

Review 2: Yes No

Are allocated risk levels and “Actions required” unchanged over the past 12 months?

Are Minimum Standards and Recommended Control Measures unchanged over 12 months?

ITD staffing details at this school have remained unchanged over the past 12 months?

If the responses are “NO” for any question, record current details here, and list all staff changes (with signatures)

Reviewed by: Designation:

Signed: Review Date :

Review 3: Yes No

Are allocated risk levels and “Actions required” unchanged over the past 12 months?

Are Minimum Standards and Recommended Control Measures unchanged over 12 months?

ITD staffing details at this school have remained unchanged over the past 12 months?

If the responses are “NO” for any question, record current details here, and list all staff changes (with signatures)

Reviewed by: Designation:

Signed: Review Date :

Review 4: Yes No

Are allocated risk levels and “Actions required” unchanged over the past 12 months?

Are Minimum Standards and Recommended Control Measures unchanged over 12 months?

ITD staffing details at this school have remained unchanged over the past 12 months?

If the responses are “NO” for any question, record current details here, and list all staff changes (with signatures)

Reviewed by: Designation:

Signed: Review Date :

Reviewed July 2018 V3.

Uncontrolled when printed Organisational Safety and Wellbeing

Page 7 of 7

You might also like

- Site Inspection 1Document24 pagesSite Inspection 1Dan ValleroNo ratings yet

- Lifting Risk AssessmentDocument4 pagesLifting Risk AssessmentMohamedSaid100% (1)

- Fall Protection Risk AssessmentDocument3 pagesFall Protection Risk Assessmentsimone0% (1)

- Safety Related QuestionsDocument5 pagesSafety Related QuestionsShivaniNo ratings yet

- PPE Manual A5 en 2Document9 pagesPPE Manual A5 en 2ANSARNo ratings yet

- 6-R A For Handling, Storage and Use of Gas CylindersDocument4 pages6-R A For Handling, Storage and Use of Gas CylindersMohamedSaidNo ratings yet

- SLM g8 Hairdresssing Module6 TambalgueDocument13 pagesSLM g8 Hairdresssing Module6 TambalgueElaeca AbenNo ratings yet

- ASP Preparation Workshop - 23rd Sep. 2022Document74 pagesASP Preparation Workshop - 23rd Sep. 2022MohamedSaidNo ratings yet

- Control MeasuresDocument4 pagesControl MeasuresCharlie Dela RosaNo ratings yet

- Kelvin TOP-SET Investigation Report TemplateDocument7 pagesKelvin TOP-SET Investigation Report TemplateMohamedSaidNo ratings yet

- Construction Site Safety Plan Template (EXAMPLE)Document25 pagesConstruction Site Safety Plan Template (EXAMPLE)roland magoNo ratings yet

- RA For Assessment For Lifting OperationsDocument19 pagesRA For Assessment For Lifting OperationsMohamedSaidNo ratings yet

- Detailed Excavation Installation of Formwork & Reinforcement ConcretingDocument29 pagesDetailed Excavation Installation of Formwork & Reinforcement ConcretingRio Handoko100% (2)

- Jigsaw AssessmentDocument8 pagesJigsaw AssessmentNur Syafiqah Abu BakarNo ratings yet

- Fire Protection and Detaction System CalculationsDocument44 pagesFire Protection and Detaction System CalculationsMohamedSaid100% (1)

- ISO 14001 2015 Audit Checklist. DQSDocument19 pagesISO 14001 2015 Audit Checklist. DQSananthu.u100% (3)

- 1.0 Health, Safety & Environment Work PracticesDocument27 pages1.0 Health, Safety & Environment Work Practices5ad7100% (1)

- LOTO Practice & 7 Other Steps - EEPDocument4 pagesLOTO Practice & 7 Other Steps - EEPxteel100% (1)

- Nebosh IGC Element 6 Principles of Control (Notes)Document6 pagesNebosh IGC Element 6 Principles of Control (Notes)kkalvi100% (26)

- Hand Out Maintenance Course For EngineersDocument109 pagesHand Out Maintenance Course For EngineersGauravNo ratings yet

- Fall Protection Risk AssessmentDocument3 pagesFall Protection Risk AssessmentsimoneNo ratings yet

- Pera Air CompressorDocument6 pagesPera Air Compressorabdulhanansamo65No ratings yet

- Pera Air CompressorDocument6 pagesPera Air CompressorJigar VekariyaNo ratings yet

- Pera Saw Radial ArmDocument7 pagesPera Saw Radial ArmHussainNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Method of StatementDocument3 pagesMethod of StatementUmit CengNo ratings yet

- General Safety, Installation, and MaintenanceDocument35 pagesGeneral Safety, Installation, and MaintenanceTuti SusilawatiNo ratings yet

- RA Personal Fall Arrest Fall Restraint Equipment 0007 July 2017Document3 pagesRA Personal Fall Arrest Fall Restraint Equipment 0007 July 2017um erNo ratings yet

- Machinery and Plant Safety at WorkDocument28 pagesMachinery and Plant Safety at WorkUlviyye Cavid-Umid ElesgerovaNo ratings yet

- Appendix D Plant Tag and Lockout ProcedureDocument2 pagesAppendix D Plant Tag and Lockout ProcedurerajuhsemNo ratings yet

- Safe Design and Operation of PlantsDocument7 pagesSafe Design and Operation of PlantsAlfie Delos Reyes100% (1)

- Form 3 Work Health and Safety PolicyDocument7 pagesForm 3 Work Health and Safety PolicyMmc MixNo ratings yet

- Hierarchy of ControlsDocument6 pagesHierarchy of Controlssharon Aisha malroyNo ratings yet

- What Is A Safe Work Procedure?: Yoursafety@Irp - Toolbox DiscussionDocument1 pageWhat Is A Safe Work Procedure?: Yoursafety@Irp - Toolbox DiscussionRoman StreliaievNo ratings yet

- Pressure Powered Pump Ppec: Installation and Maintenance InstructionsDocument11 pagesPressure Powered Pump Ppec: Installation and Maintenance InstructionsR Ibnu Arif Wibowo,S.TNo ratings yet

- Ohsas AwarenessDocument74 pagesOhsas AwarenessManoj MauryaNo ratings yet

- Flo s92-93 Om 01-2010Document14 pagesFlo s92-93 Om 01-2010Elemsa InstalacionesNo ratings yet

- Internal Memo: Hazrds and Unsafe Working ConditionsDocument4 pagesInternal Memo: Hazrds and Unsafe Working ConditionsAsad AwanNo ratings yet

- Final Test of System Safety - Julian Hanggara AdigunaDocument6 pagesFinal Test of System Safety - Julian Hanggara AdigunaThe Minh NguyenNo ratings yet

- Safe Operating Procedures: Medium To High RiskDocument6 pagesSafe Operating Procedures: Medium To High Riskmuhammad imtiazNo ratings yet

- Day 3 Job Hazard Analysis (Handout)Document6 pagesDay 3 Job Hazard Analysis (Handout)mike camsNo ratings yet

- Hazard Analysis AutomotiveDocument1 pageHazard Analysis AutomotivejaglansunilNo ratings yet

- Safeguard Design and MechanismDocument2 pagesSafeguard Design and MechanismNikkiNo ratings yet

- Download-Guide To Install PDFDocument40 pagesDownload-Guide To Install PDFTran Cong HauNo ratings yet

- 2.3.2.1 Safety Management System NotesDocument9 pages2.3.2.1 Safety Management System Noteskit_mak_5No ratings yet

- Management - U03.1 - C04: Diploma in ME/EE/EP/EU/CH/PSDocument13 pagesManagement - U03.1 - C04: Diploma in ME/EE/EP/EU/CH/PSAbhishek ChavanNo ratings yet

- Plant & Equipment, WHSPRO-020 CMDocument3 pagesPlant & Equipment, WHSPRO-020 CMJean Claude EidNo ratings yet

- Generation III Sonic Feeder Control System Manual 20576Document32 pagesGeneration III Sonic Feeder Control System Manual 20576julianmataNo ratings yet

- Chapter 6 - Housekeeping in PetrochemicalDocument25 pagesChapter 6 - Housekeeping in Petrochemicalchristina jeitolNo ratings yet

- Enter Name of ProcedureDocument2 pagesEnter Name of ProcedureDondy ZobitanaNo ratings yet

- Agtech PpeDocument27 pagesAgtech PpeNakimera JosephineNo ratings yet

- Management Chapter 4 Study MaterialDocument26 pagesManagement Chapter 4 Study MaterialVirendra PatilNo ratings yet

- Lec 3. Inspection & Prevention (CM-112)Document30 pagesLec 3. Inspection & Prevention (CM-112)Naveed AhmadNo ratings yet

- 25PT 25pe 25te 25 Pte-Im-3-017-UsDocument11 pages25PT 25pe 25te 25 Pte-Im-3-017-UsDavid RuizNo ratings yet

- Environmental Health Risk AssessmentDocument7 pagesEnvironmental Health Risk Assessmentdu dungNo ratings yet

- Technology: Risk Assessment Title: Centre Lathe AUGUST2016Document4 pagesTechnology: Risk Assessment Title: Centre Lathe AUGUST2016RadhaKrishnan RNo ratings yet

- Job Safety Analysis - N2 PurgingDocument3 pagesJob Safety Analysis - N2 Purgingbenjamin alingNo ratings yet

- Type 25P 25PA Pressure Reducing Valves-Installation Maintenance Manual PDFDocument12 pagesType 25P 25PA Pressure Reducing Valves-Installation Maintenance Manual PDFManutenção [Gemacom Tech]No ratings yet

- Work Equipment Risk AssessmentDocument6 pagesWork Equipment Risk AssessmentEmperorr Tau MtetwaNo ratings yet

- DikonversiDocument2 pagesDikonversiDondy ZobitanaNo ratings yet

- C24 SOP WAH (WORK at HEIGHT)Document10 pagesC24 SOP WAH (WORK at HEIGHT)diansafemaxNo ratings yet

- Spirax Sarco 01150200 ManualDocument12 pagesSpirax Sarco 01150200 Manualantonio sanchezNo ratings yet

- Notes 4Document12 pagesNotes 4moraine.hills3No ratings yet

- Enhanced LOTODocument29 pagesEnhanced LOTOYogi PrayogiNo ratings yet

- Appendix C Plant Heirarchy of ControlsDocument5 pagesAppendix C Plant Heirarchy of ControlsParker PhaliNo ratings yet

- Pages From NFPA 70E - Standard For Electrical Safety in The WorkplaceDocument1 pagePages From NFPA 70E - Standard For Electrical Safety in The WorkplaceMohamedSaidNo ratings yet

- Pages From NFPA 70E - Standard For Electrical Safety in The Workplace-2Document1 pagePages From NFPA 70E - Standard For Electrical Safety in The Workplace-2MohamedSaidNo ratings yet

- Inspected صوحفمDocument1 pageInspected صوحفمMohamedSaidNo ratings yet

- Pages From NFPA 70E - Standard For Electrical Safety in The Workplace-3Document1 pagePages From NFPA 70E - Standard For Electrical Safety in The Workplace-3MohamedSaidNo ratings yet

- PR GL Fragmentiser Best PracticeDocument51 pagesPR GL Fragmentiser Best PracticeMohamedSaidNo ratings yet

- RA of Manual ChippingDocument2 pagesRA of Manual ChippingMohamedSaidNo ratings yet

- Safety Leadership TrainingDocument8 pagesSafety Leadership TrainingMohamedSaidNo ratings yet

- Employee Health and Safety Safety Moments Working AloneDocument1 pageEmployee Health and Safety Safety Moments Working AloneMohamedSaidNo ratings yet

- TDS - Logicbase V-SLDocument1 pageTDS - Logicbase V-SLMohamedSaidNo ratings yet

- Level 12Document68 pagesLevel 12MohamedSaidNo ratings yet

- Crane Anti Collision DeviceDocument15 pagesCrane Anti Collision DeviceMohamedSaidNo ratings yet

- Worker Fell From Mobile Tower Scaffold: RecommendationsDocument2 pagesWorker Fell From Mobile Tower Scaffold: RecommendationsMohamedSaidNo ratings yet

- JPPL Ehs 19 03 SWP 02Document12 pagesJPPL Ehs 19 03 SWP 02MohamedSaidNo ratings yet

- ABP-HS - SA058 Battery Charging Incident - Safety AlertDocument1 pageABP-HS - SA058 Battery Charging Incident - Safety AlertMohamedSaidNo ratings yet

- Nuclear Reactor Safety Principles I1.2Document1 pageNuclear Reactor Safety Principles I1.2MohamedSaidNo ratings yet

- Excavations Are SeriousDocument3 pagesExcavations Are SeriousMohamedSaidNo ratings yet

- Safety Productivity Technologies Francois RotatDocument11 pagesSafety Productivity Technologies Francois RotatMohamedSaidNo ratings yet

- Transocean, Inc (RIG) : HFAC Stock Pitch April 24th, 2008Document28 pagesTransocean, Inc (RIG) : HFAC Stock Pitch April 24th, 2008MohamedSaidNo ratings yet

- 14a - Joe Hurt-John Auth Rig Pass PresentationDocument36 pages14a - Joe Hurt-John Auth Rig Pass PresentationMohamedSaidNo ratings yet

- ExcavationDocument4 pagesExcavationVignesh KmNo ratings yet

- Accord Marine Management Pvt. Ltd. Fleet Operation Manual: Cleaning and Gas Freeing ProcedureDocument9 pagesAccord Marine Management Pvt. Ltd. Fleet Operation Manual: Cleaning and Gas Freeing ProcedureMohamedSaidNo ratings yet