Professional Documents

Culture Documents

Fatal Accident Failure To Conduct

Uploaded by

Zaki AziziOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fatal Accident Failure To Conduct

Uploaded by

Zaki AziziCopyright:

Available Formats

HAZARD ALERT

On December 3rd, 2012, a maintenance employee at an oil refinery was

fatally injured when a rotameter failed and a mixture of propane and hy-

drofluoric acid (HF) was released. The rotameter was part of a temporary

installation on a pump seal flush line to determine flow to the pump seal.

A temporary line was run from the flush line header to a flare header. A

Failure to pressure gauge was placed in the line to determine flow. A rotameter was

conduct also added for a visual reference. The rotameter was rated for 200 psi but

the flush line had an operating pressure of between 260 and 280 psi. The

Manage- rotameter also had a glass face, which is not compatible with HF service.

ment of

Change No Management of Change (MOC) was conducted prior to the develop-

(MOC) ment of this plan or this installation being put into service.

leads to

fatality

For any Process Safety (29 CFR 1910.119) covered facility, prior to any

change that is not in kind, you must conduct a Management of Change

5 Gateway Center (MOC)

Pittsburgh, PA 15222 If you are unsure of the need for a MOC, refer to your facility’s written

safety@usw.org

412.562.2581

plan and 29 CFR 1910.119 (l).

Be sure to address the following considerations:

This hazard alert is based on

an actual incident, and reflects The technical basis for the proposed change

our best understanding of the

incident at the time it was Impact of change on safety and health

written. However, many

incidents have multiple Modifications to operating procedures

causes; this alert may not

cover all of them. The Necessary time period for the change

purpose of the alert is to

illustrate workplace hazards; Authorization requirements for the proposed change

it is not intended to be a

comprehensive report on the Employees must be effectively trained in all elements of the Process

incident.

Safety standard.

You might also like

- 7S92-06011-CO-TP-540 - MST - For - Re-Calibration of PSV-039Document15 pages7S92-06011-CO-TP-540 - MST - For - Re-Calibration of PSV-039abdelmalek boudjemaaNo ratings yet

- MOC GuidanceDocument5 pagesMOC GuidanceSergiu Lung100% (1)

- Substation Case StudyDocument10 pagesSubstation Case StudyMaribel C. MagbanuaNo ratings yet

- 7S92-06011-CO-TP-542 MST For EPDM Repair For MOV-041 & 052 r0Document21 pages7S92-06011-CO-TP-542 MST For EPDM Repair For MOV-041 & 052 r0abdelmalek boudjemaaNo ratings yet

- Turret Swivel System Operation (Rev.00)Document12 pagesTurret Swivel System Operation (Rev.00)hai dang maiNo ratings yet

- 340-RPT-ES-SYN-5004 - HVAC Improvement Recommendation Report - Rev 0 1Document148 pages340-RPT-ES-SYN-5004 - HVAC Improvement Recommendation Report - Rev 0 1Den Bagus BlitarNo ratings yet

- Management of ChangeDocument34 pagesManagement of ChangeKashyap PatelNo ratings yet

- Raising The Alarm - Understanding The Operator's Perspective On Refinery Process AlarmsDocument5 pagesRaising The Alarm - Understanding The Operator's Perspective On Refinery Process AlarmsNaiduJagarapuNo ratings yet

- IMSPTCH07-revised On 13.04.2023Document9 pagesIMSPTCH07-revised On 13.04.2023madhuramfoods.chiralaNo ratings yet

- IOM DUrcoDocument28 pagesIOM DUrcoAlex RodriguezNo ratings yet

- Manual Bomba KSB RPK 41 1118Document20 pagesManual Bomba KSB RPK 41 1118elegel1982100% (2)

- DH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0Document6 pagesDH3-31MAX-T-SCT-0021 Commissioning Procedure of EH Oil System REV.0hungNo ratings yet

- PSM Best Practices Workshop - Pre-Startup Safety Review PresentationDocument15 pagesPSM Best Practices Workshop - Pre-Startup Safety Review PresentationRod Lafrades100% (1)

- General Piping InspectionDocument13 pagesGeneral Piping InspectionKingston Rivington100% (1)

- Supplemental Report of Survey Deepwater Horizon: PreparedDocument16 pagesSupplemental Report of Survey Deepwater Horizon: PreparedOSDocs2012No ratings yet

- 6 Management of ChangeDocument49 pages6 Management of ChangeR AbdElkaderNo ratings yet

- Pre Startup Safety ReviewDocument29 pagesPre Startup Safety ReviewAhsan100% (1)

- 1 What Is Functional Safety, SIF, SISDocument17 pages1 What Is Functional Safety, SIF, SISAlice LinNo ratings yet

- Woc Hse Manual Standards: Woc LP EP DepartmentDocument12 pagesWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNo ratings yet

- Pre-Comm., Comm. Start Up & Opertion Manual R2 TerminalDocument386 pagesPre-Comm., Comm. Start Up & Opertion Manual R2 Terminalalokc100% (1)

- Fire Protection System: Testing & Commissioning Method StatementDocument14 pagesFire Protection System: Testing & Commissioning Method Statementselcuk peken50% (2)

- Partial Stroke Testing - R3Document8 pagesPartial Stroke Testing - R3Gabo Montaño MendozaNo ratings yet

- MS-ME-001-Method Statement For The Installation of Air Cooled Chillers 01Document17 pagesMS-ME-001-Method Statement For The Installation of Air Cooled Chillers 01VibinNo ratings yet

- Hazards 29 Paper 55Document11 pagesHazards 29 Paper 55Jinyoung ChoiNo ratings yet

- Safety Alert Blind RemovalDocument3 pagesSafety Alert Blind Removalav7867No ratings yet

- Mos DcsDocument13 pagesMos DcsSudam PatraNo ratings yet

- Attachment B: Engineering Standards Manual STD-342-100Document8 pagesAttachment B: Engineering Standards Manual STD-342-100SAURABH SINGHNo ratings yet

- Installation, Operation and Maintenance Manual VTP ... - RuhrpumpenDocument83 pagesInstallation, Operation and Maintenance Manual VTP ... - RuhrpumpenFelySaezNo ratings yet

- 13-06-13 Managment of Change ProcedureDocument17 pages13-06-13 Managment of Change Procedurekelvin OsemeNo ratings yet

- PEO ExampleDocument12 pagesPEO ExampleSahil Kumar50% (2)

- EP1 Thet Htoo Aung (Term Paper) (Updated 20.7.2021)Document10 pagesEP1 Thet Htoo Aung (Term Paper) (Updated 20.7.2021)အောင် ချစ်သူNo ratings yet

- Selecting Transmitters For Safety Instrumented SystemsDocument8 pagesSelecting Transmitters For Safety Instrumented Systemskir1234No ratings yet

- Safety Bulletin January-2022Document4 pagesSafety Bulletin January-2022BinayNo ratings yet

- SP 1190 Desing - For - Sour - Service - SpecificationDocument15 pagesSP 1190 Desing - For - Sour - Service - Specificationhappale2002100% (1)

- SPE/IADC 113682 MPD Planning: How Much Is Enough?Document8 pagesSPE/IADC 113682 MPD Planning: How Much Is Enough?Anonymous CLoxXdABNo ratings yet

- SOP For SMPS ChecksDocument8 pagesSOP For SMPS ChecksPavar RavitejaNo ratings yet

- Ips e in 110Document21 pagesIps e in 110ali1860No ratings yet

- MaintenanceDocument67 pagesMaintenanceBala M100% (1)

- Refinery GII Sep-2013Document22 pagesRefinery GII Sep-2013samboopathiNo ratings yet

- PSSR Pre-Commissioning SafetyDocument6 pagesPSSR Pre-Commissioning SafetymanuNo ratings yet

- CDU II Operating ManualDocument562 pagesCDU II Operating ManualRajeshwar Telang91% (11)

- Design and Development of A Pneumatic Switch Assembly System Based On PLC Control TechnologyDocument7 pagesDesign and Development of A Pneumatic Switch Assembly System Based On PLC Control Technologyquangvu16No ratings yet

- GBH Enterprises, LTD.: Process Engineering GuideDocument15 pagesGBH Enterprises, LTD.: Process Engineering GuidePaul JamesonNo ratings yet

- PIP PCECV002-2018 Pressure Regulators Selection GuidelinesDocument5 pagesPIP PCECV002-2018 Pressure Regulators Selection Guidelines刘旭No ratings yet

- Method Statement For Installation of Gate Valves & Check Valves (Ps-17, Ps40 &Psw1)Document18 pagesMethod Statement For Installation of Gate Valves & Check Valves (Ps-17, Ps40 &Psw1)shujad77100% (1)

- P3 Electronic Air Plant RS Rennerlogic Compressors O&M Rev 3Document39 pagesP3 Electronic Air Plant RS Rennerlogic Compressors O&M Rev 3anfalapNo ratings yet

- Shell Downstream Manufacturing SM-1510002-SP-30 Management of Injection Points and Mix Points1Document17 pagesShell Downstream Manufacturing SM-1510002-SP-30 Management of Injection Points and Mix Points1Gail Holt75% (4)

- Quick Start Guide Rosemount 3051g Pressure Transmitter 4 20ma Hart Protocol Revision 5 7 en 5433924Document36 pagesQuick Start Guide Rosemount 3051g Pressure Transmitter 4 20ma Hart Protocol Revision 5 7 en 5433924kasaxif851No ratings yet

- P3 Electronic Vac Plant Standard O&M Rev 10Document34 pagesP3 Electronic Vac Plant Standard O&M Rev 10anfalapNo ratings yet

- Documentos TecnicosDocument16 pagesDocumentos TecnicosDomingo esteban perez ceballoNo ratings yet

- 00 Saip 72Document6 pages00 Saip 72Erin JohnsonNo ratings yet

- Fisher 2625 Volume Booster SIS Safety ManualDocument4 pagesFisher 2625 Volume Booster SIS Safety ManualWalid FattahNo ratings yet

- Project NavigatorDocument9 pagesProject NavigatorXozanNo ratings yet

- Bomba CPKDocument20 pagesBomba CPKPatricio Andres Silva SanzanaNo ratings yet

- 4 Year BookDocument58 pages4 Year BookLalitha LatchanaNo ratings yet

- 160 76-RP1Document80 pages160 76-RP1HectorFalconLlenderrozosNo ratings yet

- M & e MST - 038 Rev. 0Document3 pagesM & e MST - 038 Rev. 0Anonymous 3eHGEDbxNo ratings yet

- Distribution Boards Method Statement Approval - SubmissionDocument20 pagesDistribution Boards Method Statement Approval - SubmissionKalesha Vali ShaikNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- PTW LOTO Permit To Work (B) DetailsDocument3 pagesPTW LOTO Permit To Work (B) DetailsZaki AziziNo ratings yet

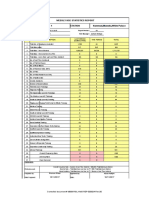

- Fire Ext Inspection FormDocument5 pagesFire Ext Inspection FormZaki AziziNo ratings yet

- Weekly Safety Report-85Document2 pagesWeekly Safety Report-85Zaki AziziNo ratings yet

- LOTO Stock RegisterDocument1 pageLOTO Stock RegisterZaki AziziNo ratings yet

- Fall Protection - Right Use of Full Body Harness-1Document20 pagesFall Protection - Right Use of Full Body Harness-1Zaki AziziNo ratings yet

- Camp InformationDocument1 pageCamp InformationZaki AziziNo ratings yet

- Federal Law No. 16 of 2007 EngDocument26 pagesFederal Law No. 16 of 2007 EngZaki AziziNo ratings yet

- WELPAREFACILITYDocument1 pageWELPAREFACILITYZaki AziziNo ratings yet

- Water Stations Details Location WiseDocument1 pageWater Stations Details Location WiseZaki AziziNo ratings yet

- PTW LOTO Permit To Work (C) DetailsDocument3 pagesPTW LOTO Permit To Work (C) DetailsZaki AziziNo ratings yet

- Warning MemoDocument10 pagesWarning MemoZaki AziziNo ratings yet

- Fatal Accident Fatal Accident InvolvingDocument1 pageFatal Accident Fatal Accident InvolvingZaki AziziNo ratings yet

- Weekly Hse Statistics (11-11-2017 To16 - 11-2017)Document2 pagesWeekly Hse Statistics (11-11-2017 To16 - 11-2017)Zaki AziziNo ratings yet

- Chemical Hygiene Plan 1Document34 pagesChemical Hygiene Plan 1Zaki AziziNo ratings yet

- TBT 131Document15 pagesTBT 131Zaki AziziNo ratings yet

- Cfats Chemicals of Interest For LabsDocument9 pagesCfats Chemicals of Interest For LabsZaki AziziNo ratings yet

- Downloaded File-4Document1 pageDownloaded File-4Zaki AziziNo ratings yet

- Access To Work AreasDocument1 pageAccess To Work AreasZaki AziziNo ratings yet

- TBT 111Document1 pageTBT 111Zaki AziziNo ratings yet

- Controlled Substance Researchers Guide Attachment A ApplicationDocument1 pageControlled Substance Researchers Guide Attachment A ApplicationZaki AziziNo ratings yet

- Personal Protective Equipment Hazard AssessmentDocument5 pagesPersonal Protective Equipment Hazard AssessmentZaki AziziNo ratings yet

- Accident PreventionDocument1 pageAccident PreventionZaki AziziNo ratings yet

- Vehicle Inspection ChecklistDocument1 pageVehicle Inspection ChecklistZaki Azizi100% (1)

- Back Safety Materials Handling Fact Sheet 0Document4 pagesBack Safety Materials Handling Fact Sheet 0Zaki AziziNo ratings yet

- Monthly Camp Inspection ChecklistDocument2 pagesMonthly Camp Inspection ChecklistZaki Azizi100% (1)

- Daily Task (Night)Document4 pagesDaily Task (Night)Zaki AziziNo ratings yet

- Crane Inspection Checklist-GSDocument1 pageCrane Inspection Checklist-GSZaki AziziNo ratings yet

- Checklists StatusDocument3 pagesChecklists StatusZaki AziziNo ratings yet

- Mothly Motor Vehicle Damage ReportDocument1 pageMothly Motor Vehicle Damage ReportZaki AziziNo ratings yet

- Air Compressor ChecklistDocument2 pagesAir Compressor ChecklistZaki AziziNo ratings yet

- POGIL - KinematicsDocument4 pagesPOGIL - KinematicsmagiclcjNo ratings yet

- 2016 MVP Tcode Key GuideDocument149 pages2016 MVP Tcode Key GuideEnrique GomezNo ratings yet

- Lesson 4 Module Title: Leadership TrainingDocument8 pagesLesson 4 Module Title: Leadership TrainingAnamae Detaro DarucaNo ratings yet

- A Crisis Intervention Model For Child Protective S PDFDocument22 pagesA Crisis Intervention Model For Child Protective S PDFKali HartvigsenNo ratings yet

- The Discipline of CounselingDocument18 pagesThe Discipline of CounselingIekzkad Realvilla0% (1)

- Week 5 TaskDocument3 pagesWeek 5 TaskSonia Martinez RamosNo ratings yet

- Wiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition System2 w202Document4 pagesWiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition System2 w202mathexscribdNo ratings yet

- Xerox Wc423 SMDocument600 pagesXerox Wc423 SMkerintNo ratings yet

- Colloquia Latina D Ooge PDFDocument104 pagesColloquia Latina D Ooge PDFHadaixx100% (1)

- Examination of Nutrition Knowledge, Attitude, and Dietary Behaviors of College Student Vegetarians, Semi-Vegetarians, and Non-VegestariansDocument11 pagesExamination of Nutrition Knowledge, Attitude, and Dietary Behaviors of College Student Vegetarians, Semi-Vegetarians, and Non-VegestariansMeilindaNo ratings yet

- Soal CehDocument99 pagesSoal CehAditya PradanaNo ratings yet

- Worksheet Digital Illustration TechniqueDocument5 pagesWorksheet Digital Illustration TechniqueJago100% (1)

- Lab Heat Experment 2Document5 pagesLab Heat Experment 2حسين عمريNo ratings yet

- Appraisal of Students Non-Test TechniqyuesDocument22 pagesAppraisal of Students Non-Test Techniqyuesmary grace sierraNo ratings yet

- A Study Code Mixing Found in Stay With Me FilmDocument21 pagesA Study Code Mixing Found in Stay With Me Filmsalvatore sketch100% (1)

- West Bengal TourismDocument6 pagesWest Bengal TourismJoseph Subham MondalNo ratings yet

- What Is The Function of The CMOS Battery?: RAM BiosDocument1 pageWhat Is The Function of The CMOS Battery?: RAM Biosrobert turkoNo ratings yet

- NCERT Solution For Cbse Class 9 Science Chapter 15 IMPROVEMENT IN FOOD RESOURCES PDFDocument7 pagesNCERT Solution For Cbse Class 9 Science Chapter 15 IMPROVEMENT IN FOOD RESOURCES PDFSanjiv KumarNo ratings yet

- maxDPUTools A1Document117 pagesmaxDPUTools A1Deepak GuptaNo ratings yet

- ISO 10628-2 2012 SymbolsDocument7 pagesISO 10628-2 2012 SymbolsSteven BosscherNo ratings yet

- Dream DeferredDocument10 pagesDream DeferredJayesh JainNo ratings yet

- Rewrite The Following Passage in The PassiveDocument2 pagesRewrite The Following Passage in The PassiveJuan david Guerrero RodríguezNo ratings yet

- 11-801 Traning Course - DeaeratorDocument26 pages11-801 Traning Course - Deaeratorpbarri100% (1)

- Coop Conference Proceeding (21-22aug 2022)Document585 pagesCoop Conference Proceeding (21-22aug 2022)oliviahuda75No ratings yet

- RealSense Depth D435i IMU CalibDocument19 pagesRealSense Depth D435i IMU Calib李秋、No ratings yet

- Ayurvedic Healing A Comprehensive Guide David Frawley.07106 - 3ayurvedicdiet PDFDocument7 pagesAyurvedic Healing A Comprehensive Guide David Frawley.07106 - 3ayurvedicdiet PDFlelis2013100% (1)

- Rodec: User ManualDocument31 pagesRodec: User ManualMaxwell SpenceNo ratings yet

- Flygt IOM 3153-095Document72 pagesFlygt IOM 3153-095jose03No ratings yet

- 1234 Sasdfasdf 12341234Document20 pages1234 Sasdfasdf 12341234NysekNo ratings yet

- GIC TestDocument5 pagesGIC TestRishabh AgarwalNo ratings yet