Professional Documents

Culture Documents

Microcontroller Bootcamp (6) : The Spi Interface

Uploaded by

Mikko FagerlundOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microcontroller Bootcamp (6) : The Spi Interface

Uploaded by

Mikko FagerlundCopyright:

Available Formats

•Projects

Microcontroller

BootCamp (6)

The SPI interface

By Serial communication with each unit of information following the previous one is

Burkhard Kainka

actually the normal situation. That’s how we talk to each other in person or by

(Germany)

phone, read and write text—or in the case of Retronics: send telegrams.

In many cases all you need is a single line to transmit data. However, adding a

clock line makes things more reliable. Let‘s find out.

On the Serial Peripheral Interface (SPI) bus, the

4094 actual data travels bit by bit over one line—for

Nr. 2 example from a microcontroller to a display, an

16 15 14 13 12 11 10 9

EEPROM or an SD card. In most cases it’s also

Q'S

VCC

Q5

Q6

Q7

Q8

OE

QS

desirable to be able to read data, so you need a

+5V 4094

second line to provide a return channel for the

GND

STR

CL

Q1

Q2

Q3

Q4

data. There’s yet another part to the picture: a

D

1 2 3 4 5 6 7 8

clock line. The clock signal always clearly indi-

28 27 26 25 24 23 22 21 20 19 18 17 16 15 cates when the next bit is available on the data

line. That eliminates the need for precise agree-

GND

AVCC

C5

C4

C3

C2

C1

C0

B5

B4

B3

B2

B1

AREF

ATmega328p ment on data timing, which both parties have

to supervise with timers. With these three lines,

GND

VCC

RES

D0

D1

D2

D3

D4

D5

D6

D7

B0

X1

X2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 data transmission is fairly bombproof.

16MHz

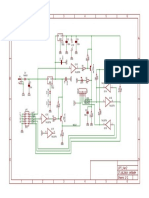

Port extension with a shift register

100n

The first thing we want to try out is actually not

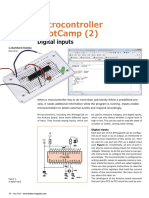

Figure 1. 22p 22p

an SPI interface, but instead something entirely

140245 - 11

Connecting a type 4094 shift different. Shift registers have been around for

register. a long time (before microcontrollers were even

30 | October 2014 | www.elektor-magazine.com

Microcontroller Bootcamp

invented) and are good for understanding how terminal emulator. This makes it easy to com-

serial data transfer works. They can also be put pare the output levels of the shift register to the

to good use in combination with a microcontrol- digital value being output.

ler. That’s because port lines are always scarce, If you need more than eight outputs, you can

especially on Arduino boards. A port extension use the Qs output of the 4094 IC. Each bit that

with a shift register can help ease the scarcity. is clocked into the shift register appears at the

With a type 4094 8-bit shift register, you need

three lines to talk to it and you end up with

eight new outputs. You can increase this to 16 Listing 1. Output using a shift register.

by connecting a second shift register, or even

'------------------------------------

80 if you connect ten shift register ICs in series. 'UNO_shift.BAS Shift Register 4094

If you need a lot of outputs, that’s an especially '------------------------------------

low-cost way to meet the requirement. $regfile = "m328pdef.dat"

$crystal = 16000000

Figure 1 shows the connections to the Uno board. $baud = 9600

The 8-bit shift register has a clock input (CL)

and a data input (D). The data is applied to the Dim Dat As Byte

D input one bit at a time, starting with the most Dim D As Byte

significant bit, and a rising edge is applied to the Dim N As Byte

clock input CL for each bit. The data is shifted Dim B As Bit

through the individual flip-flops of the register

step by step with each clock pulse. There is also

the strobe input STR. When a pulse is applied Sr Alias Portb.4 '4094 pin 1

to the strobe input, all the data present in the Da Alias Portb.3 '4094 pin 2

shift register is transferred to the type-D flip- Cl Alias Portb.2 '4094 pin 3

flops connected to the output pins. You could Config Portb = Output

also tie the strobe input to the supply voltage

...

Vcc, but then all the intermediate results of each

shift operation would appear on the outputs. By

Dat = 0

contrast, if you apply a strobe pulse after all the

Do

bits have been shifted in, you only see the final

Cls

result on the outputs.

Lcd Dat

Lcd " "

The software for all this (Listing 1) is simple. To Print Dat

output a byte D, the code first copies the most D = Dat

significant bit to the bit variable B (B = D.7) For N = 1 To 8

and puts it on the corresponding port pin. It B = D.7

then generates a positive clock pulse on CL with Da = B

a length of 1 millisecond. A microsecond would Waitms 1

also be sufficient, but the slower output is easier Cl = 1

to see on an oscilloscope. After the clock pulse, Waitms 1

a shift instruction (Shift D , Left) causes all Cl = 0

bits of D to be shifted left by one position. This Waitms 1

puts what used to be bit 6 on the output. This Shift D , Left

process is repeated until all eight bits have been Next N

shifted out. At the end comes the strobe pulse, Sr = 1

and then all eight bits are present at the outputs Waitms 1

of the 4094. Sr = 0

The code continuously increments the data byte Waitms 1

Dat = Dat + 1

to be transferred so the outputs of the shift regis-

Waitms 500

ter change while the program is running. The

Loop

current value is shown on the LCD if the Elektor

End

Extension shield is fitted, and it is output to the

www.elektor-magazine.com | October 2014 | 31

•Projects

Qs output eight clock pulses later. The D input of see the difference. There both parties have to

the next shift register can be connected to this agree on the transmission rate, and no breaks are

output. In this way you can connect as many allowed within an information unit. For example,

4094 ICs in series as desired, with the clock and if a radio operator wants to send an “X” (dash

strobe lines connected to all of them in parallel. dot dot dash) and stops in the middle to scratch

Of course, the software will have to be modi- his head, the two characters “N” (dash dot) and

fied accordingly. First it shifts out all of the bits “A” (dot dash) are sent instead. The situation is

necessary to fill the chain of shift registers (e.g. exactly the same with an asynchronous serial data

16 with two ICs or 80 with ten), and then it out- interface, where both parties have to agree on

puts the common strobe pulse. the baud rate. After the transmission of a byte

has started, all of the bits must be sent within

Manual data transmission a precise time frame. By contrast, with SPI the

Although you only need one line for the data, you timing is not critical and any desired delays are

also need a clock line when you use a clocked allowed. The additional clock signal makes the

serial interface, as in the above example with a transfer entirely independent of the speed. No

shift register or with the SPI bus. If you compare matter whether the data rate is just one bit per

this with Morse telegraphy, for example, you can minute or a million bits per second, the data will

Listing 2. SPI master and slave (very slow).

'------------------------------------- Led1 = 1

'UNO_spi1.BAS Shift in/out Waitms 200

'------------------------------------- Led1 = 0

$regfile = "m328pdef.dat" Waitms 500

$crystal = 16000000 Shift D , Left

$baud = 9600 Next N

Led1 = 0

Dim D As Byte Led2 = 0

Dim B As Bit Waitms 2000

Dim N As Byte Cls

S1 Alias Pinc.0 D = 0

Portc.0 = 1 Do

S2 Alias Pinc.1 Loop Until S1 = 1

Portc.1 = 1 For N = 0 To 7

Led1 Alias Portc.2 Shift D , Left

Ddrc.2 = 1 Do

Led2 Alias Portb.2 Loop Until S1 = 0

Ddrb.2 = 1 If S2 = 0 Then B = 1 Else B = 0

D = D + B

... Lcd B

Print B;

Do Waitms 100

D = Rnd(255) Do

Cls Loop Until S1 = 1

Lcd D Waitms 100

Print D Next N

Locate 2 , 1 Print

For N = 0 To 7 Locate 2 , 1

B = D.7 Lcd D

Lcd B Print D

Print B; Waitms 2000

Led2 = B Loop

Waitms 300 End

32 | October 2014 | www.elektor-magazine.com

Microcontroller Bootcamp

be transferred properly. On an SPI bus there is

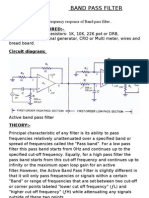

Clock Data

always an SPI master and an SPI slave. Data can LED1 LED2

travel in both directions, but the master ways

generates the clock signal. S2 S1

1k

1k

Data Clock

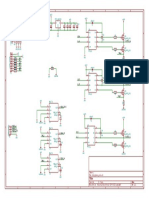

You can try this for yourself manually, where you +5V

(as the user) assume the role of master. You can

transmit a byte by pushing the two buttons S1

and S2 (Figure 2). This is not the usual way of

28 27 26 25 24 23 22 21 20 19 18 17 16 15

doing things, but it helps you understand exactly

GND

C5

C4

C3

C2

C1

C0

B5

B4

B3

B2

B1

AVCC

AREF

how it works. One of the buttons is for the data,

ATmega328p

and the other is for the clock. Aside from that

GND

VCC

RES

there’s nothing new you have to learn, since you

D0

D1

D2

D3

D4

D5

D6

D7

B0

X1

X2

1 2 3 4 5 6 7 8 9 10 11 12 13 14

already know how a byte is put together. Here’s

how it works: First you send bit 7. If it is a ‘1’, 16MHz

you press and hold button S2; otherwise you

don’t. Then you press button S1 briefly without 100n

changing the state of S2. The receiving end (the 22p 22p

140245 - 12 Figure 2.

slave, which in this case is the Arduino board) Manual input and output.

then knows when it should read the bit from the

data line. Now you repeat the process for bit 6,

bit 5, and so on until bit 0. marked by a clock pulse. It may not have been all

that easy, but the microcontroller had no problem

The program in Listing 2 displays the data in reading the data. You can regard this as a test

both directions. At first the microcontroller is of your concentration, and if the LCD shows the

the master and you are the slave. A byte with a right result, you pass the test.

random value is sent, with the clock signal indi-

cated by LED1 and the data indicated by LED2. If you look closely at Listing 2, you will see that

If you watch carefully, you can read the trans- the bits are inverted when they are read. That’s

mitted byte. However, that’s not easy, so the because pressing the data button yields a zero

byte is also shown on the LCD and sent to the bit value. This is not especially intuitive, so the

terminal emulator. The individual bits also appear result is inverted when the bit is read to make

one after the other on the LCD and the terminal things easier for you. Another interesting aspect is

emulator screen: using the instruction D = Rnd (255) to generate

a pseudo-random number. In fact, this always

83 generates the same sequence of numbers, but

01010011 the Bascom Help gives some suggestions for what

you can do about this.

Then the roles change. Now you are the master,

and your job is to send exactly the same byte From microcontroller

back to the microcontroller. Here you can see that to microcontroller

the ability to send data at any desired speed is a In this example, data is sent over the SPI bus

big advantage, since you can take all the time you from one microcontroller to another. The data

want to decide which bit value to send next. For is this case consists of 10-bit readings from the

example, suppose you want to send the decimal A/D converter. This shows another advantage of

number 100. Bit 7 corresponds to decimal 128, SPI, which is that the data width is not fixed. No

which is more than 100, so it is ‘0’. Next comes matter whether you send 8, 10, 12 or 16 bits,

bit 6 with a value of 64, so it’s a ‘1’, and you’re the procedure is always the same. If the only

left with 36 still to send. This means that bit 5 objective were to connect two microcontrollers

(32) is a ‘1’, which leaves 4. The next two bits together, it would actually be less effort to use

(bit 4 = 16 and bit 3 = 8) are ‘0’, bit 3 (4) is a an asynchronous serial interface with the TXD

‘1’, and the last two bits are ‘0’. Now you have and RXD lines. The SPI bus, by contrast, is better

sent the binary number 01100100, with each bit for controlling and communicating with external

www.elektor-magazine.com | October 2014 | 33

•Projects

Listing 3. SPI master.

'------------------------------

'UNO_spi2.BAS SPI Master Cls

'------------------------------ Cursor Off

$regfile = "m328pdef.dat"

$crystal = 16000000 Waitms 200

$baud = 9600 Do

Dim B As Bit Dout = Getadc(3) 'Pot

Dim Dout As Word Locate 1 , 1

Dim N As Byte Lcd Dout

Dim I As Byte Lcd " "

Cs = 0

Sck Alias Portb.5 Waitms 20

Ddrb.5 = 1 For N = 1 To 10

Mosi Alias Portb.3 Mosi = Dout.9

Ddrb.3 = 1 Waitms 1

Cs Alias Portb.2 Sck = 1

Ddrb.2 = 1 Waitms 1

Sck = 0

Cs = 1 Waitms 1

Mosi = 0 Shift Dout , Left

Sck = 0 Next N

Cs = 1

Config Adc = Single , Prescaler = 32 , Waitms 100

Reference = Avcc Loop

Start Adc End

Listing 4. SPI slave.

'----------------------------- Portb.2 = 1

'UNO_spi3.BAS SPI Slave ...

'-----------------------------

$regfile = "m328pdef.dat" Do

$crystal = 16000000 Do

$baud = 9600 Loop Until Cs = 0

Din = 0

Dim Addr As Byte For N = 1 To 10

Dim B As Bit Shift Din , Left

Dim Dout As Word Do

Dim Din As Word Loop Until Sck = 1

Dim N As Byte Din = Din + Mosi

Dim I As Byte Do

Loop Until Sck = 0

Next N

S1 Alias Pinc.0 Do

Portc.0 = 1 Loop Until Cs = 1

S2 Alias Pinc.1 Locate 1 , 1

Portc.1 = 1 Lcd Din

Sck Alias Pinb.5 Lcd " "

Portb.5 = 1 Print Din

Mosi Alias Pinb.3 Loop

Portb.3 = 1 End

Cs Alias Pinb.2

34 | October 2014 | www.elektor-magazine.com

Microcontroller Bootcamp

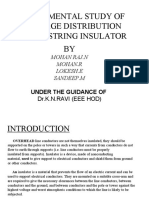

MOSI

SCK

MISO 1 2 VCC MISO 1 2 VCC

Master SCK 3 4 MOSI Slave SCK 3 4 MOSI

RESET 5 6 GND RESET 5 6 GND

10k

ICSP ICSP

CS

+5V +5V

28 27 26 25 24 23 22 21 20 19 18 17 16 15 28 27 26 25 24 23 22 21 20 19 18 17 16 15

GND

AVCC

GND

AVCC

C5

C4

C3

C2

C1

C0

B5

B4

B3

B2

B1

C5

C4

C3

C2

C1

C0

B5

B4

B3

B2

B1

AREF

AREF

ATmega328p ATmega328p

GND

GND

VCC

VCC

RES

RES

D0

D1

D2

D3

D4

D5

D6

D7

B0

D0

D1

D2

D3

D4

D5

D6

D7

B0

X1

X2

X1

X2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 2 3 4 5 6 7 8 9 10 11 12 13 14

16MHz 16MHz

100n 100n

Figure 3.

22p 22p 22p 22p

140245 - 13

An SPI connection between

two microcontrollers.

hardware. Here the main purpose of the exercise is no chip select line, but the Reset line has the

is to illustrate the transmission protocol. same effect because programming takes place

As previously with the 4094 shift register, a third with the Reset line pulled low. Now we want to

line is involved here—in this case the chip select use these lines exactly as intended. This has the

line /CS. The slash (/) means that the signal on advantage that we can use the hardware SPI unit

this line is active Low. The chip select line allows of the microcontroller, if it has one. With hard-

you to connect several slave devices to a single ware SPI we do not have use program code to

master. In that case they share the data and clock put each bit individually on the data line as in the

lines, but each one has its own chip select line. previous examples, and everything is a lot faster.

When that line is low, the corresponding slave However, we still need a chip select line, and in

knows that it is selected. There’s also another this case we use the B2 line for this purpose.

benefit from using a chip select line. If there is The master uses the MOSI line as the output

any delay in enabling the slave, there may be and generates the clock and chip select signals

some confusion about which bits have already (Listing 3). The process is slowed down a bit by

been transferred. However, if the slave waits until three 1-millisecond delays so that all the signals

it sees a falling edge on its CS input (high to low can easily be seen on the oscilloscope. Besides,

signal transition), it knows that the transfer is we don’t want to make things too difficult for the

starting. And if a noise pulse is read as a clock slave. If you wish, you can test the boundaries

signal, the rest of the data for that transfer is by reducing the delays until transmission errors

trash, but on the next access everything is again start to occur.

as it should be. The three lines are inputs for the slave device

(Listing 4). It constantly waits for specific signal

The ATmega328 also uses the SPI bus for pro- edges on the /CS and SCK lines and then reads

gram download from an external programming in a bit from the MOSI line. Since everything is

device. The following lines are therefore avail- handled by software here, the code must wait for

able on the six-pin programming connector on each edge in a Do loop. This takes a bit of time,

the Arduino board and on the Elektor Extension so data transmission must be slower than with a

shield (ICSP in Figure 3): the clock line Serial hardware SPI implementation. The received data

Clock (SCK) on B5, the write data line Master is shown on the display and on the terminal emu-

Out Slave In (MOSI) on B3, and the read data lator. When you turn the potentiometer on the

line Master In Slave Out (MISO) on B4. There master board, the change is visible on the slave.

www.elektor-magazine.com | October 2014 | 35

•Projects

SPI EEPROM 25LC512 realm, but SPI types are generally preferred in

There is a wide range of ICs available with an the professional realm because they offer espe-

SPI interface, including A/D converters, memory cially high operational reliability.

devices and display drivers. Serial EEPROMs from Figure 4 shows the connections to the Uno board.

Microchip and other companies are available at The pins of the original SPI interface (2x3 pin

low cost and are widely used. The 25LC512 (not header) are again used here. That makes it easy

to be confused with the 24C512, which has a I²C to build a convenient plug-in memory module

bus interface) has a capacity of 64 KB, and it is a by fitting the IC in a socket soldered to a small

good solution when the 1-kilobyte capacity of the 6-pin socket header. You only have to connect

ATmega328’s internal EEPROM is not sufficient. one additional line. This is the chip select line,

I²C EEPROMs are more widely used in the hobby which is again assigned to B2 because the Reset

line present on the connector cannot be used for

this purpose.

8 7 6 5

Here there are two data lines. MOSI (Master Out

HOLD

SI

VCC

SCK

Slave In) is the data output line and is connected

25LC512

to the Serial Input (SI) pin of the EEPROM, while

GND

WP

SO

CS

MISO (Master In Slave Out) is used to read data

1 2 3 4

from the Serial Output (SO) pin. The microcon-

troller is always the master, and it generates the

clock on the SCK line. To go with this exercise, we

MISO 1 2 VCC have written a subroutine (subroutines are called

SCK 3 4 MOSI

RESET 5 6 GND

“Sub” in Bascom; see the inset) that transfers

+5V data in both directions in a single go (Listing 5).

ICSP

Before the subroutine is called, the data to be

sent must be placed in the global variable Dout,

28 27 26 25 24 23 22 21 20 19 18 17 16 15 and after the call the received data is located in

the variable Din. Of course there are situations

GND

AVCC

C5

C4

C3

C2

C1

C0

B5

B4

B3

B2

B1

AREF

ATmega328p in which data is only written, but in that case

zero bits are usually sent in the other direction.

GND

VCC

RES

D0

D1

D2

D3

D4

D5

D6

D7

B0

X1

X2

1 2 3 4 5 6 7 8 9 10 11 12 13 14

The relatively complex data sheet for the 25LC512

tells you what has to be sent to the device, as well

16MHz

as when and how. After the chip select line has

100n been pulled low, the memory chip first receives a

Figure 4. 22p 22p simple byte command that specifies what action

140245 - 14

Connecting a serial EEPROM. is to be performed. To read data from the mem-

ory, you have to send a ‘3’ command followed

by two address bytes forming the high-byte and

Listing 5. Reading and writing data over MOSI and MISO.

low-byte portions of the address. After that as

Sub Spioutin many data bytes as desired can be read out with

Din = 0 automatic address incrementing (see Listing 6).

For N = 0 To 7 The program displays the sequential addresses

Shift Din , Left and the data bytes that are read out. A brand-new

Din = Din + Miso or fully erased EEPROM always delivers only the

If Dout.7 = 1 Then Mosi = 1 Else Mosi = 0 value 255. Now let’s try to program some data.

Waitus 3 For that we use the byte command ‘2’. However,

Sck = 1

a bit of preparation is necessary first. Writing

Waitus 2

must be enabled by sending the command ‘6’

Sck = 0

(Listing 7). To check whether writing is enabled

Waitus 2

you can read the EEPROM status register, which

Shift Dout , Left

requires sending the command ‘5’. Each action

Next N

is only effective if you pull /CS low at the start

End Sub

and then return it to the high level at the end.

36 | October 2014 | www.elektor-magazine.com

Microcontroller Bootcamp

Listing 6. EEPROM readout (excerpt). Subroutines

Cs = 0 Subroutines are called “Sub” in Bascom, and they are used to allow

Dout = 3 'read

a block of code to be called repeatedly from different locations in a

Spioutin

Dout = 0 'A8...A15 program. To make this possible, each subroutine must be declared at

Spioutin the start of the program. This way the name of the subroutine is known

Dout = 0 'A0...A7 to the compiler, so the it can be called using this name in the same way

Spioutin as Bascom functions.

I = 0

Do

Declare Sub Spioutin()

Locate 1 , 1

Lcd I …

Print I; Dout = 6

Print " "; Spioutin

I = I + 1 …

Spioutin

Locate 2 , 1

Lcd Din

Print Din Sub Spioutin

Waitms 200 Din = 0

Loop …

Shift Dout , Left

End Sub

If the value in the status register is 2, the IC is

enabled for write operations. Complicated? Yes,

You always have to be very careful with the variables used by a

but that makes it especially foolproof.

subroutine. In the case of the Spioutin subroutine, all of the variables

Now we are allowed to write data to the mem-

ory, but even then there’s something we have it uses are “global” variables, which are dimensioned at the start of the

to consider. The memory space is divided into main routine and are therefore valid in the entire program. However,

pages, which in the case of the 25LC512 have you could do things differently and transfer the data to the subroutine

a size of 128 bytes. Each transfer is limited to when it is called:

a maximum of 128 bytes of data, or as many

bytes as it takes to reach the next page bound- Declare Sub Spioutin (Byteout as Byte)

ary. After this you switch /CS high and then give

the EEPROM enough time to actually store the

In that case the variable Byteout would not be valid globally, but only

data. According to the data sheet, 5 ms is enough

within the subroutine. The subroutine call would then take the form:

Listing 7. Enabling write access Spioutin 6

(excerpt).

Cs = 0 This saves one line compared to the previously shown call.

Dout = 6 'write enable

You can also transfer a group of several variables to a subroutine in a

Spioutin

subroutine call, as can be seen from the example of the Bascom Spiout

Cs = 1

Waitms 20 subroutine:

Cs = 0

Dout = 5 'read status Spiout Dout , 1

Spioutin

Spioutin

For novice programmers, it’s generally safer to use only global

Cs = 1

variables in your own subroutines. For advanced programmers, on

Locate 1 , 1 'status

Lcd Din the other hand, selecting the optimal form of data transfer is a major

Print Din consideration.

www.elektor-magazine.com | October 2014 | 37

•Projects

Listing 8. Using the software SPI (excerpt).

Config Spi = Soft , Din = Pinb.4 , Dout = Portb.3 , Dout = 0 'A0...A7

Ss = None , Clock = Portb.5 , Mode = 0 Spiout Dout , 1

Spiinit I = 0

Do

Cs Alias Portb.2 Locate 1 , 1

Ddrb.2 = 1 Lcd I

Cs = 1 Lcd " "

Spiin Din , 1

Cs = 0 Locate 2 , 1

Dout = 4 'write disable Lcd Din

Spiout Dout , 1 Lcd " "

Cs = 1 Print I ;

Waitms 1 Print " ";

Cs = 0 Print Din

Dout = 3 'read Waitms 200

Spiout Dout , 1 I = I + 1

Dout = 0 'A8...A15 If I >= 65535 Then Exit Do

Spiout Dout , 1 Loop

time for storing the data. If you exceed the page data is read back, that’s exactly what you see.

boundary (I tried it), the result is chaos. Then As usual, the entire program code (UNO_spiEE1.

the data you find in memory is totally different bas) can be downloaded from the Elektor website

from what you wanted to write to memory. For [1]. It performs the following actions in sequence:

this reason, the example program carefully obeys

the rules and writes 128 bytes to the first page • Command 6, write enable

from address 0 to address 127, with the data val- • Command 5, read status register; display for

ues in ascending order from 0 to 127. When the 1 second

Listing 9. Data storage in the timer interrupt routine (excerpt).

Tim0_isr: Dout = 3

'4000 µs Addr = High(seconds)

Timer0 = 6 Dout = Addr 'A8...A15

Ticks = Ticks + 1 Spiout Dout , 1

If Ticks = 250 Then Addr = Low(seconds)

Ticks = 0 Dout = Addr 'A0...A7

U = Getadc(4) Spiout Dout , 1

U = U / 4 End If

Addr = Seconds Dout = U

Addr = Addr And 127 Spiout Dout , 1

If Addr = 0 Then 'start of page Addr = Seconds

Cs = 0 Addr = Addr And 127

Dout = 6 'write enable If Addr = 127 Then 'End of page

Spiout Dout , 1 Cs = 1

Cs = 1 End If

Waitus 100 Print Seconds

Cs = 0 Seconds = Seconds + 1

Dout = 2 'write If Seconds = 0 Then Seconds = 65535

Spiout Dout , 1 End If

Waitus 100 Return

Cs = 0

38 | October 2014 | www.elektor-magazine.com

Microcontroller Bootcamp

• Command 2, write 128 bytes starting at fer a lot of data during a single active chip select

address 0 phase. Consequently, this line (on port pin B2)

• Command 3, read memory starting at will still be operated “manually”. The Mode = 0

address 0; endless loop setting is also important, because there are four

different SPI modes.

Data logger The program excerpt in Listing 8 shows how the

One practical application for the 64-KB memory software SPI is used to read data from the serial

is a data logger. The objective here is to acquire EEPROM. The instruction Spiout Dout , 1 sends

measurement data from the ADC4 analog input exactly one byte, which is transferred in the vari-

once per second and store the data. The memory able Dout. In the other direction, the instruction

will be full in approximately 18 hours. Spiin Din , 1 reads one byte, which is then

available in the variable Din. The entire program

You don’t always have to program everything reads all the data from the EEPROM and shows

yourself, since Bascom has a lot of ready-made the contents on the display and on the terminal

functions for many situations. In this case you emulator screen.

have the option of configuring an SPI interface as As usual, the entire program code (UNO_spiLog-

a software interface using any desired port pins or ger.bas) can be downloaded from the Elektor

as a hardware interface using the microcontroller website [1]. It is too large to be listed fully here.

pins designated for this purpose. The hardware Pressing S1 starts a measurement run. It can be

SPI is especially fast and is commonly used for stopped at any time by pressing S2, after which

tasks such as driving graphical displays. However, the stored data can be read out.

this involves a whole lot of parameters that must

be configured for each specific application, which A timer interrupt routine (excerpt in Listing 9)

requires a detailed study of the ATmega328 data is used to control the timing during data acqui-

sheet. Things are a bit easier with the software sition. The voltage on ADC4 is measured and

SPI function, and it provides a reasonably high stored once per second. The 128-byte block size

transmission rate. Although writing your own SPI of the EEPROM is taken into account. At the start

procedure from the ground up is not a bad idea of each block, a write access is started and the

because it allows you to implement the timing current address is transferred, followed by 128

diagrams in the data sheets very clearly, the bytes of data. At the end of the block, the /CS

ready-made software SPI is more convenient and line is pulled high to allow the EEPROM to store

faster, which is why we use it here. the entire block. Since the /CS line is connected

The interface configuration specifies which lines to port pin PB2, LED2 on the shield is lit when the

are to be used. For Din, Dout and Clock we use line is high. The LED therefore flashes each time

the familiar MISO, MOSI and SCK lines, which a block of data has been transferred to memory.

are already available on the ICSP connector. The (140245-I)

SS line corresponds to the /CS line. In this case

Web Link

this line should not be operated automatically by

Bascom because it is usually necessary to trans- [1] www.elektor-magazine.com/140245

Tip for using the Arduino programmer in Bascom

Many readers who are using the original Arduino boot loader have encountered the following problem: if a program

performs serial output, the Arduino programmer in Bascom does not work properly the next time and hangs. Some readers

have discovered that this problem can be resolved by using the Arduino IDE before using the programmer again. Simply

transferring the Blink program, for example, is sufficient.

However, there’s an easier solution. After you launch the programmer in Bascom, briefly press the Reset button on the Uno

board three times (or more) at roughly 1-second intervals. After this the programming function will work again, even when

the previous program included a Print output. This has been discussed intensively in various topics on the Elektor forum

(now at forum.elektor.com).

If you use the MCS boot loader on the Uno board, this problem does not occur. Another alternative is to use an external

programmer.

www.elektor-magazine.com | October 2014 | 39

You might also like

- AMD 5k86 ProcDocument10 pagesAMD 5k86 Procatorresh090675No ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- MCC - PANEL - Start - Delta - StarterDocument1 pageMCC - PANEL - Start - Delta - StarterRagothamanNo ratings yet

- EiffelST SCHDocument1 pageEiffelST SCHskyddNo ratings yet

- Solar Cell I-V Cuk ConverterDocument1 pageSolar Cell I-V Cuk ConverterKORAKRIT ANANTA-AUOYPORNNo ratings yet

- Catalex-Micro-SD-Card-Module-SCH ModificadoDocument1 pageCatalex-Micro-SD-Card-Module-SCH ModificadoBabobrillNo ratings yet

- AVR-RISC Evaluation System (1) : Experiment With Atmel's Latest RISC ProcessorsDocument5 pagesAVR-RISC Evaluation System (1) : Experiment With Atmel's Latest RISC ProcessorsSanedrac AcNo ratings yet

- TVC-03 - T - 05695 - 3 - Scheme of RTCC PDFDocument11 pagesTVC-03 - T - 05695 - 3 - Scheme of RTCC PDFADE MRTNo ratings yet

- Probador rj45Document1 pageProbador rj45Manuel Rivas100% (2)

- Probador rj45Document1 pageProbador rj45Manuel Rivas100% (1)

- SparkFun Serial Basic CH340 v10Document1 pageSparkFun Serial Basic CH340 v10Muhammad AlifNo ratings yet

- Power Extra (Prototyping) Nrf24l01+ Radio Module: Title: EASY/Newbie PCB Nrf24 EditionDocument1 pagePower Extra (Prototyping) Nrf24l01+ Radio Module: Title: EASY/Newbie PCB Nrf24 EditionLorensius LondaNo ratings yet

- Title:: File: Sample & Hold - LPF - SCH SheetDocument1 pageTitle:: File: Sample & Hold - LPF - SCH SheetMochammad PraditiaNo ratings yet

- Some Simple Tachometer Input Circuits: SteveDocument3 pagesSome Simple Tachometer Input Circuits: SteveSơn PhạmNo ratings yet

- Schematic - PRIMER PROYECTO REAL - 2021-10-01Document1 pageSchematic - PRIMER PROYECTO REAL - 2021-10-01bossfp36No ratings yet

- Manual Winpic800Document1 pageManual Winpic800Igor Babiy100% (2)

- 74HC164 74HCT164: 1. General DescriptionDocument16 pages74HC164 74HCT164: 1. General DescriptionteomondoNo ratings yet

- BLDC Driver SCHDocument1 pageBLDC Driver SCHadi joko100% (1)

- Introduction To FPGA HSIODocument30 pagesIntroduction To FPGA HSIOvineeth chowdaryNo ratings yet

- Minivna SchematicDocument8 pagesMinivna SchematicWenda WidodoNo ratings yet

- Shbootmode 1Document1 pageShbootmode 1Teguh PriyonoNo ratings yet

- Implementation of FOC Algorithm Using FPGA For GaN-based Three Phase Induction Motor DriveDocument10 pagesImplementation of FOC Algorithm Using FPGA For GaN-based Three Phase Induction Motor DrivenamduongqnNo ratings yet

- PICPROGDocument8 pagesPICPROGfrankcorbet100% (4)

- Curtis1238 Programmer v1rc DIY PDFDocument1 pageCurtis1238 Programmer v1rc DIY PDFPedro Militao CoboNo ratings yet

- SB2040 SchematicDocument1 pageSB2040 Schematiccacalot93100% (1)

- Toshiba Laptop Schematic Diagram PDFDocument37 pagesToshiba Laptop Schematic Diagram PDFRamdas Kamble100% (2)

- Interface Carte Nucleo - STM32F446RE Potentiomètres: PC1 PC0Document1 pageInterface Carte Nucleo - STM32F446RE Potentiomètres: PC1 PC0Abdessamad houssainiNo ratings yet

- Tutorial Sheet - 3 2020Document2 pagesTutorial Sheet - 3 2020guddu guptaNo ratings yet

- Tutorial Sheet - 3 2020Document2 pagesTutorial Sheet - 3 2020guddu guptaNo ratings yet

- Schematic AT89S52 V3 NewDocument1 pageSchematic AT89S52 V3 NewLhthang KtvNo ratings yet

- C1 1Pps - Out - Se: Rev: Title: Document Number: Siu-Clock-BreakoutDocument1 pageC1 1Pps - Out - Se: Rev: Title: Document Number: Siu-Clock-BreakoutHuzz100% (1)

- DVD Noblex Dvd-1350: 3828 Control Borad SechmaticDocument15 pagesDVD Noblex Dvd-1350: 3828 Control Borad SechmaticMariano Ohienart100% (1)

- SchematicDocument1 pageSchematicDavid TorresNo ratings yet

- Schematic New Sentinel 2024-02-16Document1 pageSchematic New Sentinel 2024-02-16Khánh TrịnhNo ratings yet

- Schematic Rain Drop Light 2023-11-04Document1 pageSchematic Rain Drop Light 2023-11-04Daniel PerezNo ratings yet

- 3DB20024CAAATNZZA04 - V1 - 9500 MPR MPT-HC-HQAMXP-HQAMMC Quick Start GuideDocument2 pages3DB20024CAAATNZZA04 - V1 - 9500 MPR MPT-HC-HQAMXP-HQAMMC Quick Start GuideWalcemir AguiarNo ratings yet

- Pci 1603Document1 pagePci 1603DGPCTCNo ratings yet

- Elektor BusDocument6 pagesElektor BusFernando VidalNo ratings yet

- TPS3839G33DBZR U3 U1: Low PowerDocument1 pageTPS3839G33DBZR U3 U1: Low Powermarcoteran007No ratings yet

- DIY Particle Detector Schematic v1-2Document1 pageDIY Particle Detector Schematic v1-2Rafael Carmo100% (1)

- PDF Created With Fineprint Pdffactory Pro Trial VersionDocument1 pagePDF Created With Fineprint Pdffactory Pro Trial VersionJusetf ArteagaNo ratings yet

- PDF Created With Fineprint Pdffactory Pro Trial VersionDocument1 pagePDF Created With Fineprint Pdffactory Pro Trial VersionAndyNo ratings yet

- MPR Quick Start Guide For Powering and Installation 3db20024caaatnzza Ics01Document2 pagesMPR Quick Start Guide For Powering and Installation 3db20024caaatnzza Ics01Omar sameerNo ratings yet

- Bluetooth Home Prototype AutomationDocument1 pageBluetooth Home Prototype AutomationAvanish Srivastava100% (2)

- Battery PointDocument1 pageBattery Pointapi-3730505No ratings yet

- DC AC: DC Junction Box Top Bmu EMSDocument1 pageDC AC: DC Junction Box Top Bmu EMSJorge Enrrique Gomez MedinaNo ratings yet

- Lso Lan PDFDocument1 pageLso Lan PDFLê HiếuNo ratings yet

- Sony DVD Photodetector DatasheetDocument3 pagesSony DVD Photodetector DatasheetAditya Chowdary KasukurtiNo ratings yet

- FC-7688 User ManualDocument55 pagesFC-7688 User ManualTarek GARA100% (1)

- Mp4 ATJ2085 SchematicDocument1 pageMp4 ATJ2085 SchematicSneetsher Crispy100% (17)

- Memo Plus (MP 9300-0.9) 10-20KDocument32 pagesMemo Plus (MP 9300-0.9) 10-20KAbdelwhab ElsaftyNo ratings yet

- CKT 8Document1 pageCKT 8Juan Luis Hernandez CarrizalesNo ratings yet

- Blank: V1.2 1. Page27: Change RT9237 To RT9248 2. Page25: Add U39Document30 pagesBlank: V1.2 1. Page27: Change RT9237 To RT9248 2. Page25: Add U39eclothstoreNo ratings yet

- En 1997 11Document106 pagesEn 1997 11franciscocampoverde8224No ratings yet

- Lovepedal Purple Plexi 800Document1 pageLovepedal Purple Plexi 800Shibbit100% (1)

- Microcontroller Basics CourseDocument5 pagesMicrocontroller Basics CourseMikko FagerlundNo ratings yet

- Microcontroller Bootcamp (3) : Serial Interface and A/D ConverterDocument10 pagesMicrocontroller Bootcamp (3) : Serial Interface and A/D ConverterMikko FagerlundNo ratings yet

- 2 PDFDocument8 pages2 PDFMikko FagerlundNo ratings yet

- Microcontroller Bootcamp (5) : Using TimersDocument10 pagesMicrocontroller Bootcamp (5) : Using TimersMikko FagerlundNo ratings yet

- Microcontroller Bootcamp (7) : The I C BusDocument8 pagesMicrocontroller Bootcamp (7) : The I C BusMikko FagerlundNo ratings yet

- LM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionDocument42 pagesLM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 Descriptioncontrol tejidoNo ratings yet

- WLP Physics 2Document4 pagesWLP Physics 2RenlieLegaspiNo ratings yet

- Basics of Thermal Resistance and Heat Dissipation An-EDocument6 pagesBasics of Thermal Resistance and Heat Dissipation An-ERahul RaiNo ratings yet

- Band Pass FilterDocument3 pagesBand Pass FilterShruti MathurNo ratings yet

- 1600KVA ស្វាយជ្រុំRMU, LVDBDocument4 pages1600KVA ស្វាយជ្រុំRMU, LVDBmain mydriveNo ratings yet

- DE-6-India BixDocument21 pagesDE-6-India BixbhagNo ratings yet

- Lecture 02Document25 pagesLecture 02Atika Mustari SamiNo ratings yet

- Experimental Study of Voltage Distribution Along String Insulator BYDocument14 pagesExperimental Study of Voltage Distribution Along String Insulator BYmr_mohan321No ratings yet

- Argom Mayo - Junio 2020Document47 pagesArgom Mayo - Junio 2020antonio venturaNo ratings yet

- Hoja de Datos Modulo AXIpremiun BLKDocument2 pagesHoja de Datos Modulo AXIpremiun BLKYoslin RuizNo ratings yet

- Cerberus Pyrotronics Strobes 2 4952870316 2Document2 pagesCerberus Pyrotronics Strobes 2 4952870316 2Rafael DantasNo ratings yet

- NetSure 211 - 20091105Document2 pagesNetSure 211 - 20091105Michell Quiroz OlivaresNo ratings yet

- Activecomp System Catalogue Neptune DucatiDocument2 pagesActivecomp System Catalogue Neptune DucatiMauricio Oropeza CabreraNo ratings yet

- Lightning Arrester: Working Principle, Types and DifferencesDocument7 pagesLightning Arrester: Working Principle, Types and DifferencesNasifNo ratings yet

- MVB enDocument1 pageMVB enferliverpoolNo ratings yet

- E Thyristor1Document6 pagesE Thyristor1jayryapNo ratings yet

- Detector de Movimiento LEGRANDDocument4 pagesDetector de Movimiento LEGRANDDeyvi Vasquez PittmanNo ratings yet

- COURSE OUTLINE Associates Engineering Management TechnologyDocument1 pageCOURSE OUTLINE Associates Engineering Management TechnologyVesselofhonour MontagueNo ratings yet

- Minimum Size Maximum Efficiency: 3-Part Hematology AnalyzerDocument2 pagesMinimum Size Maximum Efficiency: 3-Part Hematology AnalyzerOkura JoshuaNo ratings yet

- Lab ViewDocument13 pagesLab ViewKhadir MohammedNo ratings yet

- Zerner DiodeDocument11 pagesZerner DiodeSaurabh RS100% (1)

- Edc Unit 4 Transistor BiasingDocument19 pagesEdc Unit 4 Transistor BiasingPushpalathaNo ratings yet

- Manuale-Sellaii It-Rev00 Faro SterDocument8 pagesManuale-Sellaii It-Rev00 Faro Steryasser el aliNo ratings yet

- K46 ManualDocument8 pagesK46 ManualDavid KasaiNo ratings yet

- Schneider NS800Document64 pagesSchneider NS800Anonymous Lh3Yh8basINo ratings yet

- CO Unit 1 Chap 1 NotesDocument11 pagesCO Unit 1 Chap 1 NotesAmisha ShettyNo ratings yet

- InteliLite AMF20-25Document2 pagesInteliLite AMF20-25albertooliveira100% (2)

- Everlight Itr20001 T f316 SBDocument10 pagesEverlight Itr20001 T f316 SBmatwan29No ratings yet

- TP Modulation Sous Matlab CorrigéeDocument37 pagesTP Modulation Sous Matlab CorrigéeELmokhtar HamrouniNo ratings yet

- Analyzing Circuits Lab II DLD 2021-2Document7 pagesAnalyzing Circuits Lab II DLD 2021-2octavie ahmedNo ratings yet

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102From EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Rating: 5 out of 5 stars5/5 (2)

- iPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsFrom EverandiPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsRating: 5 out of 5 stars5/5 (5)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (229)

- CompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)From EverandCompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Rating: 5 out of 5 stars5/5 (2)

- iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]From EverandiPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Rating: 5 out of 5 stars5/5 (5)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsFrom EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongNo ratings yet

- Chip War: The Fight for the World's Most Critical TechnologyFrom EverandChip War: The Fight for the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (82)

- Computer Science: A Concise IntroductionFrom EverandComputer Science: A Concise IntroductionRating: 4.5 out of 5 stars4.5/5 (14)

- CompTIA A+ Complete Practice Tests: Core 1 Exam 220-1101 and Core 2 Exam 220-1102From EverandCompTIA A+ Complete Practice Tests: Core 1 Exam 220-1101 and Core 2 Exam 220-1102No ratings yet

- How To Market Mobile Apps: Your Step By Step Guide To Marketing Mobile AppsFrom EverandHow To Market Mobile Apps: Your Step By Step Guide To Marketing Mobile AppsNo ratings yet

- Raspberry PI: Learn Rasberry Pi Programming the Easy Way, A Beginner Friendly User GuideFrom EverandRaspberry PI: Learn Rasberry Pi Programming the Easy Way, A Beginner Friendly User GuideNo ratings yet

- CompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002From EverandCompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Rating: 5 out of 5 stars5/5 (1)

- The User's Directory of Computer NetworksFrom EverandThe User's Directory of Computer NetworksTracy LaqueyNo ratings yet

- Cancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionFrom EverandCancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionRating: 5 out of 5 stars5/5 (2)

- iPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XFrom EverandiPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XRating: 3 out of 5 stars3/5 (2)

- Debugging Embedded and Real-Time Systems: The Art, Science, Technology, and Tools of Real-Time System DebuggingFrom EverandDebugging Embedded and Real-Time Systems: The Art, Science, Technology, and Tools of Real-Time System DebuggingRating: 5 out of 5 stars5/5 (1)

- Creative Selection: Inside Apple's Design Process During the Golden Age of Steve JobsFrom EverandCreative Selection: Inside Apple's Design Process During the Golden Age of Steve JobsRating: 4.5 out of 5 stars4.5/5 (49)

- Samsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneFrom EverandSamsung Galaxy S22 Ultra User Guide For Beginners: The Complete User Manual For Getting Started And Mastering The Galaxy S22 Ultra Android PhoneNo ratings yet

![iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/728318688/198x198/f3385cbfef/1715524978?v=1)